['Hazmat']

['Hazmat Special Requirements']

10/10/2024

...

DEPARTMENT OF TRANSPORTATION

Pipeline and Hazardous Materials Safety Administration

49 CFR Parts 171, 172, 173, 174, 175, 176, 178 and 180

[Docket No. PHMSA-2017-0108 (HM-215O)]

RIN 2137-AF32

Hazardous Materials: Harmonization With International Standards

AGENCY: Pipeline and Hazardous Materials Safety Administration (PHMSA), Department of Transportation (DOT).

ACTION: Final rule.

SUMMARY: PHMSA is issuing this final rule to amend the Hazardous Materials Regulations (HMR) to maintain alignment with international regulations and standards by incorporating various amendments, including changes to proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements. These revisions are necessary to harmonize the HMR with recent changes made to the International Maritime Dangerous Goods Code, the International Civil Aviation Organization's Technical Instructions for the Safe Transport of Dangerous Goods by Air, and the United Nations Recommendations on the Transport of Dangerous Goods—Model Regulations. Additionally, PHMSA is adopting several amendments to the HMR that would allow for increased alignment with the Transport Canada, Transportation of Dangerous Goods Regulations.

DATES:

Effective date: This rule is effective May 11, 2020, except for instruction 17, which is effective January 2, 2023.

Voluntary compliance date: January 1, 2019.

Delayed compliance date: May 10, 2021.

Incorporation by reference date: The incorporation by reference of certain publications listed in this rule is approved by the Director of the Federal Register as of May 11, 2020.

FOR FURTHER INFORMATION CONTACT:

Steven Webb, International Program or Aaron Wiener, International Program, telephone (202) 366-8553, Pipeline and Hazardous Materials Safety Administration, U.S. Department of Transportation, 1200 New Jersey Avenue SE, East Building, 2nd Floor, Washington, DC 20590-0001.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Executive Summary

II. Background

III. Incorporation by Reference Discussion Under 1 CFR part 51

IV. NPRM Comment Discussion

V. Section-by-Section Review

VI. Regulatory Analyses and Notices

A. Statutory/Legal Authority for This Final Rule

B. Executive Order 12866 and DOT Regulatory Policies and Procedures

C. Executive Order 13771

D. Executive Order 13132

E. Executive Order 13175

F. Regulatory Flexibility Act, Executive Order 13272, and DOT Policies and Procedures

G. Paperwork Reduction Act

H. Regulation Identifier Number (RIN)

I. Unfunded Mandates Reform Act of 1995

J. Environment Assessment

K. Privacy Act

L. International Trade Analysis and Executive Order 13609

M. National Technology Transfer and Advancement Act

List of Subjects

I. Executive Summary

The Pipeline and Hazardous Materials Safety Administration (PHMSA) is amending the Hazardous Materials Regulations (HMR; 49 CFR parts 171 to 180) to maintain alignment with international regulations and standards by incorporating various amendments, including changes to proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements. This rulemaking project is part of PHMSA's ongoing biennial process to harmonize the HMR with international regulations and standards.

As part of this biennial process, PHMSA is amending the HMR to incorporate changes from the 20th Revised Edition of the UN Model Regulations, Amendment 39-18 of the International Maritime Dangerous Goods (IMDG) Code, and the 2019-2020 International Civil Aviation Organization (ICAO) Technical Instructions, which became effective January 1, 2019.1 Notable amendments to the HMR in this final rule include the following:

1 Amendment 39-18 to the IMDG Code may be voluntarily applied on January 1, 2019; however, the previous amendment remained effective through December 31, 2019.

- Incorporation by Reference: PHMSA incorporates by reference the newest versions of various international hazardous materials (hazmat) standards, including: The 2019-2020 Edition of the International Civil Aviation Organization Technical Instructions for the Safe Transport of Dangerous Goods by Air (ICAO Technical Instructions); Amendment 39-18 to the International Maritime Dangerous Goods Code (IMDG Code); the 20th Revised Edition of the United Nations Recommendations on the Transport of Dangerous Goods (UN Model Regulations); Amendment 1 to the 6th Revised Edition of the UN Manual of Tests and Criteria; and the 7th Revised Edition of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). Additionally, we are updating our incorporation by reference of the Transport Canada, Transportation of Dangerous Goods (TDG) Regulations to include: SOR/2016-95, published June 1, 2016; SOR/2017-137, published July 12, 2017; and SOR/2017-253, published December 13, 2017. Finally, PHMSA is adopting various updated International Organization for Standardization (ISO) standards.

