['Air Programs']

['Air Quality', 'Air Emissions']

08/01/2024

...

ENVIRONMENTAL PROTECTION AGENCY

[EPA-HQ-OAR-2020-0556; FRL-8335-03-OAR]

RIN 2060-AV35

Testing Provisions for Air Emission Sources

AGENCY: Environmental Protection Agency (EPA).

ACTION: Proposed rule.

SUMMARY: This action proposes corrections and updates to regulations for source testing of emissions under various rules. This proposed rule includes corrections to inaccurate testing provisions, updates to outdated procedures, and approved alternative procedures that provide testers enhanced flexibility. The revisions will improve the quality of data but will not impose new substantive requirements on source owners or operators.

DATES: Comments must be received on or before June 27, 2022.

ADDRESSES: You may send comments, identified by Docket ID No. EPA-HQ-OAR-2020-0556 by any of the following methods:

- Federal eRulemaking Portal: https://www.regulations.gov (our preferred method). Follow the online instructions for submitting comments.

- Email: a-and-r docket@epa.gov. Include docket ID No. EPA-HQ-OAR-2020-0556 in the subject line of the message.

- Fax: (202) 566-9744.

- Mail: U.S. Environmental Protection Agency, EPA Docket Center, Office of Air and Radiation Docket, Mail Code 28221T, 1200 Pennsylvania Avenue NW, Washington, DC 20460.

- Hand Delivery or Courier (by scheduled appointment only): EPA Docket Center, WJC West Building, Room 3334, 1301 Constitution Avenue NW, Washington, DC 20004. The Docket Center's hours of operations are 8:30 a.m.-4:30 p.m., Monday through Friday (except Federal Holidays).

Instructions: All submissions received must include the Docket ID No. for this rulemaking. Comments received may be posted without change to https://www.regulations.gov/, including any personal information provided. For detailed instructions on sending comments and additional information on the rulemaking process, see the “Public Participation” heading of the SUPPLEMENTARY INFORMATION section of this document. Out of an abundance of caution for members of the public and our staff, the EPA Docket Center and Reading Room are closed to the public, with limited exceptions, to reduce the risk of transmitting COVID-19. Our Docket Center staff will continue to provide remote customer service via email, phone, and webform. We encourage the public to submit comments via https://www.regulations.gov/ or email, as there may be a delay in processing mail and faxes. Hand deliveries and couriers may be received by scheduled appointment only. For further information on EPA Docket Center services and the current status, please visit us online at https://www.epa.gov/dockets.

FOR FURTHER INFORMATION CONTACT: Mrs. Lula H. Melton, Office of Air Quality Planning and Standards, Air Quality Assessment Division (E143-02), Environmental Protection Agency, Research Triangle Park, NC 27711; telephone number: (919) 541-2910; fax number: (919) 541-0516; email address: melton.lula@epa.gov.

SUPPLEMENTARY INFORMATION:

The supplementary information in this preamble is organized as follows:

I. Public Participation and Written Comments

II. General Information

A. Does this action apply to me?

B. What action is the Agency taking?

III. Background

IV. Incorporation by Reference

V. Summary of Proposed Amendments

A. Method 201A of Appendix M of Part 51

B. General Provisions (Subpart A) of Part 60

C. Standards of Performance for New Residential Wood Heaters (Subpart AAA) of Part 60

D. Standards of Performance for New Residential Wood Heaters, New Residential Hydronic Heaters, and Forced-Air Furnaces (Subpart QQQQ) of Part 60

E. Method 1 of Appendix A-1 of Part 60

F. Method 4 of Appendix A-3 of Part 60

G. Method 7 of Appendix A-4 of Part 60

H. Method 19 of Appendix A-7 of Part 60

I. Method 25 of Appendix A-7 of Part 60

J. Method 25C of Appendix A-7 of Part 60

K. Method 26 of Appendix A-8 of Part 60

L. Performance Specification 1 of Appendix B of Part 60

M. Performance Specification 2 of Appendix B of Part 60

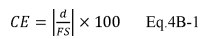

N. Performance Specification 4B of Appendix B of Part 60

O. Performance Specification 6 of Appendix B of Part 60

P. Performance Specification 12A of Appendix B of Part 60

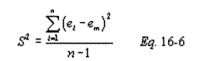

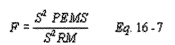

Q. Performance Specification 16 of Appendix B of Part 60

R. Procedure 1 of Appendix F of Part 60

S. Procedure 5 of Appendix F of Part 60

T. General Provisions (Subpart A) of Part 63

U. National Emission Standards for Hazardous Air Pollutants From the Pulp and Paper Industry (Subpart S) of Part 63

V. National Emission Standards for Hazardous Air Pollutants From Hazardous Waste Combustors (Subpart EEE) of Part 63

W. National Emission Standards for Hazardous Air Pollutants: Paper and Other Web Coating (Subpart JJJJ) of Part 63

X. National Emission Standards for Hazardous Air Pollutants for Stationary Reciprocating Internal Combustion Engines (Subpart ZZZZ) of Part 63

Y. National Emission Standards for Hazardous Air Pollutants: Engine Test Cells/Stands Residual Risk and Technology Review (Subpart PPPPP) of Part 63

Z. National Emission Standards for Hazardous Air Pollutants: Coal- and Oil-Fired Electric Utility Steam Generating Units (Subpart UUUUU) of Part 63

AA. Method 315 of Appendix A of Part 63

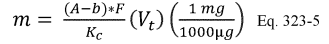

BB. Method 323 of Appendix A of Part 63

VI. Statutory and Executive Order Reviews

A. Executive Order 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulation and Regulatory Review

B. Paperwork Reduction Act (PRA)

C. Regulatory Flexibility Act (RFA)

D. Unfunded Mandates Reform Act (UMRA)

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

G. Executive Order 13045: Protection of Children From Environmental Health Risks and Safety Risks

H. Executive Order 13211: Actions Concerning Regulations That Significantly Affect Energy Supply, Distribution or Use

I. National Technology Transfer and Advancement Act and 1 CFR part 51

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations

I. Public Participation and Written Comments

Submit your comments identified by Docket ID No. EPA-HQ-OAR-2020-0556 at https://www.regulations.gov (our preferred method) or the other methods identified in the ADDRESSES section. Once submitted, comments cannot be edited or removed from the docket. The EPA may publish any comment received to its public docket. Do not submit to EPA's docket at https://www.regulations.gov/ any information you consider to be Confidential Business Information (CBI) or other information whose disclosure is restricted by statute. Multimedia submissions (audio, video, etc.) must be accompanied by a written comment. The written comment is considered the official comment and should include discussion of all points you wish to make. The EPA will generally not consider comments or comment contents located outside of the primary submission (i.e., on the web, cloud, or other file sharing system). For additional submission methods, the full EPA public comment policy, information about CBI or multimedia submissions, and general guidance on making effective comments, please visit https://www.epa.gov/dockets/commenting-epa-dockets.

Public visitors are allowed in the EPA Docket Center and Reading Room by making an appointment in advance. Our Docket Center staff will continue to provide remote customer service via email, phone, and webform. We encourage the public to submit comments via https://www.regulations.gov/ as there may be a delay in processing mail and faxes. Hand deliveries or couriers will be received by scheduled appointment only. For further information and updates on EPA Docket Center services, please visit us online at https://www.epa.gov/dockets. The EPA continues to carefully and continuously monitor information from the Centers for Disease Control and Prevention (CDC), local area health departments, and our Federal partners so that we can respond rapidly as conditions change regarding COVID-19.

II. General Information

A. Does this action apply to me?

The proposed amendments apply to industries that are subject to the current provisions of 40 CFR parts 51, 60, and 63. We did not list all of the specific affected industries or their North American Industry Classification System (NAICS) codes herein since there are many affected sources in numerous NAICS categories. If you have any questions regarding the applicability of this action to a particular entity, consult either the air permitting authority for the entity or your EPA Regional representative as listed in 40 CFR 63.13.

B. What action is the Agency taking?

This action proposes corrections and revisions to source test methods, performance specifications (PS), and associated regulations. The corrections and revisions consist primarily of typographical errors, updates to testing procedures, and the addition of alternative equipment and methods the Agency has deemed acceptable to use.

III. Background

The EPA catalogs errors and corrections, as well as necessary revisions to test methods, performance specifications, and associated regulations in 40 CFR parts 51, 60, and 63 and periodically updates and revises these provisions. The most recent updates and revisions were promulgated on October 7, 2020 (85 FR 63394). This proposed rule addresses necessary corrections and revisions identified after that final action, many of which were brought to our attention by regulated sources and end-users, such as environmental consultants and compliance professionals. These revisions will improve the quality of data obtained and give source testers the flexibility to use newly approved alternative procedures.

