['Hazmat', 'Hazardous Materials Table']

['Identification numbers - Hazmat', 'Hazmat Special Requirements', 'Hazardous materials table']

06/12/2024

...

DEPARTMENT OF TRANSPORTATION

Pipeline and Hazardous Materials Safety Administration

49 CFR Parts 171, 172, 173, 175, 176, 178, and 180

[Docket No. PHMSA-2019-0030 (HM-215P)]

RIN 2137-AF46

Hazardous Materials: Harmonization With International Standards

AGENCY: Pipeline and Hazardous Materials Safety Administration (PHMSA), Department of Transportation (DOT).

ACTION: Final rule.

SUMMARY: PHMSA is amending the Hazardous Materials Regulations (HMR) to maintain alignment with international regulations and standards by adopting various amendments, including changes to proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements. Additionally, PHMSA is amending the HMR to allow for better alignment with Transport Canada's Transportation of Dangerous Goods Regulations. PHMSA is also withdrawing the unpublished October 1, 2020, Notice of Enforcement Policy Regarding International Standards on use of select updated international standards in complying with the HMR during the pendency of this rulemaking.

DATES:

Effective date: This rule is effective August 25, 2022.

Voluntary compliance date: January 1, 2021.

Delayed compliance date: July 26, 2023.

Incorporation by reference date: The incorporation by reference of certain publications listed in this rule is approved by the Director of the Federal Register on August 25, 2022. The incorporation by reference of certain other publications listed in this rule was approved by the Director of the Federal Register as of May 11, 2020.

FOR FURTHER INFORMATION CONTACT: Candace Casey, Standards and Rulemaking, Steven Andrews, Standards and Rulemaking, or Aaron Wiener, International Program, at (202) 366-8553, Pipeline and Hazardous Materials Safety Administration, U.S. Department of Transportation, 1200 New Jersey Avenue SE, East Building, 2nd Floor, Washington, DC 20590-0001.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Executive Summary

II. Background

III. Incorporation by Reference Discussion Under 1 CFR Part 51

IV. Comment Discussion

V. Section-by-Section Review of Amendments

VI. Regulatory Analyses and Notices

A. Statutory/Legal Authority for This Rulemaking

B. Executive Order 12866 and DOT Regulatory Policies and Procedures

C. Executive Order 13132

D. Executive Order 13175

E. Regulatory Flexibility Act and Executive Order 13272

F. Paperwork Reduction Act

G. Unfunded Mandates Reform Act of 1995

H. Environment Assessment

I. Executive Order 12898

J. Privacy Act

K. Executive Order 13609 and International Trade Analysis

L. National Technology Transfer and Advancement Act

I. Executive Summary

As discussed in further detail in this final rule (see the V. Section-by-Section Review of Amendments), the Pipeline and Hazardous Materials Safety Administration (PHMSA) amends certain sections of the Hazardous Materials Regulations (HMR; 49 CFR parts 171 to 180) to maintain alignment with international regulations and standards by adopting various amendments, including changes to proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements. Furthermore, this final rule addresses the 17 sets of comments received in response to the Notice of Proposed Rulemaking (NPRM) 1 published in August 2021. Overall, the comments to the NPRM were generally supportive of the proposals made; however, PHMSA did receive a few comments seeking further clarification or revisions to the NPRM which PHMSA also addresses in this final rule.

1 86 FR 43844 (Aug. 10, 2021).

PHMSA expects that the adoption of the regulatory amendments in this final rule will facilitate transportation efficiency while maintaining the high safety standard currently achieved under the HMR. For example, the final rule will improve the safe transportation of vaccines and other medical materials associated with the ongoing response to the coronavirus disease 2019 (COVID-19) public health emergency, or any similar public health emergency that may emerge, by removing unnecessary regulatory hurdles to the international movement of those materials. This final rule will also align HMR requirements with anticipated increases in the volume of lithium batteries transported in interstate commerce from electrification of the transportation and other economic sectors. PHMSA also notes that the harmonization of the HMR with international consensus standards could reduce delays and interruptions of hazardous materials during transportation. The amendments may also lower greenhouse gas (GHG) emissions and safety risks to minority, low-income, underserved, and other disadvantaged populations, and communities in the vicinity of interim storage sites and transportation arteries and hubs.

The following list summarizes the more noteworthy amendments set forth in this final rule:

- Incorporation by Reference: PHMSA is incorporating by reference updated versions of the following international hazardous materials regulations and standards: the 2021-2022 Edition of the International Civil Aviation Organization Technical Instructions for the Safe Transport of Dangerous Goods by Air (ICAO Technical Instructions); Amendment 40-20 to the International Maritime Dangerous Goods Code (IMDG Code); the 21st revised edition of the United Nations Recommendations on the Transport of Dangerous Goods—Model Regulations (UN Model Regulations); and the International Atomic Energy Agency (IAEA) “Specific Safety Requirements Number SSR-6: Regulations for the Safe Transport of Radioactive Material 2018 Edition” (SSR-6, Rev.1). PHMSA also incorporates by reference several new or updated International Organization for Standardization (ISO) standards, as well as an updated version of the Organization for Economic Cooperation and Development (OECD) Guidelines for the Testing of Chemicals Test No. 431: In vitro skin corrosion: reconstructed human epidermis (RHE) test method.

- Transport Canada temporary certificates: PHMSA is amending the HMR to authorize the highway or rail transportation of a hazardous material within the United States pursuant to a temporary certificate issued under Transport Canada's Transportation of Dangerous Goods Regulations (TDG Regulations).