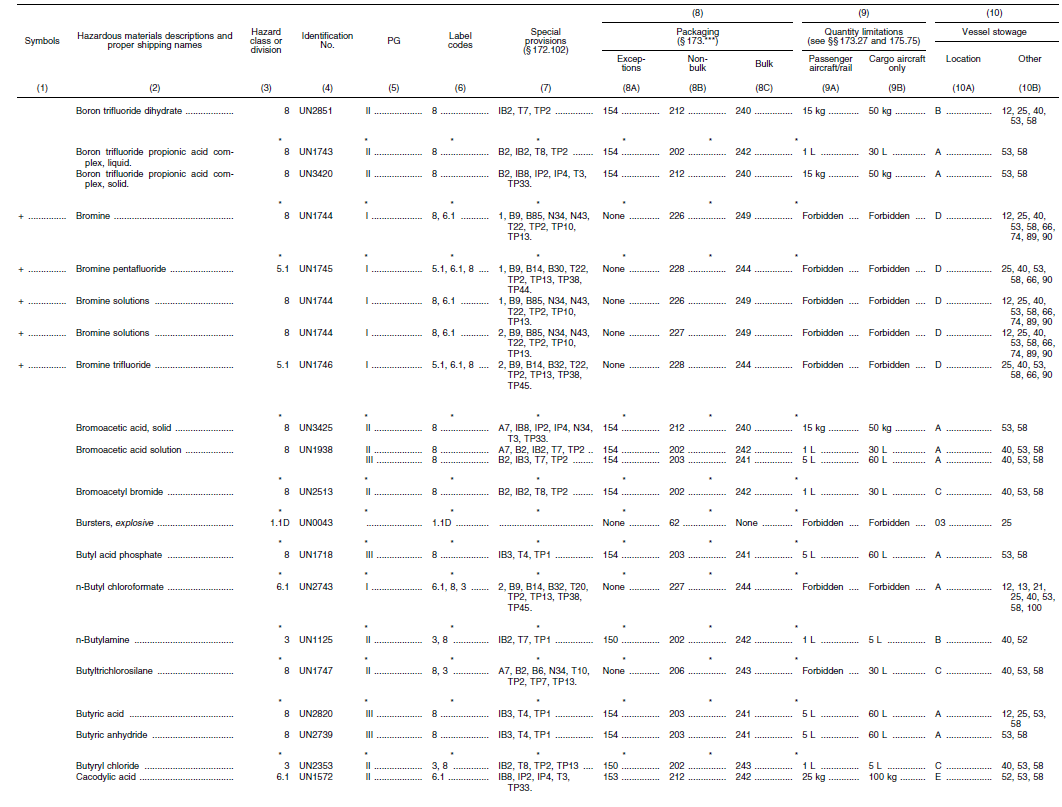

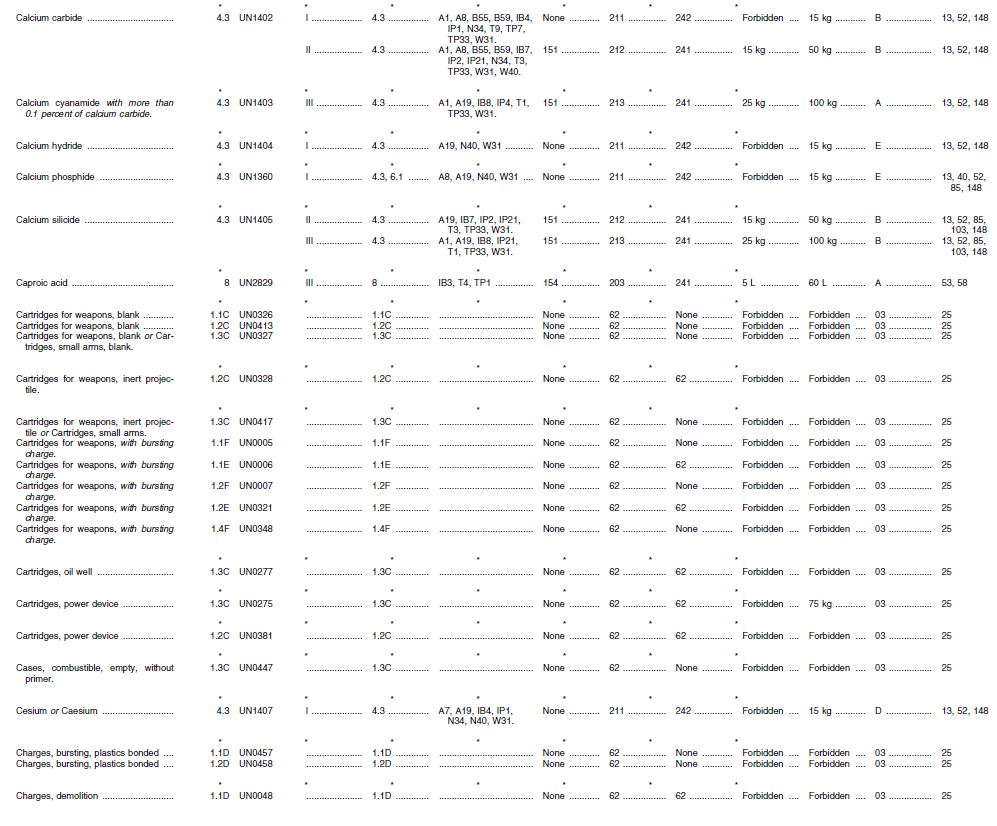

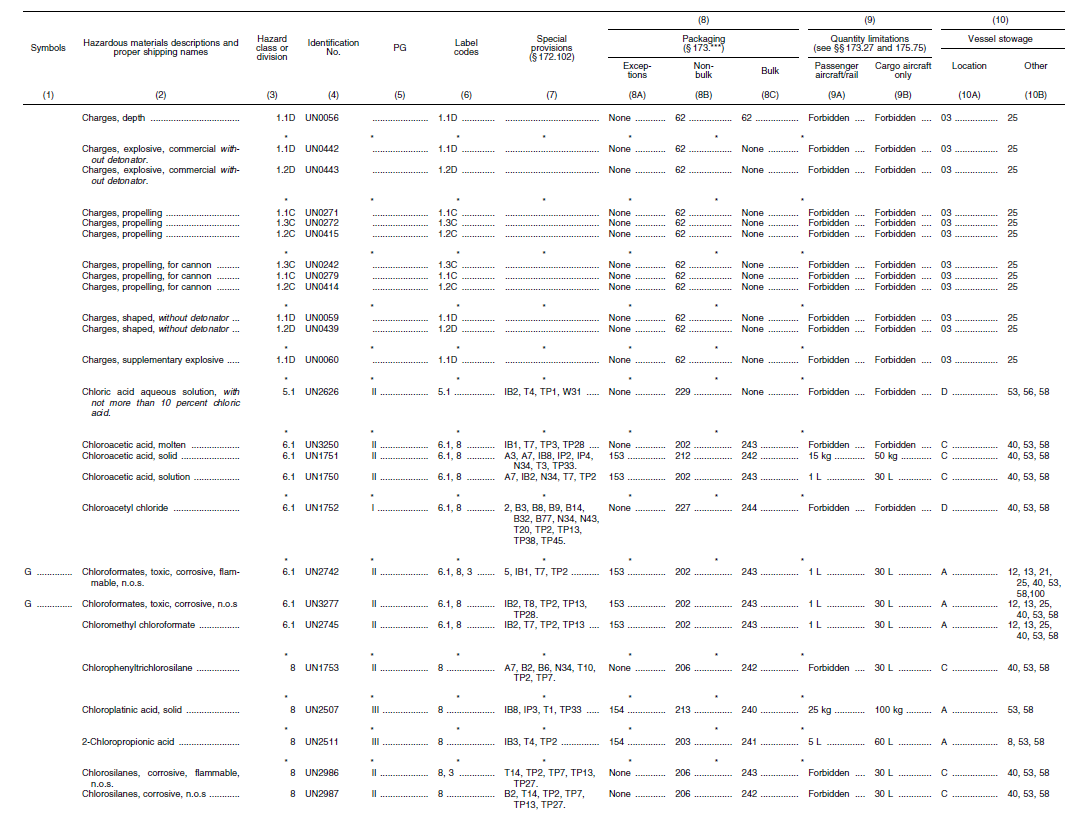

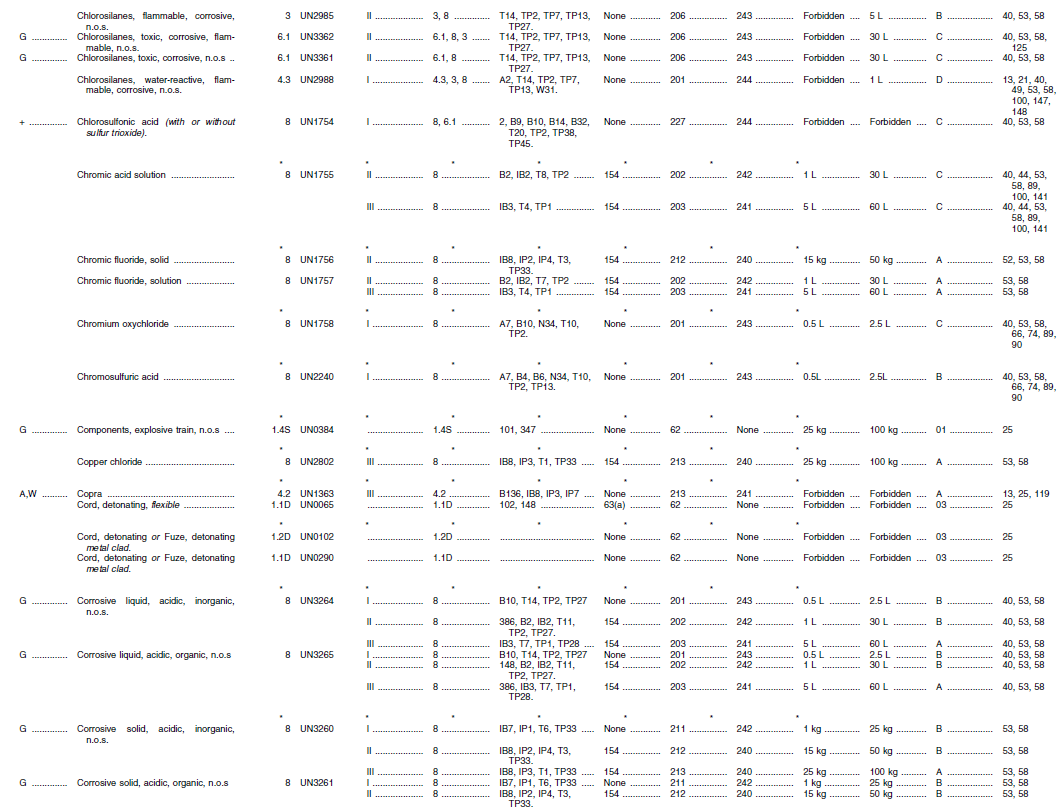

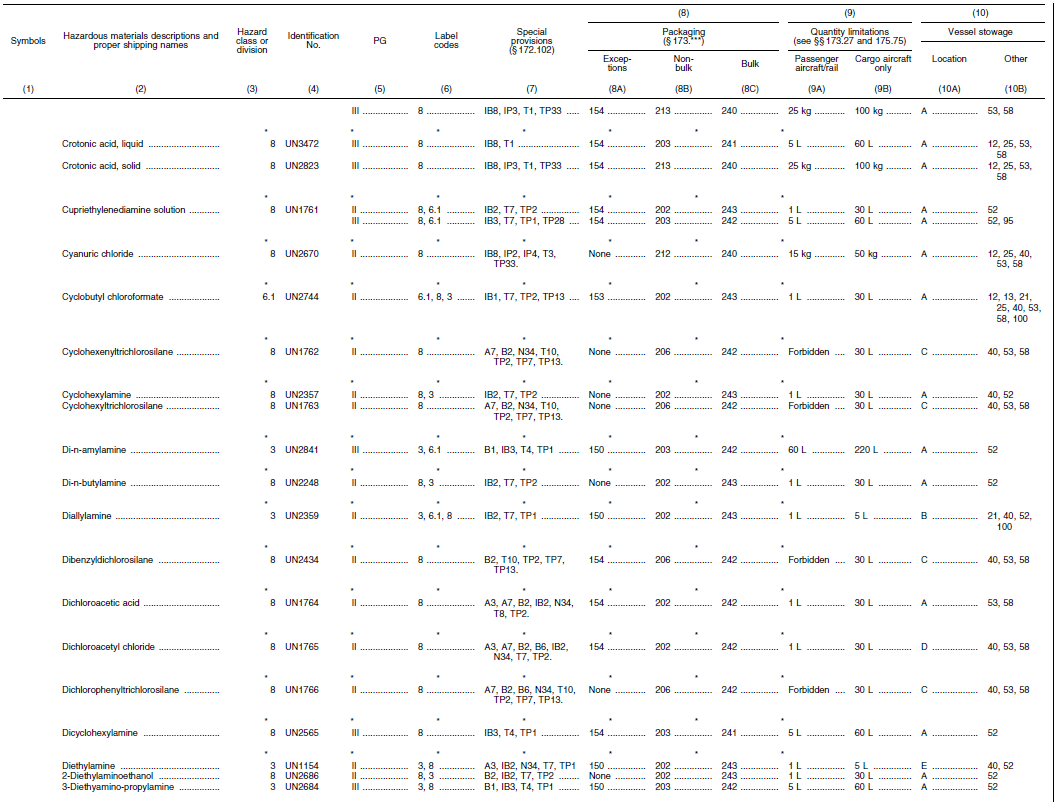

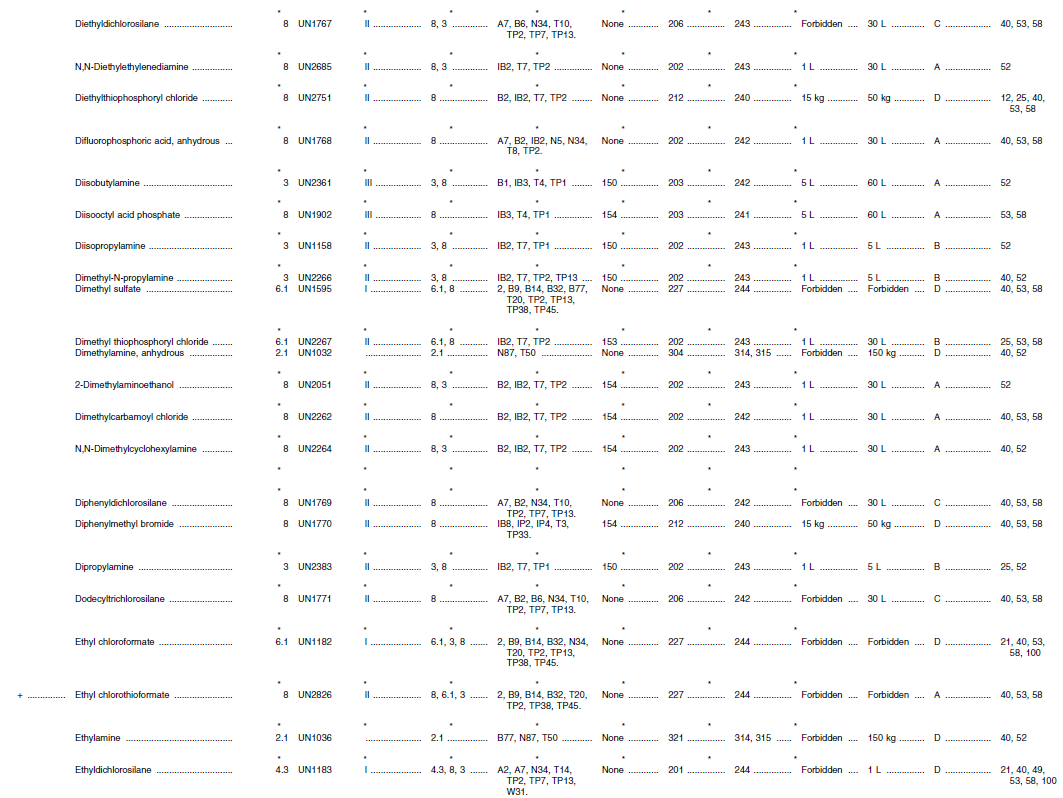

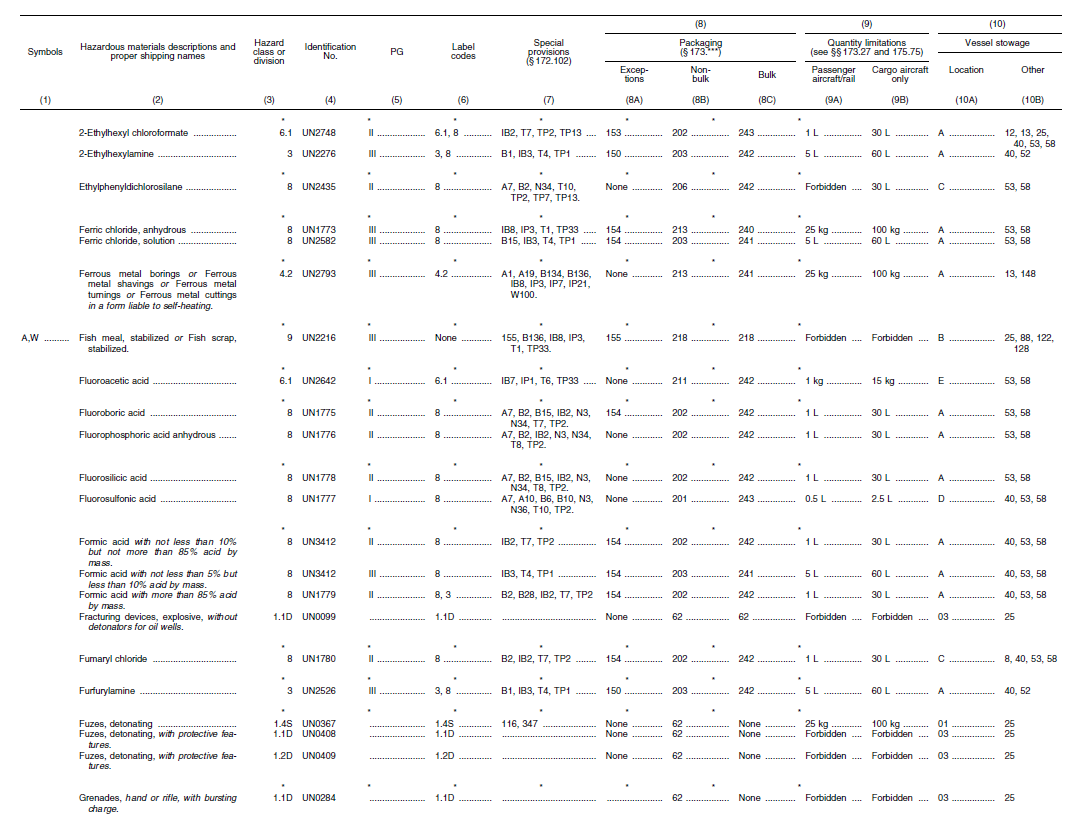

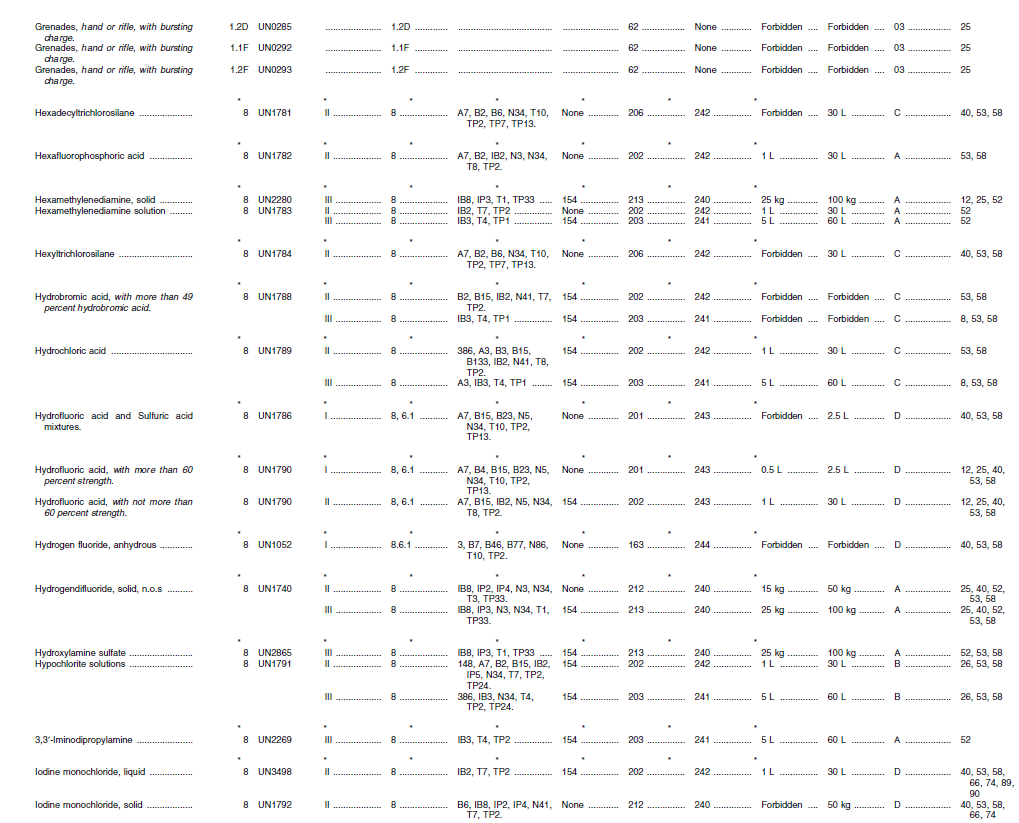

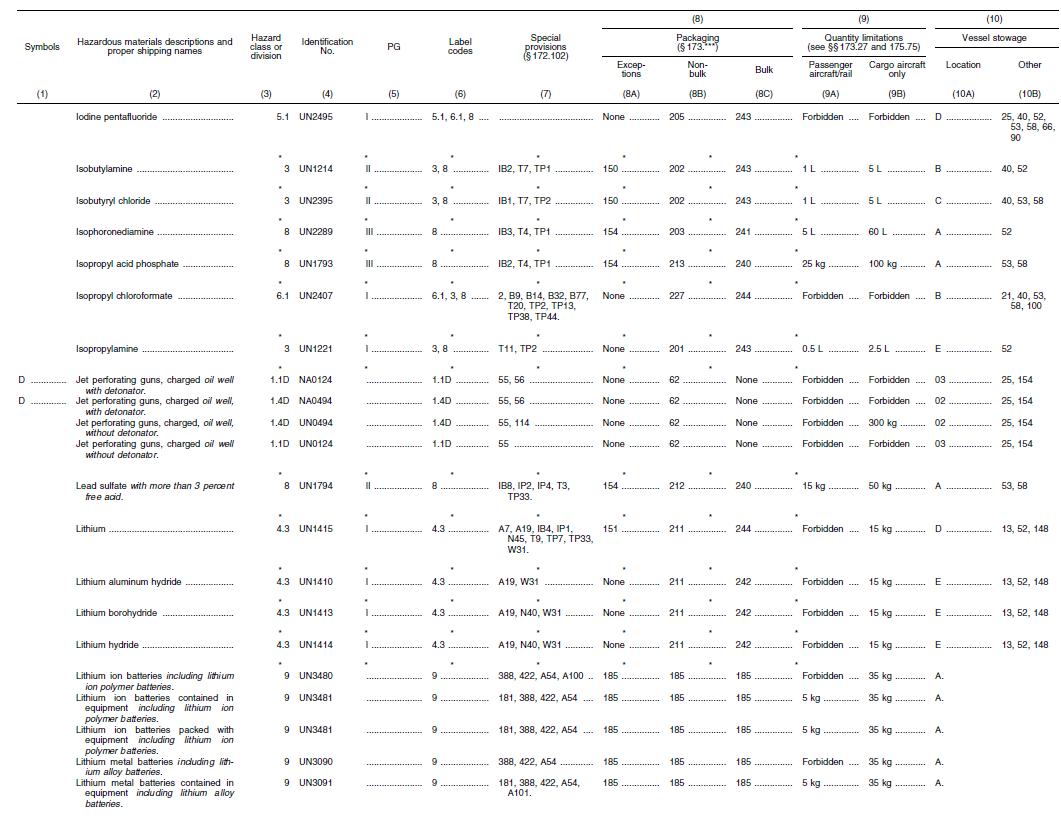

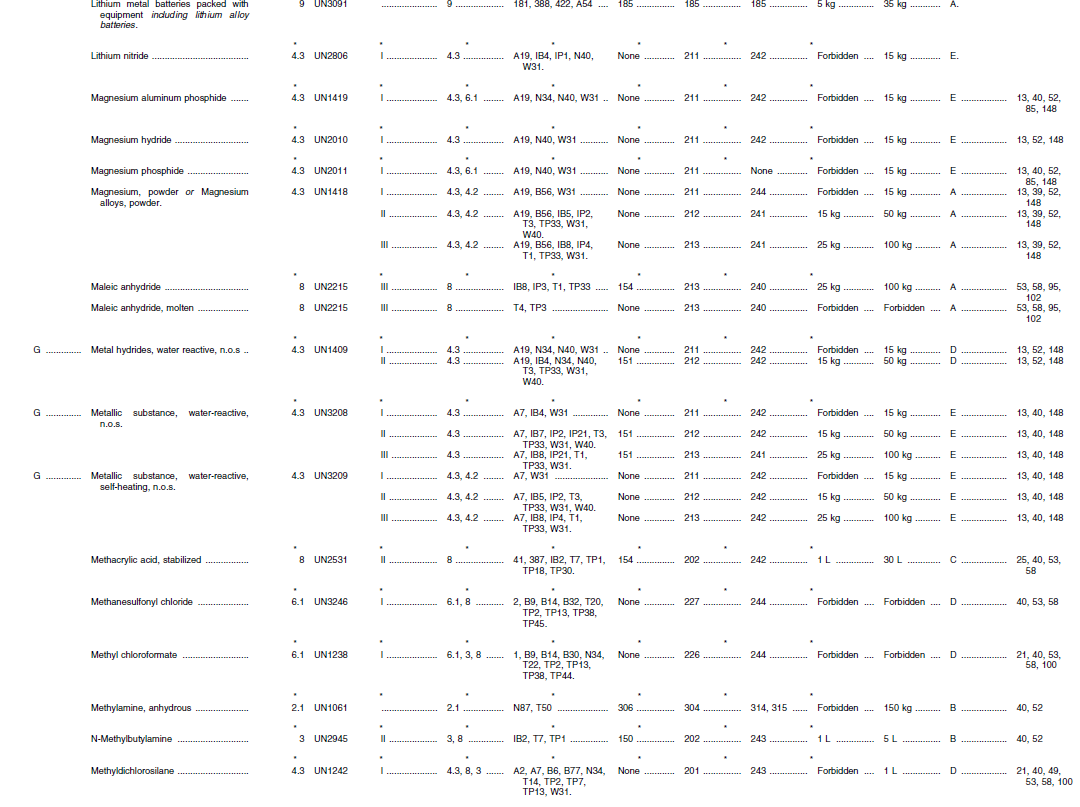

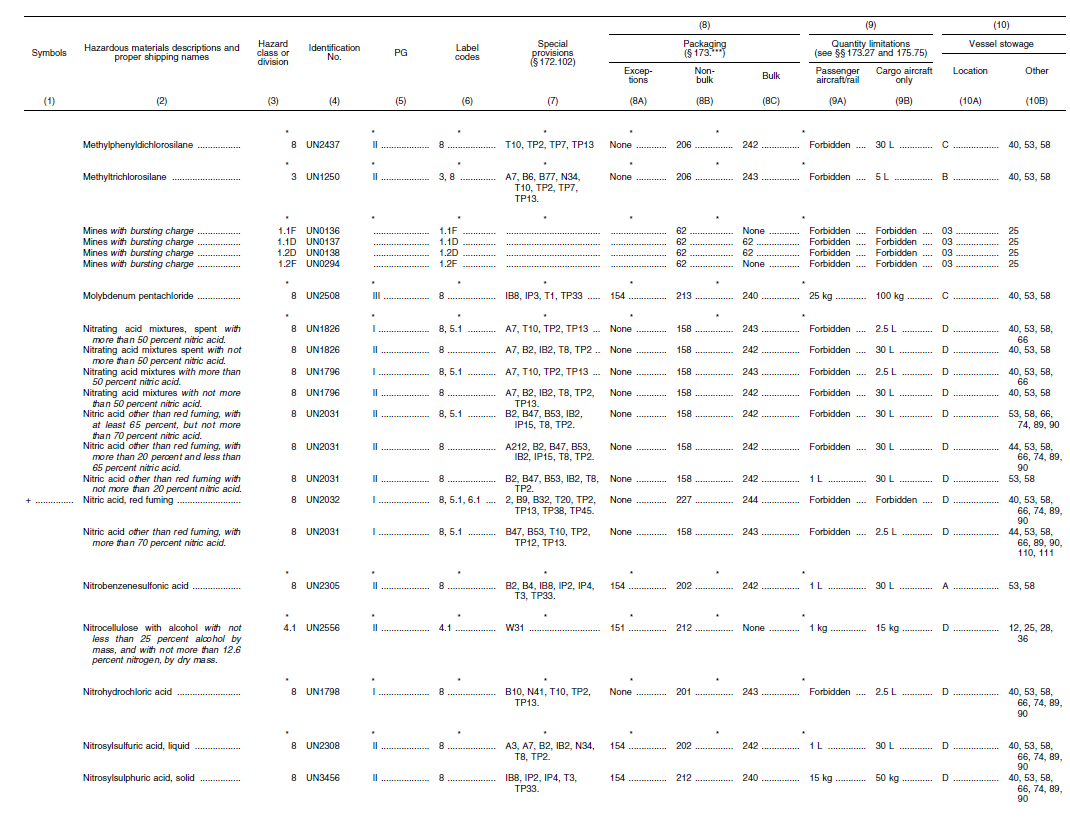

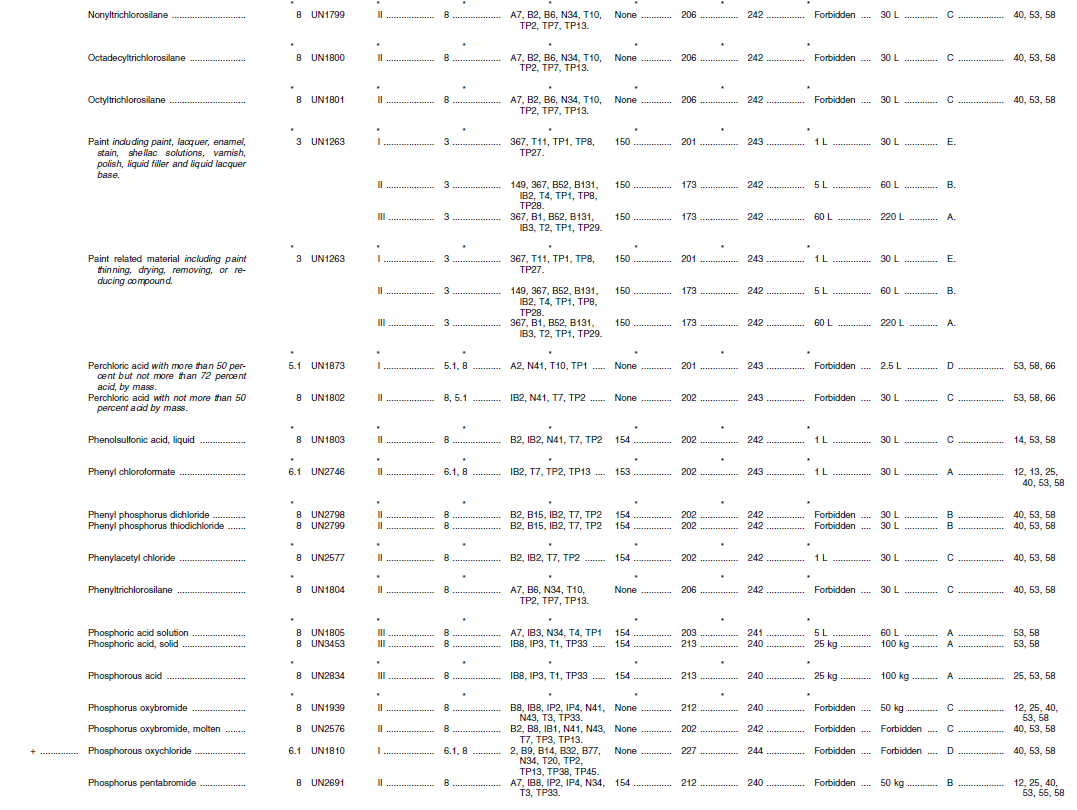

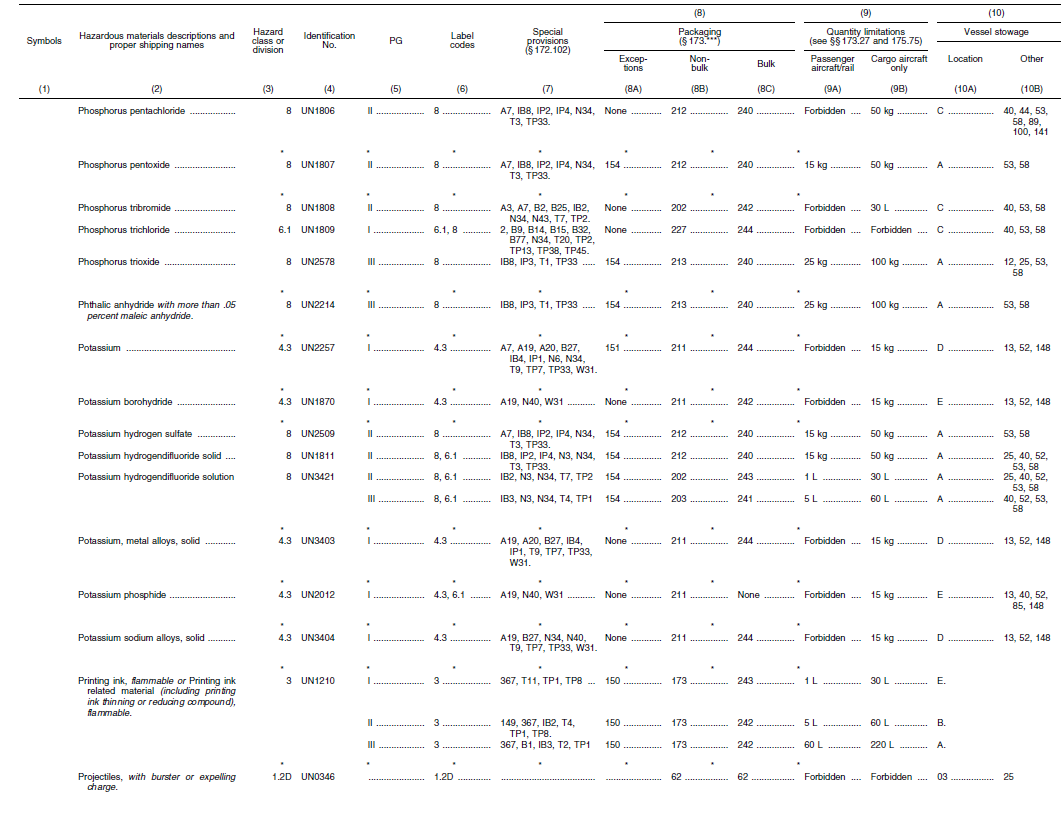

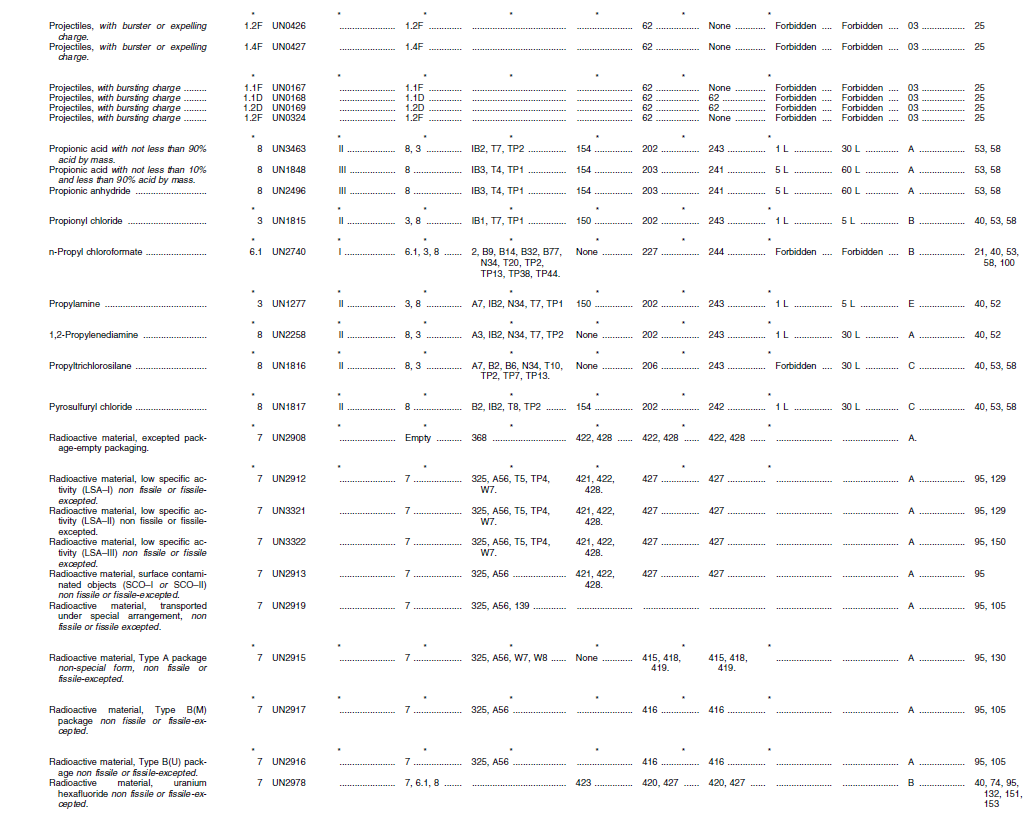

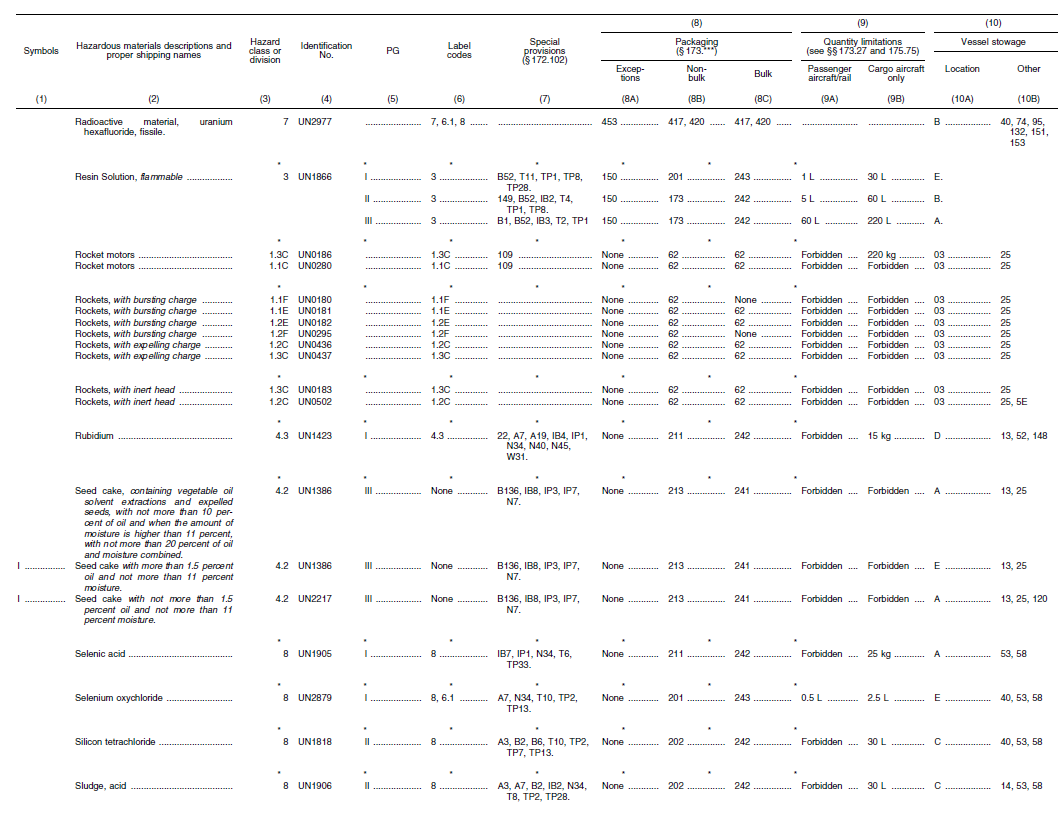

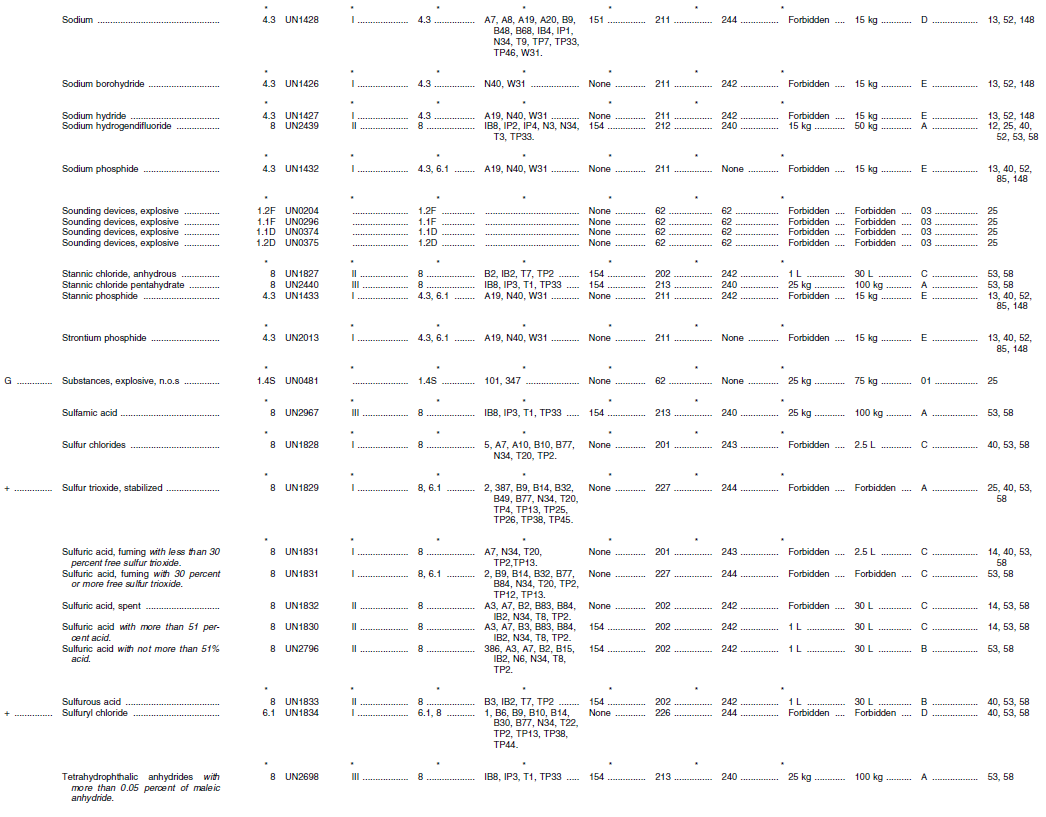

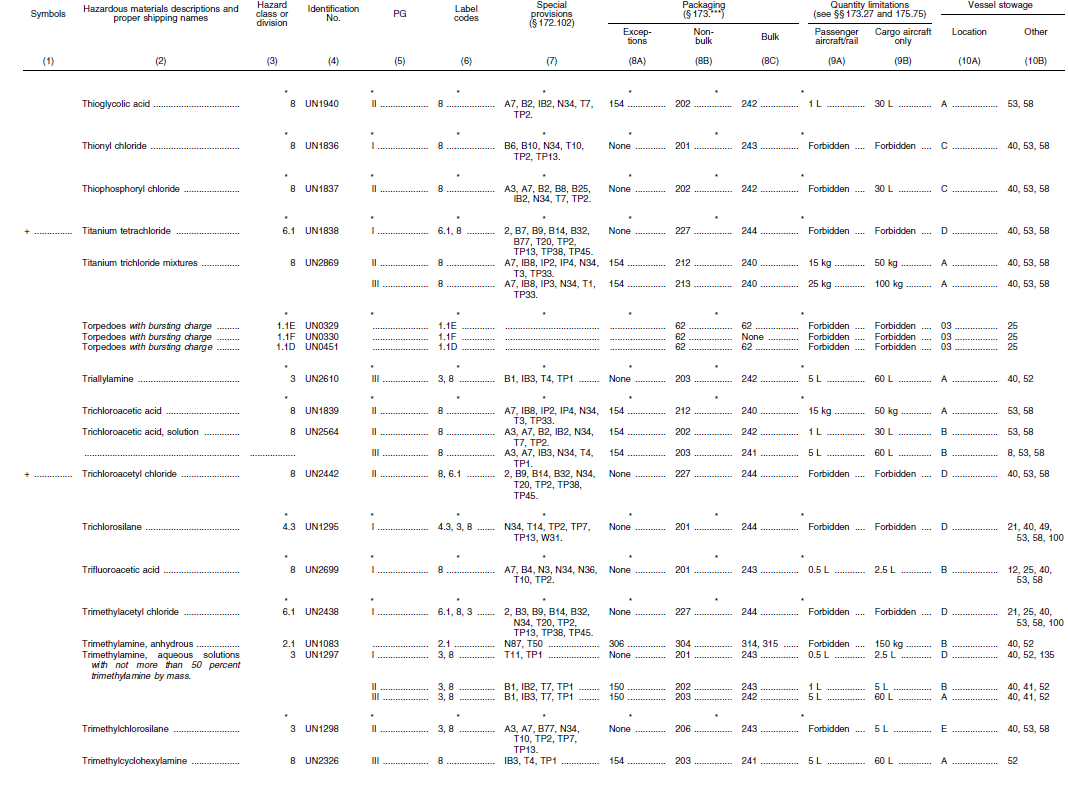

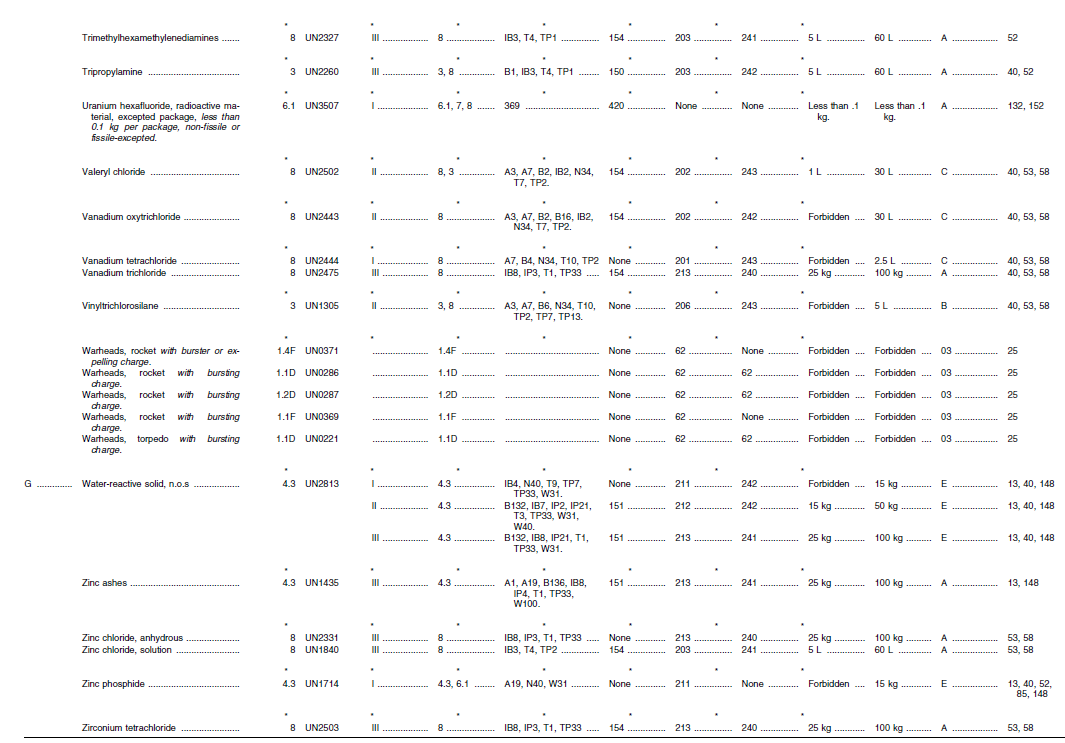

- Hazardous Materials Table: PHMSA amends the Hazardous Materials Table (HMT; §172.101) consistent with recent changes in the Dangerous Goods List of the UN Model Regulations, the IMDG Code, and the ICAO Technical Instructions. Specifically, PHMSA is making amendments to the HMT to add, revise, or remove certain proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, bulk packaging requirements, and passenger and cargo aircraft maximum quantity limits.

- Articles Containing Dangerous Goods: PHMSA adds a classification system for articles containing hazardous materials that do not already have a proper shipping name. This addresses situations in which hazardous materials or hazardous materials residues are present in articles, and authorizes a safe method to transport articles that may be too large to fit into typical packages.

