['Air Programs']

['Air Programs']

06/13/2024

...

[EPA-HQ-OAR-2019-0178; FRL-7055-02-OAR]

RIN 2060-AU37

National Emission Standards for Hazardous Air Pollutants: Ethylene Oxide Emissions Standards for Sterilization Facilities Residual Risk and Technology Review

AGENCY: Environmental Protection Agency (EPA).

ACTION: Final rule.

SUMMARY: This action finalizes the residual risk and technology review (RTR) conducted for the Commercial Sterilization Facilities source category regulated under national emission standards for hazardous air pollutants (NESHAP) under the Clean Air Act. The EPA is finalizing decisions concerning the RTR, including definitions for affected sources, emission standards for previously unregulated sources, amendments pursuant to the risk review to address ethylene oxide (EtO) emissions from certain sterilization chamber vents (SCVs), aeration room vents (ARVs), chamber exhaust vents (CEVs), and room air emissions, and amendments pursuant to the technology review for certain SCVs and ARVs. In addition, we are taking final action to correct and clarify regulatory provisions related to emissions during periods of startup, shutdown, and malfunction (SSM), including removing exemptions for periods of SSM. We are also taking final action to require owners and operators to demonstrate compliance through the use of EtO continuous emissions monitoring systems (CEMS), with exceptions for very small users of EtO; add provisions for electronic reporting of performance test results and other reports; and include other technical revisions to improve consistency and clarity. We estimate that these final amendments will reduce EtO emissions from this source category by approximately 21 tons per year (tpy).

DATES: This final rule is effective on April 5, 2024. The incorporation by reference (IBR) of certain material listed in the rule is approved by the Director of the Federal Register April 5, 2024. The incorporation by reference (IBR) of certain other material listed in the rule was approved by the Director of the Federal Register before February 27, 2021.

ADDRESSES: The U.S. Environmental Protection Agency (EPA) has established a docket for this action under Docket ID No. EPA-HQ-OAR-2019-0178. All documents in the docket are listed on the https://www.regulations.gov/ website. Although listed, some information is not publicly available, e.g., Confidential Business Information or other information whose disclosure is restricted by statute. Certain other material, such as copyrighted material, is not placed on the internet and will be publicly available only in hard copy form. Publicly available docket materials are available either electronically through https://www.regulations.gov/, or in hard copy at the EPA Docket Center, WJC West Building, Room Number 3334, 1301 Constitution Ave. NW, Washington, DC. The Public Reading Room hours of operation are 8:30 a.m. to 4:30 p.m. Eastern Standard Time (EST), Monday through Friday. The telephone number for the Public Reading Room is (202) 566-1744, and the telephone number for the EPA Docket Center is (202) 566-1742.

FOR FURTHER INFORMATION CONTACT: For questions about this final action, contact U.S. EPA, Attn: Jonathan Witt, Mail Drop: E143-05, 109 T.W. Alexander Drive, P.O. Box 12055, RTP, North Carolina 27711; telephone number: (919) 541-5645; and email address: witt.jon@epa.gov. For specific information regarding the risk modeling methodology, contact U.S. EPA, Attn: Matthew Woody, Mail Drop: C539-02, 109 T.W. Alexander Drive, P.O. Box 12055, RTP, North Carolina 27711; telephone number: (919) 541-1535; and email address: woody.matt@epa.gov.

SUPPLEMENTARY INFORMATION:

Preamble acronyms and abbreviations. We use multiple acronyms and terms in this preamble. While this list may not be exhaustive, to ease the reading of this preamble and for reference purposes, the EPA defines the following terms and acronyms here:

ADAF age-dependent adjustment factor

AEGL acute exposure guideline level

APCD air pollution control device

ARV aeration room vent

ASME American Society of Mechanical Engineers

BTF Beyond-the-Floor

BMP best management practice

CAA Clean Air Act

CDX Central Data Exchange

CEDRI Compliance and Emissions Data Reporting Interface

CEMS continuous emission monitoring system

CEV chamber exhaust vent

CFR Code of Federal Regulations

cfs cubic feet per second

dscfm dry standard cubic feet per minute

EJ environmental justice

EPA Environmental Protection Agency

ERT Electronic Reporting Tool

EtO ethylene oxide

FDA Food and Drug Administration

FIFRA Federal Insecticide, Fungicide, and Rodenticide Act

FR Federal Register

FRFA final regulatory flexibility analysis

FTIR Fourier Transform Infrared Spectroscopy

GACT generally available control technology

HAP hazardous air pollutants(s)

HEM Human Exposure Model

HQ hazard quotient

ICR Information Collection Request

ID Interim Decision

IFU instructions for use

IRFA initial regulatory flexibility analysis

IRIS Integrated Risk Information System

ISO International Organization for Standardization

km kilometer

lb pound

lb/h pounds per hour

LEL lower explosive limit

LPL lower prediction limit

MACT maximum achievable control technology

MIR maximum individual risk

mg/L milligrams per liter

NAICS North American Industry Classification System

NDO natural draft opening

NESHAP national emission standards for hazardous air pollutants

OMB Office of Management and Budget

OPP Office of Pesticide Programs

OSHA Occupational Safety and Health Administration

PID Proposed Interim Decision

ppbv parts per billion by volume

ppm parts per million

ppmv parts per million by volume

PTE permanent total enclosure

REL reference exposure level

RDL Representative detection level

RFA Regulatory Flexibility Act

RIA regulatory impact assessment

RTR risk and technology review

SAB Science Advisory Board

SBA Small Business Administration

SBAR Small Business Advocacy Review

SCV sterilization chamber vent

SER small entity representative

SSM startup, shutdown, and malfunction

TOSHI target organ-specific hazard index

tpy tons per year

UPL upper prediction limit

µg/m3 micrograms per cubic meter

UMRA Unfunded Mandates Reform Act

URE unit risk estimate

VCS voluntary consensus standards

Background information. On April 13, 2023, the EPA proposed revisions to the Commercial Sterilization Facilities NESHAP based on our RTR. In this action, we are finalizing decisions and revisions for the rule. We summarize some of the more significant comments we timely received regarding the proposed rule and provide our responses in this preamble. A summary of all other public comments on the proposal and the EPA's responses to those comments is available in Summary of Public Comments and Responses for the Risk and Technology Review for Commercial Sterilization Facilities, Docket ID No. EPA-HQ-OAR-2019-0178. A “track changes” version of the regulatory language that incorporates the changes in this action is available in the docket.

Organization of this document. The information in this preamble is organized as follows:

I. General Information

A. Executive Summary

B. Does this action apply to me?

C. Where can I get a copy of this document and other related information?

D. Judicial Review and Administrative Reconsideration

II. Background

A. What is the statutory authority for this action?

B. What is the Commercial Sterilization Facilities source category and how does the NESHAP regulate HAP emissions from the source category?

C. What changes did we propose for the Commercial Sterilization Facilities source category in our April 13, 2023, RTR proposal?

III. What is included in this final rule?

A. What are the final rule amendments addressing the affected source definitions?

B. What are the final rule amendments pursuant to CAA sections 112(d)(2), 112(d)(3), and 112(d)(5) for the Commercial Sterilization Facilities source category?

C. What are the final rule amendments based on the risk review for the Commercial Sterilization Facilities source category?

D. What are the final rule amendments based on the technology review for the Commercial Sterilization Facilities source category?

E. What are the final rule amendments addressing emissions during periods of startup, shutdown, and malfunction?

F. What other changes have been made to the NESHAP?

G. What are the effective and compliance dates of the standards?

IV. What is the rationale for our final decisions and amendments for the Commercial Sterilization Facilities source category?

