['CMV Parts and Maintenance']

['Rear bumper']

06/11/2024

...

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. NHTSA-2022-0053]

RIN 2127-AL58

Federal Motor Vehicle Safety Standards; Rear Impact Guards, Rear Impact Protection

AGENCY:

National Highway Traffic Safety Administration (NHTSA), Department of Transportation (DOT).

ACTION: Final rule.

SUMMARY: This final rule upgrades NHTSA's safety standards addressing rear underride protection in crashes of passenger vehicles into trailers and semitrailers by adopting similar requirements to Transport Canada's standard for rear impact guards. Adopting these standards will require rear impact guards to provide sufficient strength and energy absorption to protect occupants of compact and subcompact passenger cars impacting the rear of trailers at 56 kilometers per hour (km/h) (35 miles per hour (mph)). Upgraded protection will be provided in crashes in which the passenger motor vehicle hits: the center of the rear of the trailer or semitrailer; and, in which 50 percent of the width of the passenger motor vehicle overlaps the rear of the trailer or semitrailer. This rulemaking commenced in response to petitions for rulemaking from the Insurance Institute for Highway Safety (IIHS) and from Ms. Marianne Karth and the Truck Safety Coalition (TSC). This final rule responds to and fulfills the rulemaking mandate of the November 2021 Bipartisan Infrastructure Law (BIL) that directs the Secretary to upgrade current Federal safety standards for rear impact guards. NHTSA is also issuing this final rule pursuant to DOT's January 2022 National Roadway Safety Strategy, which describes the five key objectives of the Department's Safe System Approach: safer people, safer roads, safer vehicles, safer speeds, and post-crash care. One of the key Departmental actions to enable safer vehicles is to issue a final rule to upgrade existing requirements for rear impact guards on newly manufactured trailers and semitrailers.

DATES:

Effective date: This final rule is effective on January 11, 2023.

Compliance date: July 15, 2024. Optional early compliance is permitted.

Petitions for reconsideration: Petitions for reconsideration of this final rule must be received no later than August 29, 2022.

ADDRESSES: Petitions for reconsideration of this final rule must refer to the docket and notice number set forth above and be submitted to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue SE, West Building, Washington, DC 20590. All petitions received will be posted without change to https://www.regulations.gov, including any personal information provided.

Privacy Act: DOT will post any petition for reconsideration, and any other submission, without edit, to www.regulations.gov, as described in the system of records notice, DOT/ALL-14 FDMS, accessible through https://www.transportation.gov/individuals/privacy/privacy-act-system-records-notices. Anyone is able to search the electronic form of all submissions to any of our dockets by the name of the individual submitting the submission (or signing the comment, if submitted on behalf of an association, business, labor union, etc.). You may review DOT's complete Privacy Act Statement in the Federal Register published on April 11, 2000 (65 FR 19477-78).

FOR FURTHER INFORMATION CONTACT:

For technical issues: Ms. Lina Valivullah, National Highway Traffic Safety Administration, 1200 New Jersey Avenue SE, West Building, Washington, DC 20590 (telephone) 202-366-8786, (email) Lina.Valivullah@dot.gov.

For legal issues: Ms. Deirdre Fujita, Office of the Chief Counsel, National Highway Traffic Safety Administration, 1200 New Jersey Avenue SE, West Building, Washington, DC 20590, (telephone) 202-366-2992, (email) Dee.Fujita@dot.gov.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Executive Summary

a. Overview

b. NHTSA's Statutory Authority and Response to BIL

1. National Traffic and Motor Vehicle Safety Act

2. Bipartisan Infrastructure Law

3. Implementation of BIL

c. DOT National Roadway Safety Strategy

d. NTSB Recommendation

e. Impacts of This Rulemaking

f. No Significant Changes to the NPRM

II. Background

a. Current Requirements

b. Petitions

c. Summary of Proposed Changes

III. Summary of Comments

IV. Response to Comments on the Proposed Amendments

a. General Strength and Energy Absorption Requirements

b. Alternative Guard Designs

c. 700 kN Energy Absorption Test Option

d. Ground Clearance

e. Requiring Attachment Hardware To Remain Intact

f. Definition of Rear Extremity

g. Low Chassis Vehicle Correction

h. Technical Correction

V. Response to Comments on Issues Not Proposed in the NPRM

a. Vehicles Excluded From FMVSS No. 224

b. Testing on a Trailer Rather Than a Fixture

c. Low Overlap Crash Performance

d. Half-Guard Testing

e. Retrofitting

VI. Lead Time

VII. Benefit-Cost Analysis

VIII. Regulatory Notices and Analyses

I. Executive Summary

a. Overview

NHTSA is issuing this final rule to upgrade Federal Motor Vehicle Safety Standard (FMVSS) No. 223, “Rear impact guards,” and FMVSS No. 224, “Rear impact protection,” which together provide protection for occupants of passenger vehicles in crashes into the rear of trailers and semitrailers. FMVSS No. 223, an equipment standard, specifies strength and energy absorption requirements in quasi-static force tests of rear impact guards sold for installation on new trailers and semitrailers. FMVSS No. 224, a vehicle standard, requires new trailers and semitrailers with a gross vehicle weight rating (GVWR) of 4,536 kilogram (kg) (10,000 pounds (lb)) or more to be equipped with a rear impact guard meeting FMVSS No. 223. 1 The notice of proposed rulemaking (NPRM) preceding this final rule was published on December 16, 2015. 2

1 NHTSA established the two-standard approach to address compliance burdens on small trailer manufacturers, of which there is a significant number. Under FMVSS No. 223, the guard may be tested for compliance while mounted to a test fixture or to a complete trailer, at the manufacturer's option. FMVSS No. 224 requires the guard to be mounted on the trailer or semitrailer in accordance with the instructions provided with the guard by the guard manufacturer. Under this two-standard approach, a small manufacturer that produces relatively few trailers can certify its trailers to FMVSS No. 224 with assurance without having to undertake destructive testing of what could be a substantial portion of its production. The two-standard approach was designed to provide small trailer manufacturers a practicable and reasonable means of certifying to FMVSS No. 224.

2 80 FR 78417.

Rear underride crashes occur when a passenger vehicle crashes into the rear end of a generally larger vehicle, and the front end of the passenger vehicle slides under ( i.e., underrides) the rear end of the larger vehicle. Underride may occur in collisions between a passenger vehicle and the rear end of a large trailer or semitrailer (referred to in this rule collectively as “trailers”) because the bed and chassis of the trailer is often higher than the front of the passenger vehicle. In extreme underride crashes, “passenger compartment intrusion” (PCI) may occur when the passenger vehicle underrides the rear end of the trailer to such an extent that the rear end of the trailer strikes and enters the passenger compartment of the colliding passenger vehicle. PCI can result in severe injuries and fatalities to the occupants of the passenger vehicle.

Rear impact guards are mounted on the rear of trailers to prevent underride and PCI. In a collision between a passenger vehicle and the rear of a trailer equipped with a rear impact guard, the rear impact guard engages the striking passenger vehicle and prevents it from sliding too far under the struck vehicle's bed and chassis. FMVSS Nos. 223 and 224 ensure a rear impact guard is configured low and wide to impede a striking passenger vehicle, is strong enough to withstand a 48 km/h (30 mph) impact of the colliding vehicle, and has energy-absorbing capability to further mitigate harm to occupants in the striking vehicle.

NHTSA designed FMVSS No. 223 and 224 to work in conjunction with FMVSS No. 208, “Occupant crash protection,” so that occupants are protected with seat belts and air bags in the underride crash—thus maximizing the likelihood of avoiding serious or fatal injury in the impact into the guard. When FMVSS Nos. 223 and 224 were issued in 1996, FMVSS No. 208 required passenger cars to provide crash protection in a 48 km/h (30 mph) rigid barrier crash test. The agency designed the underride protection standards so that occupants would be reasonably protected in underride crashes up to 48 km/h (30 mph). Since then, FMVSS No. 208's test speed has been increased to provide high levels of occupant protection in a 56 km/h (35 mph) frontal crash.

With FMVSS No. 208 now providing crash protection up to 56 km/h (35 mph), NHTSA is amending FMVSS Nos. 223 and 224 to mandate the guards withstand crash velocities up to that speed. This final rule adopts requirements of Canada Motor Vehicle Safety Standard (CMVSS) No. 223, “Rear impact guards.” 3 CMVSS No. 223 requires rear impact guards with sufficient strength and energy absorption capability to protect occupants of compact and subcompact passenger cars impacting the rear of trailers at 56 km/h (35 mph). Under this final rule, the impacting vehicle's FMVSS No. 208 occupant protection technologies could absorb enough of the crash forces from the impact to reduce significantly the risk of fatality and serious injury to occupants of the colliding vehicle. As the current requirements in FMVSS Nos. 223 and 224 were developed with the intent of providing underride crash protection to occupants of passenger vehicles in impacts up to 48 km/h (30 mph), increasing the robustness of the trailer/guard design such that it will be able to withstand crash velocities up to 56 km/h (35 mph) represents a substantial increase in the stringency of our standards. There is a 36 percent increase in crash energy in a 56 km/h (35 mph) impact of a vehicle compared to a 48 km/h (30 mph) impact of the same vehicle.

3 This final rule also adopts Transport Canada's definition of “rear extremity” to define where aerodynamic fairings are to be located on a trailer to avoid posing a safety hazard in rear underride crashes.