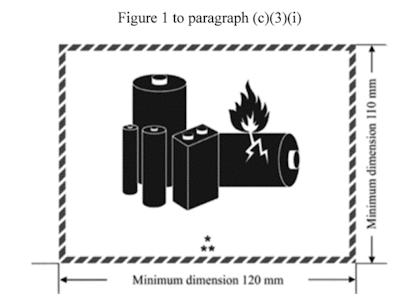

- Lithium Battery Test Summary: PHMSA adds requirements regarding lithium battery test summaries. The HMR requires lithium battery manufacturers to subject lithium batteries and cells to appropriate UN design tests to ensure they are classified correctly for transport, and to develop records of successful test completion, called a test report. The test summary includes a standardized set of elements that provide traceability and accountability, thereby ensuring that lithium cell and battery designs offered for transport contain specific information on the required UN tests. The test summary must be made available to subsequent distributors.

- Baggage Equipped with Lithium Batteries: PHMSA is amending the aircraft passenger provisions for carriage of baggage equipped with lithium batteries intended to power features such as location tracking, battery charging, digital weighing, or motors (sometimes referred to as “smart luggage”). Specifically, baggage equipped with a lithium battery or batteries will be required to be carried in the cabin of the aircraft unless the battery or batteries are removed. This restriction in checked baggage does not apply to baggage containing lithium metal batteries with a lithium content not exceeding 0.3 grams, or lithium ion batteries with a Watt-hour (Wh) rating not exceeding 2.7 Wh.