A. Amendments Addressing the Affected Source Definitions

B. Amendments Pursuant to CAA sections 112(d)(2), 112(d)(3), and 112(d)(5) for the Commercial Sterilization Facilities Source Category

C. Residual Risk Review for the Commercial Sterilization Facilities Source Category

D. Technology Review for the Commercial Sterilization Facilities Source Category

E. Amendments Addressing Emissions During Periods of SSM

F. Other Amendments to the Standards

V. Summary of Cost, Environmental, and Economic Impacts and Additional Analyses Conducted

A. What are the affected facilities?

B. What are the air quality impacts?

C. What are the cost impacts?

D. What are the economic impacts?

E. What are the benefits?

F. What analysis of environmental justice did we conduct?

VI. Statutory and Executive Order Reviews

A. Executive Orders 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulation and Regulatory Review

B. Paperwork Reduction Act (PRA)

C. Regulatory Flexibility Act (RFA)

D. Unfunded Mandates Reform Act (UMRA)

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

G. Executive Order 13045: Protection of Children From Environmental Health Risks and Safety Risks

H. Executive Order 13211: Actions Concerning Regulations That Significantly Affect Energy Supply, Distribution, or Use

I. National Technology Transfer and Advancement Act (NTTAA) and 1 CFR Part 51

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations and Executive Order 14096: Revitalizing Our Nation's Commitment to Environmental Justice for All

K. Congressional Review Act (CRA)

I. General Information

A. Executive Summary

1. Purpose of the Regulatory Action

Exercising authority under multiple provisions of section 112 of the Clean Air Act (CAA), we are finalizing revisions to the NESHAP for Commercial Sterilization Facilities (40 CFR part 63, subpart O) by both amending the current standards and establishing standards for previously unregulated emissions within this source category. First, we are finalizing emission standards under CAA sections 112(d)(2)-(3) and (d)(5) for previously unregulated emission sources of EtO. Second, we are finalizing risk-based standards under CAA section 112(f)(2) to protect public health with an ample margin of safety. Third, we are finalizing emission standards under CAA section 112(d)(6) based on our review of developments in practices, processes, and control technologies for this source category.

This final rulemaking reflects the EtO toxicological assessment that EPA's Integrated Risk Information System (IRIS) Program completed in December 2016,1 which indicated that EtO is a far more potent carcinogen than we had understood when the RTR for this source category was conducted in 2006. There are 88 commercial sterilization facilities in this source category, many of which are located near residences, schools, and other public facilities. Many of these facilities are also located in communities with environmental justice (EJ) concerns. We have determined that approximately 23 of these facilities pose high lifetime cancer risks to the surrounding communities, and some facilities pose exceptionally high risks that are among some of the highest for a CAA section 112(f)(2) risk assessment. Throughout this rulemaking process, we have engaged in outreach activities to these communities, along with their State and local governments, to discuss their concerns, along with the need and potential solutions for reducing emissions and increasing transparency on exposure and potential impacts to communities, which this final rule will achieve.

1Evaluation of the Inhalation Carcinogenicity of Ethylene Oxide, December 2016, EPA/635/R-16/350Fc.

This important action will reduce EtO emissions and lifetime cancer risks in multiple communities across the country, including communities with EJ concerns, and it updates our standards using proven and cost-effective control technologies that are already in use at some facilities in this source category. The protections offered by these standards will be especially important for children. In addition, this rule will advance the President's Cancer Moonshot,2 by preventing cancer before it starts. Recognizing that we now have additional information about the health risks of EtO that was not available at the time of the 2006 RTR, and in order to ensure that our standards for this source category adequately protect public health, we have conducted a second residual risk review under CAA section 112(f)(2), as discussed in section I.A.3 of this preamble.

2https://www.whitehouse.gov/briefing-room/statements-releases/2023/09/13/fact-sheet-as-part-of-president-bidens-unity-agenda-white-house-cancer-moonshot-announces-new-actions-and-commitments-to-end-cancer-as-we-know-it/.

In deciding to conduct this second residual risk review, we considered the health effects of EtO exposure, the impacts to surrounding communities, the advantages of EtO reductions, and the distribution of those reductions consistent with the clear goal of CAA section 112(f)(2) to protect the most exposed and susceptible populations. While commercial sterilizers provide a critical benefit for the health of all, protecting people who live near commercial sterilization facilities from the disproportionate risk of being significantly harmed by toxic air pollution is also a core responsibility for the EPA under the CAA.

At the same time, we recognize that commercial sterilization facilities play a vital role in maintaining an adequate supply of sterilized medical devices for public health needs in the U.S. According to the U.S. Food and Drug Administration (FDA), “Literature shows that about fifty percent of all sterile medical devices in the U.S. are sterilized with ethylene oxide.” FDA also notes that, “For many medical devices, sterilization with ethylene oxide may be the only method that effectively sterilizes and does not damage the device during the sterilization process.” 3 In developing this final rule, therefore, we carefully considered the important function these facilities serve, drawing from extensive engagement with industry stakeholders as well as Federal agencies with expertise in and responsibility for the medical device supply chain.

3https://www.fda.gov/medical-devices/general-hospital-devices-and-supplies/sterilization-medical-devices.

To ensure our actions with respect to this source category are based on the most accurate and complete information possible, we have had many interactions with the EtO commercial sterilization industry in recent years, including meetings, requests for information, and outreach specific to this final rulemaking. This has enabled us to work from the best possible information when conducting the analyses to support this final rulemaking, including the current configuration of facilities and the performance of control technologies that are currently used.

We have engaged with the U.S. Department of Health and Human Services, particularly FDA, regarding the potential impacts of this final rule on commercial facilities that sterilize medical devices. These discussions have focused on identifying and discussing any concerns regarding the potential impact on the availability of certain medical devices that are sterilized with EtO, in cases where alternative sterilization methods are not readily available, in particular, devices that are (1) experiencing or at risk of experiencing a shortage, (2) intended to provide life-supporting, life-sustaining care or that is intended for use in emergency medical care or during surgery, (3) used in pediatric services, and/or (4) sterilized exclusively at a particular facility.

Mindful of the vital role that commercial sterilizers play in supplying the nation with sterile medical devices, and the core objective of protecting public health under CAA section 112, the EPA has carefully evaluated the feasibility and cost of compliance with this rule, and potential implications for the medical device supply chain.4 The EPA notes that a number of the facilities covered by this final rule have already implemented one or more of the controls that will be needed for compliance. Moreover, the EPA's own experience working with facility owners, as well as State and local agencies that have regulated EtO emissions from these facilities, confirms that it is feasible for individual facilities to install the required controls well within the deadlines provided in this rule, and for multiple facilities to do so simultaneously.

4 For more information, see the document Regulatory Impact Analysis for the Final National Emission Standards for Hazardous Air Pollutants: Ethylene Oxide Commercial Sterilization and Fumigation Operations, available in the docket for this rulemaking.

In addition, as a result of the comments received, as well as the EPA's consultation with FDA and other Federal partners, the final rule incorporates several key changes from the proposed rule, including modifications to the format of certain standards and compliance flexibilities. We are also providing sufficient compliance time to enable these facilities to continue sterilizing products while installing and testing new control systems and associated equipment that will afford ample protection for nearby communities. These modifications to the proposed rule are intended to facilitate cost-effective compliance, and to avoid any impacts to the integrity of the medical device supply chain, while ensuring that these standards reduce cancer risks for communities exposed to EtO emissions.

Given that key industry players are already planning for compliance, and in light of the significant changes made between the proposal and this final rule, the EPA does not anticipate that the implementation of these standards will have any adverse impacts on the medical supply chain. However, as the Agency proceeds to implement this final rule, we intend to continue to work closely with FDA, the relevant trade associations, and facility owners to monitor the process of planning for compliance, to proactively identify any anticipated changes in facility operations that might implicate the medical supply chain, and to take appropriate steps to address any such impacts. In addition, in order to increase the resilience of the medical supply chain, we support the development and implementation of viable, safe, and cost-effective alternatives to EtO sterilization.

On April 13, 2023, the Office of Pesticide Programs (OPP) published a notice announcing the availability of a proposed interim decision (PID) as part of its periodic review of the registration of EtO under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) (88 FR 22447). The PID contained a number of measures aimed at protecting workers from excessive EtO exposure. Since the issuance of the PID, OPP has been actively collaborating with the Office of Air and Radiation to ensure that the requirements of the FIFRA Interim Decision (ID) do not interfere with the requirements of this rule, and vice versa. The ID will contain the final requirements to mitigate worker exposure to EtO, considering the comments received on the PID. Furthermore, OPP has been consulting regularly with other Federal agencies and with industry trade groups, to discuss how best to harmonize the requirements of the FIFRA ID with the requirements of this rule, and to ensure that the operative standards, once finalized, will protect both workers and neighboring communities from the risks of EtO exposure while mitigating and managing any risk to the supply chain for sterile medical devices.