IV. Incorporation by Reference

The EPA proposes to incorporate by reference two ASTM standards. Specifically, the EPA proposes to incorporate ASTM D6216-20, which covers the procedure for certifying continuous opacity monitors and includes design and performance specifications, test procedures, and QA requirements to ensure that continuous opacity monitors meet minimum design and calibration requirements necessary for accurate opacity monitoring measurements in regulatory environmental opacity monitoring applications subject to 10 percent or higher opacity standards. The EPA also proposes to update the incorporation by reference for ASTM D6784, a test method for elemental, oxidized, particle-bound, and total mercury in emissions from stationary sources, from the 2002 version to the 2016 version; this update would apply to incorporations by reference in 40 CFR part 60, appendix B, Performance Specification 12A for continuous monitoring of mercury emissions. Likewise, EPA proposes to update the incorporations by reference in 40 CFR part 63 for use of ASTM D6784 under table 5 and appendix A of Subpart UUUUU, for mercury emissions measurement and monitoring. Both the ASTM D6216-20 and ASTM D6784-16 standards were developed and adopted by ASTM. The ASTM standards may be obtained from www.astm.org or from the ASTM at 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, PA 19428-2959.

The EPA also proposes to incorporate by reference the American Public Health Association (APHA) Method 5210 Biochemical Oxygen Demand (BOD) from “Standard Methods for the Examination of Water and Wastewater.” This standard is acceptable as an alternative to Method 405.1 and is available from APHA at www.standardmethods.org or by telephone at (844) 232-3707.

The EPA is also proposing specific modifications to requirements in an existing incorporation by reference, the ASTM E2515-11 test method. The proposed stipulations would modify the post-test leak check procedures as well as add procedures for performing leak checks during a sampling run.

V. Summary of Proposed Amendments

The following amendments are being proposed.

A. Method 201A of Appendix M of Part 51

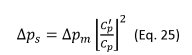

In Method 201A, the erroneous equation 25 in section 12.5 would be corrected.

B. General Provisions (Subpart A) of Part 60

In the General Provisions of part 60, §60.17(h) would be revised to add American Society for Testing and Materials (ASTM) D6216-20 and D6784-16 to the list of incorporations by reference and to re-number the remaining consensus standards that are incorporated by reference in alpha-numeric order.

C. Standards of Performance for New Residential Wood Heaters (Subpart AAA) of Part 60

Subpart AAA would be amended to add stipulations for use of the ASTM E2515-11 test method. The stipulations would modify the post-test leak check procedures as well as add procedures for performing leak checks during a sampling run. The stipulations to ASTM E2515-11 are necessary as we have learned that the quality assurance/quality control (QA/QC) requirements for leak tests required by ASTM E2515-11, section 9.6.5.1 are not sufficient to provide assurance of the sampling system integrity. Additionally, the language of ASTM E2515-11, section 9.6.5.1 currently allows for averaging the PM results from a non-leaking sampling system with those from a leaking sampling system, which effectively reduces reported PM emissions by as much as half, rendering the test method inappropriate for compliance determination.

We would revise the language in §60.534(c) and are proposing new language to replace ASTM E2515-11, section 9.6.5.1 by adding §60.534(c)(1), which specifies appropriate post-test leak check procedures and in §60.534(c)(2) by adding procedures for performing leak checks during a sampling run. We are proposing these modifications to bring appropriate QA/QC requirements to PM measurements required by the rule and to eliminate opportunity for emissions test results to be considered valid when a leaking sampling system allows dilution of the PM sample(s).

We are also proposing in §60.534(d) that the first hour PM emissions measurements be conducted using a separate ASTM E2515-11 sampling train operated concurrently with the paired ASTM E2515-11 sampling trains used in compliance PM sampling. In this manner, the first hour PM emissions would be collected appropriately, and the compliance test measurements would not be impacted by a sampling pause for filter replacement at the 1-hour mark.

The regulatory language in §60.539b(b) would be revised to include General Provisions that were added to §60.8(f)(2) (81 FR 59801, August 30, 2016) and were inadvertently exempted from inclusion in subpart AAA as that rule, as promulgated in 2015, exempted §60.8(f) in its entirety. The exemption promulgated in subpart AAA at §60.539b(b) was intended to exempt those affected sources from §60.8(f), which, at the time, consisted of what is now currently §60.8(f)(1) and is specific to compliance testing results consisting of the arithmetic mean of three replicate tests. We are proposing these modifications to ensure that emissions test reporting includes all data necessary to assess and assure the quality of the reported emissions data and appropriately describes and identifies the specific unit covered by the emissions test report. Since compliance tests in this category consist of a single test, the original regulatory exemption to the General Provisions of §60.8(f)(1) is retained.

D. Standards of Performance for New Residential Wood Heaters, New Residential Hydronic Heaters, and Forced-Air Furnaces (Subpart QQQQ) of Part 60

The erroneous PM emission limits in g/MJ in §§60.5474(b)(2), (b)(3) and (b)(6) would be corrected.

In addition, subpart QQQQ would be amended to add stipulations for use of the ASTM E2515-11 test method. The stipulations would modify the post-test leak check procedures as well as add procedures for performing leak checks during a sampling run. The stipulations to ASTM E2515-11 are necessary as we have learned that the QA/QC requirements for leak tests required by ASTM E2515-11, section 9.6.5.1 are not sufficient to provide assurance of the sampling system integrity. Additionally, the language of ASTM E2515-11, section 9.6.5.1 currently allows for averaging the PM results from a non-leaking sampling system with those from a leaking sampling system, which effectively reduces reported PM emissions by as much as half, rendering the test method inappropriate for compliance determination. The language in §60.5476(c)(5) and §60.5476(c)(6) would be replaced with the word “reserved.”

We would revise language in §60.5476(f) and are proposing new language to replace ASTM E2515-11, section 9.6.5.1 by adding §60.5476(f)(1), which specifies appropriate post-test leak check procedures and in §60.5476(f)(2) adding procedures for performing leak checks during a sampling run. We are proposing these modifications to bring appropriate QA/QC requirements to PM measurements required by the rule and eliminate opportunity for emissions test results to be considered valid when a leaking sampling system allows dilution of the PM sample(s).

We are also proposing in §60.5476(f) that first hour PM emissions measurements should be conducted using a separate ASTM E2515-11 sampling train operated concurrently with the paired ASTM E2515-11 sampling trains used in compliance PM sampling. In this manner, the first hour PM emissions will be collected appropriately, and the compliance test measurements would not be impacted by a sampling pause for filter replacement at the one-hour mark. In §60.5476(f), we would incorporate language about filter type and size acceptance currently in §60.5476(c)(5). Additionally, we would remove text relating to EN 303-5 currently found in §60.5476(f).

The regulatory language in §60.5483(b) would be revised to include General Provisions that were added to §60.8(f)(2) (81 FR 59801, August 30, 2016) and were inadvertently exempted from subpart QQQQ as that rule, as promulgated in 2015, exempted §60.8(f) in its entirety. The exemption promulgated in subpart QQQQ at §60.5483(b) was intended for those affected sources subject to §60.8(f), which, at the time, consisted of what is currently §60.8(f)(1) and is specific to compliance testing results consisting of the arithmetic mean of three replicate tests. We are proposing these modifications to ensure that emissions test reporting includes all data necessary to assess and assure the quality of the reported emissions data and appropriately describes and identifies the specific unit covered by the emissions test report. Since compliance tests in this category consist of a single test, the original regulatory exemption to the General Provisions of §60.8(f)(1) is retained.

In subpart QQQQ, in Method 28WHH, in section 13.8, the erroneous CO calculation instructions for equation 23 would be corrected to include the summation of CO emissions over four instead of three test categories.

E. Method 1 of Appendix A-1 of Part 60

In Method 1, the heading in section 11.5.1 would be moved to 11.5, and the word “procedure” would be moved to the first sentence in section 11.5.1 for clarity. Section 11.5.2 would be revised to clearly specify the number of traverse points that must be used for sampling and velocity measurements once a directional flow-sensing probe procedure has been used to demonstrate that an alternative measurement site is acceptable. The last sentence of section 11.5.2, which appears unclear as to what “same traverse point number and locations” it is referring, would be revised to instead specify the “same minimum of 40 traverse points for circular ducts and 42 points for rectangular ducts” that are used in the alternative measurement procedure of section 11.5.3.

Also, Table 1-2 would be revised to correct the erroneous requirement that calls for 99.9 percent of stack diameter from the inside wall to the traverse point to 98.9 percent.

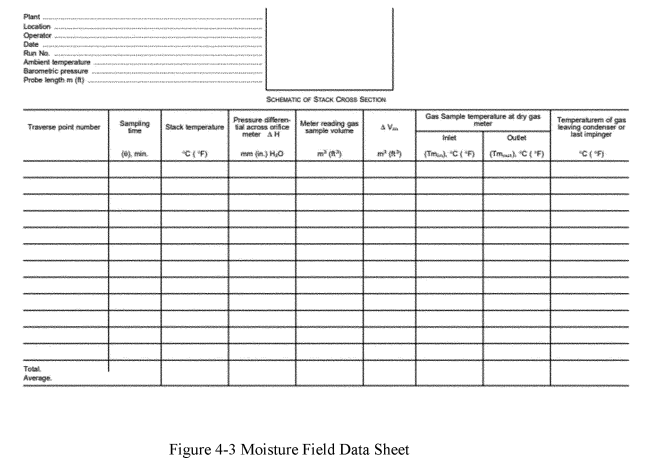

F. Method 4 of Appendix A-3 of Part 60

In Method 4, Table 4-3 would be formatted correctly.

