['Hazmat']

['Hazmat Rulemaking procedures']

05/13/2024

...

DEPARTMENT OF TRANSPORTATION

Pipeline and Hazardous Materials Safety Administration

49 CFR Parts 171, 172, 173, 175, 176, 178, and 180

[Docket No. PHMSA–2021–0092 (HM–215Q)]

RIN 2137–AF57

Hazardous Materials: Harmonization With International Standards

AGENCY: Pipeline and Hazardous Materials Safety Administration (PHMSA), Department of Transportation (DOT).

ACTION: Notice of proposed rulemaking (NPRM).

SUMMARY: PHMSA proposes to amend the Hazardous Materials Regulations to maintain alignment with international regulations and standards by adopting various amendments, including changes to proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements.

DATES: Comments must be received by July 31, 2023. To the extent possible, PHMSA will consider late-filed comments while a final rule is developed.

ADDRESSES: You may submit comments by any of the following methods:

- Federal Rulemaking Portal: http://www.regulations.gov . Follow the online instructions for submitting comments.

- Fax: 1–202–493–2251.

- Mail: Docket Management System; U.S. Department of Transportation, Docket Operations, M–30, Ground Floor, Room W12–140, 1200 New Jersey Avenue SE, Washington, DC 20590–0001.

- Hand Delivery: U.S. Department of Transportation, Docket Operations, M–30, Ground Floor, Room W12–140, 1200 New Jersey Avenue SE, Washington, DC 20590–0001 between 9 a.m. and 5 p.m., Monday through Friday, except federal holidays.

Instructions: Include the agency name and docket number PHMSA–2021–0092 (HM–215Q) or RIN 2137–AF57 for this rulemaking at the beginning of your comment. Note that all comments received will be posted without change to http://www.regulations.gov including any personal information provided. If sent by mail, comments must be submitted in duplicate. Persons wishing to receive confirmation of receipt of their comments must include a self-addressed stamped postcard.

Docket: For access to the dockets to read background documents (including the Preliminary Regulatory Impact Analysis (PRIA)) or comments received, go to http://www.regulations.gov or DOT's Docket Operations Office ( seeADDRESSES ).

Confidential Business Information: Confidential Business Information (CBI) is commercial or financial information that is both customarily and actually treated as private by its owner. Under the Freedom of Information Act (FOIA; 5 U.S.C. 552), CBI is exempt from public disclosure. If your comments responsive to this NPRM contain commercial or financial information that is customarily treated as private, that you actually treat as private, and that is relevant or responsive to this NPRM, it is important that you clearly designate the submitted comments as CBI. Please mark each page of your submission containing CBI as “PROPIN.” Submissions containing CBI should be sent to Candace Casey, U.S. Department of Transportation, 1200 New Jersey Avenue SE, Washington, DC 20590–0001. Any commentary that PHMSA receives which is not specifically designated as CBI will be placed in the public docket for this rulemaking.

FOR FURTHER INFORMATION CONTACT:

Candace Casey, Standards and Rulemaking, or Aaron Wiener, International Program, at 202–366–8553, Pipeline and Hazardous Materials Safety Administration, U.S. Department of Transportation, 1200 New Jersey Avenue SE, East Building, 2nd Floor, Washington, DC 20590–0001.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Executive Summary

II. Background

III. Incorporation by Reference Discussion Under 1 CFR Part 51

IV. Amendments Not Being Proposed for Adoption

V. Section-by-Section Review of NPRM Proposals

VI. Regulatory Analyses and Notices

A. Statutory/Legal Authority for This Rulemaking

B. Executive Order 12866 and DOT Regulatory Policies and Procedures

C. Executive Order 13132

D. Executive Order 13175

E. Regulatory Flexibility Act, Executive Order 13272, and DOT Policies and Procedures

F. Paperwork Reduction Act

G. Unfunded Mandates Reform Act of 1995

H. Environment Assessment

I. Executive Order 12898

J. Privacy Act

K. Executive Order 13609 and International Trade Analysis

L. National Technology Transfer and Advancement Act

M. Executive Order 13211

I. Executive Summary

The Pipeline and Hazardous Materials Safety Administration (PHMSA) proposes to amend certain sections of the Hazardous Materials Regulations (HMR; 49 CFR parts 171 to 180) to maintain alignment with international regulations and standards by adopting various changes, including changes to proper shipping names (PSN), hazard classes, packing groups (PG), special provisions (SP), packaging authorizations, air transport quantity limitations, and vessel stowage requirements. The proposed amendments are discussed in detail in “Section V. Section-by-Section Review of NPRM Proposals.”

Adoption of the regulatory amendments proposed in this NPRM will maintain the high safety standard currently achieved under the HMR. PHMSA also notes that because harmonization of the HMR with international regulations and consensus standards could reduce delays and interruptions of hazardous materials during transportation, the proposed amendments may also lower greenhouse gas (GHG) emissions and safety risks to minority, low-income, underserved, and other disadvantaged populations and communities in the vicinity of interim storage sites and transportation arteries and hubs.

The following list summarizes noteworthy proposals set forth in this NPRM:

- Incorporation by Reference: PHMSA proposes to incorporate by reference updated versions of the following international hazardous materials regulations and standards: the 2023–2024 edition of the International Civil Aviation Organization Technical Instructions for the Safe Transport of Dangerous Goods by Air (ICAO Technical Instructions); Amendment 41–22 to the International Maritime Dangerous Goods Code (IMDG Code); and the 22nd revised edition of the United Nations Recommendations on the Transport of Dangerous Goods—Model Regulations (UN Model Regulations);

- Hazardous Materials Table: PHMSA proposes amendments to the Hazardous Materials Table (HMT; 49 CFR 172.101) to add, revise, or remove certain PSNs, hazard classes, PGs, SPs, packaging authorizations, bulk packaging requirements, and passenger and cargo aircraft maximum quantity limits.

- Polymerizing Substances: In 2017—as part of the HM–215N final rule 1 —PHMSA added four new Division 4.1 (flammable solid) entries for polymerizing substances to the HMT and added defining criteria, authorized packagings, and safety requirements including, but not limited to, stabilization methods and operational controls into the HMR. These changes remained in effect until January 2, 2019, while PHMSA used the interim period to review and research the implications of the polymerizing substance amendments. In 2020—as part of the HM–215O 2 final rule—PHMSA extended the date the provisions remained in effect from January 2, 2019, to January 2, 2023, to allow for the additional research to be completed on the topic. In this NPRM, PHMSA proposes to remove the phaseout date (January 2, 2023) from the transport provisions for polymerizing substances to allow for continued use of the provisions.

1 82 FR 15796 (Mar. 30, 2017).

2 85 FR 27810 (May 11, 2020).

- Cobalt dihydroxide powder containing not less than 10 percent respirable particles: PHMSA proposes to add a new entry to HMT, “UN3550 Cobalt dihydroxide powder, containing not less than 10% respirable particles ” and corresponding packaging provisions. Cobalt is a key strategic mineral used in various advanced medical and technical applications around the world, including various types of batteries. Historically, this hazardous material has been classified and transported as a Class 9 material under “UN3077, Environmentally hazardous substance, solid, n.o.s.” however testing required under Registration, Evaluation, Authorisations and Restriction of Chemicals (REACH) regulations 3 for comprehensive GHS testing, determined that this material poses an inhalation toxicity hazard. Following this determination, the 22nd revised edition of the UN Model Regulations developed a new entry on the Dangerous Goods List (DGL) and packaging authorizations specifically for this hazardous material to facilitate continued global transport of this material. In this NPRM, PHMSA proposes to do likewise by adding a new entry for cobalt dihydroxide containing not less than 10 percent respirable particles and assigning it UN3550 on the HMT, in addition to adding packaging provisions, including the authorization to transport this material in flexible IBCs. PHMSA expects that these provisions will facilitate the continued transport of this material, to keep global supply chains open. See 172.101 of the Section-by-Section Review for additional discussion of these amendments.

3 Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006.

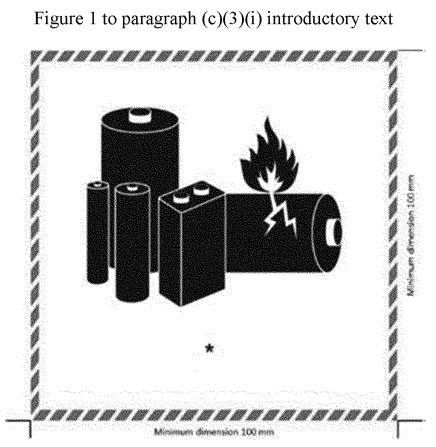

- Lithium Battery Exceptions: PHMSA proposes to remove the exceptions provided for small lithium cells and batteries for transportation by aircraft. This is consistent with the elimination of similar provisions in the ICAO Technical Instructions. See 173.185 of the Section-by-Section Review for additional discussion of these amendments.