2. Summary of the Major Provisions of the Regulatory Action in Question

We are finalizing numeric emission limits, operating limits, and management practices under CAA sections 112(d)(2)-(3), (d)(5), and (d)(6) for EtO emissions from certain emission sources, and also finalizing standards under CAA section 112(f)(2) for certain emission sources in order to ensure that the standards provide an ample margin of safety to protect public health.5

5 In 1992, pursuant to CAA section 112(c)(1), we published a list of major and area sources for regulation under CAA section 112, including major and area sources at commercial sterilization facilities. 57 FR 31576, 31586 (July 16, 1992). Area sources at commercial sterilization facilities were listed for regulation under CAA section 112(c)(3) based on our finding that they present a threat of adverse effects to human health or the environment (by such sources individually or in the aggregate) warranting regulation under that section. Id. at 31586.

For the following, previously unregulated emission sources at commercial sterilization facilities, we are setting standards under CAA sections 112(d)(2)-(3) or (d)(5): SCVs and ARVs at facilities where EtO use is less than 1 tpy,6 ARVs at facilities where EtO use is at least 1 tpy but less than 10 tpy,7 CEVs,8 and room air emissions.9

6 In developing the original rule, EPA considered potential standards for SCV and ARV at area source facilities where EtO use is less than 1 tpy but the Agency understood these sources at the time to have low emission contributions (e.g., a facility with EtO use of 1,999 lb/yr would have roughly less than 167 lb/month of usage and emissions, and less than 41 lb/week usage and emissions.) At the time, EPA considered costs for monitoring, recordkeeping, and reporting under the rule. Threshold cutoffs for area sources are at the discretion of the Agency.

7 EPA considered standards for ARV and CEV at area source facilities where EtO use is at least 1 tpy and less than 10 tpy. As noted, the Agency understood at the time that the largest emission source of EtO occurred from the SCV, and therefore finalized emission reduction standards for all SCV at facilities where EtO use is at least 1 tpy. At the time ARV sources were understood to have low emission contributions. As noted, threshold cutoffs for area sources are at the discretion of the Agency.

8 The standards for CEVs were originally promulgated on December 6, 1994. Following promulgation of the rule, we suspended certain compliance deadlines and ultimately removed the standards for CEVs due to safety concerns. In the late 1990s, there were multiple explosions at EtO commercial sterilization facilities using oxidizers to control emissions from the CEV. For CEVs, it was determined that the primary contributing issue leading to the explosions was that EtO concentrations were above a safe level (i.e., above the lower explosive limit (LEL)) within the CEV gas streams. We could not conclude at the time that the CEVs could be safely controlled, so the standards for CEVs were removed on November 2, 2001 (66 FR 55583). However, as discussed in section III.B.5 of the proposal preamble (88 FR 22790), facilities with controlled CEVs have revised their operating procedures to address the explosion issue by not exceeding 10 to 25 percent of the LEL. We have, therefore, determined that CEVs can be safely controlled.

9 As discussed in section III.A, room air emissions include emissions resulting from indoor EtO storage, EtO dispensing, vacuum pump operation, pre-aeration handling of sterilized material, and post-aeration handling of sterilized material.

Next, based on our assessment of the residual risk after considering the emission reductions from the previous standards in subpart O, as well as the standards under CAA sections 112(d)(2)-(3) or (d)(5) for the previously unregulated sources, we are finalizing more stringent standards under CAA section 112(f)(2) to address risk at the following types of sources:

- SCVs at facilities where EtO use is at least 30 tpy

- SCVs at facilities where EtO use is at least 10 tpy but less than 30 tpy

- SCVs at facilities where EtO use is at least 1 tpy but less than 10 tpy

- ARVs at facilities where EtO use is at least 30 tpy

- CEVs at area source facilities10 where EtO use is at least 400 tpy

10 As discussed in section III.B of the proposal preamble (88 FR 22790, April 13, 2023), CAA section 112(a) defines a major source as “any stationary source or group of stationary sources located within a contiguous area and under common control that emits or has the potential to emit considering controls, in the aggregate, 10 tpy or more of any HAP or 25 tpy or more of any combination of HAPs. . .”. It further defines an area source as “any stationary source of HAPs that is not a major source”. A synthetic area source facility is one that otherwise has the potential to emit HAPs in amounts that are at or above those for major sources of HAP, but that has taken a restriction so that its potential to emit is less than the threshold amounts for major sources. Most of the EtO used at these facilities is released through SCVs and ARVs, and subpart O contains emission standards for these sources at facilities where EtO use is at least 10 tpy. Some State and local governments also regulate EtO emissions from these facilities. Based on these facts, as well as our review of the permits for these facilities, it is our understanding that all facilities that use more than 10 tpy are synthetic area sources.

- CEVs at area source facilities where EtO use is at least 60 but less than 400 tpy

- Group 1 room air emissions11 at area source facilities where EtO use is at least 40 tpy

11 As discussed in section III.A, Group 1 room air emissions cover indoor EtO storage, EtO dispensing, vacuum pump operation, and pre-aeration handling of sterilized material.

- Group 2 room air emissions12 at area source facilities where EtO use is at least 20 tpy

12 As discussed in section III.A, Group 2 room air emissions cover post-aeration handling of sterilized material.

- Group 2 room air emissions at area source facilities where EtO use is at least 4 tpy but less than 20 tpy

Finally, under CAA section 112(d)(6), we are revising current standards for the following sources that were regulated in the previous 40 CFR part 63, subpart O:

- SCVs at facilities where EtO use is at least 10 tpy

- SCVs at facilities where EtO use is at least 1 tpy but less than 10 tpy

- ARVs at facilities where EtO use is at least 10 tpy

Table 1 summarizes the final CAA section 112(d) and 112(f)(2) standards.

| Emission source | Existing or new? | EtO use | Standards | CAA section |

|---|---|---|---|---|

| 1 MACT floor. | ||||

| 2 Beyond-the-Floor (BTF) standard. | ||||

| 3 To assure compliance with the emission limit, we are requiring each facility to operate area sources with these emissions in accordance with the PTE requirements of EPA Method 204 of appendix M to 40 CFR part 51. | ||||

| 4 Owners and operators may also apply for an alternative means of emission limitation under CAA section 112(h)(3). | ||||

| SCV | Existing and new | At least 30 tpy | 99.99 percent emission reduction | 112(f)(2). |

| At least 10 tpy but less than 30 tpy | 99.9 percent emission reduction | 112(f)(2). | ||

| At least 10 tpy | 99.9 percent emission reduction | 112(d)(6). | ||

| At least 1 but less than 10 tpy | 99.8 percent emission reduction | 112(f)(2) and 112(d)(6). | ||

| Less than 1 tpy | 99 percent emission reduction | 112(d)(5). | ||

| ARV | Existing | At least 30 tpy | 99.9 percent emission reduction | 112(f)(2). |

| At least 10 tpy but less than 30 tpy | 99.6 percent emission reduction | 112(f)(2). | ||

| At least 10 tpy | 99.6 percent emission reduction | 112(d)(6). | ||

| At least 1 but less than 10 tpy | 99 percent emission reduction | 112(d)(5). | ||

| Less than 1 tpy | 99 percent emission reduction | 112(d)(5). | ||

| New | At least 30 tpy | 99.9 percent emission reduction | 112(f)(2). | |

| At least 10 tpy | 99.9 percent emission reduction | 112(d)(6). | ||

| At least 1 but less than 10 tpy | 99 percent emission reduction | 112(d)(5). | ||

| Less than 1 tpy | 99 percent emission reduction | 112(d)(5). | ||

| CEVs at major source facilities | Existing and new | N/A | 99.94 percent emission reduction 1 | 112(d)(2) and 112(d)(3). |

| CEVs at area source facilities | Existing and new | At least 400 tpy | 99.9 percent emission reduction | 112(f)(2). |

| At least 60 but less than 400 tpy | 99.9 percent emission reduction | 112(f)(2). | ||

| Less than 60 tpy | 99 percent emission reduction | 112(d)(5). | ||

| Group 1 room air emissions at major sources | Existing and new | N/A | 97 percent emission reduction | 112(d)(2) and 112(d)(3). |

| Group 1 room air emissions at area sources | Existing and new | At least 40 tpy | 98 percent emission reduction 3 | 112(f)(2). |

| Less than 40 tpy | 80 percent emission reduction 3 | 112(d)(5). | ||

| Group 2 room air emissions at major sources | Existing and new | N/A | 86 percent emission reduction | 112(d)(2) and 112(d)(3). |

| Group 2 room air emissions at area sources | Existing | At least 20 tpy | 98 percent emission reduction 3 | 112(f)(2). |

| At least 4 but less than 20 tpy | 80 percent emission reduction 3 | 112(f)(2). | ||

| Less than 4 tpy | Lower the EtO concentration within each sterilization chamber to 1 ppm before the chamber can be opened 4 | 112(d)(5). | ||

| New | At least 20 tpy | 98 percent emission reduction 3 | 112(f)(2). | |

| At least 4 but less than 20 tpy | 80 percent emission reduction 3 | 112(f)(2). | ||

| Less than 4 tpy | 80 percent emission reduction 3 | 112(d)(5). | ||

To demonstrate compliance with the emission limits, we are finalizing capture requirements. We are also finalizing a requirement for facilities to monitor with an EtO continuous emissions monitoring system (CEMS), with exceptions for small users.