- Segregation of Lithium Batteries from Specific Hazardous Materials: PHMSA is adding requirements to segregate lithium cells and batteries from certain other hazardous materials, notably flammable liquids, when offered for transport or transported on aircraft. PHMSA is taking this action to promote consistency with the ICAO Technical Instructions and to implement a National Transportation Safety Board (NTSB) Safety Recommendation (A-16-001) stemming from the investigation of the July 28, 2011, in-flight fire and crash of Asiana Airlines Flight 991 that resulted in the loss of the aircraft and crew. The investigation report cited the flammable materials and lithium ion batteries that were loaded together in either the same or adjacent pallets as a contributing factor to the accident.

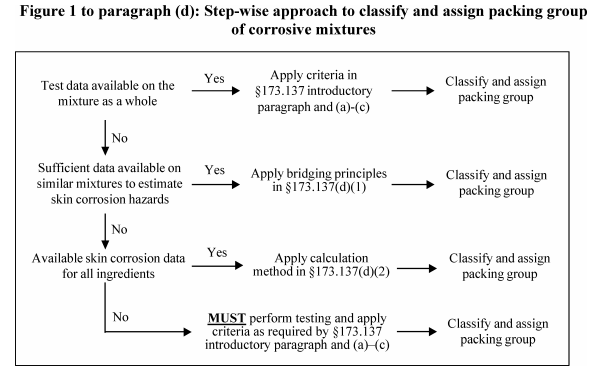

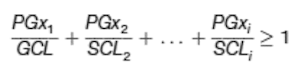

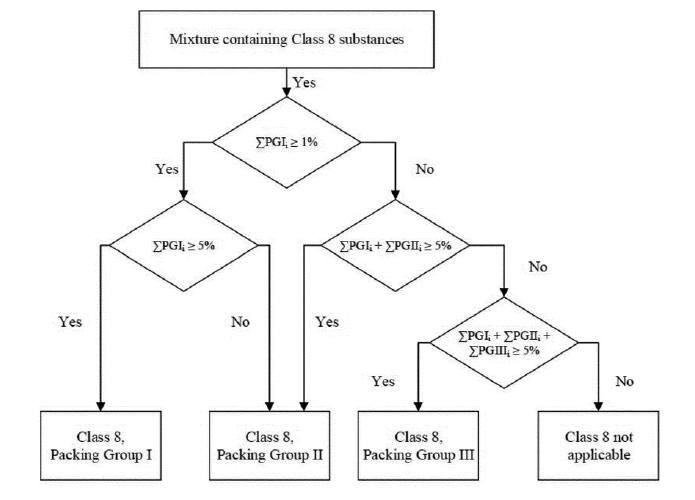

- Alternative Criteria for Classification of Corrosive Materials: PHMSA is including non-testing alternatives for classifying corrosive mixtures using existing data on its chemical properties. Currently, the HMR require offerors to classify Class 8 corrosive material and assign a packing group based on test data. The HMR authorizes a skin corrosion test and various in vitro test methods that do not involve animal testing. However, data obtained from testing is currently the only data acceptable for classification and assigning a packing group. The alternatives added in this final rule afford offerors the ability to make a classification and packing group assignment without the need to conduct physical tests.