This final rule is based on the best available science. The underlying field data used in the December 16, 2015 NPRM and this final rule are from a 2013 NHTSA-funded study conducted by the University of Michigan Transportation Research Institute (UMTRI) to supplement UMTRI's Trucks Involved in Fatal Accidents (TIFA) survey data for years 2008 and 2009. (The 2013 NHTSA-funded study is referred to in this preamble as the 2013 UMTRI Study.) 4 5 The TIFA database had analyzed FARS data to obtain more detailed information on fatal large truck crashes, and had provided more detailed information than in FARS on the involved large trucks, motor carriers, and sequence of events leading to the crash. 6 The 2013 UMTRI Study supplemented these TIFA data by collecting specific data pertaining to trailer rear extremity crashes. In the 2013 UMTRI Study, UMTRI also determined whether a rear impact guard was required, and if not required, the criterion that had excluded the vehicle. The 2013 UMTRI Study collected detailed information on fatal vehicle crashes into the rear of trailers, the relative impact velocity, and the extent of underride in these crashes. The data from the 2013 UMTRI Study enabled NHTSA to establish national estimates of rear impact crashes into heavy vehicles that resulted in PCI. Because of the detailed analysis and the supplemental information collected for each crash, the 2013 UMTRI Study forms the most comprehensive and valid data set available to inform NHTSA about crashes involving trucks and trailers and the incidence and extent of underride.

4 NHTSA discussed the results of this study in detail in Appendix A of the NPRM. See 80 FR 78447-78452.

5 Heavy-Vehicle Crash Data Collection and Analysis to Characterize Rear and Side Underride and Front Override in Fatal Truck Crashes, DOT HS 811 725, March 2013, https://www.nhtsa.gov/sites/nhtsa.gov/files/811725.pdf.

6 The TIFA survey data contain data for all trucks with a GVWR greater than 4,536 kg (10,000 lb) that were involved in fatal traffic crashes in the 50 U.S. States and the District of Columbia.

b. NHTSA's Statutory Authority and Response to BIL

1. National Traffic and Motor Vehicle Safety Act

This final rule is issued under the National Traffic and Motor Vehicle Safety Act (Safety Act) (49 U.S.C. 30101 et seq. ). Under the Safety Act, the Secretary of Transportation (NHTSA by delegation) 7 is responsible for prescribing motor vehicle safety standards that are practicable, meet the need for motor vehicle safety, and are stated in objective terms. 8 “Motor vehicle safety” is defined in the Safety Act as “the performance of a motor vehicle or motor vehicle equipment in a way that protects the public against unreasonable risk of accidents occurring because of the design, construction, or performance of a motor vehicle, and against unreasonable risk of death or injury in an accident, and includes nonoperational safety of a motor vehicle.” 9 “Motor vehicle safety standard” means a minimum performance standard for motor vehicles or motor vehicle equipment. 10 When prescribing such standards, the agency must consider all relevant, available motor vehicle safety information, and consider whether a standard is reasonable, practicable, and appropriate for the types of motor vehicles or motor vehicle equipment for which it is prescribed. 11 The agency must also consider the extent to which the standard will further the statutory purpose of reducing traffic crashes and associated deaths. 12

7 49 CFR 1.95. The Secretary also delegated to NHTSA the authority set out for Section 101(f) of Public Law 106-159 to carry out, in coordination with the Federal Motor Carrier Safety Administrator, the authority vested in the Secretary by subchapter 311 and section 31502 of title 49, U.S.C., to promulgate safety standards for commercial motor vehicles and equipment subsequent to initial manufacture when the standards are based upon and similar to a Federal Motor Vehicle Safety Standard promulgated, either simultaneously or previously, under chapter 301 of title 49, U.S.C.

8 49 U.S.C. 30111(a).

9 49 U.S.C. 30102(a)(8).

10 49 U.S.C. 30102(a)(9).

11 49 U.S.C. 30111(b).

12 Id.

2. Bipartisan Infrastructure Law

On November 15, 2021, President Biden signed the Infrastructure Investment and Jobs Act (IIJA), 13 commonly referred to as the Bipartisan Infrastructure Law (BIL). Section 23011 of BIL specifies provisions for underride protection measures for trailers and semitrailers. As discussed in detail below, the provisions direct the Secretary to upgrade current Federal safety standards for rear impact guards and conduct additional research, report to Congress on the effectiveness, feasibility, costs, and benefits of side guards, establish an advisory committee on underride protection, and implement the recommendations issued by the Government Accountability Office (GAO) on improved data collection, inspection and research of truck underride guards.

13 Public Law 117-58.

Section 23011(b)(1)(A) of BIL states that, not later than 1 year after the date of enactment of the Act, the Secretary shall promulgate regulations that revise FMVSS No. 223 and FMVSS No. 224 to require new trailers and semitrailers to be equipped with rear impact guards that are designed to prevent PCI from a trailer or semitrailer when a passenger vehicle traveling at 56 km/h (35 mph) makes an impact: (a) “in which the passenger motor vehicle impacts the center of the rear of the trailer or semitrailer” (full overlap with the rear of the trailer or semitrailer); (b) “in which 50 percent of the width of the passenger motor vehicle overlaps the rear of the trailer or semitrailer”; and (c) “in which 30 percent of the width of the passenger motor vehicle overlaps the rear of the trailer or semitrailer, if the Secretary determines that a revision of [FMVSS Nos. 223 and 224] to address such an impact would meet the requirements and considerations described in subsections (a) and (b) of section 30111 of title 49, United States Code” ( i.e., the Safety Act). Section 23011(b)(1)(B) states that the regulations promulgated under Section 23011(b)(1)(A) shall require full compliance not later than two years after the date on which those regulations are promulgated.

Section 23011(b)(2) of BIL directs the Secretary to conduct additional research on the design and development of rear impact guards that can: prevent PCI in cases in which the passenger motor vehicle is traveling at speeds of up to 65 mph; and that can protect occupants against severe injury in crashes of passenger vehicles into the rear of trailers and semitrailers at speeds up to 104.5 km/h (65 mph). Section 23011(b)(3) directs that, not later than 5 years after the date the regulations under Section 23011(b)(1)(A) are promulgated, the Secretary shall review and evaluate the need for changes to FMVSS No. 223 and FMVSS No. 224 in response to advancements in technology and update the standards accordingly. 14

14 There are also provisions relating to the Federal Motor Carrier Safety Regulations.

Section 23011(c)(1)(A) of BIL directs the Secretary to complete, not later than 1 year after enactment of the Act, additional research on side underride guards to better understand the overall effectiveness of the guards. Section 23011(c)(1)(B) requires the Secretary to assess, among other matters, the feasibility, benefits, and costs of, and any impacts on intermodal equipment, freight mobility (including port operations), and freight capacity associated with, installing side underride guards on new trailers and semitrailers within one year of enactment of BIL, and if warranted, develop performance standards for side underride guards. Section 23011(c)(3) also directs the Secretary to publish the results of the side underride guard assessment specified in Section 23011(c)(1)(B) within 90 days of completion of the assessment and provide an opportunity for public comment. It also directs that, within 90 days from the date the comment period closes, the Secretary shall submit a report to Congress on the assessment results, a summary of comments received, and a determination whether the Secretary intends to develop performance requirements for side underride guards, including any analysis that led to that determination.

Section 23011(d) of BIL directs the Secretary to establish an advisory committee on underride protection to provide advice and recommendations to the Secretary on safety regulations to reduce underride crashes and fatalities relating to underride crashes. This section also provides details on the membership of the advisory committee, frequency of meetings of the advisory committee, the Secretary's support to the advisory committee, and details of a biennial report to Congress that the advisory committee is required to submit.

Section 23011(e) of BIL directs the Secretary to implement the recommendations on truck underride guard data collection issued by the Government Accountability Office (GAO) on March 14, 2019, 15 within 1 year after the date of enactment of the Act.

15 GAO Report to Congressional Requestors, “Truck Underride Guards—Improved Data Collection, Inspections, and Research Needed,” March 14, 2019, (GAO-19-264), https://www.gao.gov/assets/gao-19-264.pdf.

3. Implementation of BIL

This final rule fulfills the BIL rulemaking mandate to NHTSA set forth in Section 23011(b). As directed by Sections 23011(b)(1)(A)(i) and (ii), this final rule revises FMVSS Nos. 223 and 224 to require trailers and semitrailers to be equipped with rear impact guards that prevent passenger compartment intrusion from a trailer or semitrailer when a passenger motor vehicle traveling at 35 miles per hour makes: (a) an impact in which the passenger motor vehicle impacts the center of the rear of the trailer or semitrailer; and (b) an impact in which 50 percent of the width of the passenger motor vehicle overlaps the rear of the trailer or semitrailer.