G. Method 7 of Appendix A-4 of Part 60

In Method 7, section 10.1.3 would be revised to change the word “should” to “shall” in the last sentence because the difference between the calculated concentration values and the actual concentrations are required to be less than 7 percent for all standards.

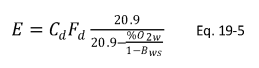

H. Method 19 of Appendix A-7 of Part 60

In Method 19, the erroneous equation 19-5 would be corrected.

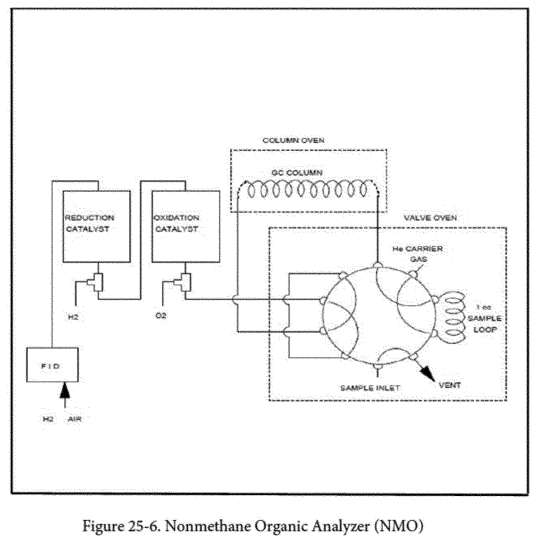

I. Method 25 of Appendix A-7 of Part 60

In Method 25, a record and report section (section 12.9) would be added to confirm that the quality control (QC) was successfully performed. Also, the erroneous Figure 25-6 would be corrected.

J. Method 25C of Appendix A-7 of Part 60

In Method 25C, the nomenclature in section 12.1 for C N2 and C mN2 would be revised to provide clarity.

K. Method 26 of Appendix A-8 of Part 60

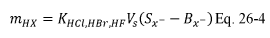

In Method 26, erroneous equations 26-4 and 26-5 in sections 12.4 and 12.5, respectively, would be revised to be consistent with the nomenclature in section 12.1.

L. Performance Specification 1 of Appendix B of Part 60

In Performance Specification 1, references to ASTM D6216-12 (in sections 2.1, 3.1, 6.1, 8.1(1), 8.1(2)(iii), 8.1(3)(ii), 8.2(1), 8.2(2), 8.2(3), 9.0, 12.1, 13.1, 13.2, and 16.0 reference 8) would be replaced with ASTM D6216-20. Note: If the initial certification of the continuous opacity monitoring system (COMS) has already occurred using D6216-98, D6216-03, D6216-07, or D6216-12, it will not be necessary to recertify using D6216-20.

Also, in Performance Specification 1, section 8.1(2)(iii) would be revised by removing the next to the last sentence, which reads, “The opacities of the two locations or paths may be measured at different times but must represent the same process operating conditions,” because the statement is confusing and unclear; furthermore, it is unlikely that one would achieve the same conditions at two different times.

M. Performance Specification 2 of Appendix B of Part 60

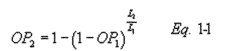

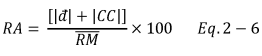

In Performance Specification 2, in section 8.3.3, a sentence would be added to clarify that during a calibration, the reference gas is to be introduced into the sampling system prior to any sample conditioning or filtration equipment and must pass through as much of the probe as is practical. In section 12.5, minor revisions would be made to clarify that relative accuracy (RA) test results are expressed as a percent of emission rate or concentration (units of the applicable standard) and the definition of the average reference method (RM) value for Equation 2-6.

N. Performance Specification 4B of Appendix B of Part 60

The entire Performance Specification 4B would be updated to the Environmental Monitoring Management Council (EMMC) methods format used for all other performance specifications.

O. Performance Specification 6 of Appendix B of Part 60

In Performance Specification 6, section 13.2 would be revised to specifically state the relative accuracy criteria including significant figures. On October 7, 2020 (85 FR 63394), we revised section 13.2 of Performance Specification 6 to make the relative accuracy calculations and criteria consistent with Performance Specification 2 and offer an alternate calculation and criterion for low emission concentration/rate situations; however, we neglected to specifically cite the alternate relative accuracy criterion from Performance Specification 2 for low emission sources and to ensure consistency with Performance Specification 2 with regard to significant figures in the relative accuracy criteria.

P. Performance Specification 12A of Appendix B of Part 60

We are proposing to revise the references (in sections 8.4.2, 8.4.4, 8.4.5, 8.4.6.1, and 17.5 and the footnote to Figure 12A-3) to ASTM D6784, Standard Test Method for Elemental, Oxidized, Particle-Bound and Total Mercury in Flue Gas Generated from Coal-Fired Stationary Sources (Ontario Hydro Method), to update them from the 2002 version to the latest version, which was authorized in 2016.

The capabilities of mercury CEMS have been improving since initially being deployed to support regulations over a decade ago. Therefore, we are proposing to revise section 13.3 to modify the alternative relative accuracy criterion such that: (1) It would apply only at mercury concentrations less than 2.5 µg/scm and (2) the difference between the average reference method and CEMS values added to the confidence coefficient would now be 0.5 µg/scm. This revised criterion is consistent with revisions that we made to the mercury monitoring requirements in 40 CFR 63, subpart UUUUU (81 FR 20172, April 6, 2016).

Q. Performance Specification 16 of Appendix B of Part 60

In Performance Specification 16, several corrections and modifications would be made to clarify the intent of the requirements. In section 1.1, we would correct the language to make it clear that if a PEMS (predictive emission monitoring system) contains a diluent component, then the diluent component must be tested as well. Also, in section 1.1, the language referring to PS-17 would be removed since PS-17 was never promulgated. In sections 3.11 and 3.12, language would be added to define commonly used acronyms, and in section 3.12, the language would be corrected to indicate that the relative accuracy test audit (RATA) is to be conducted as specified in section 8.2. In section 9.1, the QA/QC Summary chart would be corrected to reflect the language found in section 2.2, which indicates that the relative accuracy audit (RAA) is required on all PEMS and not just those classified as compliance PEMS. The QA/QC Summary Chart is also modified to align the criteria for a RAA with that found in section 13.5. In section 9.4, the language stating a RATA is to be conducted at the normal operating level would be corrected to indicate the RATA is to be conducted as specified in section 8.2 and to remove the statement that the statistical tests in section 8.3 are not required for the yearly RATA. In section 12.3.2, the alternative criteria language would be removed because it does not apply to F-factor determinations. In sections 13.1 and 13.5, the language would be modified to add the corresponding alternative criteria in units of lb/mmBtu.

R. Procedure 1 of Appendix F of Part 60

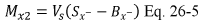

In Procedure 1, in section 4.1, a sentence would be added to clarify that during a calibration, the reference gas is to be introduced into the sampling system prior to any sample conditioning or filtration equipment and must pass through as much of the probe as is practical. Section 5.2.3 (2) would be modified to refine the alternative cylinder gas audit (CGA) criteria in response to the use of analyzers with lower span values. In section 6.2, in order to provide clarity and clear up any confusion, we would remove the language referring to the relevant performance specification and insert the language referring to the use of Equation 1-1.

S. Procedure 5 of Appendix F of Part 60

Regulated entities have pointed out that we did not include criteria for the system integrity check required in Procedure 5. In section 2.5, we would clarify that ongoing daily calibration of the Hg CEMS must be conducted using elemental mercury reference gas. This is consistent with revisions that we made to the Hg monitoring requirements in 40 CFR 63, subpart UUUUU (81 FR 20172, April 6, 2016). We would revise the title of section 4.0 and add section 4.4 to explain more explicitly the procedure for conducting the system integrity check as well as to provide the criteria for passing the check. In section 5.1.3, to add clarity we would insert language referring to Equation 1-1 of Procedure 1 for calculating relative accuracy.

T. General Provisions (Subpart A) of Part 63

In the General Provisions of part 63, §63.14 would be revised to: (1) Add ASTM D6784-16 to redesignated paragraph (i) and (2) add “Standard Methods for the Examination of Water and Wastewater” Method 5210B to new paragraph (d).

U. National Emission Standards for Hazardous Air Pollutants From the Pulp and Paper Industry (Subpart S) of Part 63

In subpart S, the existing reference in 40 CFR 63.457(c)(4) to Method 405.1 of part 136 of chapter 40 for the measurement of biochemical oxygen demand (BOD) is no longer valid, as Method 405.1 was withdrawn in 2007. It was replaced with Biochemical Oxygen Demand Standard Methods 5210 B (72 FR 11199, March 12, 2007), which has been previously approved in test plans for measuring BOD to demonstrate compliance with the requirements of subpart S. In §63.457(c)(4), Method 405.1 would be updated to reference Method 5210B. This method would also be incorporated by reference in 40 CFR 63.14.