3. EPA Authority

We note that the EPA completed a residual risk and technology review under CAA sections 112(f)(2) and 112(d)(6), respectively, for this source category in 2006 (71 FR 17712). While CAA section 112(f)(2) requires only a one-time risk review, which is to be conducted within eight years of the date the initial standards are promulgated, it does not limit our discretion or authority to conduct another risk review should we consider that such review is warranted. As discussed in more detail in section IV.C of this preamble, as our understanding of the health effects of EtO developed, we conducted a second residual risk review under CAA section 112(f)(2) for commercial sterilization facilities using EtO in order to ensure that the standards provide an ample margin of safety to protect public health.

As discussed in further detail in section IV.C, this second residual risk review also encompasses certain area sources for which we did not evaluate residual risk in our 2006 rulemaking. Although CAA section 112(f)(5) states that a risk review is not required for categories of area sources subject to generally available control technology (GACT) standards, it does not prohibit such review. In 2006, we undertook a CAA section 112(f)(2) analysis only for area source emissions standards that were issued as maximum achievable control technology (MACT) standards and exercised our discretion under CAA section 112(f)(5) not to do a CAA section 112(f)(2) analysis for those emission points for which GACT standards were established (67 FR 17715). However, as we made clear in that prior risk assessment, “[w]e have the authority to revisit (and revise, if necessary) any rulemaking if . . . significant improvements to science [suggest that] the public is exposed to significant increases in risk as compared to the [2006 risk assessment].” Id. In light of the updated IRIS cancer unit risk estimate (URE) for EtO, which is approximately 60 times greater than the value we used in our previous risk assessment, we are now exercising our discretionary authority to conduct another CAA section 112(f)(2) analysis and to include in this analysis area source commercial sterilizers using EtO for which we have promulgated, or have considered, GACT standards.

Section 112(d)(6) of the CAA requires EPA to review and revise, as necessary, standards promulgated under CAA section 112 at least every eight years, taking into account developments in practices, processes, and control technologies. We last completed this required technology review for the Ethylene Oxide Commercial Sterilization NESHAP (40 CFR 63, subpart O) in 2006. Accordingly, in this final action, we are also conducting a CAA section 112(d)(6) review of the current standards in this source category.

4. Costs and Benefits

Table 2 of this preamble summarizes the costs of this final action for 40 CFR part 63, subpart O (Ethylene Oxide Commercial Sterilization NESHAP).

| Requirement | Number of facilities w/costs associated with new requirements | Total capital investment | Total annual costs |

|---|---|---|---|

| 1 This includes the 88 facilities that are currently operating, as well as two planned facilities that are expected to start operating within the next few years. | |||

| 2 This includes $763,000 of one-time annual costs for reading the rule and developing record systems. | |||

| Permanent total enclosure | 28 | $77,500,000 | $8,280,000 |

| Additional control devices | 83 | 187,000,000 | 43,000,000 |

| Monitoring and testing | 89 | 48,100,000 | 19,400,000 |

| Recordkeeping and reporting | 1 90 | 2 2,600,000 | |

| Total | 1 90 | 313,000,000 | 74,000,000 |

The capital costs for permanent total enclosure (PTE) and additional gas/solid reactors were annualized to 20 years. We estimate that these amendments will reduce EtO emissions from this source category by 21 tpy. Table 3 of this preamble summarizes the cancer risk reductions that will result from the final amendments, which are updated based on revisions made in the final rule and described in more detail in section IV.C.2.

| Current cancer risks— actual emissions | Current cancer risks— allowable emissions | Cancer risks after implementation of final amendments | |

|---|---|---|---|

| 1 The MIR or maximum individual lifetime cancer risk is defined as the increase in estimated cancer risk associated with a 70-year lifetime of continuous exposure at the highest concentration of HAP where people are likely to live. | |||

| 2 Ranges in values account for if all facilities were performing at the level of the standards (high end) to considering facilities that are currently performing better than the standards (low end). | |||

| Maximum Individual Risk (MIR) 1 | 6,000-in-1 million | 8,000-in-1 million 3 | 100-in-1 million. |

| Number of People with Cancer Risks >100-in-1 million | 19,000 | 260,000 | 0. |

| Number of People with Cancer Risks ≥1-in-1 million | 8.5 million | 62 million | 700,000 to 1.4 million. 2 |

| Estimated Annual Cancer Incidence (cases per year) | 0.9 | 8 | 0.1 to 0.2. 2 |

As indicated in table 3, we project that the standards in the final rule will significantly reduce incremental lifetime cancer risks associated with emissions of EtO from this source category. We estimate that the current maximum increase in lifetime cancer risk associated with any facility in this source category is 6,000-in-1 million based on estimated actual emissions (or 8,000-in-1 million based on allowable emissions) under the existing standards, and that approximately 19,000 people are exposed to EtO from this source category at levels that would correspond to a lifetime cancer risk of greater than 100-in-1 million (which is our presumptive upper bound threshold for acceptable health risks), based on actual emissions. When considering allowable emissions, this number increases to 260,000. Under the final rule, no individual will be exposed to EtO at levels that correspond to a lifetime cancer risk of greater than 100-in-1 million, and the number of people with a potential risk of greater than or equal to 1-in-1 million will be reduced by approximately 92 percent.

See section V of this preamble for further discussion of the costs and a discussion of the benefits of the final standards. See section IV.F of this preamble for discussion of the revisions to monitoring, recordkeeping, reporting, and testing requirements. See section IV.C for a discussion of the risk assessment results.

B. Does this action apply to me?

Regulated entities. Categories and entities potentially regulated by this action are shown in table 4 of this preamble.

| Industrial category | NESHAP | NAICS 1 code |

|---|---|---|

| 1 North American Industry Classification System. | ||

| Surgical and Medical Instrument Manufacturing | 40 CFR part 63, subpart O | 339112 |

| Surgical Appliance and Supplies Manufacturing | 40 CFR part 63, subpart O | 339113 |

| Pharmaceutical Preparation Manufacturing | 40 CFR part 63, subpart O | 325412 |

| Spice and Extract Manufacturing | 40 CFR part 63, subpart O | 311942 |

| Dried and Dehydrated Food Manufacturing | 40 CFR part 63, subpart O | 311423 |

| Packaging and Labeling Services | 40 CFR part 63, subpart O | 561910 |

Table 4 of this preamble is not intended to be exhaustive, but rather to provide a guide for readers regarding entities likely to be affected by the final action for the source category listed. To determine whether your facility is affected, you should examine the applicability criteria in the appropriate NESHAP. If you have any questions regarding the applicability of any aspect of this NESHAP, please contact the appropriate person listed in the preceding FOR FURTHER INFORMATION CONTACT section of this preamble.

C. Where can I get a copy of this document and other related information?

In addition to being available in the docket, an electronic copy of this final action will also be available on the internet. Following signature by the EPA Administrator, the EPA will post a copy of this final action at: https://www.epa.gov/stationary-sources-air-pollution/ethylene-oxide-emissions-standards-sterilization-facilities. Following publication in the Federal Register , the EPA will post the Federal Register version and key technical documents at this same website.

Additional information is available on the RTR website at https://www.epa.gov/stationary-sources-air-pollution/risk-and-technology-review-national-emissions-standards-hazardous. This information includes an overview of the RTR program and links to project websites for the RTR source categories.