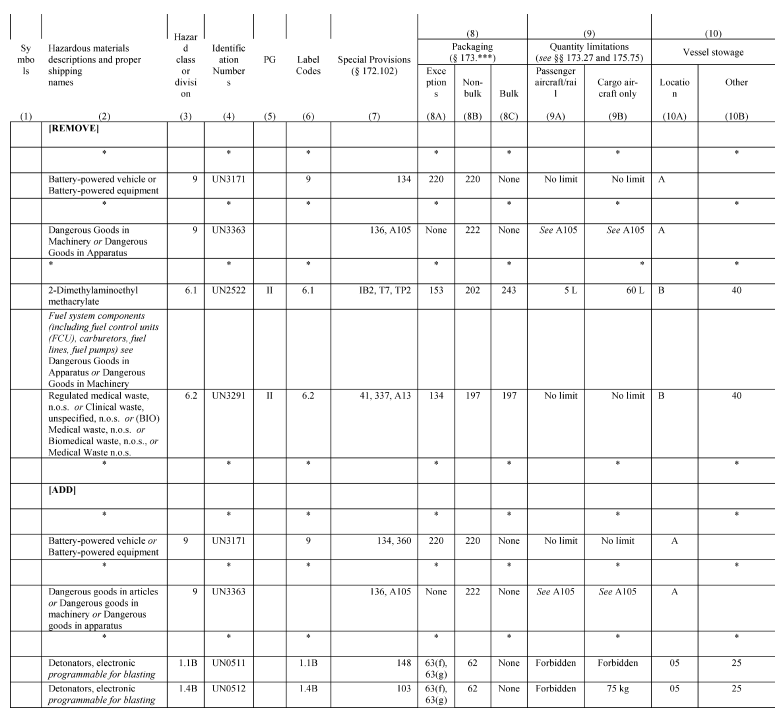

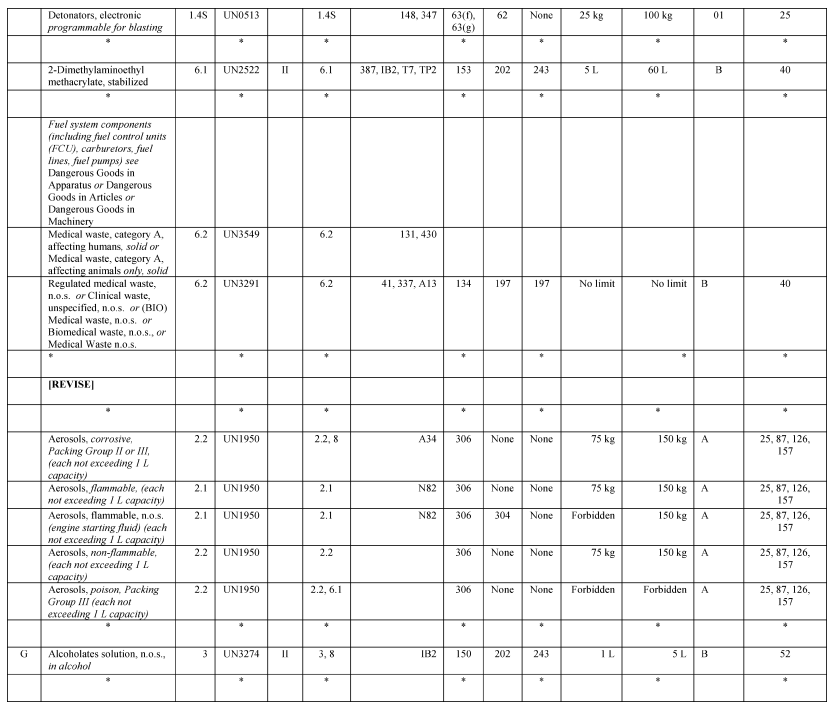

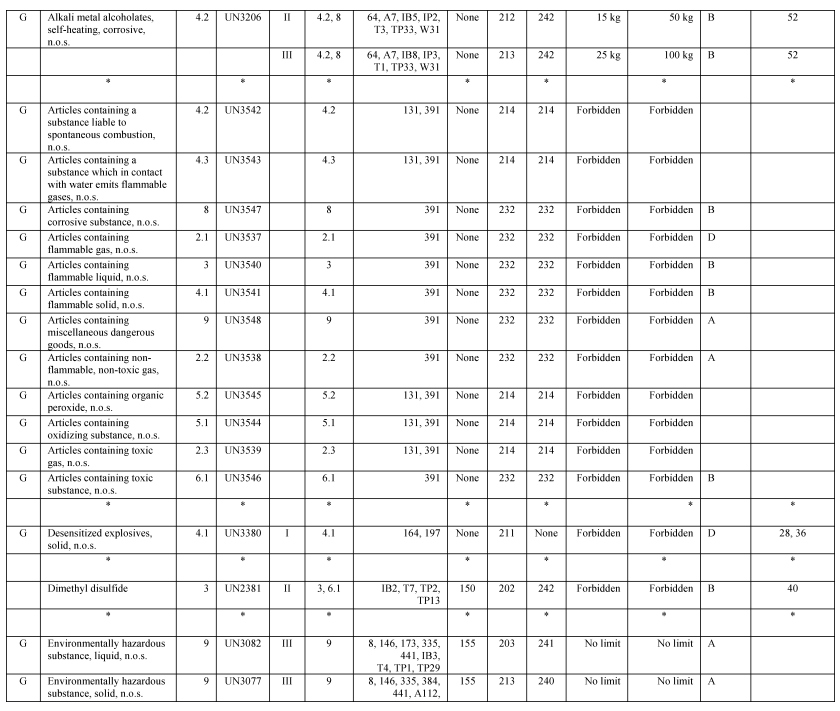

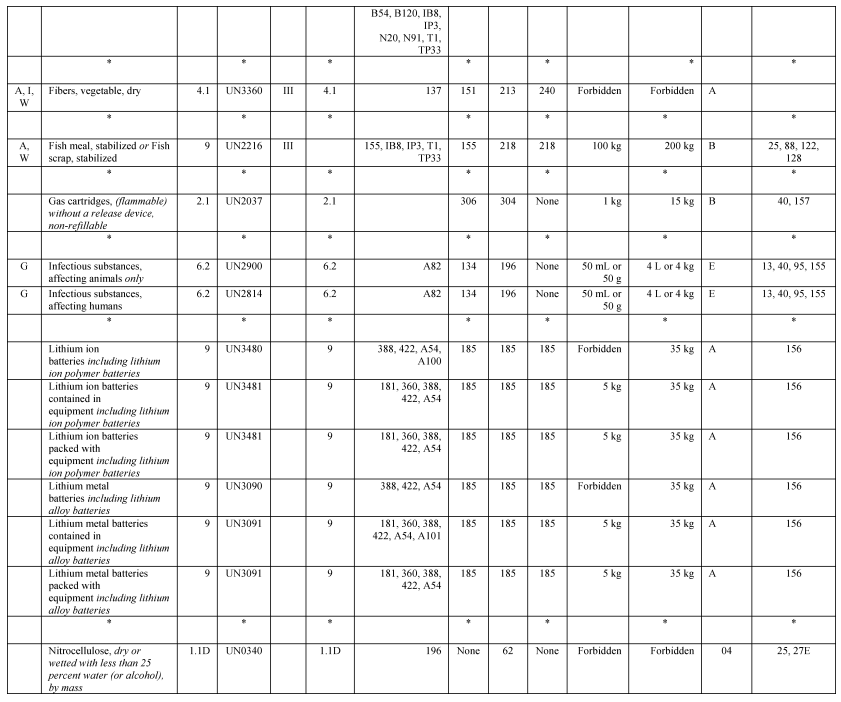

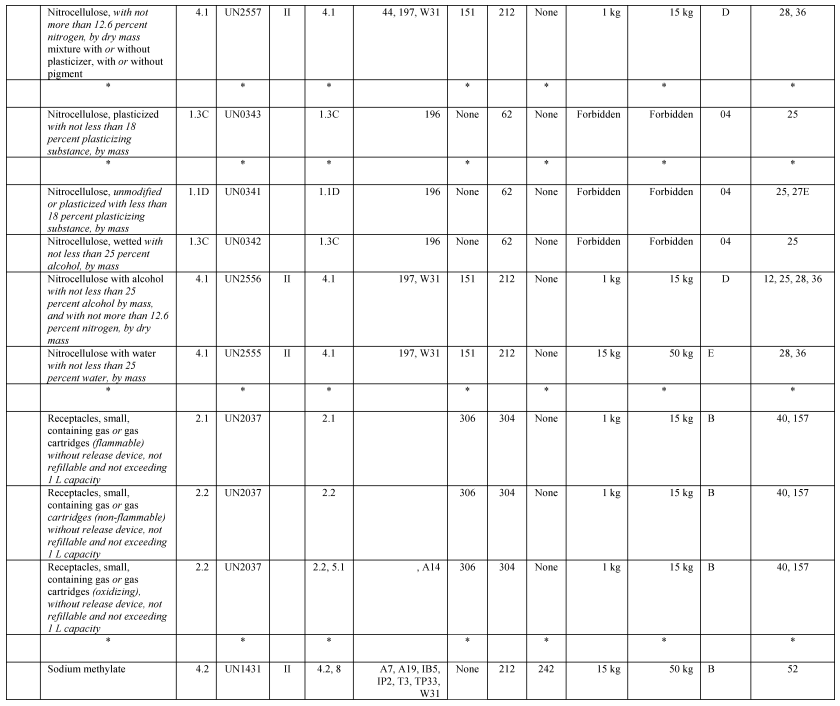

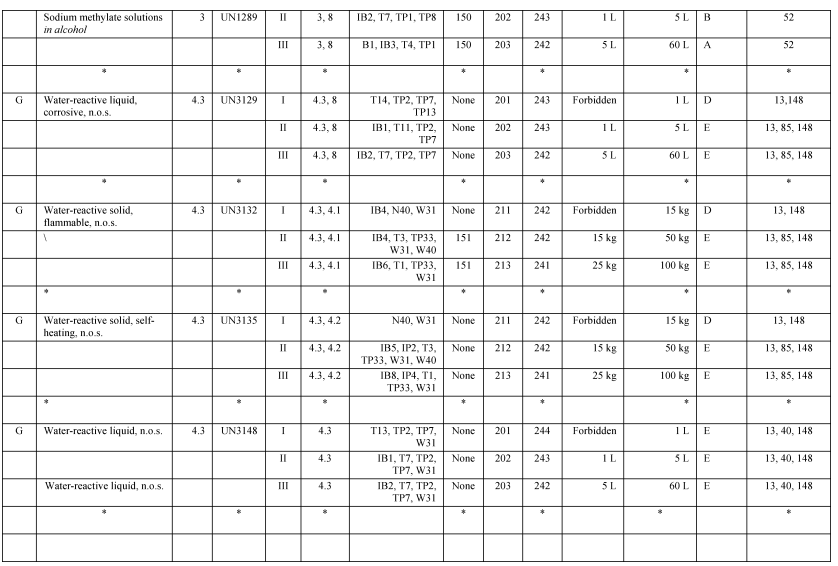

- Hazardous Materials Table: PHMSA is amending the Hazardous Materials Table (HMT; 49 CFR 172.101) to add, revise, or remove certain proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, bulk packaging requirements, and passenger and cargo aircraft maximum quantity limits.

- Data loggers: PHMSA is adopting provisions for lithium batteries in equipment that are attached to or contained in packagings, large packagings, intermediate bulk containers (IBCs), or cargo transport units as equipment in use or intended for use during transport, such as data loggers. Additionally, in response to the COVID-19 public health emergency and consistent with revisions to the 2021-2022 ICAO Technical Instructions, PHMSA is adding provisions specific to the air transportation of these items used in association with shipments of COVID-19 pharmaceuticals, including vaccines.

- Removal of metal wall thickness requirements for certain metal IBCs: PHMSA is removing the minimum wall thickness requirements for metal IBCs that have a capacity of 1500 liters (L) or less.

- Stabilized fish meal or fish scrap by air: PHMSA is authorizing the transport of stabilized fish meal or fish scrap (UN2216) on passenger and cargo aircraft. Currently, when transported as a Class 9 material, stabilized fish meal or fish scrap is only authorized for transportation by vessel. As a part of this amendment, PHMSA is also expanding the applicability of the stabilization requirements currently in place for shipments of these materials by vessel.

- UN3549 Category A Medical Wastes: PHMSA is adding an entry to the HMT for “UN3549, Medical Waste, Category A, Affecting Humans, solid or Medical Waste, Category A, Affecting Animals only, solid. ” This entry provides an additional shipping description for solid materials meeting the Category A classification criteria that are not appropriate for classification in existing entries/classes “UN2814, Infectious substances, affecting humans, 6.2” or “UN2900, Infectious substances, affecting animals only, 6.2.” Solid medical waste containing Category A infectious substances generated from the medical treatment of humans or veterinary treatment of animals (e.g., disposable personal protective equipment) may be assigned to UN3549. Although PHMSA is not adopting certain packaging provisions adopted in the UN Model Regulations (UNMR), we are assigning Special Provision 131—which directs shippers to request approval from the Associate Administrator, through a special permit, prior to transportation—to UN3549. Additionally, PHMSA is amending certain parts of §173.134, which provides definitions and exceptions for Class 6, Division 6.2 hazardous materials, to include references to this new UN number and proper shipping name.

- Additional packagings for “UN2211, Polymeric beads, expandable, evolving flammable vapor” and “UN3314, Plastic molding compound in dough, sheet or extruded rope form evolving flammable vapor”: PHMSA is expanding the authorized packagings for polymeric beads and plastic molding compound to include combination packagings rather than limiting packaging options to single packagings.

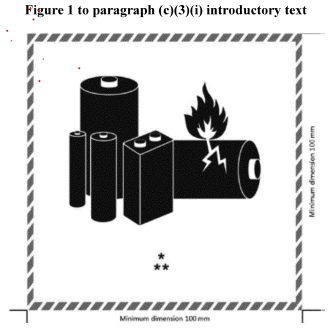

- Miscellaneous revisions of requirements pertaining to the transportation of lithium batteries: PHMSA is amending several provisions, including, but not limited to, minimum size markings and modification of stowage requirements for lithium batteries including those offered as damaged/defective or for disposal/recycling. PHMSA expects the revisions will contribute to the safe transportation of increased volumes of lithium batteries anticipated as a result of the increased use of that technology in the transportation and other economic sectors.