V. Standards of Performance for Hazardous Air Pollutants From Hazardous Waste Combustors (Subpart EEE) of Part 63

In the appendix to subpart EEE, we would remove the erroneous language regarding an Interference Response Test in the introductory paragraph of section 5 and section 5.3 in its entirety.

W. National Emission Standards for Hazardous Air Pollutants: Paper and Other Web Coating (Subpart JJJJ) of Part 63

In 2009, revisions were made to §63.3360(e)(1)(viii) to clarify that the results of Method 25 or Method 25A were being used to determine “total organic volatile matter” (85 FR 41276). At the time, the use of the terminology “total gaseous non-methane organic volatile organic matter” in §63.3360(e)(1)(vi) was overlooked. We are proposing to revise §63.3360(e)(1)(vi) by removing the term “non-methane” to be consistent with §63.3360(e)(1)(viii).

X. National Emission Standards for Hazardous Air Pollutants for Stationary Reciprocating Internal Combustion Engines (Subpart ZZZZ) of Part 63

We have received multiple inquiries regarding the requirements in Table 4 of Subpart ZZZZ to measure the exhaust gas moisture when measuring the concentration of carbon monoxide (CO), formaldehyde, or THC to demonstrate compliance with the rule. It was first pointed out that it is not always necessary to measure that exhaust gas moisture when measuring CO. We would add language to all three sections of Table 4 stating that that the moisture measurement is only necessary when needed to correct the CO, formaldehyde, THC and/or O 2 measurements to a dry basis.

Y. National Emission Standards for Hazardous Air Pollutants: Engine Test Cells/Stands Residual Risk and Technology Review (Subpart PPPPP) of Part 63

In subpart PPPPP, the existing erroneous statement in §63.9306(d)(2)(iv) would be corrected to read, “Using a pressure sensor with measurement sensitivity of 0.002 inches water, check gauge calibration quarterly and transducer calibration monthly.” Also, in subpart PPPPP, the existing erroneous statement in §63.9322(a)(1) would be corrected to read, “The capture system meets the criteria in Method 204 of appendix M to 40 CFR part 51 for a permanent total enclosure (PE) and directs all the exhaust gases from the enclosure to an add-on control device.”

Z. National Emission Standards for Hazardous Air Pollutants: Coal- and Oil-Fired Electric Utility Steam Generating Units (Subpart UUUUU) of Part 63

We are proposing to revise the references in sections 4.1.1.5 and 4.1.1.5.1 in subpart UUUUU, appendix A to ASTM Method D6784, Standard Test Method for Elemental, Oxidized, Particle-Bound and Total Mercury in Flue Gas Generated from Coal-Fired Stationary Sources (Ontario Hydro Method), to update them from the 2002 version to the latest version, which was authorized in 2016. In table 5, we are proposing to add ASTM Method D6784-16 as a mercury testing option as it was inadvertently left out previously.

AA. Method 315 of Appendix A of Part 63

Section 16.2 is mislabeled as section 6.2 and would be corrected.

BB. Method 323 of Appendix A of Part 63

In Method 323, sections 10.1 and 10.3 would be revised to require best laboratory practices. The nomenclature in section 12.1 would be revised to include “b,” which is the intercept of the calibration curve at zero concentration and revise K c ; these additions are necessary because equation 323-5 in section 12.6 would be revised to reflect changes in calibration procedures for calculating the mass of formaldehyde.

VI. Statutory and Executive Order Reviews

Additional information about these statutes and Executive Orders can be found at https://www2.epa.gov/laws-regulations/laws-and-executive-orders.

A. Executive Order 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulation and Regulatory Review

This action is not a significant regulatory action and was, therefore, not submitted to the Office of Management and Budget (OMB) for review.

B. Paperwork Reduction Act (PRA)

This action does not impose an information collection burden under the PRA. The amendments being proposed in this action to the test methods, performance specifications, and testing regulations only make corrections and minor updates to existing testing methodology. In addition, the proposed amendments clarify performance testing requirements.

C. Regulatory Flexibility Act (RFA)

I certify that this action will not have a significant economic impact on a substantial number of small entities under the RFA. This action will not impose any requirements on small entities. This proposed rule will not impose emission measurement requirements beyond those specified in the current regulations, nor does it change any emission standard.

D. Unfunded Mandates Reform Act (UMRA)

This action does not contain any unfunded mandate as described in UMRA, 2 U.S.C. 1531-1538, and does not significantly or uniquely affect small governments. The action imposes no enforceable duty on any state, local or tribal governments or the private sector.

E. Executive Order 13132: Federalism

This action does not have federalism implications. It will not have substantial direct effects on the states, on the relationship between the national government and the states, or on the distribution of power and responsibilities among the various levels of government.

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

This action does not have tribal implications, as specified in Executive Order 13175. This action would correct and update existing testing regulations. Thus, Executive Order 13175 does not apply to this action.

G. Executive Order 13045: Protection of Children From Environmental Health Risks and Safety Risks

The EPA interprets Executive Order 13045 as applying only to those regulatory actions that concern environmental health or safety risks that the EPA has reason to believe may disproportionately affect children, per the definition of “covered regulatory action” in section 2-202 of the Executive Order. This action is not subject to Executive Order 13045 because it does not concern an environmental health risk or safety risk.

H. Executive Order 13211: Actions Concerning Regulations That Significantly Affect Energy Supply, Distribution or Use

This action is not subject to Executive Order 13211 because it is not a significant regulatory action under Executive Order 12866.

I. National Technology Transfer and Advancement Act and 1 CFR Part 51

This action involves technical standards. The EPA proposes to use ASTM D6216-20 for continuous opacity monitors in Performance Specification 1. The ASTM D6216-20 standard covers the procedure for certifying continuous opacity monitors and includes design and performance specifications, test procedures, and QA requirements to ensure that continuous opacity monitors meet minimum design and calibration requirements, necessary in part, for accurate opacity monitoring measurements in regulatory environmental opacity monitoring applications subject to 10 percent or higher opacity standards. The EPA also proposes to update the version of ASTM D6784, a test method for elemental, oxidized, particle-bound, and total mercury in emissions from stationary sources, from the 2002 to 2016 version in the references contained in 40 CFR part 60, appendix B, Performance Specification 12A for continuous monitoring of mercury emissions. Likewise, EPA proposes to update the version of ASTM D6784 referenced in table 5 and appendix A of Subpart UUUUU in 40 CFR part 63, for mercury emissions measurement and monitoring. The ASTM D6216-20 and D6784-16 standards were developed and adopted by the American Society for Testing and Materials. The standards may be obtained from http://www.astm.org or from the ASTM at 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, PA 19428-2959.

The EPA also proposes to use the APHA Method 5210 Biochemical Oxygen Demand (BOD) from “Standard Methods for the Examination of Water and Wastewater.” This standard is acceptable as an alternative to Method 405.1 and is available from APHA at www.standardmethods.org or by telephone at (844) 232-3707.

Additionally, the EPA proposes language intended to correct a portion of the ASTM E2515-11 test method. The stipulations would modify the post-test leak check procedures as well as add procedures for performing leak checks during a sampling run. The stipulations to ASTM E2515-11 are necessary as we have learned that the quality assurance/quality control (QA/QC) requirements for leak tests required by ASTM E2515-11, section 9.6.5.1 are not sufficient to provide assurance of the sampling system integrity. Additionally, the language of ASTM E2515-11, section 9.6.5.1 currently allows for averaging the PM results from a non-leaking sampling system with those from a leaking sampling system which effectively reduces reported PM emissions by as much as half, rendering the test method inappropriate for compliance determination.

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations

The EPA believes that this action is not subject to Executive Order 12898 (59 FR 7629, February 16, 1994) because it does not establish an environmental health or safety standard. This action would correct and update existing testing regulations.

List of Subjects

40 CFR Part 51

Environmental protection, Air pollution control, Performance specifications, Test methods and procedures.

40 CFR Part 60

Environmental protection, Air pollution control, Incorporation by reference, Performance specifications, Test methods and procedures.

40 CFR Part 63

Environmental protection, Air pollution control, Incorporation by reference, Performance specifications, Test methods and procedures.

Michael S. Regan,

Administrator.

For the reasons set forth in the preamble, the Environmental Protection Agency proposes to amend title 40, chapter I of the Code of Federal Regulations as follows:

PART 51—REQUIREMENTS FOR PREPARATION, ADOPTION, AND SUBMITTAL OF IMPLEMENTATION PLANS

1. The authority citation for part 51 continues to read as follows:

Authority: 23 U.S.C. 101; 42 U.S.C. 7401-7671q.