All the proposed amendments are expected to maintain the HMR's high safety standard for the public and the environment. Additionally, PHMSA anticipates that there are safety benefits to be derived from improved compliance related to consistency amongst domestic and international regulations. PHMSA solicits comment on the amendments proposed in this NPRM pertaining to the need, benefits, and costs of the proposed HMR revisions; impact on safety and the environment; impact on environmental justice and equity; and any other relevant information. In addition, PHMSA solicits comment regarding approaches to reducing the costs of this rule while maintaining or increasing safety benefits. As further explained in the PRIA, PHMSA expects that the aggregate benefits of the amendments proposed in this NPRM justify their aggregate costs. Nonetheless, PHMSA solicits comment on specific changes ( e.g., greater flexibility with regard to a particular proposal) that might improve the rule.

II. Background

The Federal Hazardous Materials Transportation Law (49 U.S.C. 5101, et seq. ) directs PHMSA to participate in relevant international standard-setting bodies and encourages alignment of the HMR with international transport standards, as consistent with promotion of safety and the public interest. See 49 U.S.C. 5120. This statutory mandate reflects the importance of international standard-setting activity, in light of the globalization of commercial transportation of hazardous materials. Harmonization of the HMR with those efforts can reduce the costs and other burdens of complying with multiple or inconsistent safety requirements between nations. Consistency between the HMR and current international standards can also enhance safety by (1) ensuring that the HMR are informed by the latest best practices and lessons learned; (2) improving understanding of, and compliance with, pertinent requirements; (3) facilitating the flow of hazardous materials from their points of origin to their points of destination, thereby avoiding risks to the public and the environment from release of hazardous materials due to delays or interruptions in the transportation of those materials; and (4) enabling consistent emergency response procedures in the event of a hazardous materials incident.

PHMSA participates in the development of international regulations and standards for the transportation of hazardous materials. It also adopts within the HMR international consensus standards and regulations consistent with PHMSA's safety mission. PHMSA reviews and evaluates each international standard it considers for incorporation within the HMR on its own merits, including the effects on transportation safety, the environmental impacts, and any economic impact. PHMSA's goal is to harmonize with international standards without diminishing the level of safety currently provided by the HMR or imposing undue burdens on the regulated community.

In final rule HM–181, 4 PHMSA's predecessor, the Research and Special Programs Administration (RSPA), comprehensively revised the HMR for greater consistency with the UN Model Regulations. The UN Model Regulations constitute a set of recommendations issued by the United Nations Sub-Committee of Experts (UNSCOE) on the Transport of Dangerous Goods and on the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The UN Model Regulations are amended and updated biennially by the UNSCOE and serve as the basis for national, regional, and international modal regulations, including the ICAO Technical Instructions and IMDG Code.

4 55 FR 52401 (Dec. 21, 1990).

PHMSA has evaluated recent updates to the international standards, including review of numerous updated standards for the design, manufacture, testing, and use of packagings, and proposes to revise the HMR to adopt changes consistent with revisions to the 2023–2024 edition of the ICAO Technical Instructions, Amendment 41–22 to the IMDG Code, and the 22nd revised edition of the UN Model Regulations, all of which will be published by or in effect on January 1, 2023, 5 while also ensuring the changes are consistent with PHMSA's safety mission. Consequently, PHMSA proposes to incorporate by reference these revised international regulations, several new or updated International Organization for Standards (ISO) standards, and a new Organization for Economic Co-operation and Development (OECD) standard. The regulations and standards incorporated by reference are authorized for use for domestic transportation, under specific conditions, in part 171, subpart C of the HMR.

5 Amendment 41–22 of the IMDG Code will become mandatory on January 1, 2024. Voluntary compliance begins on January 1, 2023.

PHMSA issued an enforcement discretion on November 28, 2022, 6 stating that while PHMSA is considering the 2023–2024 Edition of the ICAO Technical Instructions and Amendment 41–22 of the IMDG Code for potential adoption into the HMR, PHMSA and other federal agencies that enforce the HMR (the Federal Railroad Administration (FRA), the Federal Aviation Administration (FAA), the Federal Motor Carrier Safety Administration (FMCSA), and the United States Coast Guard (USCG)) will not take enforcement action against any offeror or carrier who uses these standards as an alternative to complying with current HMR requirements when all or part of the transportation is by air with respect to the ICAO Technical Instructions, or by vessel with respect to the IMDG Code. In addition, PHMSA and its partners will not take enforcement action against any offeror or carrier who offers or accepts for domestic or international transportation by any mode packages marked or labeled in accordance with these standards. This notice remains in effect until withdrawn or otherwise modified.

6https://www.phmsa.dot.gov/regulatory-compliance/phmsa-guidance/phmsa-notice-enforcement-policy-regarding-international.

III. Incorporation by Reference Discussion Under 1 CFR Part 51

According to the Office of Management and Budget (OMB), Circular A–119, “ Federal Participation in the Development and Use of Voluntary Consensus Standards and in Conformity Assessment Activities, ” government agencies must use voluntary consensus standards wherever practical in the development of regulations.

PHMSA currently incorporates by reference into the HMR all or parts of numerous standards and specifications developed and published by standard development organizations (SDO). In general, SDOs update and revise their published standards every two to five years to reflect modern technology and best technical practices. The National Technology Transfer and Advancement Act of 1995 (NTTAA; Pub. L. 104–113) directs federal agencies to use standards developed by voluntary consensus standards bodies in lieu of government-written standards whenever possible. Voluntary consensus standards bodies develop, establish, or coordinate technical standards using agreed-upon procedures. OMB issued Circular A–119 to implement section 12(d) of the NTTAA relative to the utilization of consensus technical standards by federal agencies. This circular provides guidance for agencies participating in voluntary consensus standards bodies and describes procedures for satisfying the reporting requirements in the NTTAA. Accordingly, PHMSA is responsible for determining which standards currently referenced in the HMR should be updated, revised, or removed, and which standards should be added to the HMR. Revisions to materials incorporated by reference in the HMR are handled via the rulemaking process, which allows for the public and regulated entities to provide input. During the rulemaking process, PHMSA must also obtain approval from the Office of the Federal Register to incorporate by reference any new materials. The Office of the Federal Register issued a rulemaking 7 that revised 1 CFR 51.5 to require that an agency detail in the preamble of an NPRM the ways the materials it proposes to incorporate by reference are reasonably available to interested parties, or how the agency worked to make those materials reasonably available to interested parties. Proposed changes to the material incorporated by reference in the HMR are discussed in detail in the §171.7 discussion in “Section V. Section-by-Section Review of NPRM Proposals.”

7 79 FR 66278 (Nov. 7, 2014).

The UN Model Regulations, the United Nations Manual of Tests and Criteria (UN Manual of Tests and Criteria), 8 and the OECD standard ( i.e., Test No. 439) are free and easily accessible to the public on the internet, with access provided through the parent organization websites. The ICAO Technical Instructions, IMDG Code, and all ISO standard references are available for interested parties to purchase in either print or electronic versions through the parent organization websites. The price charged for those references not freely available helps to cover the cost of developing, maintaining, hosting, and accessing these standards and regulations.

8 U.N. Econ. Comm'n for Europe, Transportation Division, Manual of Tests and Criteria, 7th Rev. Ed., Amend. 1, U.N. Sales No. 21. VIII. 2 (2021).

IV. Amendments Not Being Proposed for Adoption

PHMSA determined that certain elements of updated international regulations and standards should not be adopted into the HMR because the structure of the HMR is such that it makes adoption unnecessary, or PHMSA has deemed it is a safer approach to authorize certain transport requirements through issuance of a special permit rather than allow for general applicability by adopting those requirements into the HMR. Use of a special permit allows for greater oversight and development of transport history and data prior to determining whether to adopt the terms of the special permit in the HMR for broad application.