- Definition of SADT (Self-accelerating decomposition temperature) and SAPT (Self-accelerating polymerizing temperature): PHMSA is amending the definitions of SADT and SAPT to clarify that the lowest temperature at which these chemical reactions may occur in a packaging, IBC, or portable tank.

- Periodic inspection for chemicals under pressure: PHMSA is extending the periodic inspection, from five to ten years, for cylinders that are filled with hazardous materials described as “UN3500, Chemicals under pressure, n.o.s.” that are also used as fire extinguishing agents.

- Technical name requirements for marine pollutants: PHMSA is amending provisions pertaining to the addition of technical names to the shipping description when transporting hazardous materials that contain marine pollutants. These amendments aim to provide flexibility regarding documentation and marking requirements, which currently require identifying the technical names of marine pollutant components in those materials. Additionally, PHMSA is amending §§172.203(l) and 172.322 to limit the applicability of requirements for specific marine pollutant constituents for generic entries (indicated by the letter “G” in column 1 of the Hazardous Materials Table) and those containing “n.o.s.” as part of the proper shipping names.

- Stability tests for nitrocellulose: PHMSA is adding stability testing requirements for nitrocellulose to require that these materials meet the criteria of the Bergmann-Junk test or methyl violet paper test in the UN Manual of Tests and Criteria, Appendix 10.

Some of the amendments represent clear improvements in safety, such as nitrocellulose stability testing, additional closures for packagings intended for pyrophoric materials, and on deck stowage requirements for lithium batteries transported by vessel for disposal, recycling, or those that are damaged or defective. Furthermore, all of the amendments are expected to maintain the HMR's high safety standard for the public and the environment. Additionally, PHMSA anticipates that there are safety benefits to be derived from improved compliance related to consistency amongst domestic and international regulations.

Finally, as further explained in the Regulatory Impact Analysis (RIA), PHMSA calculates that the aggregate benefits of the amendments in this final rule more than justify their aggregate costs. In fact, PHMSA estimates that the annualized quantified net cost savings of this rulemaking, using a 7 percent discount rate, are approximately $24.5 to $28.3 million per year.

II. Background

The Federal hazardous materials transportation law (49 U.S.C. 5101 et seq.) directs PHMSA to participate in relevant international standard-setting bodies and encourages alignment of the HMR with international transport standards consistent with the promotion of safety and the public interest. See 49 U.S.C. 5120. This statutory mandate reflects the importance of international standard-setting activity considering the globalization of commercial transportation of hazardous materials. Harmonization of the HMR with those efforts can reduce the costs and other burdens of complying with multiple or inconsistent safety requirements between nations. Consistency between the HMR and current international standards can also enhance safety by: (1) ensuring that the HMR is informed by the latest best practices and lessons learned; (2) improving the understanding of—and compliance with—pertinent requirements; (3) facilitating the smooth flow of hazardous materials from their points of origin to their points of destination, thereby avoiding risks to the public and the environment from release of hazardous materials from delays or interruptions in the transportation of those materials; and (4) enabling consistent emergency response procedures in the event of a hazardous materials incident.

PHMSA participates in the development of international regulations and standards for the transportation of hazardous materials. It also adopts within the HMR international standards consistent with PHMSA's safety mission. PHMSA reviews and evaluates each international standard it considers for incorporation within the HMR on its own merits, to include the effects on transportation safety, the environmental impacts, and any economic impacts. PHMSA's goal is to harmonize with international standards without diminishing the level of safety currently provided by the HMR or imposing undue burdens on the regulated community.

In a final rule published December 21, 1990, 2 PHMSA's predecessor—the Research and Special Programs Administration (RSPA)—comprehensively revised the HMR for greater consistency with the UNMR. The UNMR constitute a set of recommendations issued by the United Nations Committee of Experts (UNSCOE) on the Transport of Dangerous Goods and on the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The UNMR are amended and updated biennially by the UNSCOE and serve as the basis for national, regional, and international modal regulations, including the ICAO Technical Instructions and IMDG Code.

2 55 FR 52401 (Dec. 21, 1990).

PHMSA has evaluated recent updates to the international standards and is revising the HMR to adopt changes consistent with revisions to the 2021-2022 Edition of the ICAO Technical Instructions, Amendment 40-20 to the IMDG Code, 3 and the 21st revised edition of the UNMR, all of which were published by or in effect on January 1, 2021. PHMSA issued a Notice of Enforcement Policy Regarding International Standards 4 on October 1, 2020, stating that while PHMSA is considering the 2021-2022 Edition of the ICAO Technical Instructions and Amendment 40-20 to the IMDG Code for potential adoption into the HMR, PHMSA and other Federal agencies that enforce the HMR— e.g., the Federal Railroad Administration, the Federal Aviation Administration (FAA), the Federal Motor Carrier Safety Administration, and the United States Coast Guard—will not take enforcement action against any offeror or carrier who uses these standards as an alternative to complying with current HMR requirements when all or part of the transportation is by air with respect to the ICAO Technical Instructions, or by vessel with respect to the IMDG Code. In addition, that Notice stated PHMSA, and its modal partners will not take enforcement action against any offeror or carrier who offers or accepts for domestic or international transportation by any mode packages marked or labeled in accordance with these standards. PHMSA withdraws its October 1, 2020, Notice of Enforcement Policy Regarding International Standards as of the effective date of this final rule. Additionally, in response to the ongoing global COVID-19 public health emergency, on December 31, 2020, and February 23, 2021, ICAO published addenda to the 2021-2022 Edition of the ICAO Technical Instructions to provide additional provisions and exceptions to reduce regulatory compliance burdens for the transport of certain hazardous materials, such as alcohols and aerosols used for hygienic purposes, by air. PHMSA is including those changes to international standards in this final rule. Finally, PHMSA is incorporating by reference these new international regulations and standards as well as new requirements from the IAEA, “Specific Safety Requirements Number SSR-6: Regulations for the Safe Transport of Radioactive Material 2018 Edition” (SSR-6, Rev.1); several new or updated ISO standards; and an updated version of the OECD Guidelines for the Testing of Chemicals Test No. 431: In vitro skin corrosion: reconstructed human epidermis (RHE) test method. The standards incorporated by reference are authorized for use for domestic transportation, under specific conditions, by part 171, subpart C of the HMR.

3 Amendment 40-20 to the IMDG Code may be voluntarily complied with as of January 1, 2021; however, Amendment 39-18 will remain effective through May 31, 2022.

4 PHMSA, Notice of Enforcement Policy Regarding International Standards (Oct. 1, 2020), https://www.phmsa.dot.gov/sites/phmsa.dot.gov/files/2020-10/Notice%20of%20Enforcement%20Policy%20Regarding%20International%20Standards%20Oct%201%202020.pdf.

During PHMSA's development of the final rule, the President issued a series of Executive Orders coordinating the Federal response to the COVID-19 public health emergency—a handful of those are pertinent to this final rule. Specifically, section 2 of Executive Order 13987 (“Organizing and Mobilizing the United States Government to Provide a Unified and Effective Response to Combat COVID-19 and To Provide United States Leadership on Global Health and Security”) 5 contemplates broad-based action across the Federal Government to “produce, supply, and distribute personal protective equipment, vaccines, tests, and other supplies for the Nation's COVID-19 response.” Similarly, Executive Order 14002 (“Economic Relief Related to COVID-19 Pandemic”) 6 directs Federal agencies like PHMSA to respond to the economic harm caused by the COVID-19 public health emergency by promptly identifying actions they can take within existing authorities to provide economic relief to affected persons and businesses. Lastly, the President has announced ambitious reductions in national GHG emissions to combat climate change, identifying electrification of the transportation and other economic sectors—to include enabling more widespread use of electric storage technologies, such as lithium batteries—as a critical element of that effort. 7

5 86 FR 7019 (Jan. 20, 2021).

6 86 FR 7229 (Jan. 21, 2021).

7 See, e.g., White House, “Fact Sheet: President Biden Sets 2030 Greenhouse Gas Pollution Reduction Target Aimed at Creating Good-Paying Union Jobs and Securing U.S. Leadership on Clean Energy Technologies” (Apr. 21, 2021), https://www.whitehouse.gov/briefing-room/statements-releases/2021/04/22/fact-sheet-president-biden-sets-2030-greenhouse-gas-pollution-reduction-target-aimed-at-creating-good-paying-union-jobs-and-securing-u-s-leadership-on-clean-energy-technologies/.

III. Incorporation by Reference Discussion Under 1 CFR Part 51

According to the Office of Management and Budget (OMB), Circular A-119, “Federal Participation in the Development and Use of Voluntary Consensus Standards and in Conformity Assessment Activities,” government agencies must use voluntary consensus standards wherever practical in the development of regulations.

PHMSA currently incorporates by reference into the HMR all or parts of several standards and specifications developed and published by standard development organizations (SDOs). In general, SDOs update and revise their published standards every two to five years to reflect modern technology and best technical practices. The National Technology Transfer and Advancement Act of 1995 (NTTAA; Pub. L. 104-113) directs Federal agencies to use standards developed by voluntary consensus standards bodies in lieu of government-written standards whenever possible. Voluntary consensus standards bodies develop, establish, or coordinate technical standards using agreed-upon procedures. OMB issued Circular A-119 to implement section 12(d) of the NTTAA relative to the utilization of consensus technical standards by Federal agencies. This circular provides guidance for agencies participating in voluntary consensus standards bodies and describes procedures for satisfying the reporting requirements in the NTTAA. Accordingly, PHMSA is responsible for determining which currently referenced standards should be updated, revised, or removed, and which standards should be added to the HMR. Revisions to materials incorporated by reference in the HMR are handled via the rulemaking process, which allows for the public and regulated entities to provide input.