2. Amend section 12.5 in Method 201A of appendix M to part 51 by revising Eq. 25 to read as follows:

Appendix M to Part 51—Recommended Test Methods for State Implementation Plans

* * * * *

Method 201A—Determination of PM 10 and PM 2.5 Emissions From Stationary Sources (Constant Sampling Rate Procedure)

* * * * *

12.5 Equations. Use the following equations to complete the calculations required in this test method.

* * * * *

* * * * *

PART 60—STANDARDS OF PERFORMANCE FOR NEW STATIONARY SOURCES

3. The authority citation of part 60 is revised to read as follows:

Authority: 42 U.S.C. 7401 et seq.

4. In §60.17:

a. Revise paragraphs (a) and (h)(179) and (191);

b. Redesignate paragraphs (h)(193) through (h)(212) as (h)(194) through (h)(213) respectively; and

c. Add new paragraph (h)(193).

The additions and revisions read as follows:

§60.17 Incorporations by reference.

(a) Certain material is incorporated by reference into this part with the approval of the Director of the Federal Register under 5 U.S.C. 552(a) and 1 CFR part 51. To enforce any edition other than that specified in this section, the EPA must publish a document in the Federal Register and the material must be available to the public. All approved material is available for inspection at the EPA and the National Archives and Records Administration (NARA). Contact EPA at: The EPA Docket Center, Public Reading Room, EPA WJC West, Room 3334, 1301 Constitution Ave. NW, Washington, DC, phone (202) 566-1744. For information on the availability of this material at NARA, email fr. nspection@nara.gov, or go to www.archives.gov/federal-register/cfr/ibr-locations.html. The material may be obtained from the source(s) in the following paragraph(s) of this section.

* * * * *

(h) * * *

(179) ASTM D6216-20, Standard Practice for Opacity Monitor Manufacturers to Certify Conformance with Design and Performance Specifications, 2020; IBR approved for appendix B: Performance Specification 1.

* * * * *

(191) ASTM D6784-02, Standard Test Method for Elemental, Oxidized, Particle-Bound and Total Mercury in Flue Gas Generated from Coal-Fired Stationary Sources (Ontario Hydro Method); IBR approved for §60.56c(b).

* * * * *

(193) ASTM D6784-16, Standard Test Method for Elemental, Oxidized, Particle-Bound and Total Mercury in Flue Gas Generated from Coal-Fired Stationary Sources (Ontario Hydro Method), 2016; IBR approved for appendix B: Performance Specification 12A.

* * * * *

5. Amend §60.534 by revising paragraphs (c) and (d) to read as follows:

§60.534 What test methods and procedures must I use to determine compliance with the standards and requirements for certification?

* * * * *

(c) For affected wood heaters subject to the 2015 and 2020 particulate matter emission standards specified in §60.532(a), (b) and (c), particulate matter emission concentrations must be measured with ASTM E2515-11 (IBR, see §60.17) with the following exceptions: Eliminate section 9.6.5.1 of ASTM E2515-11 and perform the post-test leak checks as described in paragraph (c)(1) of this section. Additionally, if a component change of either sampling train is needed during sampling, then perform the leak check specified in paragraph (c)(2) of this section. Four-inch filters and Teflon membrane filters or Teflon-coated glass fiber filters may be used in ASTM E2515-11.

(1) Post-Test Leak Check: A leak check of each sampling train is mandatory at the conclusion of each sampling run before sample recovery. The leak check must be performed in accordance with the procedures of ASTM E2515-11, section 9.6.4.1 (IBR, see §60.17), except that it must be conducted at a vacuum equal to or greater than the maximum value reached during the sampling run. If the leakage rate is found to be no greater than 0.0003 m 3/min (0.01 cfm) or 4% of the average sampling rate (whichever is less), the leak check results are acceptable. If a higher leakage rate is obtained, the sampling run is invalid.

(2) Leak Checks During Sample Run: If, during a sampling run, a component (e.g., filter assembly) change becomes necessary, a leak check must be conducted immediately before the change is made. The leak check must be done according to the procedure outlined in ASTM E2515-11, section 9.6.4.1 (IBR, see §60.17), except that it must be done at a vacuum equal to or greater than the maximum value recorded up to that point in the sampling run. If the leakage rate is found to be no greater than 0.0003 m 3/min (0.01 cfm) or 4% of the average sampling rate (whichever is less), the leak check results are acceptable. If a higher leakage rate is obtained, the sampling run is invalid.

Note 1 to paragraph (c)(2): Immediately after component changes, leak checks are optional but highly recommended. If such leak checks are done, the procedure in paragraph (c)(1) of this section should be used.

(d) For all tests conducted using ASTM E2515-11 (IBR, see §60.17), with the exceptions described in §paragraphs (c)(1) and (2) of this section, and pursuant to this section, the manufacturer and approved test laboratory must also measure the first hour of particulate matter emissions for each test run by sampling with a third, identical and independent sampling train operated concurrently for the first hour of PM paired train compliance testing according to paragraph (c) of this section. The manufacturer and approved test laboratory must report the test results from this third train separately as the first hour emissions.

* * * * *

6. Amend §60.539b by revising paragraph (b) to read as follows:

§60.539b What parts of the General Provisions do not apply to me?

* * * * *

(b) Section 60.8(a), (c), (d), (e), (f) (1), and (g);

* * * * *

7. Amend §60.5474 by revising paragraph (b)(2), (3) and (6) to read as follows:

§60.5474 What standards and requirements must I meet and by when?

* * * * *

(b) * * *

(2) 2020 residential hydronic heater particulate matter emission limit: 0.10 lb/mmBtu (0.043 g/MJ) heat output per individual burn rate as determined by the crib wood test methods and procedures in §60.5476 or an alternative crib wood test method approved by the Administrator.

(3) 2020 residential hydronic heater cord wood alternative compliance option for particulate matter emission limit: 0.15 lb/mmBtu (0.064 g/MJ) heat output per individual burn rate as determined by the cord wood test methods and procedures in §60.5476 or an alternative cord wood test method approved by the Administrator.

* * * * *

(6) 2020 forced-air furnace particulate matter emission limit: 0.15 lb/mmBtu (0.064 g/MJ) heat output per individual burn rate as determined by the cord wood test methods and procedures in §60.5476 or cord wood test methods approved by the Administrator.

* * * * *

9. Amend §60.5476 by removing paragraph (c)(5) and (6) and revising paragraph (f).

The revision reads as follows:

§60.5476 What test methods and procedures must I use to determine compliance with the standards and requirements for certification?

* * * * *

(f) For affected wood heaters subject to the particulate matter emission standards, particulate matter emission concentrations must be measured with ASTM E2515-11 (IBR, see §60.17) with the following exceptions, eliminate section 9.6.5.1 of ASTM E2515-11 and perform the post-test leak checks as described in paragraph (f)(1) of this section. Additionally, if a component change of either sampling train is needed during sampling, then perform the leak check specified in paragraph (f)(2 of this section). Four-inch filters and Teflon membrane filters or Teflon-coated glass fiber filters may be used in ASTM E2515-11. For all tests conducted using ASTM 2515-11, with the exceptions described in paragraphs (f)(1) and (2) of this section, the manufacturer and approved test laboratory must also measure the first hour of particulate matter emissions for each test run by sampling with a third, identical and independent sampling train operated concurrently with the first hour of PM paired train compliance testing. The manufacturer and approved test laboratory must report the test results for this third train separately as the first hour emissions.

(1) Post-Test Leak Check: A leak check of each sampling train is mandatory at the conclusion of each sampling run before sample recovery. The leak check must be performed in accordance with the procedures of ASTM E2515-11, section 9.6.4.1 (IBR, see §60.17), except that it must be conducted at a vacuum equal to or greater than the maximum value reached during the sampling run. If the leakage rate is found to be no greater than 0.0003 m 3/min (0.01 cfm) or 4% of the average sampling rate (whichever is less), the leak check results are acceptable. If a higher leakage rate is obtained, the sampling run is invalid.

(2) Leak Checks During Sample Run: If, during a sampling run, a component (e.g., filter assembly) change becomes necessary, a leak check must be conducted immediately before the change is made. The leak check must be done according to the procedure outlined in ASTM E2515-11, section 9.6.4.1 (IBR, see §60.17), except that it must be done at a vacuum equal to or greater than the maximum value recorded up to that point in the sampling run. If the leakage rate is found to be no greater than 0.0003 m 3/min (0.01 cfm) or 4% of the average sampling rate (whichever is less), the leak check results are acceptable. If a higher leakage rate is obtained, the sampling run is invalid.

Note 1 to paragraph (f)(2): Immediately after component changes, leak checks are optional but highly recommended. If such leak checks are done, the procedure in paragraph (f)(1) of this section should be used.

* * * * *

10. Amend §60.5483 by revising paragraph (b) to read as follows:

§60.5483 What parts of the General Provisions do not apply to me?