The following is a list of international regulations and standards updates that PHMSA is not proposing for adoption in this NPRM, and the rationale for those decisions:

- Fiber-reinforced plastic UN portable tanks: The 22nd revised edition of the UN Model Regulations and Amendment 41–22 of the IMDG Code include provisions for the design, construction, approval, use, and testing of fiber-reinforced plastic (FRP) UN portable tanks. These are UN portable tanks with shells made of FRP materials instead of traditional steel. PHMSA is not proposing to make corresponding amendments to the HMR to authorize general multi-modal transport of FRP UN portable tanks. PHMSA believes further research is necessary in areas covering material fatigue, suitability of the pool fire test and impact testing as packaging qualification methods, and in the identification of the most appropriate non-destructive test methodology to qualify FRP UN portable tanks. The results of this research will be used to better gauge the appropriateness of full adoption of the provisions, amendments to the requirements for approval or use, or a continued exclusion from the HMR. However, PHMSA is proposing an amendment to §171.25—Additional requirements for the use of the IMDG Code—that would allow limited import and export of FRP UN portable tanks within a single port area. See “Section V. Section-by-Section Review of NPRM Proposals” for a discussion of §171.25 changes.

- Pressure receptacles: The 22nd revised edition of the UN Model Regulations, the 2023–2024 edition of the ICAO Technical Instructions, and Amendment 41–22 to the IMDG Code amended various definitions and other language concerning the terms “pressure receptacles” and associated requirements for assessing conformance of UN cylinders built to ISO standards. PHMSA is not proposing to make changes to the HMR consistent with these amendments. Terminology used in international standards and HMR differ such that an evaluation is necessary to determinate the full impacts beyond merely using consistent terminology. PHMSA may consider making relevant changes regarding UN cylinders as needed in future rulemakings.

- Aerosol containers: The 22nd revised edition of the UN Model Regulations, the 2023–2024 edition of the ICAO Technical Instructions, and Amendment 41–22 to the IMDG Code adopted maximum internal pressure limits for aerosol containers. Prior to these changes, these international regulations and standards had no specific pressure limits for aerosol containers. PHMSA welcomes this additional safety measure for the transport of aerosol containers, as it makes aerosol containers constructed and filled in accordance with international standards more consistent with existing domestic requirements for aerosol containers, which are subject to internal pressure limits as part of the performance standards for their construction and use. Noting existing differences in the HMR, include the definition for aerosol and the performance standards for their construction and use and thus because of the complexity involved in trying to harmonize the maximum pressure limits, PHMSA is not proposing to adopt these internationally implemented maximum internal pressure limits. Such harmonization would necessitate a review and evaluation beyond the scope of this rulemaking.

V. Section-by-Section Review of NPRM Proposals

The following is a section-by-section review of proposed amendments to harmonize the HMR with international regulations and standards.

A. Part 171

Section 171.7

Section 171.7 provides a listing of all voluntary consensus standards incorporated by reference into the HMR, as directed by the NTTAA. PHMSA evaluated updated international consensus standards pertaining to PSNs, hazard classes, PGs, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements. PHMSA contributed to the development of those standards—each of which build on the well-established and documented safety histories of earlier editions—as it participated in the discussions and working group activities associated with their proposal, revision, and approval. Those activities, in turn, have informed PHMSA's evaluation of the effect the updated consensus standards would have on safety, when incorporated by reference and with provisions adopted into the HMR. Further, PHMSA notes that some of the consensus standards proposed for incorporation by reference within the HMR in this rulemaking have already been adopted into the regulatory schemes of other countries. Additionally, as noted above, PHMSA has issued past enforcement discretions authorizing their use of the consensus standards as an interim strategy for complying with current HMR requirements. PHMSA is not aware of adverse safety impacts from that operational experience. For these reasons, PHMSA expects their incorporation by reference will maintain the high safety standard currently achieved under the HMR. Therefore, PHMSA proposes to add or revise the following incorporation by reference materials. 9

9 All other standards that are set out as part of the regulatory text of §171.7(w) were previously approved for incorporation by reference and no changes are proposed.

- In paragraph (t)(1), incorporate by reference the 2023–2024 edition of the ICAO Technical Instructions, to replace the 2021–2022 edition, which is currently referenced in §§171.8; 171.22 through 171.24; 172.101; 172.202; 172.401; 172.407; 172.512; 172.519; 172.602; 173.56; 173.320; 175.10, 175.33; and 178.3. The ICAO Technical Instructions specify detailed instructions for the international safe transport of dangerous goods by air. The requirements in the 2023–2024 edition have been amended to align better with the 22nd revised edition of the UN Model Regulations and the International Atomic Energy Agency (IAEA) Regulations for the Safe Transport of Radioactive Material. Notable changes in the 2023–2024 edition of the ICAO Technical Instructions include new packing and stowage provisions, new and revised entries on its Dangerous Goods List, and editorial corrections. The 2023–2024 edition of the ICAO Technical Instructions is available for purchase on the ICAO website at https://store.icao.int/en/shop-by-areas/safety/dangerous-goods.

- In paragraph (v)(2), incorporate by reference the 2022 edition of the IMDG Code, Incorporating Amendment 41–22 (English Edition), to replace Incorporating Amendment 40–20, 2020 Edition, which is currently referenced in §§171.22; 171.23; 171.25; 172.101; 172.202; 172.203; 172.401; 172.407; 172.502; 172.519; 172.602; 173.21; 173.56; 176.2; 176.5; 176.11; 176.27; 176.30; 176.83; 176.84; 176.140; 176.720; 176.906; 178.3; and 178.274. The IMDG Code is a unified international code that outlines standards and requirements for the transport of dangerous goods by sea ( i.e., by vessel). Notable changes in Amendment 41–22 of the IMDG Code include new packing and stowage provisions, new and revised entries on its Dangerous Goods List, and editorial corrections. Distributors of the IMDG Code can be found on the International Maritime Organization (IMO) website at: https://www.imo.org/en/publications/Pages/Distributors-default.aspx.

- In paragraph (w), incorporate by reference or remove the following ISO documents to include new and updated standards for the specification, design, construction, testing, and use of gas cylinders:

—ISO 9809, Parts 1 through 3. ISO 9809 is comprised of four parts (ISO 9809–1 through 9809–4) and specifies minimum requirements for the material, design, construction, and workmanship; manufacturing processes; and examination and testing at time of manufacture for various types of refillable seamless steel gas cylinders and tubes. PHMSA proposes to incorporate by reference the most recent versions of Parts 1 through 3.

- Incorporate by reference the third edition of ISO 9809–1:2019(E), “ Gas cylinders—Design, construction and testing of refillable seamless steel gas cylinders and tubes—Part 1: Quenched and tempered steel cylinders and tubes with tensile strength less than 1100 Mpa ” in paragraph (w)(32). Additionally, PHMSA proposes a sunset date of December 31, 2026, for continued use and phase out of the second edition of ISO 9809–1:2010, which is currently referenced in §178.37, §178.71, and §178.75. Part 1 of ISO 9809 is applicable to cylinders and tubes for compressed, liquefied, and dissolved gases and for quenched and tempered steel cylinders and tubes with a maximum actual tensile strength of less than 1100 MPa, which is equivalent to U.S. customary unit of about 160,000 psi. As part of its periodic review of all standards, ISO reviewed ISO 9809– 1:2010(E) and published an updated version, ISO 9809–1:2019(E), which was published in 2019 and adopted in the 22nd revised edition of the UN Model Regulations. The updated standard has technical revisions including limiting the bend test only for prototype tests. Updating references to this document would align the HMR with changes adopted in the 22nd revised edition of the UN Model Regulations pertaining to the design and construction of UN cylinders. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and concludes incorporation of the revised third edition will maintain or improve the safety standards associated with its use.

- Incorporate by reference the third edition of ISO 9809–2:2019(E), “ Gas cylinders—Design, construction and testing of refillable seamless steel gas cylinders and tubes—Part 2: Quenched and tempered steel cylinders and tubes with tensile strength greater than or equal to 1100 MPa ” in paragraph (w)(35). ISO 9809–2:2019 is the third edition of ISO 9809–2. Additionally, PHMSA proposes a sunset date of December 31, 2026, for continued use and phaseout of the second edition of ISO 9809–2:2010, which is currently referenced in §178.71, and §178.75. ISO 9809–2:2019 specifies minimum requirements for the material, design, construction and workmanship, manufacturing processes, examination and testing at time of manufacture for refillable seamless steel gas cylinders and tubes with water capacities up to and including 450 L. Part 2 of ISO 9809 is applicable to cylinders and tubes for compressed, liquefied, and dissolved gases and for quenched and tempered steel cylinders and tubes with an actual tensile strength greater than or equal to 1100 MPa. As part of its periodic review of all standards, ISO reviewed ISO 9809–2:2010 and published an updated version, ISO 9809–2:2019, in 2019; this updated version was adopted in the 22nd revised edition of the UN Model Regulations. The updated standard has technical revisions including expanded cylinder size ( i.e., allowed water capacity is extended from below 0.5 L to up to and including 450 L); the introduction of specific batch sizes for tubes; limiting the bend test only for prototype tests; the addition of test requirements for check analysis (tolerances modified); and the addition of new test requirements for threads. Updating references to this document would align the HMR with changes adopted in the 22nd revised edition of the UN Model Regulations pertaining to the design and construction of UN cylinders. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and concludes incorporation of the revised third edition will maintain or improve the safety standards associated with its use.