D. Judicial Review and Administrative Reconsideration

Under Clean Air Act (CAA) section 307(b)(1), judicial review of this final action is available only by filing a petition for review in the United States Court of Appeals for the District of Columbia Circuit (the Court) by June 4, 2024. Under CAA section 307(b)(2), the requirements established by this final rule may not be challenged separately in any civil or criminal proceedings brought by the EPA to enforce the requirements.

Section 307(d)(7)(B) of the CAA further provides that only an objection to a rule or procedure which was raised with reasonable specificity during the period for public comment (including any public hearing) may be raised during judicial review. This section also provides a mechanism for the EPA to reconsider the rule if the person raising an objection can demonstrate to the Administrator that it was impracticable to raise such objection within the period for public comment or if the grounds for such objection arose after the period for public comment (but within the time specified for judicial review) and if such objection is of central relevance to the outcome of the rule. Any person seeking to make such a demonstration should submit a Petition for Reconsideration to the Office of the Administrator, U.S. EPA, Room 3000, WJC South Building, 1200 Pennsylvania Ave. NW, Washington, DC 20460, with a copy to both the person(s) listed in the preceding FOR FURTHER INFORMATION CONTACT section, and the Associate General Counsel for the Air and Radiation Law Office, Office of General Counsel (Mail Code 2344A), U.S. EPA, 1200 Pennsylvania Ave. NW, Washington, DC 20460.

II. Background

A. What is the statutory authority for this action?

The statutory authority for this action is provided by sections 112 and 301 of the Clean Air Act (CAA), as amended (42 U.S.C. 7401 et seq. ). The discussion that follows identifies the relevant statutory sections and briefly explains the contours of the methodology used to implement these statutory requirements. A more comprehensive discussion appears in the document titled CAA Section 112 Risk and Technology Reviews: Statutory Authority and Methodology, in the docket for this rulemaking. Section 112 of the CAA establishes a two-stage regulatory process to address emissions of hazardous air pollutants (HAP) from stationary sources. In the first stage, we must identify categories of sources emitting one or more of the HAP listed in CAA section 112(b) and then promulgate technology-based NESHAP for those sources. Sources of HAP emissions are either major sources or area sources, and CAA section 112 establishes different requirements for major source standards and area source standards. “Major sources” are those that emit, or have the potential to emit, any single HAP at a rate of 10 tons per year (tpy) or more, or 25 tpy or more of any combination of HAP. All other sources are “area sources.” For major sources, these standards are commonly referred to as maximum achievable control technology (MACT) standards and must reflect the maximum degree of emission reductions of HAP achievable (after considering cost, energy requirements, and non-air quality health and environmental impacts). In developing MACT standards, CAA section 112(d)(2) directs the EPA to consider the application of measures, processes, methods, systems, or techniques, including, but not limited to, those that reduce the volume of or eliminate HAP emissions through process changes, substitution of materials, or other modifications; enclose systems or processes to eliminate emissions; collect, capture, or treat HAP when released from a process, stack, storage, or fugitive emissions point; are design, equipment, work practice, or operational standards; or any combination of the above.

For these MACT standards, the statute specifies certain minimum stringency requirements, which are referred to as MACT floor requirements, and which may not be based on cost considerations. See CAA section 112(d)(3). For new sources, the MACT floor cannot be less stringent than the emission control achieved in practice by the best-controlled similar source. The MACT standards for existing sources can be less stringent than floors for new sources, but they cannot be less stringent than the average emission limitation achieved by the best-performing 12 percent of existing sources in the category or subcategory (or the best-performing five sources for categories or subcategories with fewer than 30 sources). In developing MACT standards, we must also consider control options that are more stringent than the floor under CAA section 112(d)(2). We may establish standards more stringent than the floor, based on the consideration of the cost of achieving the emissions reductions, any non-air quality health and environmental impacts, and energy requirements. For area sources, CAA section 112(d)(5) allows the EPA to set standards based on GACT in lieu of MACT standards. For categories of major sources and any area source categories subject to MACT standards, the second stage in standard-setting focuses on identifying and addressing any remaining (i.e., “residual”) risk pursuant to CAA section 112(f). Section 112(f) specifically states that the EPA “shall not be required” to conduct risk review under this subsection for categories of area sources subject to GACT standards but does not limit the EPA's authority or discretion from conducting such review. As discussed in more detail in section III.C of this preamble, in light of the updated URE regarding EtO, the EPA is choosing to exercise that discretion.

In the second stage of the regulatory process, the CAA requires the EPA to undertake two different analyses, which we refer to as the technology review and the residual risk review. Under the technology review, we must review the technology-based standards and revise them “as necessary (taking into account developments in practices, processes, and control technologies)” no less frequently than every 8 years, pursuant to CAA section 112(d)(6). In conducting this review, the EPA is not required to recalculate the MACT floors that were established in earlier rulemakings. Natural Resources Defense Council (NRDC) v. EPA, 529 F.3d 1077, 1084 (D.C. Cir. 2008). Association of Battery Recyclers, Inc. v. EPA, 716 F.3d 667 (D.C. Cir. 2013). The EPA may consider cost in deciding whether to revise the standards pursuant to CAA section 112(d)(6). The EPA is required to address regulatory gaps, such as missing standards for listed air toxics known to be emitted from the source category, and any new MACT standards must be established under CAA sections 112(d)(2) and (3), or, in specific circumstances, CAA sections 112(d)(4) or (h). Louisiana Environmental Action Network (LEAN) v. EPA, 955 F.3d 1088 (D.C. Cir. 2020).

The residual risk review in the second stage of the regulatory process focuses on identifying and addressing any remaining (i.e., “residual”) risk pursuant to CAA section 112(f). For source categories subject to MACT standards, section 112(f)(2) of the CAA requires the EPA to determine whether promulgation of additional standards is needed to provide an ample margin of safety to protect public health or to prevent an adverse environmental effect. Section 112(d)(5) of the CAA provides that this residual risk review is not required for categories of area sources subject to GACT standards. Section 112(f)(2)(B) of the CAA further expressly preserves the EPA's use of the two-step approach for developing standards to address any residual risk and the Agency's interpretation of “ample margin of safety” developed in the National Emissions Standards for Hazardous Air Pollutants: Benzene Emissions from Maleic Anhydride Plants, Ethylbenzene/Styrene Plants, Benzene Storage Vessels, Benzene Equipment Leaks, and Coke By-Product Recovery Plants (Benzene NESHAP) (54 FR 38044, September 14, 1989). The EPA notified Congress in the Residual Risk Report that the Agency intended to use the Benzene NESHAP approach in making CAA section 112(f) residual risk determinations (EPA-453/R-99-001, p. ES-11). The EPA subsequently adopted this approach in its residual risk determinations, and the United States Court of Appeals for the District of Columbia Circuit upheld the EPA's interpretation that CAA section 112(f)(2) incorporates the approach established in the Benzene NESHAP. See NRDC v. EPA, 529 F.3d 1077, 1083 (D.C. Cir. 2008).

The approach incorporated into the CAA and used by the EPA to evaluate residual risk and to develop standards under CAA section 112(f)(2) is a two-step approach. In the first step, the EPA determines whether risks are acceptable. This determination “considers all health information, including risk estimation uncertainty, and includes a presumptive limit on maximum individual lifetime [cancer] risk (MIR)13 of approximately 1-in-10 thousand.” (54 FR 38045). If risks are unacceptable, the EPA must determine the emissions standards necessary to reduce risk to an acceptable level without considering costs. In the second step of the approach, the EPA considers whether the emissions standards provide an ample margin of safety to protect public health “in consideration of all health information, including the number of persons at risk levels higher than approximately 1-in-1 million, as well as other relevant factors, including costs and economic impacts, technological feasibility, and other factors relevant to each particular decision.” Id. The EPA must promulgate emission standards necessary to provide an ample margin of safety to protect public health or determine that the standards being reviewed provide an ample margin of safety without any revisions. After conducting the ample margin of safety analysis, we consider whether a more stringent standard is necessary to prevent an adverse environmental effect, taking into consideration costs, energy, safety, and other relevant factors. For more information on the statutory authority for this rule, see 88 FR 22790, April 13, 2023.

13 Although defined as “maximum individual risk,” MIR refers only to cancer risk and reflects the estimated risk if an individual were exposed to the maximum level of a pollutant for a 70-year lifetime.

B. What is the Commercial Sterilization Facilities source category and how does the NESHAP regulate HAP emissions from the source category?

