['Air Programs']

['Mobile Emission Sources']

07/23/2024

...

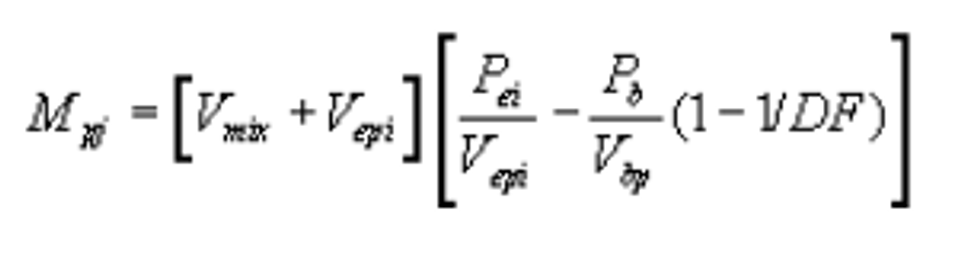

(a) The final reported test results for the mass particulate (Mp) in grams/mile shall be computed as follows.

Mp = 0.43(Mp1 + Mp2)/(Dct + Ds) + 0.57(Mp3 + Mp2)/(Dht = Ds)

where:

(1) Mp1 = Mass of particulate determined from the “transient” phase of the cold start test, in grams per test phase. (See §86.110-82(c)(1) for determination.)

(2) Mp2 = Mass of particulate determined from the “stabilized” phase of the cold start test, in grams per test phase. (See §86.110-82(c)(1) for determination.)

(3) Mp3 = Mass of particulate determined from the “transient” phase of the hot start test, in grams per test phase. (See §86.110-82(c)(1) for determination).

(4) Dct = The measured driving distance from the “transient” phase of the cold start test, in miles.

(5) Ds = The measured driving distance from the “stabilized” phase of the cold start test, in miles.

(6) Dht = The measured driving distance from the “transient” phase of the hot start test, in miles.

(b) The mass of particulate for each phase of testing is determined as follows:

where:

(1) j = 1, 2 or 3 depending on which phase the mass of particulate is being determined for (i.e., the “transient” phase of the cold start test, the “stabilized” phase of the cold start test, or the “transient” phase of the hot start test).

(2) Vmix = Total dilute exhaust volume in cubic meters per test, corrected to standard conditions 528°R (293K) and 29.92 in Hg (101.3 kPa). Vmix is further defined in §86.144.

(3) P e = mass of particulate per test on the exhaust filter(s), grams.

(4) Pb = mass of particulate on the “background” filter, grams.

(i) The background particulate level, Pb, inside the dilution air filter box at EPA is very low. Pb will be assumed = 0, and background particulate samples will not be taken with each exhaust sample. It is recommended that background particulate checks be made periodically to verify the low level.

(ii) Any manufacturer may make the same assumption without prior EPA approval.

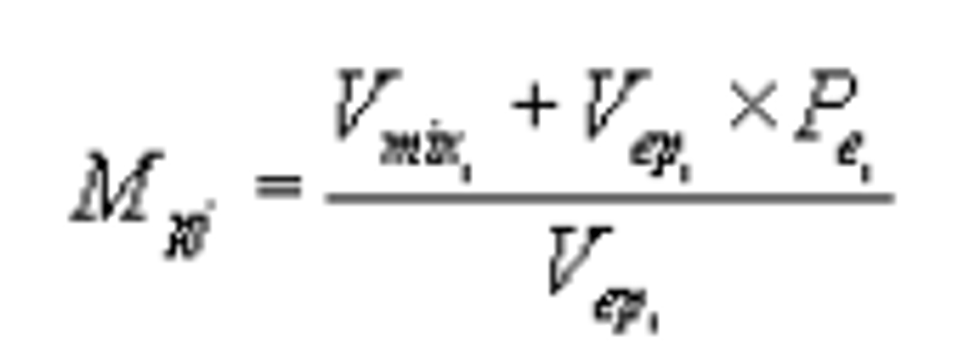

(iii) If Pb is assumed = 0, then no background correction is made. The equation for particulate mass emissions then reduces to:

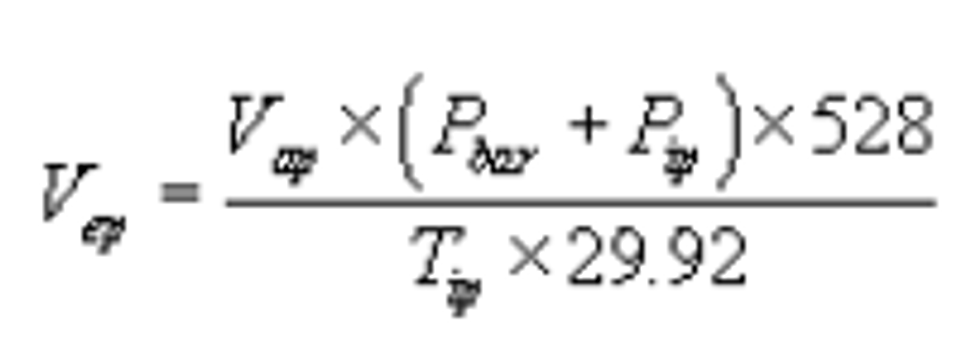

(6) Vep = total volume of sample pulled through the filter, cubic feet at standard conditions.

where:

(i) Vap = corrected (according to procedure specified in §85.120) dilute exhaust sample volume, cubic feet.

(ii) Pbar = barometric pressure, in Hg.

(iii) Pip = pressure elevation above ambient measured at the inlet to the dilute exhaust sample gas meter or flow instrument, in Hg. (For most gas meters with unrestricted discharge Pip is negligible and can be assumed = 0.)

(iv) Tip = average temperature of the dilute exhaust sample at the inlet to the gas meter or flow instrument,°R.

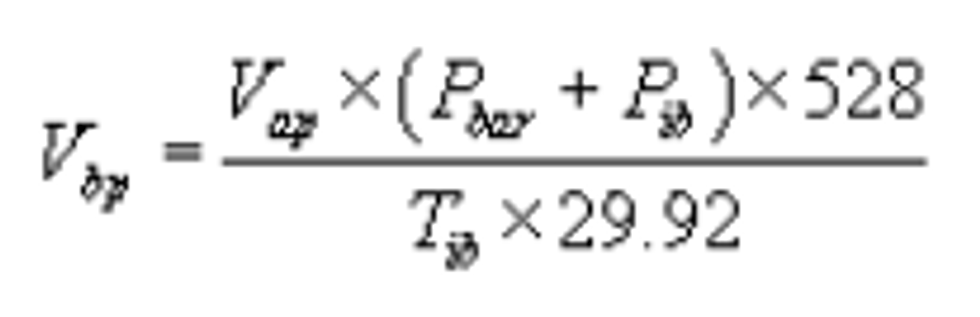

(7) Vbp = total volume of the background sample, cubic feet at standard conditions. (Vbp is not required if Pb is assumed = 0.) It is calculated using the following formula:

where:

(i) Vab = corrected (according to procedure specified in §85.120 background sample volume, cubic feet.

(ii) Pbar = barometric pressure, in. Hg.

(iii) Pib = pressure elevation above ambient measured at the inlet to the background gas meter or flow instrument, in Hg. (For most gas meters with unrestricted discharge Pib is negligible and can be assumed = 0.)

(iv) Tib = average temperature of the background sample at the inlet to the gas meter or flow instrument,°R.

(8) DF = dilution factor. (DF is not required if Pb is assumed = 0.)

[45 FR 14523, Mar. 5, 1980, as amended at 46 FR 50494, Oct. 13, 1981, and 47 FR 49807, Nov. 2, 1982]

['Air Programs']

['Mobile Emission Sources']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.