- Provisions for Polymerizing Substances: PHMSA is extending the sunset dates for provisions concerning the transportation of polymerizing substances from January 2, 2019 to January 2, 2023. This additional time will allow PHMSA to conduct research and analyze comments and data concerning the issue submitted to the docket for this rulemaking, to have a more comprehensive understanding of polymerizing substances and further consider the most appropriate transport provisions for these materials.

II. Background

Federal hazardous materials transportation law (Federal hazmat law; 49 U.S.C. 5101 et seq.) directs PHMSA to participate in relevant international standard-setting bodies and promotes consistency of the HMR with international transport standards to the extent practicable. Federal hazmat law permits PHMSA to depart from international standards where a more stringent standard or requirement is necessary in the public interest or if a different standard or requirement is unnecessary or unsafe. However, Federal hazmat law otherwise encourages domestic and international harmonization (see 49 U.S.C. 5120).

Harmonization facilitates international trade by minimizing the costs and other burdens of complying with multiple or inconsistent safety requirements for transportation of hazardous materials. Safety is enhanced by creating a uniform framework for compliance. As the volume of hazardous materials transported in international commerce continues to grow, harmonization is increasingly important.

PHMSA published a notice of proposed rulemaking (NPRM) under Docket HM-215O [83 FR 60970 (November 27, 2018)] to incorporate various amendments to harmonize the HMR with recent changes to the IMDG Code, ICAO Technical Instructions, and the United Nations Recommendations on the Transport of Dangerous Goods—Model Regulations (UN Model Regulations). When considering alignment of the HMR with international standards, PHMSA reviews and evaluates each amendment on its own merit, on the basis of its overall impact on transportation safety, and on the basis of the economic implications associated with its adoption into the HMR. PHMSA's goal is to harmonize without diminishing the level of safety currently provided by the HMR or imposing undue burdens on the regulated community.

III. Incorporation by Reference Discussion Under 1 CFR Part 51

The UN Model Regulations, Manual of Tests and Criteria, and GHS, as well as all of the Transport Canada Clear Language Amendments, are free and easily accessible to the public on the internet, with access provided through the parent organization websites. The ICAO Technical Instructions, IMDG Code, and all ISO references are available for interested parties to purchase either print or electronic versions through the parent organization websites. The specific standards are discussed in greater detail in the section-by-section review (see §171.7).