- Incorporate by reference the third edition of ISO 9809–3:2019(E), “ Gas cylinders—Design, construction and testing of refillable seamless steel gas cylinders and tubes—Part 3: Normalized steel cylinders and tubes ” in paragraph (w)(38). Additionally, PHMSA proposes a sunset date of December 31, 2026, for continued use phaseout of the second edition of ISO 9809–3:2010, which is currently referenced in §178.71 and §178.75. ISO 9809–3 is applicable to cylinders and tubes for compressed, liquefied, and dissolved gases and for normalized or normalized and tempered, steel cylinders and tubes. As part of its periodic review of all standards, ISO reviewed ISO 9809–3:2010 and published an updated version, ISO 9809–3:2019. The updated standard has technical revisions including: a wider scope of cylinders ( i.e., allowed water capacity is extended from below 0.5 L up to and including 450 L); the introduction of specific batch sizes for tubes; limiting the bend test only for prototype tests; the addition of test requirements for check analysis (tolerances modified); and the addition of new test requirements for threads. Updating references to the 2019 edition would align the HMR with changes adopted in the 22nd revised edition of the UN Model Regulations, which added this version pertaining to the design and construction of UN cylinders. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and concludes incorporation of the revised third edition will maintain or improve the safety standards associated with its use.

—Incorporate by reference supplemental amendment ISO 10462:2013/Amd 1:2019(E), “ Gas cylinders—Acetylene cylinders—Periodic inspection and maintenance—Amendment 1 ” in paragraph (w)(48). This proposed change would add a reference to ISO 10462:2013/Amd 1:2019(E) in §180.207(d)(3), where ISO 10462:2013 is currently required, and add a sunset date of December 31, 2024, for continued use and phaseout of ISO 10462:2013 without the supplemental amendment. ISO 10462:2013 specifies requirements for the periodic inspection of acetylene cylinders as required for the transport of dangerous goods and for maintenance in connection with periodic inspection. It applies to acetylene cylinders with and without solvent and with a maximum nominal water capacity of 150 L. As part of a periodic review of its standards, ISO reviewed ISO 10462:2013, and in June 2019 published a short supplemental amendment, ISO 10462:2013/Amd 1:2019. The supplemental document includes updates such as simplified marking requirements for rejected cylinders. Updating references to this document would align the HMR with documents referenced in the 22nd revised edition of the UN Model Regulations pertaining to the requalification procedures for acetylene UN cylinders. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and concludes the incorporation of the supplemental document maintains the HMR safety standards for use of acetylene cylinders.

—Incorporate by reference the third edition of ISO 11117:2019(E), “ Gas cylinders—Valve protection caps and guards—Design, construction and tests ” in paragraph (w)(56). This amendment would authorize the use of the third edition until further notice and add an end date of December 31st, 2026, to the authorization for use of the second edition, ISO 11117:2008 and the associated corrigendum, which are currently referenced in §173.301b. ISO 11117 specifies the requirements for valve protection caps and valve guards used on cylinders for liquefied, dissolved, or compressed gases. The changes in this revised standard pertain to the improvement of the interoperability of both the valve protection caps and the valve guards, with the cylinders and the cylinder valves. To that end, the drop test, the marking, and test report requirements have been revised and clarified. Updating references to this document would align the HMR with changes adopted in the 22nd revised edition of the UN Model Regulations pertaining to valve protection on UN pressure receptacles. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and does not expect any degradation of safety standards in association with its use.

—Incorporate by reference ISO 11118:2015/Amd 1:2019(E), “ Gas cylinders—Non-refillable metallic gas cylinders—Specification and test methods—Amendment 1 ” in paragraph (w)(59). ISO 11118:2015/Amd 1:2019(E) is a short supplemental amendment that is intended to be used in conjunction with ISO 11118:2015, which is currently referenced in §178.71. This amendment would authorize the use of this supplemental amendment in conjunction with ISO 11118:2015 until further notice and add an end date of December 31, 2026, until which ISO 11118:2015 may continue to be used without this supplemental amendment. ISO 11118:2015, which specifies minimum requirements for the material, design, inspections, construction and workmanship, manufacturing processes, and tests at manufacture of non-refillable metallic gas cylinders of welded, brazed, or seamless construction for compressed and liquefied gases including the requirements for their non-refillable sealing devices and their methods of testing. ISO 11118:2015/Amd 1:2019 corrects the identity of referenced clauses and corrects numerous typographical errors. The amendment also includes updates to the marking requirements in the normative Annex A, which includes clarifications, corrections, and new testing requirements. Updating references to this document would align the HMR with documents referenced in the 22nd revised edition of the UN Model Regulations pertaining to non-refillable UN cylinders. PHMSA has reviewed this amended document as part of its regular participation in the review of amendments proposed for the UN Model Regulations and determined that the added corrections and clarifications provide important additional utility for users of ISO 11118:2015(E) and does not expect any degradation of safety standards in association with its use.

—Incorporate by reference ISO 11513:2019, “ Gas cylinders—Refillable welded steel cylinders containing materials for sub-atmospheric gas packaging (excluding acetylene)—Design, construction, testing, use and periodic inspection ” in paragraph (w)(71). ISO 11513:2019 is the second edition of ISO 11513. This amendment would authorize the use of the second edition and add an end date to the authorization for use of the first edition, ISO 11513:2011 (including Annex A), which is currently referenced in §173.302c, §178.71, and §180.207. ISO 11513 specifies minimum requirements for the material, design, construction, workmanship, examination and testing at manufacture of refillable welded steel cylinders for the sub-atmospheric pressure storage of liquefied and compressed gases. The second edition has been updated to amend packing instructions and remove a prohibition on the use of ultrasonic testing during periodic inspection. Updating references to this document would align the HMR with documents referenced in the 22nd revised edition of the UN Model Regulations pertaining to the shipment of adsorbed gases in UN pressure receptacles. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and does not expect any degradation of safety standards in association with its use.

—Incorporate by reference ISO 16111:2018, “ Transportable gas storage devices

—Hydrogen absorbed in reversible metal hydride ” in paragraph (w)(80). ISO 16111:2018 is the second edition of ISO 16111. This amendment would authorize the use of the second edition until further notice and add an end date of December 31, 2026, on the authorization to use the first edition, ISO 16111:2008, which is referenced in §§173.301b, 173.311, and 178.71. ISO 16111 defines the requirements applicable to the material, design, construction, and testing of transportable hydrogen gas storage systems which utilize shells not exceeding 150 L internal volume and having a maximum developed pressure not exceeding 25 MPa. This updated standard includes additional information pertaining to service temperature conditions which have been described in detail; new references related to shell design; modified drop test conditions; modified acceptance criteria for leak testing; modified hydrogen cycling conditions; new warning labelling; and updated information on safety data sheets. Updating references to this document would align the HMR with documents referenced in the 22nd revised edition of the UN Model Regulations pertaining to metal hydride storage systems. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and does not expect any degradation of safety standards in association with its use.

—Incorporate by reference ISO 17871:2020(E), “ Gas cylinders—Quick-release cylinder valves—Specification and type testing ” in paragraph (w)(83). ISO 17871:2020 is the second edition of ISO 17871. This amendment would authorize the use of the second edition and add an end date of December 31st, 2026, to the authorization for use of the first edition, ISO 17871:2015(E), which is currently referenced in 173.301b. This document, in conjunction with ISO 10297 and ISO 14246, specifies design, type testing, marking, and manufacturing tests, and examinations requirements for quick-release cylinder valves intended to be fitted to refillable transportable gas cylinders, pressure drums and tubes which convey certain gases such as compressed or liquefied gases or extinguishing agents charged with compressed gases to be used for fire-extinguishing, explosion protection, and rescue applications. As part of its regular review of its standards, ISO updated and published the second edition of ISO 17871 as ISO 17871:2020. The 2020 edition of this standard broadens the scope to include quick release valves for pressure drums and tubes and specifically excludes the use of quick release valves with flammable gases. Other notable changes include the addition of the valve burst test pressure, the deletion of the flame impingement test, and the deletion of internal leak tightness test at −40 °C for quick release cylinder valves used only for fixed fire-fighting systems installed in buildings. Updating references to this document would align the HMR with changes adopted in the 22nd revised edition of the UN Model Regulations pertaining to the shipment of gases in UN pressure receptacles. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and does not expect any degradation of safety standards in association with its use.