The EPA promulgated the EtO Commercial Sterilization Facilities NESHAP on December 6, 1994 (59 FR 62585). The standards are codified at 40 CFR part 63, subpart O. The EtO commercial sterilization industry consists of facilities operating a sterilizer process that uses EtO to sterilize or fumigate materials (e.g., medical equipment and supplies, spices, and other miscellaneous products and items). The source category covered by this MACT standard currently includes 88 facilities.

The original 1994 rulemaking for this source category set standards for EtO emissions originating from three emission points: sterilization chamber vents (SCV), aeration room vents (ARV), and chamber exhaust vents (CEV). The SCV evacuates EtO from the sterilization chamber following sterilization, fumigation, and any subsequent gas washes before the chamber door is opened. The ARV evacuates EtO-laden air from the aeration room or chamber that is used to facilitate off-gassing of the sterile product and packaging. The CEV evacuates EtO-laden air from the sterilization chamber after the chamber door is opened for product unloading following the completion of sterilization and associated gas washes. Other sources of emissions within this source category are room air emissions from equipment used to charge EtO into sterilization chambers, as well as EtO residuals desorbing from sterilized products within the facility, but the current EtO Commercial Sterilization NESHAP does not include standards for room air emissions.

In the chamber EtO sterilization process, items to be sterilized are placed in a chamber and exposed to EtO gas at a predetermined concentration, temperature, humidity, and pressure for a period of time known as the dwell period. Following the dwell period, the EtO gas is evacuated from the chamber, and the sterilized materials are then aerated to remove EtO residuals from the product. After the aeration step, sterilized materials are typically moved to a shipping/warehouse area for storage until they are ready to be distributed to the customer. Sterilizer process equipment and emission control configurations vary across facilities. The most common sterilizer process equipment configuration includes a separate sterilizer chamber, separate aeration room, and chamber exhaust on the sterilizer chamber (also referred to as a back-vent). Another common configuration includes a combination sterilizer where the sterilization and aeration steps of the process occur within the same chamber.

Another EtO sterilization process is single-item sterilization where small individual items are sterilized in sealed pouches. EtO gas is introduced into the sealed pouch, either by injection or use of an EtO ampule, and the sealed pouch is then placed in a chamber where the sterilization step and aeration step occur.

In 2006, we finalized a residual risk review and a technology review under CAA section 112(f)(2) and CAA section 112(d)(6), respectively (71 FR 17712, April 7, 2006). No changes were made to the EtO Commercial Sterilization NESHAP in that action.

The current emission standards for commercial sterilization facilities in 40 CFR part 63, subpart O are shown in table 5:

| Existing and new sources subcategory (in any consecutive 12-month period) 1 | Sterilization chamber vent (SCV) | Aeration room vent (ARV) | Chamber exhaust vent (CEV) 2 |

|---|---|---|---|

| 1 Determined on a rolling 12-month basis. | |||

| 2 The CEV emission source was included in the original standard but was later eliminated from the 40 CFR part 63, subpart O regulation in 2001. | |||

| Sources using 10 tons or more of EtO | 99 percent emission reduction (see 40 CFR 63.362(c)) | 1 part per million (ppm) maximum outlet concentration or 99 percent emission reduction (see 40 CFR 63.362(d)) | No control. |

| Sources using 1 ton or more of EtO but less than 10 tons of EtO | 99 percent emission reduction (see 40 CFR 63.362(c)) | No control | No control. |

| Sources using less than 1 ton of EtO | No control required; minimal recordkeeping requirements apply (see 40 CFR 63.367(c)).) | No control required; minimal recordkeeping requirements apply (see 40 CFR 63.367(c)).) | No control required; minimal recordkeeping requirements apply (see 40 CFR 63.367(c)).). |

For more information on the commercial sterilization industry and the current standards under 40 CFR part 63, subpart O, see 88 FR 22790, April 13, 2023.

We note that hospital sterilizers are regulated under a different NESHAP (40 CFR part 63, subpart WWWWW), which is not addressed in this rulemaking. 14 We are aware of the potential risk posed by EtO emissions from this source category and will address hospital sterilizers in a future rulemaking.

14 Hospitals are defined at 40 CFR 63.10448 to mean facilities that provide medical care and treatment for patients who are acutely ill or chronically ill on an inpatient basis under supervision of licensed physicians and under nursing care offered 24 hours per day. Hospitals include diagnostic and major surgery facilities but exclude doctor's offices, clinics, or other facilities whose primary purpose is to provide medical services to humans or animals on an outpatient basis.

C. What changes did we propose for the Commercial Sterilization Facilities source category in our April 13, 2023, RTR proposal?

On April 13, 2023, the EPA published a proposed rule in the Federal Register for the EtO Commercial Sterilization NESHAP, 40 CFR part 63, subpart O, that took into consideration the RTR analyses. In the proposed rule, we proposed emission standards under CAA sections 112(d)(2)-(3) or (d)(5) for a number of unregulated emission sources of EtO. We then proposed tightening certain of these proposed standards and existing standards with risk-based standards under CAA section 112(f)(2) in order to protect public health with an ample margin of safety. Finally, we proposed revisions to certain existing standards under CAA section 112(d)(6) based on our review of developments in practices, processes, and control technologies for this source category.

For the following emission sources that were unregulated, we proposed to set standards under CAA sections 112(d)(2)-(3) or (d)(5):

- SCVs, ARVs, and CEVs at facilities where EtO use is less than 1 tpy,

- ARVs and CEVs at facilities where EtO use is at least 1 tpy but less than 10 tpy,

- CEVs at facilities where EtO use is at least 10 tpy, and

- Room air emissions.

Next, based on our assessment of the residual risk after considering the emission reductions from the standards in subpart O, as well as the proposed standards for the unregulated sources, we proposed more stringent standards under CAA section 112(f)(2) to address risk for the following types of sources:

- SCVs at facilities where EtO use is at least 40 tpy,

- SCVs at facilities where EtO use is at least 10 tpy but less than 40 tpy,

- SCVs at facilities where EtO use is at least 1 tpy but less than 10 tpy, and

- Group 2 room air emissions at area source facilities where EtO use is at least 20 tpy.

Finally, under CAA section 112(d)(6), we proposed to revise standards for the following sources that were regulated in the previous 40 CFR part 63, subpart O:

- SCVs at facilities where EtO use is at least 10 tpy,

- SCVs at facilities where EtO use is at least 1 tpy but less than 10 tpy, and

- ARVs at facilities where EtO use is at least 10 tpy.

Table 6 summarizes the proposed section CAA section 112(d) and 112(f)(2) standards.

| Emission source | Existing or new? | EtO use | Standards | CAA section |

|---|---|---|---|---|

| 1 To assure compliance with the emission limit, we proposed requiring each facility to operate areas with these emissions in accordance with the PTE requirements of EPA Method 204 of appendix M to 40 CFR part 51. | ||||

| SCV | Existing and new | At least 40 tpy | 99.94 percent emission reduction | 112(f)(2). |

| At least 10 tpy but less than 40 tpy | 99.94 percent emission reduction | 112(f)(2). | ||

| At least 10 tpy | 99.94 percent emission reduction | 112(d)(6). | ||

| At least 1 but less than 10 tpy | 99.8 percent emission reduction | 112(f)(2) and 112(d)(6). | ||

| Less than 1 tpy | 99 percent emission reduction | 112(d)(5). | ||

| ARV | Existing | At least 10 tpy | 99.6 percent emission reduction | 112(d)(6). |

| At least 1 but less than 10 tpy | 99 percent emission reduction | 112(d)(5). | ||

| Less than 1 tpy | 99 percent emission reduction | 112(d)(5). | ||

| New | At least 10 tpy | 99.9 percent emission reduction | 112(d)(6). | |

| At least 1 but less than 10 tpy | 99 percent emission reduction | 112(d)(5). | ||

| Less than 1 tpy | 99 percent emission reduction | 112(d)(5). | ||

| CEV | Existing and new | At least 10 tpy | 3.2E-4 lb/h | 112(d)(2) and (3). |

| At least 1 but less than 10 tpy | 99.9 percent emission reduction | 112(d)(5). | ||

| Less than 1 tpy | 99 percent emission reduction | 112(d)(5). | ||

| Group 1 room air emissions | Existing and new | N/A | 1.3E-3 lb/h 1 | 112(d)(2) and 112(d)(3). |

| Group 1 room air emissions at area sources | Existing and new | N/A | 1.3E-3 lb/h 1 | 112(d)(5). |

| Group 2 room air emissions at major sources | Existing and new | N/A | 2.8E-3 lb/h 1 | 112(d)(2) and 112(d)(3). |

| Group 2 room air emissions at area sources | Existing | At least 20 tpy Less than 20 tpy | 2.8E-3 lb/h 1 Follow either the Cycle Calculation Approach or the Bioburden/Biological Indicator Approach to achieve sterility assurance in accordance with ISO 11135:2014 (July 15, 2014) and ISO 11138-1:2017 (March 2017) | 112(f)(2). 112(d)(5). |

| New | N/A | 2.8E-3 lb/h 1 | 112(d)(5). | |

To demonstrate compliance with the emission limits, we proposed capture requirements. We also proposed that facilities either monitor with an EtO CEMS or conduct initial and annual performance tests with continuous parameter monitoring.