The UNMR, the UN Manual of Tests and Criteria, the IAEA Regulations for the Safe Transport of Radioactive Material, and the OECD Guidelines for the Testing of Chemicals Test No. 431: In vitro skin corrosion: reconstructed human epidermis (RHE) test method are free and easily accessible to the public on the internet, with access provided through the parent organization websites. The ICAO Technical Instructions, IMDG Code, and all ISO standard references are available for interested parties to purchase in either print or electronic versions through the parent organization websites. The price charged for those standards not freely available helps to cover the cost of developing, maintaining, hosting, and accessing these standards. The specific standards are discussed in greater detail in “V. Section-by-Section Review of Amendments Section” of this document.

IV. Comment Discussion

In response to the NPRM, PHMSA received 17 sets of comments 8 from the following persons:

8 https://www.regulations.gov/docket/PHMSA-2019-0030/comments.

- Airbus

- Amazon

- Anonymous

- Council on the Safe Transportation of Hazardous Articles (COSTHA)

- Dangerous Goods Advisory Council (DGAC)

- Dow Chemical Company (Dow)

- Elanore Tessitore

- Healthcare Waste Institute (HWI)

- Institute for the Makers of Explosives (IME)

- Luxfer Canada

- Luxfer Gas Cylinders

- Medical Device Transport Council (MDTC)

- The Rechargeable Battery Association (PRBA)

- Reggie Valentine

- Rigid Intermediate Bulk Container Association (RIBCA)

- Reusable Industrial Packaging Association (RIPA)

- Stericycle

PHMSA received comments from Amazon, DGAC, COSTHA, MDTC, and PRBA, all providing general support for harmonization with international standards with additional support from Luxfer Gas Cylinders for the incorporation by reference of the ISO standards applicable to cylinders. In addition, PHMSA received a comment from IME encouraging expeditious adoption of changes to international regulations into the HMR.

Comments concerning the sunset provisions for polymerizing substances, damaged or defective batteries, and comments outside the scope of this rulemaking are discussed below. All other comments specific to proposed changes to HMR sections are addressed in the “V. Section-by-Section Review of Amendments” of this document.

A. Comments Outside the Scope of This Rulemaking

PHMSA received a comment from an anonymous person noting that PHMSA did not propose to update the publications referenced in §173.58(c). This section addresses the assignment of Class and Divisions for new explosives and paragraph (c) specifically addresses classification of Division 1.6 explosives. The anonymous commenter states the provisions of §173.58(c) are outdated relative to the 21st revised edition of the UNMR and the UN Manual of Tests and Criteria 7th revised edition. The anonymous commenter suggests that PHMSA review and amend §173.58(c) to maintain alignment with international regulations. Specifically, the commenter notes that the UN provisions (as outlined in the UN Manual of Test and Criteria) currently specify that explosive substances in Division 1.6 articles must be “predominantly containing an extremely insensitive substance” and must no longer be “exclusively containing an extremely insensitive substance” as currently cited in §173.58(c). Additionally, the commenter adds that a Division 1.6 article fragment impact test has been added to the UN provisions (as outlined in the UN Manual of Test and Criteria) for Division 1.6 articles and that test is not cited within §173.58(c).

PHMSA acknowledges the commenter's concerns over the testing requirements for Division 1.6 explosives in §173.58(c). However, PHMSA did not propose changes to this section in the NPRM and, therefore, declines to make such revisions in this final rule without further evaluation by PHMSA subject matter experts and an opportunity for stakeholders to comment on the issue. If the commenter has a proposal to revise the regulatory text §173.58(c), PHMSA encourages the commenter to submit a petition for rulemaking in accordance with 49 CFR 106.100 and provide specific justification that the regulatory text at §173.58(c) must be updated to mirror language in the updated industry standards referenced elsewhere in §173.58.

In its comments on the NPRM, MDTC noted that PHMSA did not address the inclusion of Special Provision A201—approval of the State of Origin and the operator—and other provisions codified in the HM-224I Interim Final Rule (IFR). 9 While PHMSA appreciates the comments from MDTC, we are not addressing comments to the HM-224I IFR in this final rule. PHMSA will address and respond to all comments on the HM-224I IFR in a future HM-224I final rule.

9 84 FR 8006 (Mar. 6, 2019).

B. Polymerizing Substances

Dow and DGAC provided comments on the sunset dates for polymerizing substances as outlined in a previously issued international harmonization final rule, HM-215O. 10 In HM-215O, PHMSA extended the sunset dates to January 2, 2023, for polymerizing substances to allow PHMSA to complete an ongoing research project and analyze all comments and data concerning the issue submitted to the docket for the HM-215O 11 NPRM. Dow and DGAC are concerned that the next international harmonization rule will be published after January 2, 2023, resulting in polymerizing substances regulations no longer being in effect for transportation in accordance with the HMR. PHMSA expects to address these concerns regarding sunset dates for transportation of polymerizing substances in a final rule prior to the expiration of the sunset dates.

10 79 FR 46012 (Aug. 16, 2014).

11 85 FR 27810 (May 11, 2020).

C. Guidance on Damaged or Defective Batteries

In its comments, MDTC and PRBA requested that PHMSA include a note from Special Provision 376 of the UNMR for determining whether a lithium battery is damaged or defective within the amendments adopted in this final rule. The commenters state this note will better assist shippers on how to evaluate whether a lithium battery is considered damaged or defective. PHMSA appreciates MDTC and PRBA bringing this issue to our attention and concurs that more guidance is needed to help in the determination of when a lithium battery is considered damaged or defective. However, the note to Special Provision 376 of the UNMR is guidance and not prescriptive language within that international standard. While PHMSA does not believe it is appropriate to codify the note to Special Provision 376 of the UNMR within the HMR currently, PHMSA acknowledges the value of the Special Provision 376 language in providing guidance on the shipment of damaged or defective batteries. Towards that end, PHMSA has issued a safety advisory notice on the shipment of damaged or defective batteries. 12 Within this safety advisory notice, PHMSA has paraphrased and cited the guidance presented in the note to Special Provision 376 of the UNMR for determining when a battery is damaged or defective. PHMSA encourages the shippers of damaged or defective batteries to review this notice for assistance in the shipment of damaged or defective lithium batteries.

12 See the “Safety Advisory Notice for the Disposal and Recycling of Lithium Batteries in Commercial Transportation” issued on May 17, 2022, at: https://www.phmsa.dot.gov/news/phmsa-safety-advisory-notice-transportation-lithium-batteries-disposal-or-recycling.

D. Support for PHMSA's Decision Not To Propose Certain Amendments

DGAC provided comments on revisions in the 21st revised edition of the UNMR that contain packing instructions for several electric battery entries in the UNMR. The 21st revised edition of the UNMR contains amendments to Packing Instruction P801, applicable to used batteries assigned the following UN numbers: “UN2794, Batteries, wet, filled with acid, electric storage;” “UN2795, Batteries, wet, filled with alkali, electric storage;” and “UN3028, Batteries, dry, containing potassium hydroxide solid, electric storage.” These amendments were adopted to correct issues unique to the UNMR pertaining to the required use of stainless-steel boxes and plastic bins as packaging for these used batteries. DGAC provided comments in support of PHMSA's decision to not propose adopting these unique packaging requirements into the HMR and concurs with PHMSA's position that there is not a sufficient safety justification to limit the transport of used batteries. DGAC concludes the new provisions to P801 for these batteries would not substantially improve their safe transportation.

V. Section-by-Section Review of Amendments

The following is a section-by-section review of the amendments in this final rule.

A. Part 171

Section 171.7

Section 171.7 provides a listing of all voluntary consensus standards incorporated by reference into the HMR, as directed by the NTTAA. For this rulemaking, PHMSA evaluated updated international consensus standards pertaining to proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements. PHMSA contributed to the development of those updated standards—each of which build on the well-established and documented safety histories of earlier editions—as it participated in the discussions and working group activities associated with their proposal, revision, and approval. Those activities have, in turn, informed PHMSA's evaluation of the effect on safety those updated consensus standards would have when incorporated by reference and their provisions adopted into the HMR. Further, PHMSA notes that some of the consensus standards incorporated by reference within the HMR in this rulemaking have already been adopted into the regulatory schemes of other countries, noting again that PHMSA itself has issued an enforcement discretion authorizing their use as an interim strategy for complying with current HMR requirements. PHMSA is not aware of adverse safety impacts from that operational experience. For these reasons, PHMSA expects their adoption will maintain the high safety standard currently achieved under the HMR. PHMSA received a comment from DGAC in support of these incorporation by reference revisions. Therefore, PHMSA is adding or revising the following incorporation by reference materials:

- In paragraph (s)(1), incorporate by reference the 2018 edition of the IAEA Regulations for the Safe Transport of Radioactive Material, Safety Standards Series No. SSR-6 (Rev.1), to replace the 2012 edition, which is currently referenced in §§171.22; 171.23; 171.26; 173.415; 173.416; 173.417; 173.435; and 173.473. The IAEA regulations establish standards of safety for control of the radiation, criticality, and thermal hazards to people, property, and the environment that are associated with the transport of radioactive materials. Notable changes from the previous 2012 edition include clarification of certain marking requirements, a new group of surface contaminated objects SCO-III for “UN2914,” and amendments to basic radionuclide values (activity of the radionuclide as listed in §173.435) for seven specific radionuclides (Ba-135m, Ge-69, Ir-193m, Ni-57, Sr-83, Tb-149 and Tb-161). The Regulations for the Safe Transport of Radioactive Material are available for download (free PDF) and purchase in hard copy on the IAEA website at: https://www.iaea.org/publications/12288/regulations-for-the-safe-transport-of-radioactive-material.