This final rule fulfills these BIL rulemaking mandates of Sections 23011(b)(1)(A)(i) and (ii) and achieves, effectively and expeditiously, the Congressional goal that focuses on improving rear impact guard performance. The 2015 NPRM proposed to adopt the Canadian quasi-static test requirements for rear impact guards, which ensure rear impact guards provide sufficient strength and energy absorption to protect occupants of compact and subcompact passenger cars impacting the rear of trailers at 56 km/h (35 mph). 16 The NPRM reported on crash tests conducted by IIHS that showed that rear impact guards installed on trailers that were designed to the proposed requirements were able to prevent PCI in 35 mph crashes of a passenger vehicle into the rear of the trailer where: (a) the front end of the passenger vehicle fully overlapped the rear of the trailer (full overlap crash); and (b) 50 percent of the width of the front end of the passenger vehicle overlapped the rear of the trailer (50 percent overlap crash). These data show that trailers and semitrailers equipped with rear impact guards meeting the requirements of this final rule will have guards that are designed to prevent PCI when a passenger motor vehicle traveling at 35 mph impacts the center of the rear of the trailer or semitrailer, or makes impact in which 50 percent of the width of the passenger vehicle overlaps the rear of the trailer or semitrailer, in accordance with BIL.

16 At the time of enactment of BIL, the agency's December 16, 2015 NPRM upgrading FMVSS No. 223 and FMVSS No. 224 had been published and DOT's work was close to completion on the final rule. BIL provides a very short timeframe (1 year) for issuance of a final rule. The short timeframe is indicative of Congress's intent that a final rule based on the 2015 NPRM will complete the rulemaking proceedings specified in Section 23011(b)(1)(A) of the Act.

NHTSA's work on this final rule also meets the BIL mandate in Section 23011(b)(1)(A)(iii). In developing this rule, the agency considered a requirement that rear impact guards withstand a 56 km/h (35 mph) crash of a passenger vehicle into the rear of a trailer in which only 30 percent of the width of the passenger motor vehicle overlaps the rear of the trailer or semitrailer (30 percent overlap crash). After analyzing the issue, we determined such a standard would not meet the requirements and considerations of Sections 30111(a) and (b) of the Safety Act. Our consideration of this matter is discussed below.

Sections 30111(a) and 30111(b)

The provision at 49 U.S.C. 30111(a) of the Safety Act authorizes the Secretary (NHTSA, by delegation) to prescribe Federal motor vehicle safety standards that are practicable, meet the need for motor vehicle safety, and are stated in objective terms. “Motor vehicle safety” is defined in the Safety Act as “the performance of a motor vehicle or motor vehicle equipment in a way that protects the public against unreasonable risk of accidents occurring because of the design, construction, or performance of a motor vehicle, and against unreasonable risk of death or injury in an accident, and includes nonoperational safety of a motor vehicle.” 17

17 49 U.S.C. 30102(a)(8).

The provision at 49 U.S.C. 30111(b) specifies that, when prescribing such standards, the Secretary must, among other things, consider all relevant, available motor vehicle safety information, consider whether a standard is reasonable, practicable, and appropriate for the types of motor vehicles or motor vehicle equipment for which it is prescribed, and consider the extent to which the standard will further the statutory purpose of reducing traffic crashes and associated deaths and injuries. NHTSA has considered the factors in Section 30111(b) and concludes that available data do not show that a standard for a 30 percent overlap crash at 35 mph would be reasonable, practicable, or appropriate for all the vehicles subject to FMVSS No. 223 and FMVSS No. 224. Accordingly, NHTSA cannot conclude that a Federal mandate for such a requirement for all trailers is warranted at this time.

Rear impact guards are designed to absorb energy and prevent PCI by attaching to substantial structural elements of a trailer or semitrailer, such as the chassis longitudinal frame rails, by way of vertical support members. The vertical members of the rear impact guard usually attach to the longitudinal frame rails so that impact loads are directly transmitted to the frame rails with minimal or no damage to the overall trailer structure. The test results from the initial testing at IIHS reported in the NPRM show that in the 30 percent overlap crashes, only a small lateral portion of the rear impact guard (about 22 percent of the guard width) engaged with the front end of the passenger vehicle. This small lateral portion did not include a vertical support member of the guard, so when a Chevy Malibu test vehicle struck this small lateral portion of the guard, the guard deformed locally and did not prevent PCI. In these initial IIHS crash tests, only the Manac rear impact guard was able to prevent PCI in the Chevy Malibu in the 56 km/h (35 mph) full overlap, 50 percent overlap, and 30 percent overlap crash test conditions. NHTSA believes the Manac performed this way because, unlike most trailer designs where the vertical members of the rear impact guard attach directly to the longitudinal frame rails of the trailer, the vertical members of the Manac rear impact guard were located further outboard from the location of the trailer longitudinal frame rails and were attached to a reinforced floor section of the trailer.

While the more outboard vertical supports of the Manac guard could withstand the force from the 30 percent low overlap crash of the Malibu, data suggest the further outboard vertical supports may reduce guard strength near the center of the horizontal member of the rear impact guard. In the 56 km/h (35 mph) full overlap crash tests of the Malibu, the greatest amount of underride (1,350 mm) was in the test with the Manac trailer. (In contrast, the extent of the underride was 990 mm in the test with the Wabash trailer.) NHTSA found this observation critical because it indicated that trailers that have the main vertical supports for the guard more outboard may not perform as well in full overlap crashes as trailers that have the vertical supports more inboard. This finding was of key concern because full and 50 percent overlap crashes are more frequent than low overlap (30 percent or less) crashes. NHTSA seeks not to amend FMVSS No. 223 in a manner that could reduce safety in the more frequent crash conditions.

Further, data indicate that most fatal light vehicle crashes into the rear of trailers are at speeds much higher than 56 km/h (35 mph). The agency is concerned that adopting requirements to mitigate PCI in 30 percent low overlap crashes could result in rear impact guard designs that may reduce protection against PCI in higher speed crashes. NHTSA remains concerned about potential negative safety consequences if a final rule were to adopt requirements that result in moving the vertical members of rear impact guards more outward laterally to prevent underride in a 56 km/h (35 mph) 30 percent low overlap crash, at the expense of protection against higher speed crashes. The agency believes this issue should be more fully explored before possibly adopting a 30 percent low overlap requirement.

NHTSA has estimated the benefits and costs of adopting performance requirements to mitigate underride in low overlap (30 percent or lower overlap) crashes based on available information. We estimate 0.75 to 1.5 fatalities would be prevented annually if this rule included requirements to mitigate PCI in 30 percent overlap crashes at 56 km/h (35 mph) impact speed. (This estimate does not account for the possible dis-benefits in full and 50 percent offset crashes resulting from a low overlap requirement, discussed in the paragraph above.) The 0.75 to 1.5 fatalities prevented is based on an estimated 5.8—11.5 annual fatalities in low overlap crashes into the rear of trailers (crashes where 30 percent or less of the front end of the impacting vehicle overlaps the rear of the trailer) and a 13 percent effectiveness of rear impact guards with 30 percent overlap crash protection in mitigating fatalities.

To prevent PCI in 30 percent overlap crashes, designs would have to either: (a) add additional vertical members at the lateral edge of the rear impact guard that connect to the trailer's transverse floor beam and strengthen the transverse floor beam of the trailer to withstand the loads transmitted from these vertical members at the edge of the guard; or (b) considerably strengthen the rear impact guard member so it would not deform locally in the 30 percent overlap crash. Both these approaches would add significant weight to the vehicles because they involve adding more vertical members, strengthening the floor beams, or strengthening the guard itself. Additionally, some guard designs may have restrictions in intermodal operations at loading docks and may not be practicable for all types of trailers covered by FMVSS No. 224.

NHTSA is required by Section 1 of Executive Order 12866 to conduct a benefit-cost analysis of any intended regulation. 18 NHTSA estimates that the annual minimum and average incremental fleet cost of equipping all new applicable trailers 19 with rear impact guards that mitigate PCI in 30 percent overlap crashes would be $9.9 million and $30.3 million, respectively. The total minimum to average undiscounted incremental lifetime fuel cost due to increase in weight is estimated to be $93 million to $130 million. The overall undiscounted cost increase (material cost and lifetime fuel cost) is a minimum of $103 million to on average $161 million.

18 “Significant” actions are also subject to Section 6's requirements for a benefit-cost analysis.

19 There were 211,807 new trailers sold in 2020, among which 65 percent (137,675 = 211,807 × 0.65) are required to be equipped with rear impact guards. Among applicable trailers, 28 percent are already equipped with guards that mitigate PCI in 30 percent overlap crashes.

Using the estimate of 0.75 to 1.5 fatalities that would be prevented annually, the undiscounted cost per life saved using the minimum cost estimate ranges from $69 million to $151 million. The undiscounted cost per life saved using the average cost estimate ranges from $183 million to $215 million. The Department of Transportation has recently updated the value of a statistical life, consistent with Office of Management and Budget (OMB) Circular A-4, to $11.6 million. 20 Therefore, a requirement for equipping all new applicable trailers with rear impact guards that mitigate PCI in 30 percent overlap crashes is not cost-effective. 21 This indicates that total costs of such a requirement exceed overall benefits.

20 For more information on the value of a statistical life, see a 2021 Office of the Secretary memorandum on the “Guidance on Treatment of the Economic Value of a Statistical Life in U.S. Department of Transportation Analyses—2021 Update.” https://www.transportation.gov/office-policy/transportation-policy/revised-departmental-guidance-on-valuation-of-a-statistical-life-in-economic-analysis. Circular A-4 provides OMB's guidance to Federal agencies on the development of a regulatory analysis required under Section 6 of E.O. 12866.