We also proposed the following amendments:

• Corrections and clarifications to regulatory provisions related to emissions during periods of SSM, including removing general exemptions for periods of SSM and adding work practice standards for periods of SSM where appropriate.

• Revisions to monitoring and performance testing requirements and addition of provisions for electronic reporting of performance test results and reports, performance evaluation reports, and compliance reports.

• Requiring all area source facilities to obtain a title V operating permit, and

• Compliance requirements for facilities using combined emission streams.

III. What is included in this final rule?

This action finalizes the EPA's determinations pursuant to the RTR provisions of CAA section 112 for the Commercial Sterilization Facilities source category and amends the EtO Commercial Sterilization NESHAP based on those determinations. This action also finalizes other changes to the NESHAP, including adding requirements and clarifications for periods of SSM; requiring the use of CEMS to demonstrate compliance for facilities where EtO use is at least 100 pounds (lb)/year; adding provisions for electronic reporting of performance test results and reports, performance evaluation reports, and compliance reports; and other minor editorial and technical changes. This action also reflects several changes to the April 2023 proposal in consideration of comments received during the public comment period described in section IV of this preamble.

A. What are the final rule amendments addressing the affected source definitions?

The previous subpart O did not contain definitions for affected sources, which meant that the definition of an “affected source” at 40 CFR 63.2 applied. 15 We did not believe that this was appropriate because a facility may not route all emissions from a particular type of point source to the same control system, thus making compliance demonstration with the standards difficult. For SCVs, ARVs, and CEVs, we are finalizing, as proposed, the affected source definition as the individual vent. For Group 1 and Group 2 room air emissions, we are finalizing, as proposed, the affected source definition as the collection of all room air emissions for each group at any sterilization facility. Group 1 room air emissions are defined as emissions from indoor EtO storage, EtO dispensing, vacuum pump operations, and pre-aeration handling of sterilized material. Group 2 room air emissions are defined as emissions from post-aeration handling of sterilized material.

15 40 CFR 63.2 defines an affected source as “the collection of equipment, activities, or both within a single contiguous area and under common control that is included in a section 112(c) source category or subcategory for which a section 112(d) standard or other relevant standard is established pursuant to section 112 of the Act.”

Section IV.A.3 of this preamble provides a summary of key comments we received on the affected source definitions and our responses.

B. What are the final rule amendments pursuant to CAA sections 112(d)(2), 112(d)(3), and 112(d)(5) for the Commercial Sterilization Facilities source category?

We are finalizing EtO emissions standards pursuant to CAA sections 112(d)(2)-(3) and 112(d)(5) for major and area sources that were previously unregulated. Please note that the final standards for some of these sources are further tightened pursuant to CAA section 112(f)(2), as shown in table 1 in section I.A above and discussed in more detail below in sections III.C and IV. 16

16 These sources include CEVs at area source facilities where EtO use is at least 60 tpy, Group 1 room air emissions at area source facilities where EtO use is at least 40 tpy, and Group 2 room air emissions at area source facilities where EtO use is at least 4 tpy.

Pursuant to CAA section 112(d)(2)-(3) or 112(d)(5), we are establishing in this final rule the following emission standards for the previously unregulated sources:

• 99 percent reduction for new and existing SCVs at facilities where EtO use is less than 1 tpy,

• 99 percent reduction for new and existing ARVs facilities where EtO use is at least 1 tpy less than 10 tpy,

• 99 percent reduction for new and existing ARVs at facilities where EtO use is less than 1 tpy,

• 99.94 percent reduction for new and existing CEVs at major source facilities,

• 99 percent emission reduction for new and existing CEVs at area source facilities,

• 97 percent reduction for new and existing Group 1 room air emissions at major source facilities,

• 80 percent emission reduction for new and existing Group 1 room air emissions at area source facilities,

• 86 percent reduction for new and existing Group 2 room air emissions at major source facilities, and

• 80 percent emission reduction for new Group 2 room air emissions at area source facilities.

As discussed in more detail below in section IV.C.3 of this notice, we are not finalizing any of the alternative emission limits for percent reduction standards on which we had solicited comment as part of the proposed rulemaking. Further, based on comments received on the proposed rulemaking, we are finalizing a revised best management practice (BMP) as the GACT standard under CAA section 112(d)(5) for existing Group 2 room air emissions at area sources. The BMP requires the in-chamber EtO concentration to be lowered to 1 part per million (ppm) before the chamber can be opened, as opposed to the proposed measure that would have required these facilities to follow either the Cycle Calculation Approach or the Bioburden/Biological Indicator Approach to achieve sterility assurance in accordance with International Organization for Standardization (ISO) 11135:2014 and ISO 11138-1:2017. In addition, we are finalizing, as proposed, a requirement that facilities operate all areas with room air emissions subject to an emission standard in accordance with the PTE requirements of EPA Method 204, irrespective of which CAA section 112 authority is invoked. Lastly, we are finalizing the removal of the 1 ppm alternative for ARVs at facilities where EtO use is at least 10 tpy. Section IV.B of this preamble provides in more detail the standards we are finalizing pursuant to CAA section 112(d)(2), 112(d)(3), and 112(d)(5), our rationales for the final standards and for changes since proposal, and a summary of key comments we received on the proposed standards and our responses.

C. What are the final rule amendments based on the risk review for the Commercial Sterilization Facilities source category?

This section introduces the final amendments to the Commercial Sterilization Facilities NESHAP being promulgated pursuant to CAA section 112(f). As in the proposal, we determined that the risks for this source category were unacceptable under the previous provisions, and we are making a final determination of unacceptability as part of this final action, warranting necessary emission reductions as directed under the provisions we are finalizing pursuant to CAA sections 112(d)(2), 112(d)(3), and 112(d)(5) in this rulemaking. When risks are unacceptable after considering the emission reductions from the standards in subpart O, we must determine the emissions standards necessary to reduce risk to an acceptable level. As such, we are promulgating final amendments to the Commercial Sterilization Facilities NESHAP pursuant to CAA section 112(f)(2) that will reduce risk to an acceptable level and will also provide an ample margin of safety to protect public health (see section IV.C of the preamble for further discussion). Based on comments received during the proposed rulemaking, we are finalizing the following EtO emissions standards under CAA section 112(f)(2):

• 99.99 percent reduction for SCVs at facilities where EtO use is at least 30 tpy,

• 99.9 percent reduction for SCVs at facilities where EtO use is at least 10 tpy but less than 30 tpy,

• 99.8 percent reduction for SCVs at facilities where EtO use is at least 1 tpy but less than 10 tpy,

• 99.9 percent reduction for ARVs at facilities where EtO use is at least 30 tpy,

• 99.9 percent reduction for CEVs at area source facilities where EtO use is at least 60 tpy,

• 98 percent reduction for Group 1 room air emissions at area sources facilities where EtO use is at least 40 tpy,

• 98 percent reduction for Group 2 room air emissions at area sources facilities where EtO use is at least 20 tpy, and

• 80 percent reduction for Group 2 room air emissions at area source facilities where EtO use is at least 4 tpy but less than 20 tpy.

We are not finalizing alternative emission limits for percent reduction standards for the same reasons discussed in section III.B of this preamble. Further, based on comments received during the proposed rulemaking, we are not finalizing any of the work practice standards that were proposed for facilities where the MIR remained greater than 100-in-1 million after the imposition of requirements under “Control Option 1”. 17 These standards would have required facilities to limit their Group 2 room air emissions to a maximum volumetric flow rate of 2,900 dry standard cubic feet per minute (dscfm) and a maximum EtO concentration of 30 parts-per-billion by volume (ppbv).