- In paragraph (t)(1), incorporate by reference the 2021-2022 edition of the ICAO Technical Instructions, to replace the 2019-2020 Edition, which is currently referenced in §§171.8; 171.22; 171.23; 171.24; 172.101; 172.202; 172.401; 172.407; 172.512; 172.519; 172.602; 173.56; 173.320; 175.10, 175.33; and 178.3. The ICAO Technical Instructions specify detailed instructions for the safe international transport of dangerous goods by air. The requirements in the 2021-2022 edition have been amended to better align with the 21st revised edition of the UNMR and the IAEA Regulations for the Safe Transport of Radioactive Material. Notable changes in the 2021-2022 edition of the ICAO Technical Instructions include new packing and stowage provisions, new and revised entries on the Dangerous Goods List, and editorial corrections. The 2021-2022 edition of the ICAO Technical Instructions are available for purchase on the ICAO website at https://store.icao.int/en/shop-by-areas/safety/dangerous-goods.

- In paragraph (v)(2), incorporate by reference the 2020 edition of the IMDG Code, Incorporating Amendment 40-20 (English Edition), to replace Incorporating Amendment 39-18, 2018 Edition, which is currently referenced in §§171.22; 171.23; 171.25; 172.101; 172.202; 172.203; 172.401; 172.407; 172.502; 172.519; 172.602; 173.21; 173.56; 176.2; 176.5; 176.11; 176.27; 176.30; 176.83; 176.84; 176.140; 176.720; 176.906; 178.3; and 178.274. The IMDG Code is a unified international code that outlines standards and requirements for the transport of dangerous goods by vessel. Notable changes in Amendment 40-20 include new packing and stowage provisions, new and revised entries on the Dangerous Goods List, and editorial corrections. Distributors of the IMDG Code can be found on the International Maritime Organization (IMO) website at: https://www.imo.org/en/publications/Pages/Distributors-default.aspx.

- In paragraph (w), incorporate by reference or remove the following ISO documents to include new and updated standards for the specification, design, construction, testing, and use of gas cylinders:

- ISO 10156:2017, “Gas cylinders—Gases and gas mixtures—Determination of fire potential and oxidizing ability for the selection of cylinder valve outlets” in paragraph (w)(38) and referenced in §173.115. ISO 10156 specifies methods for determining whether a gas or gas mixture is flammable in air and whether a gas or gas mixture is more or less oxidizing than air under atmospheric conditions. It is intended to be used for the classification of gases and gas mixtures including the selection of gas cylinder valve outlets. This amendment removes ISO 10156:2010, third edition, and the associated corrigendum (ISO 10156:2010/Cor.1:2010(E)), from the HMR and adds the revised ISO 10156:2017(E), fourth edition, as the former documents have been withdrawn by ISO and replaced with the updated 2017 versions. As part of the five-year periodic review of all standards, ISO reviewed ISO 10156:2010 and published an updated version, ISO 10156:2017, which was published in September 2017 and adopted in the 21st revised edition of the UNMR. While many of the edits in this 2017 version were editorial changes made to suit the ISO publication rules, the standard has also been supplemented with a test method to determine the flammability limits of gases and gas mixtures in air and a calculation method to determine the lower flammability limit of a gas mixture. PHMSA expects that the latter change will enhance safety by providing improved instruction on the determination of flammability of gases and gas mixtures which aids in the proper selection of a valve. (See §173.115 of the Section-by-Section Review of Amendments for additional discussion of this change).

- ISO 10297:2014/Amd 1:2017, “Gas cylinders—Cylinder valves—Specification and type testing” in paragraph (w)(42) and referenced in §§173.301b and 178.71. ISO published this supplemental amendment to the 2014 version of this document (i.e., ISO 10297:2014) to clarify valve requirements for tubes and pressure drums and to correct errors found in the 2014 version. PHMSA references this amendment in §§173.301b and 178.71, where use of ISO 10297:2014 is required. PHMSA reviewed this document and determined that the amendments provide additional safety benefits for hazardous materials in transportation.

- ISO 10462:2013, “Gas cylinders—Transportable cylinders for dissolved acetylene—Periodic inspection and maintenance.” PHMSA is deleting the second edition of ISO 10462 currently in paragraph (w)(44) from the list of materials incorporated by reference. PHMSA requires the use of ISO 10462 for the requalification of a dissolved acetylene cylinder in §180.207. In final rule HM-215N, 13 PHMSA incorporated by reference the updated third edition of ISO 10462; however, the rule included a sunset provision to allow continued used of this second edition until December 31, 2018. Because this date has since passed, and the second edition is no longer authorized for use under §180.207, PHMSA is removing the reference to this edition in §171.7, as well as making a conforming revision to remove the sunset provision in §180.207.

13 82 FR 15796 (Mar. 30, 2017). - ISO 11114-1:2012/Amd 1:2017(E), “Gas cylinders—Compatibility of cylinder and valve materials with gas contents—Part 1: Metallic materials—Amendment 1.” In paragraph (w)(47), PHMSA is referencing—ISO 11114-1:2012/Amd 1:2017(E), in §§172.102, 173.301b, and 178.71. The 2017 ISO 11114-1:2012/Amd 1:2017(E) document supplements ISO 11114-1:2012(E), which provides requirements for the selection of safe combinations of metallic cylinder and valve materials, and cylinder gas contents. As part of ISO's regular five-year review of its standards, the 2012 version of this document was amended through the issuance of this supplemental document, ISO 11114-1:2012/Amd 1:2017(E). The ISO 11114-1:2012/Amd 1:2017(E) document amends the 2012 version by providing more explicit instructions on the permissible concentrations of gases containing halogens in aluminum cylinders. It also provides amended requirements for butylene, hydrogen cyanide, hydrogen sulfide and nitric oxide. Consequently, the 21st revised edition of the UNMR updated all references to the 2012 edition to include a reference to the supplemental amendment (ISO 11114-1:2012/Amd 1:2017(E)). PHMSA revises the HMR likewise, by amending Special Provision 379, §§173.301b and 178.71 where ISO 11114-1:2012(E) is permitted or required, to also require compatibility with ISO 11114-1:2012/Amd 1:2017(E).

- ISO 11119-1:2012(E), “Gas cylinders—Refillable composite gas cylinders and tubes—Design, construction and testing—Part 1: Hoop wrapped fibre reinforced composite gas cylinders and tubes up to 450 l,” found in paragraph (w)(55). This document specifies requirements for composite gas cylinders and tubes between 0.5 L and 450 L water capacity, for the storage and conveyance of compressed or liquefied gases. ISO 11119-1:2012(E) is currently incorporated by reference in §178.71; however, PHMSA is further incorporating by reference in §178.75 to allow for the use of this ISO standard for specification multi-element gas containers (MEGCs).

- ISO 11119-2:2012(E), “Gas cylinders—Refillable composite gas cylinders and tubes—Design, construction and testing—Part 2: Fully wrapped fibre reinforced composite gas cylinders and tubes up to 450 l with load-sharing metal liners” found in paragraph (w)(57). ISO 11119-2:2012 specifies requirements for composite gas cylinders and tubes between 0.5 L and 450 L water capacity, for the storage and conveyance of compressed or liquefied gases. ISO 11119-2:2012(E) is currently incorporated by reference in §178.71; however, PHMSA further incorporates by reference in §178.75 use of this ISO standard for specification MEGCs.

- ISO 11119-2:2012/Amd.1:2014(E), “Gas cylinders—Refillable composite gas cylinders and tubes—Design, construction and testing—Part 2: Fully wrapped fibre reinforced composite gas cylinders and tubes up to 450 L with load-sharing metal liners, Amendment 1” found in paragraph (w)(58). ISO 11119-2:2012/Amd. 1:2014(E) is currently incorporated by reference in §178.71; however, PHMSA further incorporates by reference in §178.75 the use of this ISO standard for specification MEGCs. This supplemental amendment was published to align the drop test originally provided in ISO 11119-2 with the drop test outlined in ISO 11119-3 “Gas cylinders of composite construction—Specification and test methods—Part 3: Fully wrapped fibre reinforced composite gas cylinders with non-load-sharing metallic or non-metallic liners”.

- ISO 11119-3:2013(E), “Gas cylinders of composite construction—Specification and test methods—Part 3: Fully wrapped fibre reinforced composite gas cylinders with non-load-sharing metallic or non-metallic liners” listed in paragraph (w)(60). This document is currently incorporated by reference in §178.71; however, PHMSA is additionally incorporating by reference in §178.75. ISO 11119-3:2013 specifies requirements for composite gas cylinders up to 150 L water capacity and composite tubes above 150 L water capacity and up to 450 L water capacity, for the storage and conveyance of compressed or liquefied gases.

- ISO 11119-4:2016, “Gas cylinders—Refillable composite gas cylinders—Design, construction and testing—Part 4: Fully wrapped fibre reinforced composite gas cylinders up to 150 l with load-sharing welded metallic liners,” in (w)(61), which PHMSA references in §§178.71 and 178.75. This standard provides requirements for composite gas cylinders with load-sharing welded liners between 0.5 L and 150 L water capacity and a maximum test pressure of 450 bar 14 for the storage and conveyance of compressed or liquefied gases. PHMSA is requiring UN composite cylinders and tubes to conform to this standard in §178.71. See 178.71 of Section-by-Section Review of Amendments for additional discussion on this new incorporation by reference.

14 1 Bar = 100 kPa = 14.504 psi. - ISO 14246:2014/Amd 1:2017, “Gas cylinders—Cylinder valves—Manufacturing tests and examinations—Amendment 1,” in paragraph (w)(71). PHMSA is adding a reference to this document in §178.71. This one-page amendment, published in 2017, is intended for use in conjunction with ISO 14246:2014, which specifies the procedures and acceptance criteria for manufacturing testing and examination of cylinder valves that have been manufactured to achieve type approval. This 2017 document amends the 2014 version by updating the pressure test and leakproofness test specifically for acetylene valves. Consequently, the 21st revised edition of the UNMR updated all references to the 2014 edition to include a reference to the supplemental amendment (ISO 14246/Amd 1:2017). Therefore, PHMSA is likewise adding a reference to this supplement in §178.71, which requires inspection and testing in accordance with ISO 14246:2014. See 178.71 of the Section-by-Section Review of Amendments for additional discussion.