21 Cost-effectiveness represents a measure of the average monetary cost per unit of change (benefit). In regulatory analyses for safety policies, cost-effectiveness generally measures the average estimated change in total costs per unit improvement in safety ( e.g., cost per life saved). A policy alternative can be considered cost-effective if the estimated cost per unit increase is less than an appropriate benchmark. For example, a proposed safety standard could be considered cost-effective if the average cost per life saved equivalent ( i.e., combining lives saved and injuries avoided, weighted by the relative values of injuries to fatalities) under the proposed standard were less than the comprehensive economic cost of a fatality ($11.6 million in 2020 dollars). That is, the proposed standard would yield safety benefits at a lower cost than the benchmark value for those benefits.

For the above reasons, NHTSA has determined that requirements to mitigate PCI in a 30 percent overlap crash at 56 km/h (35 mph) would not meet the requirements of Section 30111(a) of the Safety Act. We have decided that an FMVSS that requires all covered vehicles (trailers and semitrailers) to provide rear impact protection in full-frontal, 50 percent overlap, and 30 percent overlap crashes at 56 km/h (35 mph) impact speed would not be reasonable or practicable for this FMVSS and would not meet the requirements of Sections 30111(a) and (b) of the Safety Act for issuance of Federal motor vehicle safety standards. Accordingly, based on all available data, we have decided that a Federal mandate for a 30 percent overlap crash for all vehicles subject to FMVSS Nos. 223 and 224 is not reasonable at this time.

However, while NHTSA cannot conclude that the data and science currently available for agency decision-making support mandating installation of a rear impact guard that prevents PCI in all three overlap conditions (full, 50 percent, and 30 percent overlap) on all vehicles, the Federal standards act as a floor, not a ceiling, to establish the minimum level of performance that meet the safety needs presented by the data. FMVSS are written in terms of minimum performance requirements for motor vehicles or motor vehicle equipment to protect the public against unreasonable risk of injury and death in crashes. Manufacturers have flexibility in design as long as their products comply with applicable FMVSS. There are rear impact guard designs in the current trailer and semitrailer market that prevent PCI in all three crash conditions described in Section 23011(b)(1)(A) of BIL: (1) full overlap crash, (2) 50 percent overlap crash, and (3) 30 percent overlap crash at 56km/h impact speed. This final rule does not preclude these designs from the trailer and semitrailer market, as long as they meet all requirements of the FMVSS to ensure adequate protection in (1) and (2), above.

In response to the research mandate in Section 23011(b)(2) of BIL, NHTSA is conducting additional research on the design and development of rear impact guards that can prevent underride and protect passengers in crashes into the rear of trailers at crash speeds up to 104.5 km/h (65 mph). As part of this research effort, NHTSA will also evaluate potential cost-effective rear impact guard designs that could improve protection in the less-frequent 30 percent low overlap crashes while enhancing protection in full and 50 percent overlap crashes at higher speeds.

NHTSA is also working on implementing the other provisions of Section 23011 of BIL.

c. DOT National Roadway Safety Strategy

This final rule accords with DOT's January 2022 National Roadway Safety Strategy to address the rising numbers of transportation deaths occurring on the country's streets, roads, and highways. 22 At the core of this strategy is the Department-wide adoption of the Safe System Approach, which focuses on five key objectives: safer people, safer roads, safer vehicles, safer speeds, and post-crash care. DOT announced it will launch new programs, coordinate and improve existing programs, and adopt a foundational set of principles to guide this strategy. The National Roadway Safety Strategy includes issuing a final rule to upgrade existing requirements for rear impact guards on newly manufactured trailers and semitrailers as a key Departmental action to enable safer vehicles. 23

22 https://www.transportation.gov/sites/dot.gov/files/2022-01/USDOT_National_Roadway_Safety_Strategy_0.pdf .

23 Id., p. 31.

d. NTSB Recommendation

This final rule accords with an April 3, 2014 recommendation from the National Transportation Safety Board (NTSB) regarding tractor-trailer safety (H-14-004). NTSB recommended that NHTSA revise FMVSS Nos. 223 and 224 to ensure that newly manufactured trailers over 4,536 kg (10,000 lb) GVWR provide adequate protection of passenger vehicle occupants from fatalities and serious injuries resulting from full-width and offset trailer rear impacts. In its recommendation, NTSB made favorable reference to IIHS's petition for rulemaking (the petition is discussed below).

e. Impacts of This Rulemaking

NHTSA has issued a Final Regulatory Evaluation (FRE) that analyzes the potential impacts of this final rule. The FRE is available in the docket for this rule. 24

24 The FRE may be obtained by downloading it or by contacting Docket Management at the address or telephone number provided at the beginning of this document.

NHTSA estimates that 94 percent of new trailers sold in the U.S. subject to FMVSS Nos. 223 and 224 are already designed to comply with CMVSS No. 223. The agency estimates that about 0.56 lives and 3.5 serious injuries would be saved annually by requiring all trailers covered by Standard No. 224 to be equipped with CMVSS No. 223 compliant guards. The undiscounted equivalent lives saved are 1.4 per year.

Considering that 94 percent of applicable trailers already have CMVSS compliant guards, the annual average incremental fleet cost of equipping all applicable trailers with CMVSS No. 223 rear impact guards is estimated to be $2.10 million in 2020 dollars. In addition, the added weight of 48.9 pounds per vehicle would result in an estimated annual fleet fuel cost of approximately $4.43 million and $5.59 million discounted at 7% and 3%, respectively. As such, the total incremental cost would range from $6.54 million to $7.69 million discounted at 7% and 3%, respectively, as shown in Table 1.

| Discount rate | Undiscounted | 3% | 7% |

|---|---|---|---|

| * Material costs are not discounted since they occur at the time of purchase | |||

| Material * | $2.10 | $2.10 | $2.10 |

| Fuel | 6.90 | 5.59 | 4.43 |

| Total | 9.00 | 7.69 | 6.54 |

The estimated equivalent lives saved (ELS) ranges from 0.90 lives to 1.14 lives discounted at 7% and 3%, respectively. The cost of the final rule is the regulatory cost and ranges from $6.54 million to $7.69 million discounted at 7% and 3%, respectively. The cost per ELS ranges from $6.77 million to $7.25 million discounted at 3% and 7%, respectively, as shown in Table 2 below.

| Discount rate | Undiscounted | 3% | 7% |

|---|---|---|---|

| Total cost | $9.00 | $7.69 | $6.54 |

| Equivalent lives saved | 1.40 | 1.14 | 0.90 |

| Cost per ELS | $6.42 | $6.77 | $7.25 |

The net benefit of the final rule is the difference between the comprehensive benefit and the total cost. The estimated net benefit ranges from $4.36 million to $6.04 million discounted at 7% and 3%, respectively, as shown in Table 3 below.

| Discounted rate | Undiscounted | 3% | 7% |

|---|---|---|---|

| Comprehensive benefit | $16.96 | $13.73 | $10.90 |

| Total cost | 9.00 | 7.69 | 6.54 |

| Net benefit | 7.96 | 6.04 | 4.36 |

Table 4 summarizes the total costs, comprehensive benefits, and net benefits for both 3 and 7 percent discount rates.

| Discount rate | Material cost | Fuel cost | Total costs | Comprehensive benefits | Net benefits |

|---|---|---|---|---|---|

| 3% | $2.10 | $5.59 | $7.69 | $13.73 | $6.04 |

| 7% | 2.10 | 4.43 | 6.54 | 10.90 | 4.36 |

f. No Significant Changes to the NPRM

After carefully reviewing the comments, NHTSA is adopting most of the proposed rule, while clarifying the wording that attachment hardware remain intact during quasi-static load tests in FMVSS No. 223. NHTSA is also making a technical correction to the citation referenced in the definition of “temporary living quarters” in FMVSS No. 224.

II. Background

a. Current Requirements

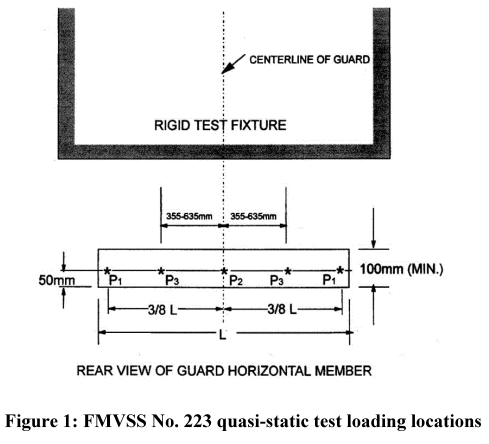

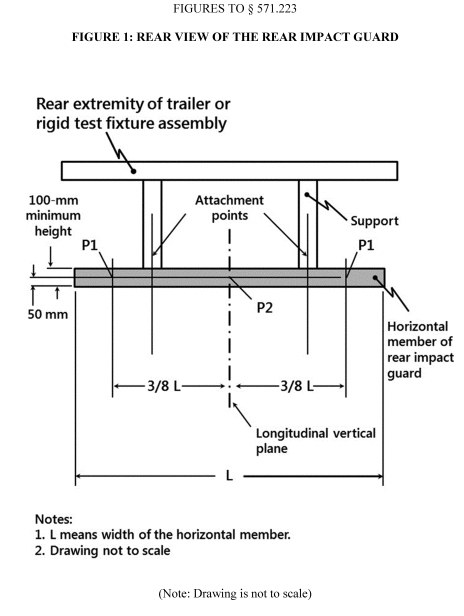

FMVSS No. 223 requires rear impact guards to meet the strength requirements and energy absorption requirements of the standard at certain specified test locations. Test locations P1, P2, and P3 are depicted in Figure 1. Test location P1 is 3/8th of the width of the horizontal member from the centerline on either side of the horizontal member. Test location P2 is at the centerline of the horizontal member. Test location P3 is 355 millimeters (mm) (14 inches) to 635 mm (25 inches) from the horizontal member centerline. The strength tests are conducted separately from the energy absorption test.