* * * * *

(b) Section 60.8(a), (c), (d), (e), (f) (1), and (g);

* * * * *

11. Amend Appendix A-1 to part 60 by revising sections 11.5, 11.5.1, and 11.5.2, and Table 1-2 in Method 1 to read as follows:

Appendix A-1 to Part 60—Test Methods 1 Through 2F

* * * * *

Method 1—Sample and Velocity Traverses For Stationary Sources

* * * * *

11.5 Alternative Measurement Site Selection Procedure. The alternative site selection procedure may be used to determine the rotation angles in lieu of the procedure outlined in section 11.4.

11.5.1 This alternative procedure applies to sources where measurement locations are less than 2 equivalent or duct diameters downstream or less than one-half duct diameter upstream from a flow disturbance. The alternative should be limited to ducts larger than 24 inches in diameter where blockage and wall effects are minimal. A directional flow-sensing probe is used to measure pitch and yaw angles of the gas flow at 40 or more traverse points; the resultant angle is calculated and compared with acceptable criteria for mean and standard deviation.

Note:

Both the pitch and yaw angles are measured from a line passing through the traverse point and parallel to the stack axis. The pitch angle is the angle of the gas flow component in the plane that INCLUDES the traverse line and is parallel to the stack axis. The yaw angle is the angle of the gas flow component in the plane PERPENDICULAR to the traverse line at the traverse point and is measured from the line passing through the traverse point and parallel to the stack axis.

11.5.2 Traverse Points. Use a minimum of 40 traverse points for circular ducts and 42 points for rectangular ducts for the gas flow angle determinations. Follow the procedure outlined in section 11.3 and Table 1-1 or 1-2 of this method for the location and layout of the traverse points. If the alternative measurement location is determined to be acceptable according to the criteria in this alternative procedure, use the same minimum of 40 traverse points for circular ducts and 42 points for rectangular ducts that were used in the alternative measurement procedure for future sampling and velocity measurements.

* * * * *

| Traverse point number on a diameter | Number of traverse points on a diameter | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | |

| 1 | 14.6 | 6.7 | 4.4 | 3.2 | 2.6 | 2.1 | 1.8 | 1.6 | 1.4 | 1.3 | 1.1 | 1.1 |

| 2 | 85.4 | 25.0 | 14.6 | 10.5 | 8.2 | 6.7 | 5.7 | 4.9 | 4.4 | 3.9 | 3.5 | 3.2 |

| 3 | 75.0 | 29.6 | 19.4 | 14.6 | 11.8 | 9.9 | 8.5 | 7.5 | 6.7 | 6.0 | 5.5 | |

| 4 | 93.3 | 70.4 | 32.3 | 22.6 | 17.7 | 14.6 | 12.5 | 10.9 | 9.7 | 8.7 | 7.9 | |

| 5 | 85.4 | 67.7 | 34.2 | 25.0 | 20.1 | 16.9 | 14.6 | 12.9 | 11.6 | 10.5 | ||

| 6 | 95.6 | 80.6 | 65.8 | 35.6 | 26.9 | 22.0 | 18.8 | 16.5 | 14.6 | 13.2 | ||

| 7 | 89.5 | 77.4 | 64.4 | 36.6 | 28.3 | 23.6 | 20.4 | 18.0 | 16.1 | |||

| 8 | 96.8 | 85.4 | 75.0 | 63.4 | 37.5 | 29.6 | 25.0 | 21.8 | 19.4 | |||

| 9 | 91.8 | 82.3 | 73.1 | 62.5 | 38.2 | 30.6 | 26.2 | 23.0 | ||||

| 10 | 97.4 | 88.2 | 79.9 | 71.7 | 61.8 | 38.8 | 31.5 | 27.2 | ||||

| 11 | 93.3 | 85.4 | 78.0 | 70.4 | 61.2 | 39.3 | 32.3 | |||||

| 12 | 97.9 | 90.1 | 83.1 | 76.4 | 69.4 | 60.7 | 39.8 | |||||

| 13 | 94.3 | 87.5 | 81.2 | 75.0 | 68.5 | 60.2 | ||||||

| 14 | 98.2 | 91.5 | 85.4 | 79.6 | 73.8 | 67.7 | ||||||

| 15 | 95.1 | 89.1 | 83.5 | 78.2 | 72.8 | |||||||

| 16 | 98.4 | 92.5 | 87.1 | 82.0 | 77.0 | |||||||

| 17 | 95.6 | 90.3 | 85.4 | 80.6 | ||||||||

| 18 | 98.6 | 93.3 | 88.4 | 83.9 | ||||||||

| 19 | 96.1 | 91.3 | 86.8 | |||||||||

| 20 | 98.7 | 94.0 | 89.5 | |||||||||

| 21 | 96.5 | 92.1 | ||||||||||

| 22 | 98.9 | 94.5 | ||||||||||

| 23 | 96.8 | |||||||||||

| 24 | 98.9 | |||||||||||

* * * * *

12. Amend Method 4 in Appendix A-3 to part 60 by revising Figure 4-3 to read as follows:

Appendix A-3 to Part 60—Test Methods 4 Through 5I

* * * * *

Method 4—Determination of Moisture Content in Stack Gases

* * * * *

* * * * *

13. Amend Appendix A-4 to part 60 by revising section 10.1.3 in Method 7 of to read as follows:

Appendix A-4 to Part 60—Test Methods 6 Through 10B

* * * * *

Method 7—Determination of Nitrogen Oxide Emissions From Stationary Sources

* * * * *

10.1.3 Spectrophotometer Calibration Quality Control. Multiply the absorbance value obtained for each standard by the K c factor (reciprocal of the least squares slope) to determine the distance each calibration point lies from the theoretical calibration line. The difference between the calculated concentration values and the actual concentrations (i.e., 100, 200, 300, and 400 μg NO 2) shall be less than 7 percent for all standards.

* * * * *

16. Amend Appendix A-7 to part 60 by:

a. In Method 19, revising Equation 19-5;

b. In Method 25, adding sections 12.9 and 12.9.1 through 12.9.16, and revising Figure 25-6; and

c. In Method 25C, revising section 12.1.

The revisions and additions read as follows:

Appendix A-7 to Part 60—Test Methods 19 Through 25E

* * * * *

Method 19—Determination of Sulfur Dioxide Removal Efficiency and Particulate Matter, Sulfur Dioxide, and Nitrogen Oxide Emission Rates

* * * * *

* * * * *

Method 25—Determination of Total Gaseous Nonmethane Organic Emissions As Carbon

* * * * *

12.9 Record and Report Initial Method Checks as follows:

12.9.1 Calibration and Linearity Check Gas Certifications (Section 7.2 and 7.4)

12.9.2 Condensate Trap Blank Check (Section 8.1.1)

12.9.3 Pretest Leak-Check (Section 8.1.4)

12.9.4 Condensate Recovery Apparatus (Section 10.1.1)

12.9.5 Carrier Gas and Auxiliary O 2 Blank Check (Section 10.1.1.1)

12.9.6 Oxidation Catalyst Efficiency Check. (Section 10.1.1.2)

12.9.7 System Performance Check. (Section10.1.1.3)

12.9.8 Oxidation Catalyst Efficiency Check. (Section 10.1.2.1)

12.9.9 Reduction Catalyst Efficiency Check (Section 10.1.2.2)

12.9.10 NMO Analyzer Linearity Check Calibration. (Section 10.1.2.3)

12.9.11 NMO Analyzer Daily Calibration. (Section 10.2)

12.9.12 Condensate Recovery. (Section 11.1)

12.9.13 Daily Performance Checks. (Section 11.1.1)

12.9.14 Leak-Check. (Section 11.1.1.1)

12.9.15 System Background Test. (Section 11.1.1.2)

12.9.16 Oxidation Catalyst Efficiency Check. (Section 11.1.1.3)

* * * * *

* * * * *

Method 25C—Determination of Nonmethane Organic Compounds (NMOC) in Landfill Gases

* * * * *

12.1 Nomenclature.

* * * * *

C N2 = N 2 concentration in the landfill gas sample

C mN2 = Measured N 2 concentration, diluted landfill gas sample

* * * * *

17. In Appendix A-8 to part 60:

a. Revise sections 12.4 and 12.5 in Method 26.

b. Revise section 13.8 in Test Method 28WHH.

The revisions read as follows:

Appendix A-8 to Part 60—Test Methods 26 Through 30B

* * * * *

Method 26—Determination of Hydrogen Halide and Halogen Emissions From Stationary Sources Non-Isokinetic Method

* * * * *

12.4 Total ug HCl, HBr, or HF Per Sample.

12.5 Total ug Cl 2 or Br 2 Per Sample.

* * * * *

Test Method 28WHH for Measurement of Particulate Emissions and Heating Efficiency of Wood-Fired Hydronic Heating Appliances

* * * * *

13.8 Carbon Monoxide Emissions.

For each minute of the test period, the carbon monoxide emissions rate (g/min) shall be calculated as:

Total CO emissions for each of the four test periods (CO_1, CO_2, CO_3, CO_4) shall be calculated as the sum of the emissions rates for each of the 1-minute intervals.

Total CO emissions for the test run, CO T, shall be calculated as the sum of CO_1, CO_2, CO_3 and CO_4.