- ISO 17879:2017, “Gas cylinders—Self-closing cylinder valves—Specification and type testing,” in paragraph (w)(75). PHMSA is adding a reference to this standard in §§173.301b and 178.71. This standard provides the design, type testing, marking, and manufacturing tests and examination requirements for self-closing cylinder valves intended to be fitted to refillable transportable gas cylinders used to transport compressed, liquefied, or dissolved gases.

- ISO 20475:2018, “Gas cylinders—Cylinder bundles—Periodic inspection and testing” in paragraph (w)(77). This standard provides the requirements for the periodic inspection and testing of cylinder bundles containing compressed, liquefied, and dissolved gas. PHMSA is adding a reference to this standard in §180.207, which provides the requirements for requalification of UN pressure receptacles.

- All ISO standards are available for preview and purchase at: https://www.iso.org/standards.html.

- In paragraph (aa)(3), incorporate by reference the updated 2016 version of the OECD Guidelines for the Testing of Chemicals “Test No. 431: In vitro skin corrosion: reconstructed human epidermis (RHE) test method.” PHMSA is updating the version of OECD Guidelines for the Testing of Chemicals Test No. 431 referenced in §173.137, to maintain alignment with the UNMR. This document is used for the identification of corrosive chemical substances and mixtures. This updated edition includes in vitro methods allowing for better differentiation between hazard categories, which had not been possible under earlier editions due to the limited set of well-known in vivo corrosive sub-category chemicals against which to validate in vitro testing results. Therefore, this updated test protocol may provide clearer distinctions between severe and less severe skin corrosives. OECD test methods can be found in the OECD iLibrary available at: https://www.oecd-ilibrary.org/.

- In paragraph (dd), incorporate by reference United Nations standards including:

- “Recommendations on the Transport of Dangerous Goods—Model Regulations,” 21st revised edition (2019), Volumes I and II, in paragraph (dd)(1), which are referenced in §§171.8; 171.12; 172.202; 172.401; 172.407; 172.502; 172.519; 173.22; 173.24; 173.24b; 173.40; 173.56; 173.192; 173.302b; 173.304b; 178.75; and 178.274. The UNMR provide framework provisions promoting uniform development of national and international regulations governing the transportation of hazardous materials by various modes of transport. At its ninth session on December 7, 2018, the UNSCOE on the Transport of Dangerous Goods and on the GHS adopted amendments to the UNMR concerning, inter alia: electric storage systems (including lithium batteries installed in cargo transport units and defective batteries), explosives, infectious waste of Category A, waste gas cartridges, harmonization with the 2018 edition of IAEA's Regulations for the Safe Transport of Radioactive Material, listing of dangerous goods, update of LC50 values for some toxic gases, and use of in vitro skin corrosion methods for classification. Therefore, PHMSA is adopting this revised edition in order to reflect these important updates.

- The Manual of Tests and Criteria, 7th revised edition (2019), in paragraph (dd)(2), which is referenced in §§171.24, 172.102; 173.21; 173.56; 173.57; 173.58; 173.60; 173.115; 173.124; 173.125; 173.127; 173.128; 173.137; 173.185; 173.220; 173.221; 173.224; 173.225; 173.232; part 173, appendix H; 175.10; 176.905; and 178.274. The Manual of Tests and Criteria contains instruction for the classification of hazardous materials for purposes of transportation according to the UNMR. PHMSA replaces the sixth revised edition (2015) and the sixth revised edition, Amendment 1 (2017) with the 7th revised edition. The amendments adopted in 2018 for the 7th revised edition include: a full review of the text of the Manual to facilitate its use in the context of the GHS; a new test under test series 8 to determine the sensitiveness of a candidate ammonium nitrate, emulsion or suspension, or gel, intermediate for blasting explosive, to the effect of intense localized thermal ignition under high confinement; new provisions addressing classification of polymerizing substances for transport; stability tests for nitrocellulose mixtures (new Appendix 10); and a compilation of classification results on industrial nitrocellulose in accordance with Chapter 2.17 of the GHS, which can be used for the classification of industrial nitrocellulose based products (new Appendix 11). Additionally, the Committee considered that the reference to the “Recommendations on the Transport of Dangerous Goods” in the title of the manual was no longer appropriate and decided that the manual should be entitled “Manual of Tests and Criteria.” Therefore, PHMSA amends the title of this document in the list of reference material in §171.7 to reflect this change. Finally, PHMSA is adopting this revised edition in order to reflect these important updates.

- “Globally Harmonized System of Classification and Labelling of Chemicals”, eighth revised edition (2019) in paragraph (dd)(3), which is referenced in §172.401. The GHS standard provides a basic scheme to identify the hazards of substances and mixtures and to communicate the hazards. At its ninth session on December 7, 2018, the Committee adopted a set of amendments to the 7th revised edition of the GHS which include, inter alia: new classification criteria, hazard communication elements, decision logics, and guidance for chemicals under pressure; new provisions for the use of in vitro/ex vivo data and non-test methods to assess skin corrosion and skin irritation; miscellaneous amendments to clarify the classification criteria for Specific Target Organ Toxicity; revised and further rationalized precautionary statements and an editorial revision of Sections 2 and 3 of Annex 3; new examples of precautionary pictograms to convey the precautionary statement “Keep out of reach of children”; a new example in Annex 7 addressing labelling of sets or kits; and guidance on the identification of dust explosion hazards and the need for risk assessment, prevention, mitigation, and hazard communication. Therefore, PHMSA is adopting this revised edition in order to reflect these important updates.

- “Agreement concerning the International Carriage of Dangerous Goods by Road,” in (dd)(4), which is referenced in §171.23. The Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) outlines regulations concerning the international carriage of dangerous goods by road within the EU and other countries that are party to the agreement. PHMSA removes references to the 2019 edition of the ADR, ECE/TRANS/257, and adds references to volumes I and II and the corrigendum of the 2020 edition, ECE/TRANS/300. The ADR can be accessed at: https://www.unece.org/trans/danger/publi/adr/adr_e.html. The main changes to the 2020 edition include revisions to the P200 packaging section for cylinders and updates to reference various updated ISO publications. As such, PHMSA is adopting this revised edition in order to reflect these important updates.

The following standards are already incorporated by reference in the section(s) in which they appear in the regulatory text: ISO 10297:1999(E), ISO 10297:2006(E), ISO 10297:2014(E), ISO 10461:2005(E), ISO 10462:2013(E), ISO 10692-2:2001(E), ISO 10692-2:2001(E), ISO 11114-1:2012(E), ISO 11114-2:2013(E), ISO 11117:1998(E): ISO 11117:2008(E), ISO 11117:2008/Cor.1:2009(E): ISO 11118(E), ISO 11118:2015(E), ISO 11119-1(E), ISO 11119-2(E), ISO 11119-3(E), ISO 11120(E), ISO 11120:2015(E), ISO 11513:2011(E), ISO 11621(E), ISO 11623(E), ISO 11623:2015(E), ISO 13340:2001(E); ISO 13736:2008(E), ISO 14246:2014(E), ISO 16111:2008(E), ISO 16148:2016(E), ISO 17871:2015(E), ISO 18172-1:2007(E), ISO 20703:2006(E), ISO 21172-1:2015(E), ISO 22434:2006(E), and ISO/TR 11364:2012(E); European Directive 2010/35/EU; Transport Canada TDG Regulations; Test Nos. 404, 430, and 435.

Section 171.8

Section 171.8 defines terms used throughout the HMR that have broad or multi-modal applicability. Currently, the definitions provided in §171.8 for SADT and SAPT— i.e., “self-accelerating decomposition temperature” and “self-accelerating polymerization temperature”—only spell out the abbreviations and direct users to §173.21—Forbidden materials and packages—for the actual defining criteria. In the NPRM, we proposed to make editorial changes to improve the utility of the definitions of SADT and SAPT by providing a clear explanation of these terms in the context of packaging within the HMR. As such, DGAC provided comments in response to the NPRM in support of PHMSA's proposed revision of the definitions for SADT and SAPT; and confirmed that these changes will clarify understanding of these terms and assist selection of the proper packaging of these materials. Therefore, PHMSA is making editorial changes to improve the utility of the definitions of SADT and SAPT by providing a clear explanation of these terms in the context of packaging within the HMR.

Section 171.12

Paragraph (a) of §171.12 prescribes requirements for the use of the TDG Regulations for hazardous materials transported from Canada to the United States, from the United States to Canada, or through the United States to Canada or a foreign destination. In this final rule, PHMSA amends §171.12(a)(1) to authorize the use of a temporary certificate issued by Transport Canada for motor carrier or rail transportation of a hazardous material.

In a 2017 rulemaking—HM-215N 15 —PHMSA authorized hazardous materials to be offered for transportation or transported by motor carrier and rail in accordance with an equivalency certificate issued by Transport Canada, as an alternative to transportation of these items under the TDG Regulations as provided in §171.22. The HMR amendment resulted from negotiations by the U.S.-Canada Regulatory Cooperation Council (RCC), a government-to-government forum established in 2011 by the President of the United States and the Canadian Prime Minister for PHMSA and Transport Canada, respectively, to identify and resolve—with input from stakeholders—impediments to cross-border transportation of hazardous materials. Among the initiatives agreed upon by PHMSA and Transport Canada within the RCC was modification of their respective regulations to ensure reciprocal recognition of special permits (PHMSA) and certificates (Transport Canada) specifying the terms and conditions authorizing deviations from their respective regulatory requirements governing transportation of hazardous materials.