The strength requirements (S5.2.1) specify that the guard must resist the following force levels without deflecting by more than 125 mm (4.9 inches):

- 50,000 Newtons (N) (or 50 kiloNewtons (kN)) at P1 on either the left or the right side of the guard;

- 50,000 N at P2; and,

- 100,000 N at P3 on either the left or the right side of the guard.

In the strength test, the force is applied by a force application device (rectangular rigid steel solid face of 203 mm x 203 mm and thickness of 25 mm) until the force level is exceeded or until the displacement device is displaced at least 125 mm, whichever occurs first.

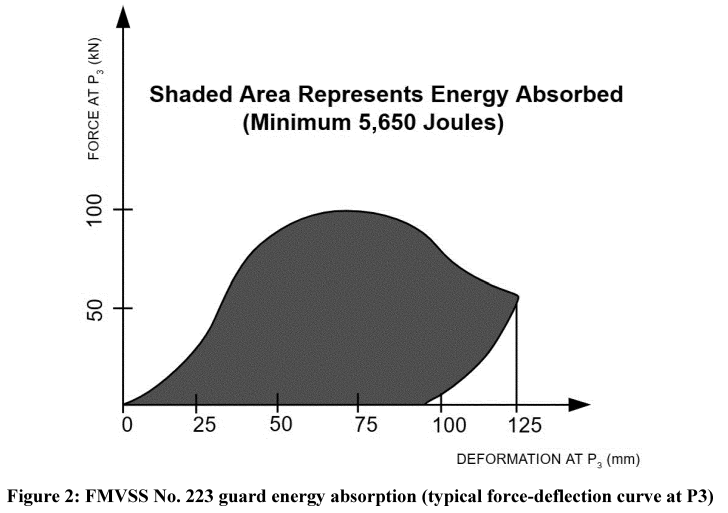

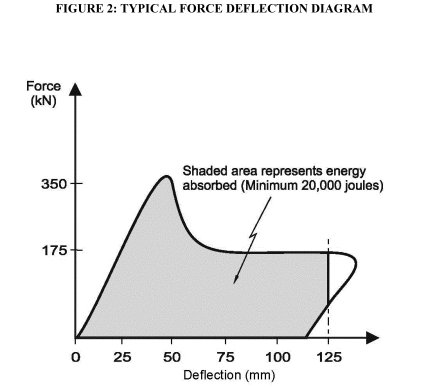

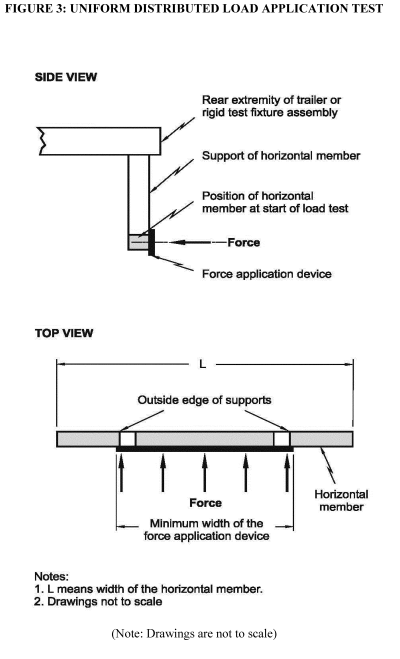

The energy absorption requirements (S5.2.2) specify that a guard (other than a hydraulic guard) must absorb, by plastic deformation, within the first 125 mm of deflection at least 5,650 Joules (J) of energy at each test location P3. In the test procedure, force is applied to the guard using the force application device until displacement of the device has reached 125 mm, recording the value of force at least 10 times per 25 mm of displacement. The force is then reduced until the guard no longer offers resistance to the force application device. A force versus deflection diagram is plotted with deflection (measured displacement of the force application device) along the abscissa (x-axis) and the measured force along the ordinate (y-axis), as shown in Figure 2, and the energy absorbed by the guard is determined by calculating the shaded area bounded by the curve in the diagram.

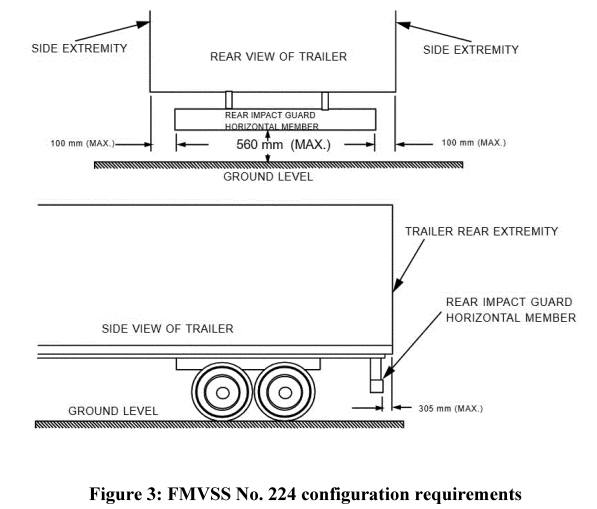

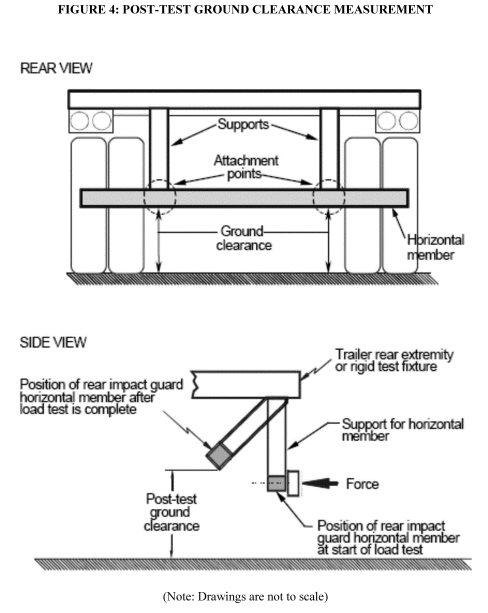

FMVSS No. 224 requires each vehicle to be equipped with a rear impact guard certified to FMVSS No. 223 and attached to the vehicle's chassis in accordance with installation instructions that the guard manufacturer provided pursuant to FMVSS No. 223. Standard No. 224 specifies that the ground clearance (vertical distance of the bottom of the horizontal member from ground) of the rear impact guard be no more than 560 mm (22 inches) and located not more than 305 mm (12 inches) forward of the rear extremity of the trailer and extend laterally to within 100 mm (4 inches) of each side of the vehicle as shown in Figure 3.

b. Petitions

IIHS requested, among other things, that NHTSA upgrade rear impact guard strength requirements, reduce the number of exempted vehicles to provide occupant protection in higher speed crashes and move the P1 test location farther outboard to improve crash protection in low overlap conditions. IIHS requested that NHTSA require attachment hardware to remain intact for the duration of the quasi-static test or until reaching a force threshold “much higher than that required for the guard itself.” 25 The Karth/TSC petition asked that NHTSA improve the safety of rear impact guards. In later correspondence with NHTSA, these petitioners state that if FMVSS No. 223 were amended to be equivalent to CMVSS No. 223, injuries and fatalities could be avoided. 26 We provided a detailed discussion of the petitions, and our response to them, in the NPRM preceding this final rule.

25 After submitting its petition in 2011, IIHS conducted additional crash tests of a 2010 Chevrolet Malibu at 56 km/h (35 mph) into eight guard/trailers: A 2011 Wabash, 2012 Manac, 2012 Stoughton, 2013 Great Dane, 2012-2013 Hyundai, 2013 Strick, 2013 Utility, and 2013 Vanguard, all of which were certified as complying with CMVSS No. 223. NHTSA included a summary of the IIHS tests in the December 16, 2015 NPRM. 80 FR 78452-78460. All eight trailers were able to prevent PCI with 100 percent overlap. In the tests with 50 percent overlap, apart from the 2013 Vanguard trailer, the remaining seven guard/trailers were able to prevent PCI. The rear impact guard on the 2013 Vanguard failed at the attachments where the bolts sheared off during the crash resulting in PCI.