* * * * *

18. Amend Appendix B to part 60 by:

a. In Performance Specification 1, revising sections 2.1, 3.1, 6.1, 8.1(1), 8.1(2)(iii), 8.1(3)(ii), 8.2(1), 8.2(2), 8.2(3), 9.0, 12.1, 13.1, 13.2, and 16.0 reference 8;

b. In Performance Specification 2, revising sections 8.3.3 and 12.5;

c. Revising Performance Specification 4B;

d. In Performance Specification 6, revising section 13.2;

e. In Performance Specification 12A, revising sections 8.4.2, 8.4.4, 8.4.5, 8.4.6.1, 13.3, 17.5, and footnote to Figure 12A-3;

f. In Performance Specification 16, revising sections 1.1, 3.11, 3.12, 9.1, 9.4, 12.3.2, 13.1, and 13.5.

The revisions read as follows:

Appendix B to Part 60—Performance Specifications

* * * * *

Performance Specification 1—Specifications and Test Procedures for Continuous Opacity Monitoring Systems in Stationary Sources

* * * * *

2.1 ASTM D6216 (IBR, see §60.17) is the reference for design specifications, manufacturer's performance specifications, and test procedures. The opacity monitor manufacturer must periodically select and test an opacity monitor, that is representative of a group of monitors produced during a specified period or lot, for conformance with the design specifications in ASTM D6216. The opacity monitor manufacturer must test each opacity monitor for conformance with the manufacturer's performance specifications in ASTM D6216. Note: If the initial certification of the opacity monitor occurred before [the effective date of the final rule] using ASTM D6216-98, D6216-03, D6216-07, or D6216-12, it is not necessary to recertify using ASTM D6216-20.

* * * * *

3.1 All definitions and discussions from section 3 of ASTM D6216 are applicable to PS-1.

* * * * *

6.1 Continuous Opacity Monitoring System. You, as owner or operator, are responsible for purchasing an opacity monitor that meets the specifications of ASTM D6216, including a suitable data recorder or automated data acquisition handling system. Example data recorders include an analog strip chart recorder or more appropriately an electronic data acquisition and reporting system with an input signal range compatible with the analyzer output.

* * * * *

8.1 * * *

(1) You must purchase an opacity monitor that complies with ASTM D6216 and obtain a certificate of conformance from the opacity monitor manufacturer.

(2) * * *

(iii) Alternative Locations and Light Beam Paths. You may select locations and light beam paths, other than those cited above, if you demonstrate, to the satisfaction of the Administrator or delegated agent, that the average opacity measured at the alternative location or path is equivalent to the opacity as measured at a location meeting the criteria of sections 8.1(2)(i) and 8.1(2)(ii). The opacity at the alternative location is considered equivalent if {1} the average opacity value measured at the alternative location is within ±10 percent of the average opacity value measured at the location meeting the installation criteria, and {2} the difference between any two average opacity values is less than 2 percent opacity (absolute). You use the following procedure to conduct this demonstration: Simultaneously measure the opacities at the two locations or paths for a minimum period of time (e.g., 180-minutes) covering the range of normal operating conditions and compare the results. You may use alternative procedures for determining acceptable locations if those procedures are approved by the Administrator.

(3) * * *

(ii) Calibration Error Check. Conduct a three-point calibration error test using three calibration attenuators that produce outlet pathlength corrected, single-pass opacity values shown in ASTM D6216, section 7.5. If your applicable limit is less than 10 percent opacity, use attenuators as described in ASTM D6216, section 7.5 for applicable standards of 10 to 19 percent opacity. Confirm the external audit device produces the proper zero value on the COMS data recorder. Separately, insert each calibration attenuators (low, mid, and high-level) into the external audit device. While inserting each attenuator, {1} ensure that the entire light beam passes through the attenuator, {2} minimize interference from reflected light, and {3} leave the attenuator in place for at least two times the shortest recording interval on the COMS data recorder. Make a total of five nonconsecutive readings for each attenuator. At the end of the test, correlate each attenuator insertion to the corresponding value from the data recorder. Subtract the single-pass calibration attenuator values corrected to the stack exit conditions from the COMS responses. Calculate the arithmetic mean difference, standard deviation, and confidence coefficient of the five measurements value using equations 1-3, 1-4, and 1-5. Calculate the calibration error as the sum of the absolute value of the mean difference and the 95 percent confidence coefficient for each of the three test attenuators using equation 1-6. Report the calibration error test results for each of the three attenuators.

* * * * *

8.2 * * *

(1) Conduct the verification procedures for design specifications in section 6 of ASTM D6216.

(2) Conduct the verification procedures for performance specifications in section 7 of ASTM D6216.

(3) Provide to the owner or operator, a report of the opacity monitor's conformance to the design and performance specifications required in sections 6 and 7 of ASTM D6216 in accordance with the reporting requirements of section 9 in ASTM D6216.

9.0 What quality control measures are required by PS-1?

Opacity monitor manufacturers must initiate a quality program following the requirements of ASTM D6216, section 8. The quality program must include:

(1) A quality system and

(2) A corrective action program.

* * * * *

12.1 Desired Attenuator Values. Calculate the desired attenuator value corrected to the emission outlet pathlength as follows:

Where:

OP 1 = Nominal opacity value of required low-, mid-, or high-range calibration attenuators.

OP 2 = Desired attenuator opacity value from ASTM D6216, section 7.5 at the opacity limit required by the applicable subpart.

L 1 = Monitoring pathlength.

L 2 = Emission outlet pathlength.

* * * * *

13.1 Design Specifications. The opacity monitoring equipment must comply with the design specifications of ASTM D6216.

13.2 Manufacturer's Performance Specifications. The opacity monitor must comply with the manufacturer's performance specifications of ASTM D6216.

* * * * *

16.0 * * *

8. ASTM D6216-20: Standard Practice for Opacity Monitor Manufacturers to Certify Conformance with Design and Performance Specifications. ASTM. September 2020.

* * * * *

Performance Specification 2—Specifications and Test Procedures for SO 2 and NO X Continuous Emission Monitoring Systems in Stationary Sources

* * * * *

8.3.3 Conduct the CD test at the two points specified in section 6.1.2. Introduce to the CEMS the reference gases, gas cells, or optical filters (these need not be certified). When using reference gases, introduce the reference gas prior to any sample conditioning or filtration equipment and ensure that it passes through all filters, scrubbers, conditioners, and other monitor components used during normal sampling. The reference gas should pass through as much of the sampling probe as practical. Record the CEMS response and subtract this value from the reference value (see example data sheet in Figure 2-1).

* * * * *

12.5 Relative Accuracy. Calculate the RA, expressed as a percentage, of a set of data as follows:

Where:

| d | = Absolute value of the mean differences (from Equation 2-3).

| CC | = Absolute value of the confidence coefficient (from Equation 2-3).

RM = Average RM value. In cases where the average emissions for the test are less than 50 percent of the applicable emission standard, substitute the applicable emission standard value in the denominator of Eq. 2-6 in place of the average RM value. In all other cases, use RM.

* * * * *

Performance Specification 4B—Specifications and Test Procedures for Carbon Monoxide and Oxygen Continuous Monitoring Systems in Stationary Sources

1.0 Scope and Application

Analytes

| Analyte | CAS No. |

|---|---|

| Carbon Monoxide (CO) | 630-08-0 |

| Oxygen (O 2) | 7782-44-7 |

Applicability

This specification is to be used for evaluating the acceptability of carbon monoxide (CO) and oxygen (O 2) continuous emission monitoring systems (CEMS) at the time of or soon after installation and whenever specified in the regulations. The CEMS may include, for certain stationary sources, (a) flow monitoring equipment to allow measurement of the dry volume of stack effluent sampled, and (b) an automatic sampling system.

This specification is not designed to evaluate the installed CEMS' performance over an extended period of time, nor does it identify specific calibration techniques and auxiliary procedures to assess the CEMS' performance. The source owner or operator, however, is responsible to properly calibrate, maintain, and operate the CEMS. To evaluate the CEMS' performance, the Administrator may require, under section 114 of the Act, the operator to conduct CEMS performance evaluations at times other than the initial test.

The definitions, installation and measurement location specifications, test procedures, data reduction procedures, reporting requirements, and bibliography are the same as in PS 3 (for O 2) and PS 4A (for CO) except as otherwise noted below.

Summary of Performance Specification

Installation and measurement location specifications, performance specifications, test procedures, and data reduction procedures are included in this specification. Reference method tests, calibration error tests, calibration drift tests, and interferant tests are conducted to determine conformance of the CEMS with the specification.

Definitions

The definitions are the same as in section 3.0 of PS2 with the following definitions added:

Continuous Emission Monitoring System (CEMS). This definition is the same as PS 2 section 3.0 with the following addition. A continuous monitor is one in which the sample to be analyzed passes the measurement section of the analyzer without interruption.

Response Time (RT). The time interval between the start of a step change in the system input and when the pollutant analyzer output reaches 95 percent of the final value.