15 82 FR 15796 (Mar. 30, 2017).

Subsequently, Transport Canada recognized PHMSA's special permits, which are issued based on either being in the public interest or on the basis that the permit provides a demonstrable equivalent level of safety. See §107.105(d). In HM-215N, PHMSA revised the HMR to recognize equivalency certificates by Transport Canada based on a finding of safety equivalence with the TDG Regulations. That rulemaking did not, however, reflect the fact that Transport Canada also issues temporary certificates authorizing deviation from the TDG Regulations on a finding that transportation of certain hazardous materials is in the public interest. Transport Canada issues temporary certificates after a technical review by its subject matter experts of an applicant's supporting documentation demonstrating shipment of the hazardous material is in the public interest. Temporary certificates are of limited duration and specify terms and conditions—often extensive—to mitigate risks to public safety and the environment. Transport Canada posts all temporary certificates to its publicly available website. 16

16 See Transport Canada, “Approvals—Search by Certificate Number,” https://wwwapps.tc.gc.ca/Saf-Sec-Sur/3/approvals-approbations/SearchCertificates.aspx (last visited Apr. 16, 2021).

PHMSA has evaluated Transport Canada's practices in reviewing and issuing temporary certificates and expects that PHMSA's recognition of those certificates for motor carrier or rail transportation of hazardous materials will not adversely affect safety. As noted above, Transport Canada issues those certificates only after a technical review is completed by its own subject matter experts to mitigate residual risks to public safety and the environment as outlined by the certificates' terms and conditions, including limiting duration of those temporary certificates. Additionally, other regulatory requirements (of Transport Canada or PHMSA) not excepted by a temporary certificate remain in effect. PHMSA further notes that, consistent with the HMR's existing authorization in §171.12 for reliance on the TDG Regulations to authorize certain shipments in the United States, the new authorization to use a temporary certificate applies only for the duration of a shipment. In other words, once a shipment offered in accordance with a temporary certificate reaches its destination, any subsequent offering of packages imported under a Transport Canada temporary certificate must be completed in full compliance with the HMR. PHMSA's revisions to §171.12 further mitigates risk to public safety and the environment by applying only to motor carrier and rail.

The recognition of Transport Canada-issued temporary certificates improves cross-border movement of hazardous materials responding to the COVID-19 public health emergency or other future emergencies. For example, among the temporary certificates recently issued by Transport Canada are several authorizing exceptions from TDG Regulations to enable movement of hand sanitizer chemicals and COVID-19 test samples. 17 These revisions to the HMR help to ensure that, should Transport Canada issue additional temporary certificates responding to the COVID-19 public health emergency or another cross-border threat to public safety or the environment, the HMR will not be an obstacle to those efforts. Dow, DGAC, and COSTHA all provided comments in support of the amendment to improve cross-border movement of hazardous materials. Commenters added that this revision will improve efforts in responding to the COVID-19 and other potential public health emergencies.

17 See Transport Canada, “Temporary Certificates,” https://tc.canada.ca/en/dangerous-goods/temporary-certificates (last visited Apr. 16, 2021).

Section 171.23

Section 171.23 outlines the requirements for specific materials and packagings transported under the ICAO Technical Instructions, IMDG Code, Transport Canada TDG Regulations, or the IAEA Regulations. It also includes provisions that authorize the use—under specific conditions—of pi-marked pressure vessels, which are pressure vessels and pressure receptacles that comply with ECE/TRANS/257, the ADR, and the EU Directive 2010/35/EU, and marked with a pi (π) symbol to denote such compliance. PHMSA is amending §171.23(a) to update the reference to ECE/TRANS/257 to: (1) reference the 2020 edition of this document, ECE/TRANS/300; and (2) reference both volumes I and II of the ADR. Specifically, §171.23(a) authorizes cylinders that comply with the requirements of Packing Instruction P200 (packing instruction for cylinders, tubes, pressure drums, and bundles of cylinders) or P208 (packing instruction for Class 2 adsorbed gases) and 6.2 (requirements for the construction and testing of pressure receptacles, aerosol dispensers, small receptacles containing gas (gas cartridges), and fuel cell cartridges containing liquefied flammable gas) of the ADR, published in 2019 as document ECE/TRANS/257. Upon review of the 2020 edition of this document, ECE/TRANS/300, PHMSA did not find any substantive changes to the provisions in 6.2, P200, or P208, and therefore, does not expect that incorporating by reference ECE/TRANS/300 will impose any safety risk or economic impact. However, updating the version incorporated by reference to reflect the edition that is currently in force facilitates access to foreign markets by U.S. manufacturers and businesses.

B. Part 172

Section 172.101 Hazardous Materials Table (HMT)

The HMT summarizes terms and conditions governing transportation of certain hazardous materials under the HMR. For each entry, the HMT identifies information such as the proper shipping name, UN identification number, and hazard class. The HMT specifies additional information or reference requirements in the HMR such as hazard communication, packaging, quantity limits aboard aircraft, and stowage of hazardous materials aboard vessels. In this final rule, PHMSA amends certain entries in the HMT to reflect the regulatory amendments discussed below in the Section-by-Section Review of Amendments. For purposes of the Government Publishing Office's typesetting procedures, changes to the HMT appear under three sections of the HMT: “remove,” “add,” and “revise.” Certain entries in the HMT, such as those with revisions to the proper shipping names, appear as a “remove” and “add.” Amendments to the HMT include the following:

New HMT Entries

- UN0511, Detonators, electronic programmable for blasting

- UN0512, Detonators, electronic programmable for blasting

- UN0513, Detonators, electronic programmable for blasting

- UN3549, Medical Waste, Category A, Affecting Humans, solid or Medical Waste, Category A, Affecting Animals only, solid

The UNMR contain a new entry to its Dangerous Goods List for regulated medical waste in Category A (see above list for UN3549). In the NPRM, PHMSA proposed to add this new entry for this proper shipping name and UN number and assigning Special Provision 131 to inform offerors that an approval is required when shipping this material.

DGAC and HWI provided comments supporting the inclusion of a new entry in the HMT for “UN3549, Medical Waste, Category A, Affecting Humans, solid or Medical Waste, Category A, Affecting Animals only, solid.” However, DGAC and HWI believe that PHMSA should include the corresponding packing provisions in the UNMR associated with “UN3549, Medical Waste, Category A, Affecting Humans, solid or Medical Waste, Category A, Affecting Animals only, solid.” DGAC asserts that PHMSA should accept the internationally recognized packaging for these materials as a part of the international harmonization process. Both DGAC and HWI believe that continuing to require special permits or approvals for the packaging of these materials does little to enhance transportation safety. HWI adds that the special permit process can take a significant amount of time and recommends that PHMSA provide initial packaging guidance for Category A medical wastes, so that generators have an immediate, safe, and compliant packaging solution.

PHMSA is adding “UN3549, Medical Waste, Category A, Affecting Humans, solid or Medical Waste, Category A, Affecting Animals only, solid” to the HMT in order to provide a more detailed proper shipping name for the shipment of biological waste. PHMSA acknowledges that in biological emergency response crises, such as the response to Ebola outbreaks, it is critical to have approved packagings for cleanup of biological waste. However, PHMSA asserts that due to the unknown nature of any infectious agent that may produce a category A biological waste, it is necessary to retain greater oversight of the safety and operational controls associated with approved packagings via the special permit process. PHMSA's special permit process can accommodate emergency processing of applications for instances associated with transportation of hazardous materials during a public health emergency or natural disaster. For these reasons PHMSA is not assigning baseline packaging provisions in the HMT for to the new proper shipping name “UN3549, Medical Waste, Category A, Affecting Humans, solid or Medical Waste, Category A, Affecting Animals only, solid.” However, PHMSA is assigning Special Provision 131 to state that approval from the Associate Administrator, through a special permit, is required when offering this material for transportation.

PHMSA assigns a new special provision, Special Provision 430, to specify the appropriate use of this proper shipping name. The addition of a proper shipping name that more specifically describes the material in transportation is expected to reduce regulatory burdens in shipping this material internationally and domestically. By limiting the scope of transport by way of special provision approval requirements for each shipment, PHMSA can exercise greater oversight of the transport of these materials to, from, or within the United States.

PHMSA is adding three new entries for the proper shipping name “Detonators, electronic programmable for blasting” with the following new UN numbers: UN0511, UN0512, and UN0513. These entries were added in the 21st revised edition of UNMR as result of a proposal from the Australian Explosives Industry and Safety Group (AEISG) and ensuing discussions held by the UN Working Group on Explosives (EWG) of the Sub-Committee of Experts on the Transport of Dangerous Goods in 2017 and 2018. 18 AEISG proposed adding new entries in the UNMR for electronic detonators to distinguish them from electric detonators, which have significantly different design characteristics.

18 https://unece.org/fileadmin/DAM/trans/doc/2018/dgac10c3/ST-SG-AC.10-C.3-2018-58e.pdf.

The HMT has nine entries for detonators—not used for ammunition—which include: “Detonators, non-electric for blasting,” “Detonators, electric for blasting,” and “Detonator assemblies, non-electric for blasting,” which may fall in to one of three hazard classes (1.1B, 1.4B, or 1.4S). Under the hazardous materials classification scheme, based on the existing available entries, electronic detonators are required to be transported as “Detonators, electric for blasting” which is not the most accurate description. While using this name does not pose inherent risks during transportation, it creates potential for risks in down-stream storage, use, and handling operations. Because electronic detonators are significantly different from other electric and non-electric detonators, PHMSA is adding new entries for these devices rather than including them within the existing entries for electric detonator types. As with other explosives, the proper classification of these devices depends on packaging and testing, hence new entries must include all possible hazard classifications (1.1B, 1.4B, and 1.4S). For other newly added hazardous materials assigned a UN number on the Dangerous Goods List in the UNMR, PHMSA is adding: UN0511 (1.1B), UN0512 (1.4B), and UN0513 (1.4S) to the HMT to facilitate proper classification and handling across governmental and modal jurisdictions. PHMSA determined that this change provides clarity and enhanced safety by adding more specific proper shipping names to describe the difference between electronic detonators and electric detonators. PHMSA received a comment from IME in support of including these three new hazardous materials descriptions for electronic detonators in the HMT.