Incorporate by reference ISO 21172–1:2015/Amd 1:2018, “Gas cylinders—Welded steel pressure drums up to 3000 litres capacity for the transport of gases—Design and construction—Part 1: Capacities up to 1000 litres—Amendment 1 ” in paragraph (w)(89). ISO 21172–1:2015/Amd1:2018 is a short supplemental amendment that is intended to be used in conjunction with ISO 21172–1:2015, which is currently referenced in §178.71. This amendment would authorize the use of this supplemental document in conjunction with the first edition, ISO 21172–1:2015. It would also add an end date of December 31, 2026, until which ISO 21172–1:2015 may continue to be used without this supplemental amendment. ISO 21172–1:2015 specifies the minimum requirements for the material, design, fabrication, construction, workmanship, inspection, and testing at manufacture of refillable welded steel gas pressure drums of volumes 150 L to 1000 L and up to 300 bar (30 MPa) test pressure for compressed and liquefied gases. This supplemental amendment includes updated references and removes the restriction on corrosive substances. Updating references to this document would align the HMR with documents referenced in the 22nd revised edition of the UN Model Regulations pertaining to the design and construction of UN pressure drums. PHMSA has reviewed this edition as part of its regular participation in the review of amendments proposed for the UN Model Regulations and does not expect any degradation of safety standards in association with its use.

—Incorporate by reference ISO 23088:2020, “Gas cylinders—Periodic inspection and testing of welded steel pressure drums—Capacities up to 1000 l ” in paragraph (w)(91). This amendment would incorporate by reference the first edition of ISO 23088, which specifies the requirements for periodic inspection and testing of welded steel transportable pressure drums of water capacity from 150 L up to 1,000 L and up to 300 bar (30 MPa) test pressure intended for compressed and liquefied gases in §180.207. This new standard was adopted in the 22nd revised edition of the UN Model Regulations because it fulfills the need for specific periodic inspection instructions for pressure drums constructed in accordance with ISO 21172–1. Incorporating by reference this document would align the HMR with standards adopted in the 22nd revised edition of the UN Model Regulations pertaining to the design, construction, and inspection of UN pressure drums. PHMSA has reviewed this document as part of its regular participation in the review of amendments proposed for the UN Model Regulations and expects that its addition will facilitate the continued use of UN pressure drums with no degradation of safety.

- In paragraph (aa)(3), incorporate by reference the OECD Guidelines for the Testing of Chemicals “Test No. 439: In Vitro Skin Irritation: Reconstructed Human Epidermis Test Method” (2015). This Test Guideline (TG) provides an in vitro procedure that may be used for the hazard identification of irritant chemicals. PHMSA proposes to reference this test in §173.137, and to authorize the use of this test method in addition to those already referenced in that section. This test method is used to specifically exclude a material from classification as corrosive and to maintain alignment with the 22nd revised edition of the UN Model Regulations. This test method provides an in vitro procedure that may be used for the hazard identification of irritant chemicals (substances and mixtures). OECD test methods can be found in the OECD iLibrary available at https://www.oecd-ilibrary.org/.

- In paragraph (dd), incorporate by reference United Nations standards including:

—“The Recommendations on the Transport of Dangerous Goods—Model Regulations,” 22nd revised edition (2021), Volumes I and II, in paragraph (dd)(1), which are referenced in §§171.8; 171.12; 172.202; 172.401; 172.407; 172.502; 172.519; 173.22; 173.24; 173.24b; 173.40; 173.56; 173.192; 173.302b; 173.304b; 178.75; and 178.274. The Model Regulations provide framework provisions promoting uniform development of national and international regulations governing the transportation of hazardous materials by various modes of transport. At its tenth session on December 11, 2020, the UNSCOE on the Transport of Dangerous Goods adopted amendments to the UN Model Regulations on the Transport of Dangerous Goods concerning, inter alia, electric storage systems (including modification of the lithium battery mark and provisions for transport of assembled batteries not equipped with overcharge protection), requirements for the design, construction, inspection and testing of portable tanks with shells made of fiber reinforced plastics (FRP) materials, modified listings of dangerous goods; and additional harmonization with the IAEA Regulations for the Safe Transport of Radioactive Material. PHMSA participates in the development of the UN Model Regulations and has determined that the amendments adopted in the 22nd revised edition support the safe transport of hazardous materials and as such are appropriate for incorporation in the HMR. The 22nd revised edition of the UN Model Regulations is available online at: https://unece.org/transport/dangerous-goods/un-model-regulations-rev-22.

—“The Manual of Tests and Criteria, Amendment 1 to the Seventh revised edition” (Rev.7/Amend.1) (2021), in paragraph (dd)(2)(ii), which is referenced in §§171.24, 172.102; 173.21; 173.56; 173.57; 173.58; 173.60; 173.115; 173.124; 173.125; 173.127; 173.128; 173.137; 173.185; 173.220; 173.221; 173.224; 173.225; 173.232; part 173, appendix H; 175.10; 176.905; and 178.274. The Manual of Tests and Criteria contains instruction for the classification of hazardous materials for purposes of transportation according to the UN Model Regulations. At its tenth session the Committee of Experts on the Transport of Dangerous Goods and on the Globally Harmonized System of Classification and Labelling of Chemicals adopted a set of amendments to the seventh revised edition of the Manual, which were circulated and collected in amendment 1 to the seventh revised edition. The new amendments adopted in December 2020 pertain to the transport of explosives, including alignment with revised Chapter 2.1 of the GHS, classification of self-reactive substances and polymerizing substances, and the assessment of the thermal stability of samples and temperature control assessment for transport of self-reactive substances and organic peroxides. PHMSA has reviewed and approved the amendments adopted in this document and further expects that their incorporation in the HMR will provide an additional level of safety. PHMSA proposes to incorporate by reference this document as a supplement, to be used in conjunction with the seventh revised edition (2019). The amendments to the manual can be accessed at https://unece.org/transport/dangerous-goods/rev7-files.

—“Globally Harmonized System of Classification and Labelling of Chemicals (GHS),” ninth revised edition (2021) in paragraph (dd)(3), which is referenced in §172.401. The GHS standard provides a basic scheme to identify the hazards of substances and mixtures and to communicate these hazards. At its tenth session on December 11, 2020, the Committee of Experts on the Transport of Dangerous Goods and on the Globally Harmonized System of Classification and Labelling of Chemicals adopted a set of amendments to the eighth revised edition of the GHS which include, inter alia: revisions to Chapter 2.1 (explosives) to better address their explosion hazard when they are not in their transport configuration; revisions to decision logics; revisions to classification and labelling summary tables in Annex 1; revisions and additional rationalization of precautionary statements; and updates of references to OECD test guidelines for the testing of chemicals in Annexes 9 and 10. PHMSA has reviewed and approved the amendments incorporated in this document and further expects that its incorporation in the HMR will provide an additional level of safety. The ninth revised edition of the GHS can be accessed at https://unece.org/transport/standards/transport/dangerous-goods/ghs-rev9-2021.

Section 171.12

Section 171.12 prescribes requirements for shipments of hazardous materials in North America, including use of the Transport Canada (TC) Transportation of Dangerous Goods (TDG) Regulations. In rule HM–215N, 10 PHMSA amended the HMR to expand recognition of cylinders and pressure receptacles, and certificates of equivalency—Transport Canada's equivalent of a special permit—approved in accordance with the TDG Regulations. The goal of these amendments was to promote flexibility and permit the use of modern technology for the requalification and use of pressure receptacles, to expand the universe of pressure receptacles authorized for use in hazardous material transport, to reduce the need for special permits, and to facilitate cross-border transportation of these pressure receptacles. In accordance with §171.12(a)(4), when the provisions of the HMR require the use of either a DOT specification or a UN pressure receptacle for transport of a hazardous material, a packaging authorized by Transport Canada's TDG Regulations may be used only if it corresponds to the DOT specification or UN standard. HM–215N revised paragraph (a)(4)(iii) to include a table listing Canadian Railway Commission (CRC), Board of Transport Commissioners for Canada (BTC), Canadian Transport Commission (CTC) or Transport Canada (TC) specification cylinders, in accordance with the TDG Regulations, and in full conformance with the TDG Regulations, that correspond with a DOT specification cylinder.