Calibration Error (CE). The difference between the concentration indicated by the CEMS and the known concentration generated by a calibration source when the entire CEMS, including the sampling interface is challenged. A CE test procedure is performed to document the accuracy and linearity of the CEMS over the entire measurement range.

Interferences [Reserved]

Safety

This performance specification may involve hazardous materials, operations, and equipment. This performance specification may not address all of the safety problems associated with its use. It is the responsibility of the user to establish appropriate safety and health practices and determine the applicable regulatory limitations prior to performing this performance specification. The CEMS user's manual should be consulted for specific precautions to be taken with regard to the analytical procedures.

Equipment and Supplies

Same as section 6.0 of PS 2, except for the following:

Data Recorder Scale. For O 2, same as specified in PS 3, except that the span must be 25 percent. The span of the O 2 may be higher if the O 2 concentration at the sampling point can be greater than 25 percent. For CO, same as specified in PS 4A, except that the low-range span must be 200 ppm and the high range span must be 3000 ppm. In addition, the scale for both CEMS must record all readings within a measurement range with a resolution of 0.5 percent.

Reagents and Standards

Sample Collection, Preservation, Storage, and Transport

Installation and Measurement Location Specifications

The CEMS Installation. This specification is the same as PS 2 section 8.1.1 with the following additions. Both the CO and O 2 monitors should be installed at the same general location. If this is not possible, they may be installed at different locations if the effluent gases at both sample locations are not stratified and there is no in-leakage of air between sampling locations.

Measurement Location. Same as PS 2 section 8.1.2.

Point CEMS. The measurement point should be within or centrally located over the centroidal area of the stack or duct cross section.

Path CEMS. The effective measurement path should: (1) Have at least 70 percent of the path within the inner 50 percent of the stack or duct cross sectional area, or (2) be centrally located over any part of the centroidal area.

Reference Method (RM) Measurement Location and Traverse Points

This specification is the same as PS 2 section 8.1.3 with the following additions. When pollutant concentration changes are due solely to diluent leakage and CO and O 2 are simultaneously measured at the same location, one half diameter may be used in place of two equivalent diameters.

Pretest Preparation. Install the CEMS, prepare the RM test site according to the specifications in section 8.1, and prepare the CEMS for operation according to the manufacturer's written instructions.

Stratification Test Procedure. Stratification is defined as the difference in excess of 10 percent between the average concentration in the duct or stack and the concentration at any point more than 1.0 meter from the duct or stack wall. To determine whether effluent stratification exists, a dual probe system should be used to determine the average effluent concentration while measurements at each traverse point are being made. One probe, located at the stack or duct centroid, is used as a stationary reference point to indicate change in the effluent concentration over time. The second probe is used for sampling at the traverse points specified in Method 1 (40 CFR part 60 appendix A). The monitoring system samples sequentially at the reference and traverse points throughout the testing period for five minutes at each point.

Calibration Drift Test Procedure. Same as section 8.3 in PS 2.

Note: The CE and RT tests must be conducted during the CD test period.

Calibration Error Test Procedure. Challenge each monitor (both low and high range CO and O 2) with zero gas and EPA Protocol 1 cylinder gases at three measurement points within the ranges specified in Table 4B-1 (in section 18.0).

Operate each monitor in its normal sampling mode as nearly as possible. The calibration gas must be injected into the sample system as close to the sampling probe outlet as practical and should pass through all CEMS components used during normal sampling. Challenge the CEMS three non-consecutive times at each measurement point and record the responses. The duration of each gas injection should be sufficient to ensure that the CEMS surfaces are conditioned.

Response Time Test Procedure. Same as section 8.3 in PS 4A and must be carried out for both the CO and O 2 monitors.

Relative Accuracy Test Procedure. Sampling Strategy for Reference Method (RM) Tests, Number of RM Tests, and Correlation of RM and CEMS Data are the same as PS 2, sections 8.4.3, 8.4.4, and 8.4.5, respectively.

Quality Control [Reserved]

Calibration and Standardization [Reserved]

Analytical Procedure

Sample collection and analysis are concurrent for this Performance Specification (see section 8.0). Refer to the RM for specific analytical procedures.

Calculation and Data Analysis

Summarize the results on a data sheet as shown in Figure 4B-1 (in section 18.0).

Calibration Error (CE) is the average the differences between the instrument response and the certified cylinder gas value for each gas. Calculate the CE results for the CO monitor according to:

Where:

d = mean difference between the CEMS response and the known reference concentration, and

FS = span value.

The CE for the O 2 monitor is the average percent O 2 difference between the O 2 monitor and the certified cylinder gas value for each gas.

Method Performance

Calibration Drift Performance Specification. For O 2, same as specified in PS 3. For CO, the same as specified in PS 4A except that the CEMS calibration must not drift from the reference value of the calibration standard by more than 3 percent of the span value on either the high or low range.

Calibration Error (CE) Performance Specification. The mean difference between the CEMS and reference values at all three test points (see Table 4B-1) must be no greater than 5 percent of span value for CO monitors and 0.5 percent for O 2 monitors.

Response Time Performance Specification. The response time for the CO or O 2 monitor must not exceed 240 seconds.

Relative Accuracy (RA) Performance Specification. For O 2, same as specified in PS 3. For CO, the same as specified in PS 4A.

Pollution Prevention [Reserved]

Waste Management [Reserved]

Alternative Procedure

Alternative RA Procedure. Under some operating conditions, it may not be possible to obtain meaningful results using the RA test procedure. This includes conditions where consistent, very low CO emission or low CO emissions interrupted periodically by short duration, high level spikes are observed. It may be appropriate in these circumstances to waive the RA test and substitute the following procedure.

Conduct a complete CEMS status check following the manufacturer's written instructions. The check should include operation of the light source, signal receiver, timing mechanism functions, data acquisition and data reduction functions, data recorders, mechanically operated functions, sample filters, sample line heaters, moisture traps, and other related functions of the CEMS, as applicable. All parts of the CEMS must be functioning properly before the RA requirement can be waived. The instrument must also successfully pass the CE and CD specifications. Substitution of the alternate procedure requires approval of the Regional Administrator.

Reference

40 CFR part 266, Appendix IX, section 2, “Performance Specifications for Continuous Emission Monitoring Systems.”

Tables, Diagrams, Flowcharts, and Validation Data

| Measurement point | CO Low range (ppm) | CO High range (ppm) | O 2 (%) |

|---|---|---|---|

| 1 | 0-40 | 0-600 | 0-2 |

| 2 | 60-80 | 900-1,200 | 8-10 |

| 3 | 140-160 | 2,100-2,400 | 14-16 |

| Run No. | Calibration value | Monitor response | Difference | ||

|---|---|---|---|---|---|

| Zero | Mid | High | |||

| 1-Zero 2-Mid 3-High 4-Mid 5-Zero 6-High 7-Zero 8-Mid 9-High | |||||

| Mean Difference = | |||||

| Calibration Error = | % | % | % | ||

* * * * *

Performance Specification 6—Specifications and Test Procedures for Continuous Emission Rate Monitoring Systems in Stationary Sources

* * * * *

13.2 CERMS Relative Accuracy. Calculate the CERMS Relative Accuracy (RA) expressed as a percentage using Eq. 2-6 of section 12 of Performance Specification 2. The RA of the CERMS shall be no greater than 20.0 percent in terms of the units of the emission standard. If the average emissions for the test are less than 50 percent of the applicable emission standard, substitute the applicable emission standard value in the denominator of Eq. 2-6 in place of the average RM value; in this case, the RA of the CERMS shall be no greater than 10.0 percent consistent with section 13.2 of Performance Specification 2.

* * * * *

Performance Specification 12A—Specifications and Test Procedures for Total Vapor Phase Mercury Continuous Emission Monitoring Systems in Stationary Sources

* * * * *

8.4.2 Reference Methods (RM). Unless otherwise specified in an applicable subpart of the regulations, use Method 29, Method 30A, or Method 30B in appendix A-8 to this part or ASTM D6784 (IBR, see §60.17) as the RM for Hg concentration. For Method 29 and ASTM D6784 only, the filterable portion of the sample need not be included when making comparisons to the CEMS results. When Method 29, Method 30B, or ASTM D6784-16 is used, conduct the RM test runs with paired or duplicate sampling systems and use the average of the vapor phase Hg concentrations measured by the two trains. When Method 30A is used, paired sampling systems are not required. If the RM and CEMS measure on a different moisture basis, data derived with Method 4 in appendix A-3 to this part must also be obtained during the RA test.

* * * * *

8.4.4 Number and Length of RM Test Runs. Conduct a minimum of nine RM test runs. When Method 29, Method 30B, or ASTM D6784 is used, only test runs for which the paired RM trains meet the relative deviation criteria (RD) of this PS must be used in the RA calculations. In addition, for Method 29 and ASTM D6784, use a minimum sample time of 2 hours and for Methods 30A and 30B use a minimum sample time of 30 minutes.

* * * * *