Column (1) Symbols

Section 172.101(b) describes column (1) of the HMT and symbols providing for additional requirements for transportation of listed hazardous materials that may be indicated in the column. As provided in §172.101(b)(1): (1) the symbol “A” identifies a material that is subject to the requirements of the HMR only when offered or intended for transportation by aircraft; (2) the symbol “W” identifies a material that is subject to the requirements of the HMR only when offered or intended for transportation by vessel; and (3) the symbol “I” identifies proper shipping names which are appropriate for describing materials in international transportation. The UNMR were amended for consistency with the ICAO Technical Instructions to indicate that in addition to being regulated by vessel, the following entries are also regulated for air transport: “UN1372, Fibers, animal or Fibers, vegetable burnt, wet or damp,” “UN1387, Wool waste, wet,” “UN1856, Rags, oily,” “UN1857, Textile waste, wet,” and “UN3360, Fibers, vegetable, dry.” In the case of these particular entries, they are forbidden for air transport in the ICAO Technical Instructions. While reviewing this amendment, PHMSA found that all of these entries except for “UN3360, Fibers, vegetable, dry,” are also identified as only being regulated for air and vessel transportation as denoted by the symbols “A” and “W” in column (1). For UN3360, the symbols “I” and “W” are presently assigned in column (1) and the quantity limit in column (9) is “No Limit” for both passenger and cargo air. This is inconsistent with the ICAO Technical Instructions which forbid this material for transport by air. Therefore, consistent with the ICAO Technical Instructions for the UN3360 entry, PHMSA adds the symbol “A” to column (1) and amends column (9) to read “Forbidden.” This is further consistent with the entries for similar materials “UN1372, Fibers, animal or Fibers, vegetable” and “UN1373, Fibers or Fabrics, animal or vegetable or Synthetic, n.o.s.” that are also assigned the symbol “A” in column (1) and “Forbidden” in column (9). PHMSA determines that this change will facilitate international air transportation and save shippers time and costs by preventing delayed and rejected shipments.

Column (2) Hazardous Materials Descriptions and Proper Shipping Names

Section 172.101(c) describes column (2) of the HMT and the requirements for hazardous materials descriptions and proper shipping names. The UNMR contain the entry “UN3363, Dangerous Goods in Articles or Dangerous Goods in Machinery or Dangerous Goods in Apparatus,” in its Dangerous Goods List; however, the HMT entry UN3363 does not include “Dangerous Goods in Articles or,” in the proper shipping name. PHMSA is adding “Dangerous Goods in Articles or,” to the proper shipping name. This change provides flexibility for shippers selecting the most appropriate proper shipping name by adding a third option in the proper shipping name associated with this UN Number. Additionally, for the proper shipping name “Fuel system components (including fuel control units (FCU), carburetors, fuel lines, fuel pumps)” which currently directs HMT users to “see Dangerous Goods in Apparatus or Dangerous Goods in Machinery”, PHMSA is amending the directions to include a reference to “Dangerous Goods in Articles.” PHMSA expects that these changes will improve hazard communication by including a more specific description for articles containing hazardous materials.

Additionally, for the entry “UN2522, 2-Dimethylaminoethyl methacrylate,” PHMSA is adding the word “stabilized” to this proper shipping name to identify this material as a polymerizing substance. Discussions held by the UNSCOE identified “UN2522, 2-Dimethylaminoethyl-methacrylate” as having a similar molecular structure and polymerization behaviors to “UN 3302, 2-Dimethylaminoethyl acrylate, stabilized.” Under the HMR and international regulations, polymerizing substances require verification that a sufficient level of stabilization is provided prior to transportation. This requirement for stabilization is also indicated by assignment of Special Provision 387 in the HMT, which PHMSA adds for UN2522.

Finally, for the entry “UN3171, Battery-powered vehicle or Battery-powered equipment,” PHMSA is making an editorial change to italicize the “or” in the hazardous material description. Currently, the “or” is in roman type and not italicized. Section 172.101(c) introductory text instructs that proper shipping names are limited to those in roman type. Moreover, the current form of the entry is such that a person may confuse the proper shipping name with the whole description and not the option of “Battery-powered vehicle” or “Battery-powered equipment.” Therefore, PHMSA revises the entry to read “Battery-powered vehicle or Battery-powered equipment.”

Column (5) Packing Group

Section 172.101(f) describes column (5) of the HMT, which specifies one or more packing groups—PG I, II, or III—assigned to certain materials. A PG designation indicates the required level of packaging according to the degree of danger presented by hazardous materials. PG I indicates the greatest level of danger, PG II corresponds to a medium level of danger, and PG III corresponds to a minor danger.

In the NPRM, PHMSA proposed to remove the assignment of PG II as indicated in column (5) for the entry “UN3291, Regulated medical waste, n.o.s. or Clinical waste, unspecified, n.o.s. or (BIO) Medical waste, n.o.s. or Biomedical waste, n.o.s., or Medical Waste n.o.s.” This entry is the only entry with a Division 6.2 classification that has PG II assigned in column (5).

HWI provided comments in support of harmonizing with international standards by removing the assignment of PG II from column (5) of the HMT for the “UN 3291, Regulated medical waste, n.o.s.” entry. However, HWI notes that “PG II” is currently widely utilized as part of the proper shipping description marking on regulated medical waste containers, of which many of their members have a significant inventory. HWI seeks confirmation that that packages with “PG II” printed on the package as part of the proper shipping description can still be used permissively.

PHMSA confirms that packages marked with “PG II” as part of the proper shipping name can permissively be used if the package otherwise complies with §§172.303 and 172.304 marking requirements. HWI further suggests PHMSA clarify that PG II containers are still required to meet the packaging requirements in §173.197 and that the removal of the packing group from the HMT does not negate authorized packaging at the PG II performance level. PHMSA agrees that the PG II performance level requirements for packaging used for regulated medical waste in §173.197 would still apply; however, we do not believe further clarification is necessary as we did not propose changes to the packaging provisions. It is clear that §173.197 is assigned to “UN3291” material in the HMT for authorized non-bulk packagings, for example, and that the packaging requirements in paragraph (b) required UN standard packagings at the PG II performance level.

Therefore, PHMSA is amending this entry to not include PG II in column (5) of the HMT and to align with international regulations and §172.101(f), which specifically states that Division 6.2 materials are not assigned packing groups in the HMR. For packaging purposes, any requirement for a specific packaging performance level is set out in the applicable packaging authorizations of part 173. Instead of having PG II indicated in Column (5), packaging provisions for these materials would continue to be outlined in §173.197. PHMSA expects this editorial change will maintain the current level of safety as no packaging provisions are changing.

Column (6) Label Codes

Section 172.101(g) describes column (6) of the HMT, which contains label codes representing the hazard warning labels required for specific hazardous materials in the HMT. In the HM-215O final rule, 19 PHMSA added twelve HMT entries as part of a classification scheme for articles containing hazardous materials not otherwise specified by name (i.e., n.o.s. entries) in the HMR. The entries were inadvertently added without label codes in column (6). PHMSA is correcting the entries here by adding the appropriate label codes to the following:

19 85 FR 27810 (May 11, 2020).

- UN3537, Articles containing flammable gas, n.o.s.

- UN3538, Articles containing non-flammable, non-toxic gas, n.o.s.

- UN3539, Articles containing toxic gas, n.o.s.

- UN3540, Articles containing flammable liquid, n.o.s.

- UN3541, Articles containing flammable solid, n.o.s.

- UN3542, Articles containing a substance liable to spontaneous combustion, n.o.s.

- UN3543, Articles containing a substance which in contact with water emits flammable gases, n.o.s.

- UN3544, Articles containing oxidizing substance, n.o.s.

- UN3545, Articles containing organic peroxide, n.o.s.

- UN3546, Articles containing toxic substance, n.o.s.

- UN3547, Articles containing corrosive substance, n.o.s.

- UN3548, Articles containing miscellaneous dangerous goods, n.o.s.

Column (7) Special Provisions

Section 172.101(h) describes column (7) of the HMT, which assigns special provisions for each HMT entry. Section 172.102 provides for the meaning and requirements of the special provisions assigned to entries in the HMT. The revisions to column (7) of certain entries in the HMT are discussed below. Also, see §172.102 of the Section-by-Section Review of Amendments below for a detailed discussion of the special provision amendments addressed in this final rule.

Special Provisions 196 and 197

PHMSA is adding new Special Provision 196 to the following HMT entries to outline thermal stability testing requirements for their transportation:

- UN0340, Nitrocellulose, dry or wetted with less than 25 percent water (or alcohol), by mass

- UN0341, Nitrocellulose, unmodified or plasticized with less than 18 percent plasticizing substance, by mass

- UN0342, Nitrocellulose, wetted with not less than 25 percent alcohol, by mass

- UN0343, Nitrocellulose, plasticized with not less than 18 percent plasticizing substance, by mass.

PHMSA is assigning new Special Provision 197 to the following entries in the HMT to outline thermal stability testing requirements for their transportation:

- UN2555, Nitrocellulose with water with not less than 25 percent water, by mass

- UN2556, Nitrocellulose with alcohol with not less than 25 percent alcohol by mass, and with not more than 12.6 percent nitrogen, by dry mass

- UN2557, Nitrocellulose, with not more than 12.6 percent nitrogen, by dry mass mixture with or without plasticizer, with or without pigment

- UN3380, Desensitized explosives, solid, n.o.s.