10 82 FR 15796 (Mar. 30, 2017).

However, there are currently no TC specification cylinders corresponding to DOT specification cylinders listed in the table for DOT–8 and DOT–8AL cylinders used to transport acetylene. During the development of HM–215N, PHMSA conducted a comparative analysis of DOT and TC cylinder specifications and only those TC cylinder specifications that corresponded directly to DOT cylinder specifications were included. The result was that PHMSA did not include TC–8WM and TC–8WAM specifications for the transport of acetylene in the table of corresponding cylinders at §171.12(a)(4)(iii). This omission was primarily due to concerns over differing solvent authorizations, calculations, and methods of construction for the design associated with the TC–8WM and TC–8WAM specifications. PHMSA conducted a second comparative analysis of DOT and TC cylinder specifications for transport of acetylene and concluded that the initial concerns were unwarranted. Therefore, PHMSA proposes to add TC–8WM and TC–8WAM specifications to the table of corresponding DOT specifications in §171.12(a)(4)(iii) as comparable cylinders to DOT–8 and DOT–8AL, respectively.

PHMSA's supplemental review indicates the differences between the TC and DOT specifications for transport of acetylene are minor and the standard for safety of transportation of acetylene in cylinders under the HMR is maintained. This proposal would allow for TC acetylene cylinders manufactured in Canada to be filled, used, and requalified (including rebuild, repair, reheat-treatment) in the United States, facilitating cross border movement of acetylene and eliminates the need for a special permit to allow transport of acetylene in these TC–8WM and TC–8AWM cylinders while maintaining an equivalent level of safety. Additionally, this proposal would provide reciprocity to Transport Canada's authorized use of DOT–8 and DOT–8AL cylinders for acetylene transport.

Section 171.23

Section 171.23 outlines the requirements for specific materials and packagings transported under the ICAO Technical Instructions, IMDG Code, Transport Canada TDG Regulations, or the IAEA Regulations. It also includes authorized use, under specific conditions, of pi-marked pressure receptacles that comply with the Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR), and the EU Directive 2010/35/EU, 11 and marked with a pi (π) symbol to denote such compliance for transport of hazardous materials. PHMSA proposes to amend the language in the provisions for pi-marked pressure receptacles in paragraph (a)(3) to clarify the scope of pressure receptacles authorized by this section. Pressure receptacles is a collective term that may be used to refer to many types of pressurized containers of various sizes, such as cylinders, tubes, pressure drums, closed cryogenic receptacles, metal hydride storage systems, bundles of cylinders or salvage pressure receptacles. When PHMSA adopted the provisions for pi-marked pressure receptacles, 12 we did not intend to broadly apply the scope to all pressure receptacle types. Instead, PHMSA's intent was to apply the authorized use of pi-marked pressure receptacles domestically to only cylinders, as indicated in current paragraph (a)(3)(iii), which specifically references cylinders. Some of the pressure receptacles authorized in accordance with the ADR standard do not have an equivalent packaging authorized in the HMR, and some have large capacities, both of which give pause to PHMSA with respect to the hazardous materials authorized in these packagings. Therefore, PHMSA proposes to replace the words “pressure receptacles” in paragraph (a)(3) with “cylinders with a water capacity not exceeding 150 L,” as defined in §171.8, to specify the scope of pi-marked pressure receptacles authorized under §171.23. PHMSA expects that this amendment will improve safety by providing additional clarity with regard to the scope of authorized use of pi-marked pressure receptacles for transport of hazardous material in the United States. PHMSA is aware of growing interest in the authorization for use of other pi-marked pressure receptacles and PHMSA plans to address that issue in a future rulemaking.

11 U.N. Econ. Comm'n for Europe, Transportation Division, Agreement Concerning the Int'l Carriage of Dangerous Goods by Road, 110th Sess., ECE/TRANS/300, U.N. Sales No. E. 21. VIII. 1 (2020).

12 85 FR 75680 (Nov. 25, 2020).

Section 171.25

Section 171.25 outlines additional requirements for the use of the IMDG Code in addition to those found in §171.22 and §171.23. As discussed above in Section IV. Amendments Not Being Considered for Adoption, specifically Issue #1, PHMSA is not proposing to adopt provisions for UN FRP portable tanks in the HMR. However, to facilitate limited import and export of these tanks in international commerce, and to gain additional experience with their transport, PHMSA proposes to add a new paragraph §171.25(c)(5) that would prohibit the general transportation of UN FRP portable tanks designed and constructed in accordance with Chapter 6.10 of the IMDG Code within the United States, yet allow for the tanks to be transported within a single port area in the United States in accordance with the provisions of §171.25(d) covering the use of the IMDG Code in port areas. This action will maintain the safe transportation of hazardous material under the HMR while facilitating international commerce by permitting the import or export of hazardous materials in UN FRP portable tanks and limiting their use and movement within the confines of a single port area.

B. Part 172

Section 172.101 Hazardous Materials Table (HMT)

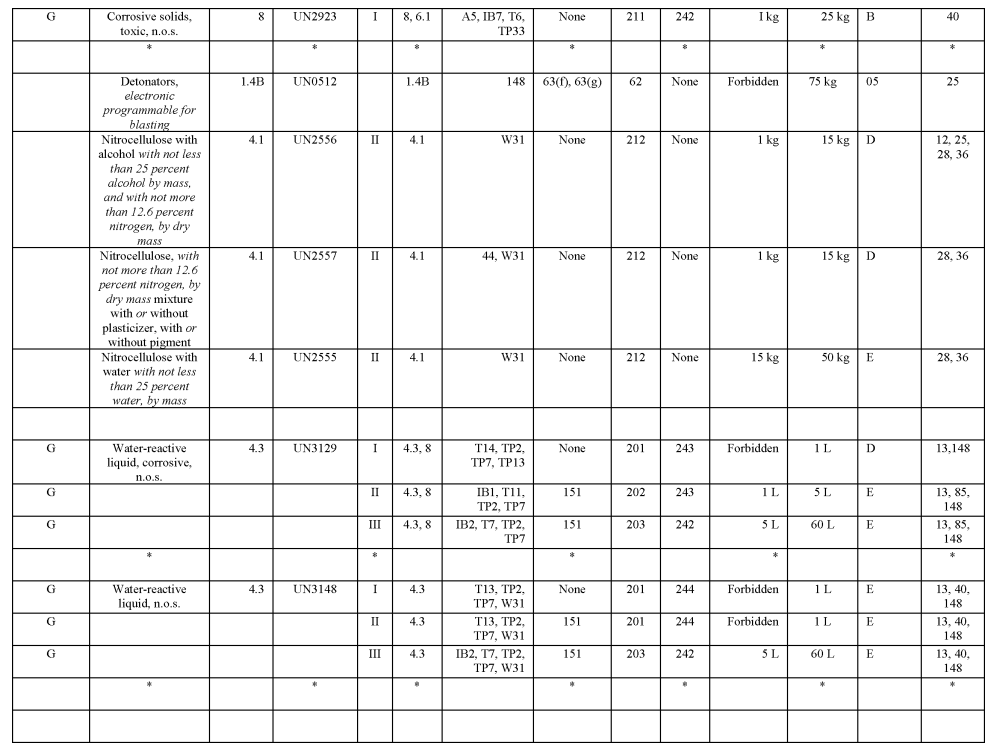

The HMT summarizes terms and conditions governing transportation of listed hazardous materials under the HMR. For each entry, the HMT identifies information such as the PSN, UN identification number, and hazard class. The HMT specifies additional information or reference requirements in the HMR such as hazard communication, packaging, quantity limits aboard aircraft, and stowage of hazardous materials aboard vessels. PHMSA proposes several changes to the HMT as discussed below. For purposes of the Government Publishing Office's typesetting procedures, proposed changes to the HMT appear under three sections of the HMT: “remove,” “add,” and “revise.” Certain entries in the HMT, such as those with revisions to the PSNs, appear as a “remove” and “add.” Proposed amendments to the HMT include the following:

New HMT Entry

PHMSA proposes to add new entry, “UN3550, Cobalt dihydroxide powder, containing not less than 10% respirable particles, Division 6.1, PG I” to the HMT. Cobalt is a key strategic mineral used in various advanced medical and technical applications around the world, and it is essential to keep the global supply chains for this material open. This material has a 40-year history of safe global transport as “UN3077, Environmentally hazardous substance, solid, n.o.s., Class 9” in different forms, including as crude material directly from mines, high moisture content paste, and very fine refined powders in flexible IBCs rated for PG III. However, recent testing required for compliance with the REACH Regulation in the European Union, and subsequent evaluation against the hazard classification criteria of the EU Classification, Labelling, and Packaging (CLP) Regulation resulted in a classification of Acute toxicity by inhalation Category 1, which is equivalent to the Division 6.1 hazard classification. As a result of this testing, it was determined that when this material is in fine powder form, it must no longer be transported as Class 9 miscellaneous hazard material. In powder form, cobalt dihydroxide powder must now be classified as a Division 6.1 toxic-by-inhalation solid material, for which a unique UN identification number and associated classification, hazard communication, and packing instructions does not currently exist in the HMT. This change in classification led to the development of the new UN identification number UN3550 and associated transportation requirements by the UNSCOE. To that end, the UNSCOE developed appropriate packaging provisions, including a special packaging condition, which permits the continued use of certain flexible IBCs. PHMSA notes that other forms of cobalt dihydroxide powder may continue to be classified and described as “UN3077, Environmentally hazardous, solid, n.o.s., 9, PG III.” Specifically, the UNSCOE addressed shipper concerns that flexible IBCs are not otherwise permitted for transport of Division 6.1 toxic solids, yet there is a 40-year record of safe transport of the refined material as UN3077 material in flexible IBCs, with no recorded accidents, incidents, or health issues. PHMSA proposes to also add a corresponding special provision (IP22) to indicate that the use of certain flexible IBCs is permitted for UN3550, which is discussed further in §172.102 of this Section-by-Section Review). The other packaging provisions for this cobalt dihydroxide powder are consistent with those for other Division 6.1 solid materials assigned PG I, such as “UN3467, Organometallic compound, solid, toxic, n.o.s.” An entry for UN3550 was also added in the 2023–2024 ICAO Technical Instructions and aligns with the proposed packaging requirements in this NPRM. PHMSA agrees with the UN provision to allow for the continued transport of this hazardous material in flexible IBCs, or in accordance with other special provisions and packaging requirements outlined in Part 173. The addition of this new HMT entry will maintain the HMR's safety standard for transportation of Division 6.1 solid materials.

HMT Corrections

PHMSA proposes to make corrections to multiple HMT entries that were inadvertently modified in previous rulemakings. Specifically, for the PGII and PGIII entries for “UN3129, Water-reactive liquid, corrosive, n.o.s” and “UN3148, Water-reactive liquid, n.o.s”, the references to exceptions in §173.151 in Column 8A were removed and replaced with the word “None”. While there are no exceptions these materials when assigned to PGI, PHMSA did not intend to remove the exceptions for PGII and III materials. Additionally, for the PGIII entry for “UN3148, Water-reactive liquid, n.o.s”, the “G” in Column 1, which indicates that a technical name must be provided in association with the proper shipping name, was also inadvertently deleted. PHMSA expects that making these editorial corrections will prevent frustrations in shipping due to the inadvertent removal of the reference to authorized shipping exceptions and confusion regarding the required shipping description. PHMSA also proposes a correction to the entry “UN0512, Detonators, electronic programmable for blasting”. In HM–215P, PHMSA added three new entries for electronic detonators to distinguish them from electric detonators, which have different functioning characteristics but similar regulatory provisions for their transport. PHMSA incorrectly assigned an obsolete special provision, Special Provision 103, which was removed from the HMR by final rule HM–219C. 13 UN0512 is comparable to the entry UN0255 and therefore should reflect the same special provision, Special Provision 148. Therefore, PHMSA proposes to remove the reference to Special Provision 103 in Column 7 for UN0512 and replace it with Special Provision 148 consistent with the entry of UN0255. PHMSA expects that this correction will remove confusion surrounding additional provisions for these detonators. Lastly, PHMSA proposes a correction to the proper shipping name for UN3380, which should read “Desensitized explosive, solid, n.o.s.”. In the previous HM–215 rulemaking, the word “explosive” was inadvertently made plural. This spelling is in conflict with a similar material on the HMT, “UN3379. Desensitized explosive, liquid, n.o.s.” and international regulations. Therefore, PHMSA expects that this correction will remove confusion surrounding the proper shipping name for these materials.

13 85 FR 75680 (November 25, 2020).

Lastly, PHMSA proposes to make a correction to the HMT entry for “UN1791, Hypochlorite Solutions”. In HM–215O, PHMSA added stowage codes 53 and 58—which require stowage “separated from alkaline compounds” and “separated from cyanides,” respectively—to Column 10B of the HMT for several hazardous materials for consistency with changes included in Amendment 39–18 of the IMDG Code. These stowage codes were intended to be applied to several HMT entries to ensure proper segregation between acids and both amines and cyanides but should not have included UN1791. Therefore, PHMSA proposes to remove stowage codes 53 and 58 from Column 10B for this entry. PHMSA expects that this correction will remove the burden faced by shippers who have had to segregate hypochlorite solutions for compliance with the HMR, which is inconsistent with the requirements of the IMDG Code.

Column (2) Hazardous Materials Descriptions and Proper Shipping Names

Section 172.101(c) describes column (2) of the HMT and the requirements for hazardous materials descriptions and PSNs. PHMSA proposes to consolidate two entries in the HMT that are currently listed under “UN1169, Extracts, aromatic, liquid” (PGII and PGIII) and “UN1197, Extracts, flavoring, liquid” (PGII and PGIII). Specifically, PHMSA proposes to remove the table entry for “UN1169, Extracts, aromatic, liquid” and modify the PSN associated with the table entry for UN1197 to reflect materials that have been historically transported separately under UN1169 and UN1197. The 22nd revised edition of the UN Model Regulations made these same changes, deleting UN1169 from the Dangerous Goods List and changing the PSN for UN1197 to “Extracts, liquid, for flavor or aroma” to remove confusion associated with selection of the appropriate PSNs across the various languages of nations engaged in international shipments of the material. It became apparent that, whether for a flavor extract or aroma extract, the PSNs were often used interchangeably as there is no difference between the two with regard to classification, hazard communication, and packaging for transport. PHMSA agrees that the existence of two interchangeable UN numbers does not provide any additional value and, therefore, proposes to remove the table entry for UN1169 and modify the PSN for UN1197 to read “Extracts, liquid, for flavor or aroma ”. Additionally, PHMSA proposes to amend the text of paragraph (c)(12)(ii), which outlines requirements for generic or n.o.s. descriptions. The text of this paragraph provides an example using “Extracts, flavoring, liquid.” Therefore, PHMSA proposes to amend the wording of that example by replacing “Extracts, flavoring, liquid” with “Extracts, liquid, for flavor or aroma” to correspond to the amended PSN for UN1197. This proposed action maintains the current level of safety for transportation of liquid extracts.

Column (3) Hazard Class or Division

Section 172.101(d) describes column (3) of the HMT, which designates the hazard class or division corresponding to the PSN of that entry. Consistent with changes adopted in the 22nd revised edition of the UN Model Regulations, PHMSA proposes to change the primary hazard classification for the entry “UN1891, Ethyl Bromide,” from a toxic liquid of Division 6.1 to a Class 3 flammable liquid. This change in classification is consistent with the change adopted in the 2023–2024 ICAO Technical Instructions as well as the UN Model Regulations and is based on new test data indicating that the flash point and boiling point of ethyl bromide has a core flammability hazard according to the Class 3 classification criteria of the ICAO Technical Instructions. More specifically, different data sources showed that its flash point of −20 °C (−4 °F) and its boiling point of 38 °C (100.4 °F) meet the criteria for assignment as a Class 3 at the PG II level—the criteria of which is having a flash point <23 °C and boiling point >35 °C. Additionally, rather than classifying ethyl bromide solely as a Class 3 flammable liquid, it was determined that the Division 6.1 hazard still applies and should remain assigned as a subsidiary hazard. This is consistent with the HMR precedence of the hazard table in §173.2a that instructs for a material that meets criteria for classification as both Class 3 and Division 6.1 (except for when a material meets the PG I poison-by-inhalation criteria), the flammability hazard takes precedence and is the primary hazard. These changes in hazard class and associated packaging requirements were adopted to ensure that the hazards of ethyl bromide are accurately communicated and appropriately packaged. PHMSA reviewed these findings and agrees that it is appropriate to classify ethyl bromide as a flammable liquid, with a subsidiary Division 6.1 hazard. Because of this change in hazard class, additional conforming changes to the HMT entry for ethyl bromide are required in column (6), as discussed below. Additionally, PHMSA expects that clearly identifying the flammability hazard posed by this material will improve safety by ensuring that the material is handled appropriately before and during transport.