26 NHTSA responded to the Karth/TSC petition by issuing two separate notices, one of which was the NPRM preceding this final rule (July 10, 2014; 79 FR 39362). The other was an advanced notice of proposed rulemaking (ANPRM) published on July 23, 2015 (80 FR 43663) pertaining to the agency's estimated benefits and costs of rear impact guards for single unit trucks (SUTs) and of an alternative of increasing the conspicuity of SUTs through conspicuity tape. FMVSS No. 108, “Lamps, reflective devices, and associated equipment,” requires retroreflective material on the rear and sides of trailers to improve the conspicuity of the vehicles to other motorists as a means of preventing underride crashes. The ANPRM analyzed estimated benefits and costs of requiring similar tape for SUTs. NHTSA will follow up on the ANPRM in a document separate from this final rule.

c. Summary of Proposed Changes

NHTSA proposed to adopt requirements of Transport Canada's standard for rear impact guards, which require rear impact guards to provide sufficient strength and energy absorption to protect occupants of compact and subcompact passenger cars impacting the rear of trailers at 56km/h (35 mph). The NPRM proposed the following specific changes to FMVSS Nos. 223 and 224. 27

27 In addition, we proposed a few housekeeping amendments. We proposed to add back “low chassis vehicles” into the list of vehicles excluded from FMVSS No. 224 in the applicability section (S3). The vehicles were excluded from the standard in the January 24, 1996 final rule establishing FMVSS No. 224 (61 FR 2035) but were inadvertently omitted from S3 when S3 was amended by a final rule responding to petitions for reconsideration (63 FR 3654, January 26, 1998). We also proposed to correct typographical errors in the standards. We make these changes in this final rule.

Performance Requirements

NHTSA proposed that the loading and performance requirements of FMVSS No. 223 adopt the specifications in CMVSS No. 223. Specifically:

- The NPRM proposed to amend FMVSS No. 223 to require rear impact guards (except as noted below) to resist a uniform distributed load of 350,000 N without deflecting more than 125 mm, while absorbing at least 20,000 J of energy by plastic deformation within the first 125 mm of deflection;

- Alternatively, guards may resist a minimum uniform distributed load of 700,000 N without deflecting 125 mm.

- In accordance with CMVSS No. 223, we proposed to require that rear impact guards be required to maintain a ground clearance after the energy absorption test not exceeding 560 mm. For rear impact guards with strength exceeding 700,000 N in the uniform distributed load test, the post-test ground clearance is measured after the uniform distributed load test. A definition of “ground clearance” would be added to FMVSS No. 223.

- We proposed that FMVSS No. 223 require that any portion of the rear impact guard and attachments not separate from their mounting structure after completion of FMVSS No. 223's uniform distributed loading test and the energy absorption test.

Definition of “Rear Extremity” 28

28 We sought to further harmonize FMVSS No. 224 with CMVSS No. 223.

We proposed to replace the current definition of “rear extremity” in FMVSS No. 224 with that specified in CMVSS No. 223. The change was intended to ensure that aerodynamic fairings are located within a certain safe zone at the rear of the trailer. Aerodynamic fairings on the rear of trailers, also known as “boat tails,” are rear-mounted panels on trailers that reduce aerodynamic drag and fuel consumption. The safety concern about boat tails is that they generally extend beyond the rear extremity of trailers and thus can negate the crash protection provided by rear impact guards. That is, there is a possibility that a boat tail can protrude so far rearward that it can intrude into the passenger compartment in a crash and cause injury, notwithstanding the presence of an upgraded rear impact guard.

III. Summary of Comments

NHTSA received fifty (50) comments on the NPRM. 29 Ten comments were received from the three petitioners (IIHS, Ms. Marianne Karth (with her husband Mr. Jerry Karth), and the TSC), one comment was received from the National Transportation Safety Board (NTSB), six comments were received from industry associations (the Recreation Vehicle Industry Association (RVIA), the Truck Trailer Manufacturers Association (TTMA), the American Trucking Association, Inc. (ATA), the National Truck Equipment Association (NTEA), and the National Propane Gas Association (NPGA)), two comments were received from trailer manufacturers (Strick Trailers, LLC (Strick) and the Wabash National Corporation (Wabash)), seven comments were received from engineers (the Mechanical Engineering Underride Design Group at Virginia Tech (VT Group), Seven Hills Engineering, LLC (Seven Hills), Batzer Engineering, Inc. (Batzer), and Mr. Aaron Kiefer), two comments were received from attorneys (Mr. D.J. Young, III and Mr. Andy Young), ten comments were received from advocacy groups ( e.g., Underride Network, Road Safe America (RSA), and Advocates for Highway and Auto Safety (AHAS)), and twelve comments were received from individual members of the general public.

Comments were generally in favor of upgrading rear impact guard performance. The petitioners, NTSB, engineers, attorneys, advocacy groups, and individuals from the general public argued, however, for increasing the stringency of FMVSS Nos. 223 and 224 beyond what was proposed in the NPRM. These groups also suggested that NHTSA take other actions suggested in the initial IIHS and Karth/TSC petitions that NHTSA had not proposed in the NPRM. The industry associations and trailer manufacturers were generally in favor of the proposed rule and opposed further changes to it. Comments also covered issues such as alternative guard designs, NHTSA's benefit-cost analysis, the proposed lead time, retrofitting issues, and side and front guards.

IV. Response to Comments on the Proposed Amendments

a. General Strength and Energy Absorption Requirements

In the NPRM, NHTSA proposed to harmonize FMVSS No. 223's test and performance requirements to those specified in CMVSS No. 223 by replacing the current quasi-static point load test at the P3 location with a uniform distributed load test of 350,000 N. Under this test, NHTSA proposed that the rear impact guard must resist the 350,000 N load without deflecting more than 125 mm, absorb at least 20,000 J of energy within 125 mm of guard deflection, and have a ground clearance not exceeding 560 mm after completion of the test.

Comments Received

Commenters supported upgrading FMVSS No. 223's requirements as proposed, but most also suggested that NHTSA issue requirements more stringent than those proposed. Multiple commenters argued that, because 93 percent of trailers already comply with CMVSS No. 223 according to the NPRM, the proposed requirements would make little tangible difference and not prevent the underride injuries that are still occurring. The Underride Network (Network) stated that NHTSA's proposal would only “upgrade the standard as basically existed in 1996,” without going further to include technological improvements made for rear impact guards. Wabash, on the other hand, suggested that even though most new trailers currently adhere to CMVSS No. 223, there is still a benefit to the proposed requirements. Wabash argued that adopting the proposed requirements would both mandate that the remaining portion of the new trailer fleet adopt upgraded rear impact guards and allow NHTSA to take enforcement action against any company that fails to install upgraded rear impact guards.

Some commenters also urged NHTSA not to adopt a proposal that only provides protection against underride at impact speeds up to 56 km/h (35 mph), stating that these crashes only represent a fraction of all rear underride crashes. These commenters remarked that NHTSA should do more to provide protections for underride crashes that occur at greater speeds. Some commenters suggested specific requirements that they believed NHTSA should adopt instead of those proposed in the NPRM. Network requested that the quasi-static loading tests use a force of 200 (kN) at the P1 and P2 test locations and 100 kN at the P3 test location. Mr. Kiefer suggested that rear impact guards should be quasi-statically tested to “at least 80% of reasonable crash pulse loadings.” Mr. Karth referenced what he called a “new Australian/New Zealand proposed rule” and asked NHTSA to use that as a basis for its standards. According to Mr. Karth, the Australian/New Zealand proposed rule states that current vehicle crashworthiness technology can protect passengers in collisions with a deformable barrier at impact speeds around 64 km/h (40 mph) and that energy absorbing rear impact guards could reduce injury at higher speeds. Ms. Karth echoed this point, stating that adopting the Australian/New Zealand proposed rule would save more lives than adopting standards based on CMVSS No. 223. These and all other relevant comments are address below.

Agency Response

After reviewing the comments, NHTSA is adopting the strength and energy absorption standards as proposed in the NPRM. NHTSA recognizes that many commenters have asked NHTSA to require rear impact guards to provide protection against underride at impact speeds beyond 56 km/h (35 mph). As discussed below, NHTSA is researching this area. However, based on available data, the agency does not believe that such increased requirements are reasonable or practicable at this time. Rear impact guards are meant to work with passenger vehicle safety features to protect occupants of the vehicle during a collision. For these passenger vehicle safety features to activate, the passenger vehicle must collide with the rear impact guard, and this collision itself poses risks to passenger safety. Currently, FMVSS No. 208 requires passenger vehicles to provide protection in front collisions at speeds up to 56 km/h (35 mph). Even if a rear impact guard were to prevent PCI at impact speeds above 56 km/h (35 mph), a passenger vehicle in compliance with FMVSS No. 208 may not be able to protect the vehicle's occupants at speeds above 56 km/h (35 mph) in a collision with a rear impact guard. Commenters did not provide data showing current passenger vehicle safety features would prevent injuries in underride collisions above 56 km/h (35 mph). Accordingly, NHTSA concludes it is appropriate for this final rule to align the requirements in FMVSS Nos. 223 and 224 with those in FMVSS No. 208 and CMVSS No. 223, as proposed in the NPRM. This final rule adopts those proposed requirements.

Further, the 56 km/h (35 mph) crash speed accords with Section 23011(b)(1)(A) of BIL. BIL states that, not later than 1 year after the date of enactment of the Act, the Secretary shall promulgate regulations that revise FMVSS No. 223 and FMVSS No. 224 to require new trailers and semitrailers to be equipped with rear impact guards that are designed to prevent PCI from a trailer or semitrailer when a passenger vehicle traveling at 56 km/h (35 mph) makes an impact into the center of the rear of the trailer or semitrailer and in which 50 percent of the width of the passenger motor vehicle overlaps the rear of the trailer or semitrailer. This final rule's adoption of the NPRM's proposed test speed meets the BIL statutory mandate within the timeframe directed by the Act, and meets the requirements for FMVSSs required by the Safety Act.