IV. NPRM Comment Discussion

In response to the November 27, 2018 NPRM [83 FR 60970], PHMSA received comments from the following organizations and individuals:

- Air Line Pilots Association, International (ALPA)

- Alaska Airlines

- Amazon

- American Coatings Association (ACA)

- Anonymous

- Anonymous 2

- Association of American Railroads and the American Short Line and Regional Railroad Association (AAR and ASLRRA)

- Association of Hazmat Shippers (AHS)

- The Basic Acrylic Monomer Manufacturers, Inc. (BAMM)

- Compressed Gas Association (CGA)

- Council on Safe Transportation of Hazardous Articles (COSTHA)

- Dangerous Goods Advisory Council (DGAC)

- The Dow Chemical Company (Dow)

- Frits Wybenga

- Gases and Welding Distributors Association

- Institute of Makers of Explosives (IME)

- Interested Parties for Hazardous Materials Transportation (Interested Parties)

- International Air Transport Association (IATA)

- International Vessel Operators Dangerous Goods Association (IVODGA)

- Yvonne Keller

- Medical Device Battery Transport Council (MDBTC)

- National Retail Federation (NRF)

- The Rechargeable Battery Association (PRBA)

- Reusable Industrial Packaging Association (RIPA)

- Transport Canada (TC)

- U.S. Chamber of Commerce (Chamber)

- Utility Solid Waste Activities Group (USWAG)

PHMSA received comments from the ACA, CGA, ALPA, IATA, DGAC, and the Chamber all providing general support for harmonization with international standards and additional support from CGA for the incorporation by reference of the proposed ISO standards. In addition, PHSMA received a comment from IME in support of updating the edition of the GHS that is incorporated by reference.

Comments concerning the issuance of a direct final rule, the sunset provisions for polymerizing substances, compliance and applicability dates for the test summary, fuel gas containment systems, damaged and defective lithium batteries, competency based training, and safety devices in dedicated handling devices are discussed below. PHMSA concluded that comments made by Anonymous 2, portions of comments made by MDBTC concerning “receipted for in one lot,” in §173.185,2 portions of comments made by Alaska Airlines concerning air transport provisions for fish meal, and portions of comments made by IME concerning amendments to packaging instruction US 1 in §173.62,3 are outside the scope of this rulemaking. Therefore, PHMSA did not address these comments in this rulemaking. All other comments specific to the respective HMR sections are addressed in the “Section-by-Section Review” of this document.4

2 Section 173.185 defines consignment to mean “one or more packages of hazardous materials accepted by an operator from one shipper at one time and at one address, receipted for in one lot and moving to one consignee at one destination address.”

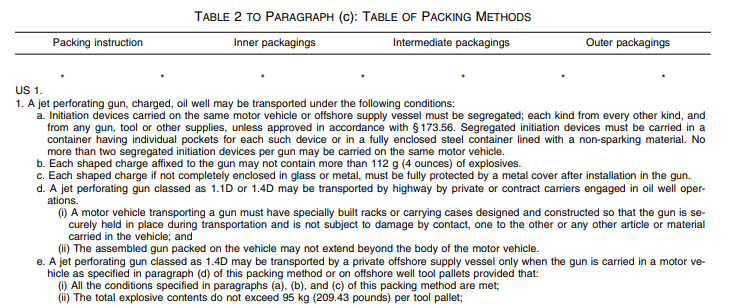

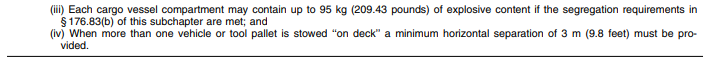

3 Section 173.62 establishes specific packing requirements for explosives. US 1 is a packing instruction that is “particular to the United States and not found in applicable international regulations.”

4 Comments which were outside the scope of this rulemaking are not addressed in this final rule.

Delays in Issuing the Final Rule

PHMSA received a comment from AAR and ASLRRA that indicated the delay associated with publication of a final rule “presents immediate challenges for shippers and carriers involved in the transportation of hazardous materials across U.S. borders” and suggested alternative ways for proceeding with the rulemaking. PHMSA recognizes that a delay in publication of this final rule may have presented challenges for shippers and carriers. To mitigate these challenges, on December 18, 2018, PHMSA issued a Notice of Enforcement Policy Regarding International Standards authorizing the use of the applicable international standards.5 The notice explained that PHMSA would not take enforcement action against any offeror or carrier using the updated standards when all or part of the transportation is by air with respect to the ICAO TI, or all or part of the transportation is by vessel with respect to the IMDG code.

5https://www.phmsa.dot.gov/sites/phmsa.dot.gov/files/docs/international-program/70251/notice-enforcement-policy-international-standards.pdf.

Sunset Provisions for Polymerizing Substances

In the March 30, 2017, final rule [HM-215N; 82 FR 15796], PHMSA added four new Division 4.1 entries for polymerizing substances to the HMT, and added defining criteria, authorized packagings, and safety requirements including, but not limited to, stabilization methods and operational controls into the HMR. In this prior rulemaking, PHMSA indicated that these changes would be in effect until January 2, 2019. During the interim time period between publication of that final rule and January 2, 2019, PHMSA indicated it would review and research the implications of the polymerizing substance amendments, and readdress the issue in the next international harmonization rulemaking. In the HM-215O NPRM, PHMSA proposed to extend the sunset dates for provisions concerning the transportation of polymerizing substances from January 2, 2019 to January 2, 2021 as the research is still in progress. PHMSA received comments from BAMM, DGAC, and Dow expressing support for the extension of the sunset provisions proposed in the HM-215O NPRM. These commenters also requested that PHMSA harmonize the requirements for temperature control of polymerizing substances in portable tanks and testing requirements for these substances intended to be carried in portable tanks or intermediate bulk containers (IBCs) with those found in the transport international standards while awaiting the results of a currently underway research project.

DGAC and Dow requested that the previously adopted changes to §173.21 in the March 30, 2017, final rule [HM-215N; 82 FR 15796], requiring temperature control at 50 °C for portable tanks carrying polymerizing substances be harmonized with the internationally adopted 45 °C, while PHMSA awaits the outcome of ongoing research into polymerizing substances. BAMM, DGAC, and Dow requested that PHMSA not require polymerizing substances intended to be transported in portable tanks or IBCs to undergo the Test Series E heating under confinement testing. The commenters requested that the provisions for polymerizing substances be harmonized with those found in the applicable international standards while PHMSA awaits the outcome of ongoing research into polymerizing substances. DGAC and Dow commented that differing domestic and international temperature control thresholds before temperature control is required would result in materials with a self-accelerating polymerization temperature (SAPT) greater than 45 °C and less than or equal to 50 °C being subject to temperature control when transported in portable tanks in the United States, but not elsewhere in the world. BAMM, DGAC, and Dow expressed their view that because the recommended test methods for Test Series E were not specifically designed for polymerizing substances that the test results would be meaningless. The commenters did not raise any new reasons for not adopting the provisions beyond those previously addressed in the March 30, 2017 final rule [HM-215N; 82 FR 15796]. PHMSA understands the concerns raised by the commenters, but to ensure the safe and efficient transportation of these commodities, PHMSA is adopting the provisions as proposed in the NPRM and codified in the March 30, 2017, final rule for the reasons that were previously outlined [HM-215N; 82 FR 15796, 15798-99]. In brief, the rationale for adopting the 50 °C SAPT threshold before temperature control is required for transport in portable tanks is primarily that 50 °C is the maximum temperature reasonable expected to be experienced by any selfreactive, organic peroxide, and/or polymerizing substance. The rationale for requiring Test Series E testing for polymerizing substances intended to be transported in portable tanks or IBC is that Test Series E (or an equivalent performance measure) provides information on how the material behaves when heated under confinement. For additional discussion of these issues refer to the March 30, 2017 final rule [HM-215N; 82 FR 15796, 15798-99].

To accommodate additional potential delays in completion and reviewing the results of the research project on polymerizing substances, PHMSA is extending the date for the sunset provisions for an additional two years beyond the date proposed in the NPRM. The new sunset date for transport provisions concerning polymerizing substances is January 2, 2023.

Lithium Battery Test Summary

In the NPRM, PHMSA proposed the inclusion of lithium battery test summary requirements. The test summary includes a standardized set of elements that provide traceability and accountability to ensure that lithium cell and battery designs offered for transport contain specific information on the required UN tests. PHMSA proposed that manufacturers and subsequent distributers of lithium cells and batteries manufactured after June 30, 2003 must make test summaries available to others in the supply chain. In the international standards, and as proposed in the NPRM, the lithium battery test summary requirements would have an effective date of January 1, 2020.

In response to the comments received, in this final rule, PHMSA is providing additonal background on the test summary. The development of the test summary by the United Nations Sub-Committee of Experts on the Transport of Dangerous Goods spanned several years. The work was the outgrowth of an industry-identified problem concerning lack of availability of information needed to verify compliance and facilitate transportation. Specifically, the inability of shippers to access documentation verifying that lithium cells and batteries have successfully passed the tests prescribed in part III, sub-section 38.3 of the UN Manual of Tests and Criteria. In 2014, a trade association representing major rechargeable battery manufacturers relayed to the UN Sub-Committee that shippers were experiencing difficulties in verifying compliance with the UN 38.3 tests (See UN/SCETDG/46/INF.11, paragraph 15).6 It was the industry group's suggestion to work within the UN Sub-Committee towards a summary format that would facilitate making available essential compliance information to all concerned. This suggestion led the UN Sub-Committee over the next two years in cooperation with government and industry stakeholders to develop a standardized list of information to be included in a test summary (see ST/SG/AC.10/C.3/100, paragraph 56).7 PHMSA received several comments, which are discussed throughout this rulemaking and the associated RIA, concerning the potential costs of the test summary provisions. While providing no specific cost estimates, these commenters indicated that they believed implementing the test summary provisions as proposed would be more burdensome than PHMSA estimated. In this final rule, PHMSA is adopting changes to the compliance date, the implementation date, and several other variatons from the NPRM proposals that will reduce the burden on lithium cell and battery manufacturers and distributors.

6https://www.unece.org/fileadmin/DAM/trans/doc/2014/dgac10c3/UN-SCETDG-46-INF11e.pdf.

7https://www.unece.org/fileadmin/DAM/trans/doc/2016/dgac10c3/ST-SG-AC10-C3-100e.pdf.