Column (6) Label Codes

Section 172.101(g) describes column (6) of the HMT, which contains label codes representing the hazard warning labels required for a package filled with a material conforming to the associated hazard class and proper shipping name, unless the package is otherwise excepted from labeling. The first code is indicative of the primary hazard of the material. Additional label codes are indicative of subsidiary hazards. As discussed above, PHMSA proposes to modify the primary hazard class for “UN1891, Ethyl bromide” to Class 3. Consistent with this change, PHMSA proposes to assign Class 3 as the primary hazard label and Division 6.1 as a subsidiary hazard label. Consequently, PHMSA proposes to amend column (6) of the HMT for this entry to reflect the warning labels required for the transport of this hazardous material. PHMSA expects that this proposed change will improve safety by clearly communicating the transportation hazards of this material.

Column (7) Special Provisions

Section 172.101(h) describes column (7) of the HMT, which assigns special provisions for each HMT entry. Section 172.102 provides for the meaning and requirements of the special provisions assigned to entries in the HMT. The proposed revisions to column (7) of certain entries in the HMT are discussed below.

Special Provision 396

PHMSA proposes to add a new special provision, Special Provision 396, and assigning it to “UN3538, Articles containing non-flammable, non-toxic gas, n.o.s.” For additional information, see §172.102 of the Section-by-Section Review.

Special Provision 398

PHMSA proposes to assign a newly added special provision, Special Provision 398, which pertains to the potential classification of butylene and butylene mixtures as UN1012. This special provision clarifies that butylene mixtures and certain butylene isomers may be assigned to UN1012, while specifically excluding isobutylene from this UN classification. For additional information, see §172.102 of the Section-by-Section Review.

Special Provisions A4 and A5

PHMSA proposes to assign Special Provision A4 to the entry “UN2922, Corrosive liquid, toxic, n.o.s.” and Special Provision A5 to the entry “UN2923, Corrosive solid, toxic, n.o.s.”. Special Provisions A4 and A5 address liquids and solids in PG I that also pose an inhalation toxicity hazard by limiting or prohibiting their transportation on aircraft. In principle, all liquids or solids that have an inhalation toxicity hazard, and assigned PG I, should be subject to one of the two special provisions, as appropriate. However, UN2922 and UN2923 are assigned Class 8 as the primary hazard and Division 6.1 as a subsidiary hazard because of classification guidelines which require hazardous materials that meet the criteria of Class 8 and that have an inhalation toxicity of dusts and mists (LC50) in the range of PG I, but toxicity through oral ingestion or dermal contact only in the range of PG III or less, must be assigned to Class 8 as the primary hazard rather than Division 6.1. In reviewing these provisions, the ICAO Dangerous Goods Panel (DGP) determined that additional restrictions should be implemented for these hazardous materials as the corrosive classification assigned to UN2922 and UN2923 does not negate the inhalation toxicity hazard. Because of the inhalation hazard posed by these materials, the 2023–2024 ICAO Technical Instructions included an amendment to impose quantity limits for transportation of these materials by air. PHMSA agrees with this determination and therefore proposes to assign Special Provision A4 to UN2922, which prohibits it from transport on passenger and cargo aircraft. PHMSA also proposes to assign Special Provision A5 to UN2923, which prohibits this material on passenger aircraft and limits the amount that may be transported on cargo aircraft. PHMSA expects that correcting this conflict will improve safety by prohibiting corrosive materials that also pose inhalation hazards on passenger aircraft and limiting their transport on cargo aircraft.

Special Provisions A224 and A225

PHMSA proposes to add two new air special provisions, A224 and A225, and assign them to HMT entries “UN3548, Articles containing miscellaneous dangerous goods, n.o.s.” and “UN3538, Articles containing non-flammable, non-toxic gas, n.o.s.,” respectively. These special provisions would allow for transport on both passenger aircraft and cargo aircraft under certain conditions. For additional information, see 172.102 of the Section-by-Section Review. Also, see §172.102 of the Section-By-Section Review below for a detailed discussion of the special provision amendments addressed in this NPRM.

Column (8) Packaging

Section 172.101(i) explains the purpose of column (8) in the HMT. Columns (8A), (8B), and (8C) specify the applicable sections for exceptions, non-bulk packaging requirements, and bulk packaging requirements, respectively. Columns (8A), (8B), and (8C) are completed in a manner which indicates that “§173.” precedes the designated numerical entry. Column (8A) contains exceptions from some of the requirements of this subchapter. The referenced exceptions are in addition to those specified in subpart A of part 173 and elsewhere in subchapter C. The word “None” in this column means no packaging exceptions are authorized, except as may be provided by special provisions in column (7). For example, the entry “151” in column (8A), associated with the proper shipping name “Nitrocellulose with water,” indicates that, for this material, packaging exceptions are provided in §173.151 of this subchapter.

PHMSA proposes to remove references to §173.151, which provide exceptions for Class 4 hazardous materials, in column (8A), and add the word “None” for three solid desensitized explosive entries: “UN2555, Nitrocellulose with water with not less than 25 percent water by mass ”; “UN2556, Nitrocellulose with alcohol with not less than 25 percent alcohol by mass, and with not more than 12.6 percent nitrogen, by dry mass ”; and “UN2557, Nitrocellulose, with not more than 12.6 percent nitrogen, by dry mass mixture with or without plasticizer, with or without pigment.” These changes would remove the applicability of the limited quantity exceptions for these hazardous materials to correct an inconsistency regarding solid desensitized explosives. Consistent with the UN Model Regulations, PHMSA has not authorized limited quantity packaging exceptions for 30 other solid desensitized explosives. 14 Solid desensitized explosives are explosive substances which are wetted with water or alcohols or are diluted with other substances to form a homogeneous solid mixture to suppress their explosive properties. Like PG I materials, solid desensitized explosives in PG II are specifically prohibited from transport under the limited quantity provisions in the UN Model Regulations. However, this inconsistency was identified with respect to air transport by the ICAO DGP (Dangerous Goods Panel), resulting in a similar amendment in the 2023–2024 ICAO Technical Instructions. In this NPRM, PHMSA also proposes related editorial amendments in §173.27, general requirements for transportation by aircraft ( see additional discussion in §173.27 of Section-by-Section Review). PHMSA expects that correcting this oversight to require that these nitrocellulose mixtures be transported in accordance with all requirements of the HMR, rather than permitting the use of the limited quantity exceptions in §173.151, will not only add an additional level of safety, but that it will also facilitate the transport of these materials by streamlining packaging and hazard communication requirements to be consistent with requirements for similar materials and with international regulations.

14 UN1310, UN1320, UN1321, UN1322, UN1336, UN1337, UN1344, UN1347, UN1348, UN1349, UN1354, UN1355, UN1356, UN1357, UN1517, UN1571, UN2555, UN2556, UN2557, UN2852, UN2907, UN3317, UN3319, UN3344, UN3364, UN3365, UN3366, UN3367, UN3368, UN3369, UN3370, UN3376, UN3380, and UN3474.UN1517, UN1571, UN2555, UN2556, UN2557, UN2852, UN2907, UN3317, UN3319, UN3344, UN3364, UN3365, UN3366, UN3367, UN3368, UN3369, UN3370, UN3376, UN3380, and UN3474.

Column (9) Quantity Limitations

Section 172.101(j) explains the purpose of column (9) in the HMT. Column (9) specifies quantity limitations for packages transported by air and rail. Column (9) is divided into two columns: column (9A) provides quantity limits for passenger aircraft/rail, and column (9B) provides quantity limits for cargo aircraft.

Consistent with changes adopted in the 2023–2024 edition of the ICAO Technical Instructions, PHMSA proposes to amend the quantity limitations for UN 1891, Ethyl bromide, when transported by passenger aircraft. Previously, the maximum net quantity per package for passenger aircraft was 5 L on the Dangerous Goods List of the ICAO Technical Instructions; this same quantity limit is currently in place for passenger aircraft, as indicated in column (9A) of the HMT. As a result of the reclassification of UN1891 as a Class 3 flammable liquid, the permitted quantity was reduced in the ICAO Technical Instructions to 1L per packaging. This change is in line with the quantity limits for many other Class 3 materials. PHMSA proposes to make a corresponding change for passenger aircraft limits in column (9A). With regard to cargo aircraft, no changes to the 60 L maximum net quantity were made in the ICAO Technical Instructions, as that limit is the same for Class 3 and Division 6.1 materials. PHMSA expects that this change will provide an additional level of safety commensurate to the newly recognized flammability hazard posed by this material.