In response to the research mandate in Section 23011(b)(2) of BIL, NHTSA is conducting additional research on the design and development of rear impact guards that can prevent underride and protect passengers in crashes into the rear of trailers at crash speeds up to 104.5 km/h (65 mph). After the completion of this research, NHTSA will evaluate potential requirements for rear impact guards for preventing underride and protecting occupants at impact speeds greater than 35 mph.

Commenters also referred to guard designs and recommendations developed by third parties that claim to offer greater protection at higher impact speeds than guards currently in use. There is no evidence that any have been finalized, implemented, and proven feasible for commercial use. The Intelliguard/Impact Project, a design source cited by Mr. Karth, explicitly stated, “The guard needs, however, further optimization to become commercially feasible.”

Network asked NHTSA to test rear impact guards “at real world speeds,” arguing that the Federal Highway Administration (FHWA) tests crash attenuators at 100 km/h (62.2 mph) and that NHTSA should crash test rear impact guards at similar speeds. In response, NHTSA notes, first, that it did not propose to test at highway speeds in the NPRM and believes this request may be outside the scope of this rulemaking. Further, NHTSA does not believe that Network's comparison of rear impact guards and FHWA roadside crash attenuators is appropriate. Roadside crash attenuators are stationary barriers placed alongside roads that are designed to absorb a colliding vehicle's energy and safely redirect the vehicle or bring it to a stop. A typical crash attenuator system is 50 feet long. In contrast, rear impact guards are structures attached to the rear of mobile trailers to mitigate underride of the impacting vehicle. Roadside crash attenuators, therefore, are designed for a different environment than a rear impact guard, have different performance requirements, 30 and have fewer operational and practical restrictions on their size and weight versus rear impact guards. Similar performance for truck rear impact guards at highway speeds has not been shown to be technically feasible.

30 Roadside crash barriers, guardrails and other roadside safety features installed along U.S. highways undergo crashworthiness testing in accordance with the American Association of State Highway and Transportation Officials (AASHTO) Manual for Assessing Safety Hardware (MASH). The AASHTO MASH was updated in 2016 and includes vehicle crash testing at 6 different test levels (TL-1 to TL-6) based on the type of crash attenuator, type of road, and traffic patterns.

- TL-1: Cars and trucks—31 mph

- TL-2: Cars and trucks—44 mph

- TL-3: Cars and trucks—62 mph

- TL-4: Cars, trucks, and single unit trucks—62 mph and 56 mph respectively

- TL-5: Cars, trucks, and tractor trailers—62 and 50 mph respectively

- TL-6: Cars, trucks, and tractor tank trailers—62 and 50 mph respectively

In terms of specific standards suggested by commenters, these commenters unfortunately did not provide sufficient information to warrant modifying the proposed requirements. Commenters did not provide data showing the extent to which guards compliant with these various standards are superior to the Canadian guards. NHTSA notes that the “Australian/New Zealand proposed rule” referenced by Mr. and Ms. Karth is not a regulatory requirement, but rather is an industry design guideline created by Standards Australia and Standards New Zealand. These guidelines do not provide information to warrant modifying NHTSA's proposal. In terms of rear impact guards performing at impact speeds above 56 km/h (35 mph), the guidelines only conjecture that guards could be developed that reduce serious injury to vehicle occupants at speeds above 70 km/h; they do not provide instructions on how to design such guards or data regarding practicability, effectiveness or performance. Not enough is known about these standards to assess the need for them or whether adopting them would meet the requirements of the Safety Act.

b. Alternative Guard Designs

Based on tests conducted by Transport Canada showing that a CMVSS No. 223 compliant guard was able to prevent PCI in 56 km/h (35 mph) vehicle impacts into the rear of trailers with 100 percent and 50 percent overlap, NHTSA proposed to adopt CMVSS No. 223's strength and energy absorption requirements.

Comments Received

NHTSA received many comments arguing that the proposed standards were inadequate because rear impact guards generally meet them already. Advocates and IIHS referred to a 2011 Wabash guard, involved in the tests conducted by IIHS, to argue that the guard exceeded the CMVSS force requirements by more than 70 percent in quasi-static tests. Other commenters also mentioned that they believed it possible to design a rear impact guard that could provide protection for rear underride crashes at speeds greater than 56 km/h (35 mph), several pointing to testing conducted by third parties to support these claims. Network and Mr. Karth stated that the Monash University Accident Research Centre (MUARC) tested energy-absorbing guards to 75 km/h (47 mph) in the early 1990s. They also claimed that the Impact Project had tested energy-absorbing guards to 40 mph with computer modeling showing that the guards might be able to perform at 50 mph or more. Mr. Young noted that the VC-Compat project is “currently proposing and recommending stronger rear impact guards to meet higher speeds.”

Other commenters stated that they personally were either developing or had seen rear impact guards that were improvements over guards meeting the current and proposed standards. Mr. Karth pointed to a design developed by the VT Group which, he claimed, “shows promise of greatly improving the current standard at a reasonable cost.” Mr. Kiefer stated that he had developed a rear guard system that will exceed the proposed standards. Mr. Karth stated that he was told by a Mr. Sicking that he “can design a system which will prevent underride guard failures” that occur “at much higher speeds.”

Agency Response

NHTSA has evaluated the data from IIHS and other research groups provided by the commenters and cannot agree that the information forms a technical basis for modifying the proposed requirements. Advocates and IIHS argued that rear impact guards could provide protection at speeds higher than 56 km/h (35 mph) because the Wabash guard exceeded CMVSS No. 223 force requirements by “more than 70 percent” in tests conducted by IIHS. Our analysis of the comment, however, determined that IIHS's tests were different than, and not comparable to, the CMVSS No. 223 tests. IIHS conducted a point load test at P3, which is very different than the uniform distributed load specified in CMVSS No. 223 and this final rule. 31 As the tests are not comparable, it cannot be concluded that the Wabash guard exceeded the CMVSS No. 223 force requirement by more than 70 percent. Additionally, the data do not show that the guard would provide better crash protection in dynamic impacts above 56 km/h (35 mph). I.e., the data did not link IIHS's quasi-static test values to evidence of actual dynamic crash performance at higher impact speeds.

31 A point load test applies a concentrated load to a focused point. The uniform distributed load tests specified in CMVSS No. 223 and this final rule apply the test load over a wider area.

Section 1 of E.O. 12866 requires agencies to base their decisions on the best reasonably available scientific, technical, economic, and other information on the need for, and consequences of, the intended regulation. In accordance with the E.O., this final rule will complete the upgrade of Standard No. 223 to the Canadian standard as proposed, as it is based on the best information reasonably available at this time. However, while the commenters' information does not form a comprehensive or complete basis for modifying the rear impact guard requirements above that which was proposed, NHTSA is continuing to research this area in response to BIL. Pursuant to the research mandate in BIL Section 23011(b)(2), NHTSA is conducting additional research on the design and development of rear impact guards that prevent underride and protect passengers in crashes into the rear of trailers at crash speeds up to 104.5 km/h (65 mph). The results of this research and other information will provide more data and other information that can guide decisions about updating the rear impact guard standards at a future date.

In response to commenters, NHTSA also reviewed guard designs and recommendations developed by third parties (MUARC, VT group, Aaron Kiefer, Sickling) that several commenters believed could offer greater protection at higher impact speeds than rear impact guards currently in use. 32 As these guards have not been finalized, implemented, proven effective or shown feasible for commercial use in the industry, the agency could not reasonably include requirements for these guards in FMVSS Nos. 223 and 224 at this time. 33 Also, not enough is known about the rationale for various specifications of the experimental guards. For instance, MUARC, an organization favorably cited by many commenters, stated 34 that it had designed a guard which prevented PCI in a 75 km/h (46 mph) centered impact test and recommended that guards be able to absorb 50 kiloJoules (kJ) and quasi-static forces of 200 kN at the P1 location, 100 kN at the P2 location, and 200 kN at the P3 location. It is unclear how MUARC developed these quasi-static test recommendations and how these recommendations relate to dynamic crash test performance. Further, MUARC's 50 kJ and the 100 kJ energy absorption recommendation does not specify the degree of deflection at which the guard must meet this energy absorption requirement, and the experimental guard designed by MUARC never advanced beyond the proof-of-concept phase. 35 There is no information on the long term durability and costs of a MUARC guard since it is not available for purchase and installation, nor can NHTSA know if such a guard can be feasibly and effectively used for different types of trailers, such as those with unique geometry.

32 The petitioners, the attorney commenters, UN, AHAS, Seven Hills, Aaron Kiefer, and Andy Young cited design testing conducted by the Intelliguard/Impact Project, the VT Group, VC-Compat, MUARC, and Aaron Kiefer to support claims that guards with greater crash protection at higher impact velocities are feasible.

33 Section 23011 (b)(1) of BIL requires a regulation revising FMVSS No. 223 and No. 224 not later than 1 (one) year after the November 15, 2021, date of enactment of the Act.

34 MUARC discussed its research in a 2001 submission to the International Technical Conference on the Enhanced Safety of Vehicles. Rechnitzer, G., Powell, C., and Seyer, K., “Performance Criteria, Design, and Crash Tests of Rear Underride Barriers for Heavy Vehicles,” Proceedings of the Seventeenth International Technical Conference on the Enhanced Safety of Vehicles, Paper No. 218, https://www-esv.nhtsa.dot.gov/Proceedings/17/00189.pdf.