17 Refer to section III.D.1.b of the proposal preamble (88 FR 22790, April 13, 2023) for further discussion of Control Option 1.

Section IV.C.3 of this preamble provides a summary of key comments we received regarding the risk review and our responses.

D. What are the final rule amendments based on the technology review for the Commercial Sterilization Facilities source category?

We determined that there are developments in practices, processes, and control technologies that warrant revisions to the previous standards for this source category. Therefore, to satisfy the requirements of CAA section 112(d)(6), we are revising the standards to include, as in the proposed rule:

• 99.8 percent reduction for SCVs at facilities where EtO use is at least 1 tpy but less than 10 tpy,

• 99.6 percent reduction for existing ARVs at facilities where EtO use is at least 10 tpy, and

• 99.9 percent reduction for new ARVs at facilities where EtO use is at least 10 tpy.

Based on comments received during the proposed rulemaking, we are finalizing a 99.9 percent emission reduction standard for SCVs at facilities where EtO use is at least 10 tpy, which is different from the 99.94 percent emission reduction standard that was proposed (see section IV.D.3.a of this document for further discussion). We are not finalizing any of the alternative emission limits for percent reduction standards that we had solicited comment on as part of the proposed rulemaking. As part of the technology review, we also identified regulatory gaps (previously unregulated processes or pollutants) and are establishing new standards to fill those gaps as described in section III.B of this preamble. Section IV.D.3 of this preamble provides a summary of key comments we received regarding the technology review and our responses.

E. What are the final rule amendments addressing emissions during periods of startup, shutdown, and malfunction?

In its 2008 decision in Sierra Club v. EPA, 551 F.3d 1019 (D.C. Cir. 2008), the United States Court of Appeals for the District of Columbia Circuit vacated portions of two provisions in our CAA section 112 regulations governing the emissions of HAP during periods of SSM. Specifically, the court vacated the SSM exemption contained in 40 CFR 63.6(f)(1) and 40 CFR 63.6(h)(1), holding that under section 302(k) of the CAA, emissions standards or limitations must be continuous in nature and that the SSM exemption violates the CAA's requirement that some section 112 standards apply continuously. We have eliminated the SSM exemption in this rule. Consistent with Sierra Club v. EPA, the EPA has established standards in this rule that apply at all times. We have also revised table 6 in subpart O (the General Provisions Applicability Table) in several respects as is explained in section III.G.1 of the proposal preamble (88 FR 22790). For example, we have eliminated and revised certain recordkeeping that is related to the SSM exemption as described in detail in the proposed rule and summarized again in section IV.E.1 of this preamble.

In establishing standards in this rule, we have considered startup and shutdown periods and, for the reasons explained in section III.G.1 of the proposal preamble and section IV.E of this preamble, have not established alternate standards for those periods.

The EPA is also finalizing provisions related to malfunctions as proposed. Periods of startup, normal operations, and shutdown are all predictable and routine aspects of a source's operations. Malfunctions, in contrast, are neither predictable nor routine. Instead, they are, by definition, sudden, infrequent, and not reasonably preventable failures of emissions control, process, or monitoring equipment. (40 CFR 63.2) (Definition of malfunction). The EPA interprets CAA section 112 as not requiring emissions that occur during periods of malfunction to be factored into development of CAA section 112 standards. This reading has been upheld as reasonable by the D.C. Circuit in U.S. Sugar Corp. v. EPA, 830 F.3d 579, 606-610 (2016).

Section IV.E.3 of this preamble provides a summary of key comments we received on the SSM provisions and our responses.

F. What other changes have been made to the NESHAP?

This rule also finalizes, as proposed, revisions to several other requirements in the Commercial Sterilization Facilities NESHAP. We describe these revisions in this section as well as other proposed provisions that have changed since proposal.

1. Demonstrating Compliance

In the majority of instances, parametric monitoring is used to good effect as an ongoing means of ensuring that these devices continue to get necessary emission reductions. 18 However, given the nature of EtO, in which small amounts can have large risk impacts, parametric monitoring alone will not be sensitive enough to detect very small fluctuations in EtO concentration. Based on comments received during the proposed rulemaking, the EPA is finalizing a requirement to use EtO CEMS for demonstrating compliance. However, facilities where EtO use is less than 100 lb/year will have the option to use EtO CEMS or performance testing and parametric monitoring to demonstrate compliance. Based on comments received during the proposed rulemaking, we are promulgating the following requirements:

18 Parametric monitoring is an approach that measures one or more key indicators of process operation or emission control device operation, typically on a continuous basis. The parameters are known to affect emission levels associated with the process or the control efficiency of the source's air pollution control device.

• Quarterly reporting of EtO CEMS data,

• Minimum data availability of 90 percent for EtO CEMS, and

• Use of either outlet volumetric flow rate monitors or differential pressure monitors to demonstrate continuous compliance with EPA Method 204.

Based on comments received during the proposed rulemaking, we are not finalizing a requirement for the mass of EtO being routed to a control device from an SCV to be determined through inlet testing. Based on comments received during the proposed rulemaking, we are finalizing revisions to parametric monitoring requirements, and we are finalizing technical edits to Performance Specification 19 and QA Procedure 7.

2. Electronic Reporting

To increase the ease and efficiency of data submittal and data accessibility, we are finalizing, as proposed, a requirement that owners or operators of commercial sterilization facilities submit compliance reports (being finalized at 40 CFR 63.366(b) and (c)), performance test reports (being finalized at 40 CFR 63.366(f)), and performance evaluation reports (being finalized at 40 CFR 63.366(g)) electronically through the EPA's Central Data Exchange (CDX) using the Compliance and Emissions Data Reporting Interface (CEDRI). The final rule requires that performance test results collected using test methods that are supported by the EPA's Electronic Reporting Tool (ERT) as listed on the ERT website 19 at the time of the test be submitted in the format generated through the use of the ERT and that other performance test results be submitted in portable document format (PDF) using the attachment module of the ERT. Similarly, performance evaluation results of CEMS measuring relative accuracy test audit pollutants that are supported by the ERT at the time of the test must be submitted in the format generated through the use of the ERT and other performance evaluation results be submitted in PDF using the attachment module of the ERT. For compliance reports, the final rule requires that owners or operators use the appropriate spreadsheet template to submit information to CEDRI. The final version of the template for these reports is in the docket and will be located on the CEDRI website. 20 Furthermore, we are finalizing as proposed provisions that allow facility operators the ability to seek extensions for submitting electronic reports for circumstances beyond the control of the facility, i.e., for a possible outage in the CDX or CEDRI or for a force majeure event in the time just prior to a report's due date, as well as the process to seek such an extension.

19https://www.epa.gov/electronic-reporting-air-emissions/electronic-reporting-tool-ert.

20https://www.epa.gov/electronic-reporting-air-emissions/cedri.

For a more detailed discussion of these final amendments to the Commercial Sterilization Facilities NESHAP, see section IV.G.2.g of the proposal preamble (88 FR 22790, April 13, 2023), as well as section VI.B below on compliance with the Paperwork Reduction Act. For a more thorough discussion of electronic reporting, see the memorandum, Electronic Reporting Requirements for New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) Rules, which is available in the docket for this rulemaking (see Docket Item No. EPA-HQ-OAR-2019-0178-0398).

3. Title V Permitting

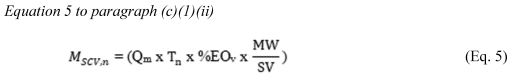

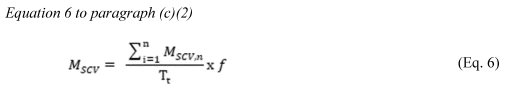

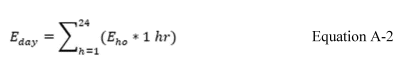

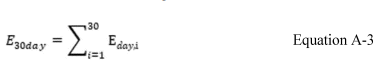

Because of the lack of other Federal requirements under the CAA that commercial sterilization facilities are subject to, as well as the robust monitoring and reporting requirements of the final rule, we are not finalizing a requirement for area source facilities subject to subpart O to obtain a title V permit from the delegated authority in which the source is located.