35 Federal regulations in Australia for rear impact guards are similar to those in Europe and Australia. The MUARC recommendations are not used as performance requirements in Australian Federal standards and there are no manufacturers in Australia voluntarily designing their guards to meet the MUARC recommendations.

NHTSA has the same concerns with the experimental guards described by the Impact Project, the VC-Compat project, the VT Group, Mr. Kiefer, and Mr. Sicking. Commenters did not provide information that the guards are effective at providing protection at impact speeds beyond 56 km/h (35 mph) and failed to provide a verifiable relationship between the results of the dynamic crash tests and quasi-static specifications that NHTSA relies on in FMVSS No. 223. In the absence of such data, there is insufficient information supporting using these experimental guards to form the requirements for FMVSS Nos. 223 and 224. As discussed above, however, NHTSA will continue researching guard performance in higher speed crashes in response to BIL and anticipates obtaining more comprehensive information about the performance and other features of potential guards designed for higher speed impacts.

c. 700 kN Energy Absorption Test Option

The NPRM proposed to include an option from CMVSS No. 223 permitting a rear impact guard not to meet the energy absorption requirements of the uniform distributed load test detailed above if it is able to resist 700,000 N (700 kN) of force without deflecting more than 125 mm and maintain a ground clearance of 560 mm after completion of the test. NHTSA noted in the NPRM that it did not believe that guards will likely be manufactured to this test but sought comment on whether this alternative testing option should be included in FMVSS No. 223.

Comments Received

Commenters were divided in their support of the 700 kN test option. TTMA stated in support that keeping this as an option would allow TTMA members to retain needed flexibility. Batzer asserted in support that, since passenger vehicles have improved their energy absorbing characteristics since the 1996 final rule, NHTSA does not need to require that rear impact guards meet an energy absorption requirement as long as the guards can provide a certain level of resistance force. Network stated that this option “might make sense,” but also stated that rear impact guards must be able to absorb a minimum of 50 kJ, and preferred that guards be able to absorb 100 kJ. Ms. Wood agreed that rear impact guards must be able to absorb at least 50 kJ. The VT Group disagreed with including the 700 kN test, stating that doing so would afford manufacturers the ability to omit a horizontal member from a rear impact guard. The VT Group claimed that without a horizontally distributing structure, “a minor impact more closely resembles a pole strike.”

Agency Response

NHTSA agrees with TTMA and Batzer and believes it appropriate to adopt the 700 kN test option. Network and the VT Group expressed reservations about the option, but they did not provide data or other evidence demonstrating that this option would be detrimental to safety. They did not provide any further information supporting the request for a 50 kJ or 100 kJ energy absorption requirement, nor did they explain how the 700 kN test option would allow manufacturers to omit a horizontal member. FMVSS No. 223 S5.1 specifies that the vertical height of the horizontal member must be at least 100 mm and FMVSS No. 224 S5.1 specifies geometric requirements for the rear impact guard that remain unchanged by this test option.

Transport Canada developed the 700 kN test option based on rigid barrier crash test results suggesting that a resistance to a uniform load of at least 700 kN would help ensure that the rear impact guard will stay in place and prevent underride in an impact with a passenger car at impact speeds of 56 km/h (35 mph). 36 NHTSA concludes that the data from Transport Canada, cited in the NPRM, demonstrate the effectiveness and feasibility of this option in preventing underride at 35 mph. 37

36 Canada Gazette Part II, Vol. 138, No. 20, 2004-10-06, p. 1349.

37 Boucher, D., “Heavy Trailer rear underride crash tests performed with passenger vehicles,” Technical Memorandum No. TMVS-0001, Transport Canada, Road Safety and Motor Vehicle Regulation Directorate, July 2000.

d. Ground Clearance

NHTSA proposed maintaining the current ground clearance requirement of 560 mm (22 inches) (S5.1.2, FMVSS No. 224) but also proposed updating FMVSS No. 223 to require rear impact guards to maintain a ground clearance of 560 mm (22 inches) after completion of the load application during the energy absorption test. Due to deformation that may occur upon loading, NHTSA noted that this requirement may correspond to an initial ground clearance on the trailer that is actually less than 560 mm (22 inches).

Comments Received

Many commenters suggested lowering the ground clearance requirement. These commenters generally argued that rear impact guards must align with the height of car bumpers and since NHTSA mandates that passenger car bumpers be 16 to 20 inches (406.4 to 508 mm) off the ground, NHTSA must lower the ground clearance requirement to this level. The VT Group stated that NHTSA's bumper standards in “49 CFR 581 requires a light vehicle bumper height of 16 to 20” inches and that lowering ground clearance to this level “could ensure proper initial engagement with light vehicle safety systems.” Batzer similarly stated that the most effectively designed rear impact guard “would engage the bumper of the striking passenger vehicle.” Commenters also suggested that, because the average guard height for trailers currently is 18 inches (457.2 mm), there is no need for NHTSA to allow for a higher ground clearance. Mr. D.J. Young, III and Mr. Andy Young stated that technology exists that can raise or lower rear impact guards, and therefore NHTSA should not be concerned that a lower ground clearance requirement could result in a rear impact guard scrapping or snagging along the ground.

Agency Response

NHTSA proposed amending FMVSS No. 223 to require that, after the energy absorption test where the guard is displaced 125 mm, the rear impact guard has to maintain a ground clearance not exceeding 560 mm (22 inches) but did not propose to alter the 560 mm (22 inches) ground clearance requirement in FMVSS No. 224. The NPRM explicitly stated that NHTSA was denying the request made by petitioners to lower the ground clearance requirement and NHTSA did not propose such a change in the NPRM. The suggestions to lower the ground clearance requirement are thus not within the scope of this rulemaking. Further, NHTSA included in the NPRM its rationale for denying the request to lower the ground clearance requirement, and, after reviewing the comments and other information, NHTSA has not changed its position on these points. In the interest of discussion, NHTSA will briefly repeat its reasoning here. 38

38 NHTSA's entire rationale is detailed in the NPRM for this final rule. See 80 FR 78424-78426.

Comments stating that NHTSA should modify the ground clearance requirement to align with NHTSA's bumper standard (49 CFR part 581) misunderstood the purpose of the bumper standard and repeat a concern to which NHTSA responded in the 1996 final rule establishing FMVSS Nos. 223 and 224. 39 The bumper standard under 49 CFR part 581 is designed to prevent damage to a car body and its safety related equipment in impacts of 3.2 km/h (2 mph) across the full width of the bumper and 1.6 km/h (1 mph) on the corners. The bumper standard is not, in other words, intended to provide occupant protection from crashes at injury-causing impact speeds. That function is instead performed by the vehicle's chassis energy-management design and its energy-absorbing frame rails, which rely on the engagement of the vehicle's major structural components with the rear impact guard.

39 See final rule, 61 FR 2004, 2017; January 24, 1996.

Nor is it the case that the major structural components of vehicles have been so lowered as to necessitate lowering the ground clearance requirement. To the contrary, the height of the top of the engine block appears to have increased since NHTSA promulgated the 1996 final rule that required the 560 mm (22 inches) ground clearance. Using engine block height as a suitable metric to represent a major structural element of the striking vehicle that would engage the rear impact guard, when NHTSA issued the 1996 final rule, NHTSA determined the typical height of the top of the engine block as between 660 and 790 mm (26 and 31 inches). 61 FR 2017. In contrast, as discussed in the 2015 NPRM for this final rule, data show that the current height of the top of the engine block is between 739 mm (29.1 inches) and 1300 mm (51.2 inches), with an average height of 889 mm (35 inches) (80 FR 78425). Thus, passenger vehicle designs have changed in years since the establishment of the 560 mm (22 inches) ground clearance specification such that there is a greater likelihood of engagement of their major structural components with the rear impact guard.

Further, NHTSA is concerned that some trailers may face operational issues if NHTSA lowered the ground clearance requirement. Trailers may snag and scrape at loading docks and steep railroad crossings, resulting in damage to the guard, if guards were required to be lower to the ground. The commenters advocating for a lower ground clearance requirement provided no data to show that this possible risk can be overcome or is offset by any potential benefits. Similarly, NHTSA does not believe it is appropriate to lower the ground clearance requirement and then force operators involved in intermodal operations to possess trailers with rear impact guards that can be raised and lowered. Doing so would unnecessarily burden the industry and raise costs, and commenters have not identified any associated benefits that would justify this decision.

e. Requiring Attachment Hardware To Remain Intact

The NPRM focused on ensuring the attachment hardware of the rear impact guard remained intact in the quasi-static loading tests. It proposed to prohibit the complete separation of any portion of the guard and the guard attachments from its mounting structure after completion of the quasi-static uniform distributed load test (proposed S5.2.1). NHTSA stated in the NPRM (80 FR at 48429) that it was interpreting “`any portion of the guard and the guard attachment completely separating from its mounting structure' to mean the condition where any member of the guard becomes detached from any other member of the guard or from the trailer such that the joint is no longer mechanically bound together.” The agency further stated that it would not consider a partial separation of the members at a joint where there is still some degree of mechanical connection between the members as a “complete separation.” Id. NHTSA sought comment on this proposed performance criterion and whether its objectivity could be improved by, e.g., specifying the percentage of fasteners or welds that remain intact during the test.