Compliance Date

PHMSA received comments from Alaska Airlines, Amazon, Chamber, COSTHA, DGAC, MDBTC, NRF, PRBA, and an anonymous commenter concerning the proposed effective date of January 1, 2020 for the proposed test summary requirements. These commenters requested that PHMSA provide additional time to comply. Alaska Airlines commented that they hope the test summary requirements can be implemented by January 1, 2021. PRBA, Amazon, MDBTC, the Chamber, and NRF indicated that PHMSA should allow manufacturers and subsequent distributors until January 1, 2022 to comply with the test summary requirements. The DGAC recommended a one-year transition period following publication of the final rule. The commenters opined that the proposed compliance deadline of January 1, 2020 would not allow sufficient time for U.S. manufacturers and subsequent distributors of these products to establish procedures for preparing and securing test summaries. In their comments, NRF commented that it will take significant time for manufacturers and shippers, especially small companies, to develop and prepare the test summaries for their products. NRF opined that a longer implementation time will give companies enough time to identify, develop, and prepare the materials that are needed for compliance.

PHMSA agrees that additional time may be required to fully integrate systems, processes, and policies for preparing test summaries. The additional time can be used to help ensure the availability of test summaries and to prepare procedures for making test summaries available to subsequent distributors. In this final rule, the required compliance date for both the creation of and subsequent distribution upon request for test summaries is January 1, 2022.

COSTHA noted that using the same implementation date for both battery manufacturers and distributors presents the possibility that manufacturers could wait until December 31, 2021 to prepare the documents and distributors would not have any additional time to receive and make available the test summaries throughout the supply chain. COSTHA requested a staggered implementation date that would allow distributors an additional year to comply. PHMSA believes that the extended transition period for domestic implementation of the test summary requirements (two years after the requirements enter the IMDG Code and ICAO Technical Instructions) will mitigate this concern over shared implementation dates for shippers and distributors by providing additional time for battery distributers to work with manufacturers to acquire the necessary information and establish mechanisms for further distribution.

Applicability Date

PHMSA received comments from PRBA, NRF, DGAC, MDBTC, Amazon, and the Chamber requesting that PHMSA reconsider which lithium batteries require a test summary be created and made available. PHMSA proposed a requirement that a test summary be made available for all lithium cells and batteries manufactured after June 30, 2003, and that manufacturers and subsequent distributers of lithium cells and batteries manufactured after June 30, 2003, must make this information available to others in the supply chain.

PRBA commented that “[i]t is not practicable to require the post-hoc generation of a Test Summary for batteries that were manufactured as far back as 2003,” and asked that PHMSA adopt a date that requires the creation of test summaries and subsequent distribution for only batteries and cells manufactured after the effective date of the provisions. In conjunction with its request to extend the compliance date for the test summary generally to January 1, 2022, PRBA requests that only batteries and cells manufactured after this date require test summaries and subsequent distribution. The Chamber also requested that the applicability be limited to lithium cells and batteries manufactured after January 1, 2022 noting that “there may be times when distributors are shipping older battery designs that were manufactured by a company that is no longer in business. In instances like this, it may be impossible for shippers to acquire the necessary information for the TS.” The NRF and Amazon commented with similar requests to limit the scope of batteries subject to the test summary by using the effective date of the requirement which would then apply the requirements to cells and batteries currently in production and those made going forward. The NRF noted that it would be incredibly difficult and burdensome to locate a test certification and create a test summary for batteries dating back up to 17 years. MDBTC supported requiring test summary documents for only lithium cells and batteries manufactured after January 1, 2014.

PHMSA recognizes the comments noting the potential difficulty in obtaining test summaries for older batteries, particularly in cases where a manufacturer may no longer be in business or has merged with another company. Therefore, PHMSA is applying the test summary requirements only to cells and batteries manufactured after January 1, 2008. This date is the effective date of the final rule that required all lithium batteries (including small batteries) be of the type proven to meet the criteria in part III, sub-section 38.3 of the UN Manual of Tests and Criteria (“Hazardous Materials; Transportation of Lithium Batteries,” August 9, 2007, 72 FR 44929). As of January 1, 2008, all batteries transported in accordance with the HMR should have valid test reports that will help facilitate the creation of and availability of test summaries. PHMSA believes that amending the scope of cells and batteries that require a test summary to those manufactured after January 1, 2008 will lead to fewer instances where insufficient information will be available to create the required test summary while still capturing the majority of batteries and cells being offered for transportation.

PHMSA reiterates the importance of the test summary in providing confirmation to users that the battery is from a legitimate and compliant source and allowing those in the transport chain to more easily identify non-counterfeit products. Additionally, PHMSA maintains that the creation and subsequent distribution of test summaries for lithium batteries provides an enhanced mechanism for shippers to meet their existing requirement to only offer lithium cells and batteries of a type proven to meet the criteria in part III, sub-section 38.3 of the UN Manual of Tests and Criteria. The availability of specific information in the test summary document will enhance the users' ability to obtain the information needed to ensure they are receiving, and potentially reoffering for transportation, a battery that is of a tested and approved type.

Fuel Gas Containment Systems

In the NPRM, PHMSA discussed amendments to international standards that are not being considered for adoption. As stated in the NPRM, the 20th Revised Edition to the UN Model Regulations added a special provision to allow for the transportation of vehicle fuel gas containment systems containing certain gases, such as compressed natural gas and liquified petroleum gas, transported for disposal, recycling, repair, inspection, maintenance, or from where they are manufactured to a vehicle assembly plant. The provisions allow for gaseous fuels to be transported in fuel tanks designed for vehicles meeting certain European automotive standards rather than specification pressure receptacles. In the NPRM, PHMSA explained that the vehicle specification pressure vessels that are incorporated and authorized by the UN Model Regulations do not apply to U.S. domestic transportation as most of the fuel gas containment standards that are addressed in the UN Model Regulations are more appropriate for European road and rail regulations. PHMSA solicited comments on the fuel gas containment systems amendment in the UN Model Regulations and asked whether it would benefit industry to include a similar amendment in the HMR.

PHMSA received a comment from COSTHA on the decision not to include provisions for fuel gas containment decisions. The commenter disagreed with the view that the amendments are more appropriate for European regulations. COSTHA commented on the benefits of adopting the provisions into the HMR. COSTHA opined that when fuel tanks are removed from the vehicle and offered for transportation they are constructed to meet motor vehicle standards, but the tanks will not be permitted for transport of gaseous fuels under the HMR without the gas being completely removed from the tank. COSTHA further commented that the gas removal process has the potential to lead to dangerous situations at repair shops, dealers, and disposal locations not equipped to properly empty these fuel tanks. COSTHA notes that U.S. automobile manufacturers often use UN or Global Technical Regulations to demonstrate compliance with equivalent Federal Motor Vehicle Safety Standards (FMVSS).8 In addition, COSTHA supports referencing applicable FMVSS in the HMR to facilitate U.S. domestic gas containment system transport.

8 National Highway Transportation Safety Administration issues FMVSS. The regulations establishing the FMVSS are primarily found at 49 CFR part 571. https://www.nhtsa.gov/laws-regulations/fmvss.

PHMSA thanks COSTHA for its comments on this topic, and PHMSA understands the concerns related to difficulties in ensuring gas is removed from these cylinders prior to transport, but it would be premature to adopt the FMVSS requirements into the HMR. The FMVSS requirements are not presently incorporated in the UN Model Regulations, and adoption of the FMVSS requirements would require additional coordination with Federal agencies outside of PHMSA. PHMSA may consider this action in a future rulemaking and invites COSTHA to file a petition for rulemaking in accordance with 49 CFR 106.95, 106.100 and 106.105, to formally request this change be made in the HMR. Additonally, PHMSA believes that a more comprehensive review of the current domestic standards used by vehicle fuel gas containment systems is necessary prior to incorporation in the HMR to help ensure safety standards that most closely align with existing practices are incorporated. The request could be further evaluated for merit to address in an upcoming rulemaking.

Damaged and Defective Lithium Batteries

In the NPRM, PHMSA discussed amendments to international standards not being considered for adoption. As stated in the NPRM, the 20th Revised Edition of the UN Model Regulations adopted transportation provisions for damaged and defective cells and batteries liable to rapidly disassemble, dangerously react, or produce a flame, a dangerous evolution of heat, or a dangerous emission of toxic, corrosive, or flammable gases or vapors under normal conditions of transport (UN Nos. 3090, 3091, 3480 and 3481). In the NPRM, PHMSA explained that the existing packaging and hazard communication requirements in §173.185(f) sufficiently address consignments of this nature. PHMSA received one comment from MDBTC in support of not adopting the provisions for damaged and defective lithium batteries.

Competency-Based Training

PHMSA received comments from AAR and ASLRRA, ACA, AHS, Alaska Airlines, CGA, COSTHA, DGAC, Dow, IATA, IME, Interested Parties, IVODGA, MDBTC, and RIPA in response to our request for comments on the principles of Competency-Based Training, recently published in the attachments of the ICAO Technical Instructions. As noted in the NPRM, the provisions concerning Competency-Based Training were not finalized or adopted in the 2017-2018 ICAO Technical Instructions and there were no proposals concerning this topic in the NPRM. PHMSA thanks all commenters for their views on the issue and, as noted in the NPRM, comments will be considered for the betterment of PHMSA's work in various international forums.

Safety Devices in Dedicated Handling Devices

PHMSA received a comment from COSTHA concerning safety devices in dedicated handling devices. COSTHA commented that PHMSA should align the provisions of §173.166(e)(4)(i) with the UN Model Regulations and the IMDG Code to authorize unpackaged articles in dedicated handling devices, vehicles, or containers to, from, or between where they are manufactured and an assembly plant including intermediate handling locations. PHMSA notes that the provisions adopted by the UN and the IMDG Code are currently authorized in §§173.166(e)(4)(i) and (ii), therefore no additional action is required.

V. Section-By-Section Review

The following is a section-by-section review of the amendments adopted in this final rule:

Part 171—General Information, Regulations, and Definitions

Section 171.7 Reference Material

Section 171.7 provides a listing of all voluntary consensus standards incorporated by reference into the HMR, as directed by the “National Technology Transfer and Advancement Act of 1995.” According to the Office of Management and Budget (OMB), Circular A-119, “Federal Participation in the Development and Use of Voluntary Consensus Standards and in Conformity Assessment Activities,” and in accordance with Sec 12(d)(1) of the “National Technology Transfer and Advancement Act of 1995,” government agencies must use voluntary consensus standards wherever practical in the development of regulations. When properly conducted, agency adoption of industry standards promotes productivity and efficiency in government and industry, expands opportunities for international trade, conserves resources, improves health and safety, and protects the environment.

PHMSA actively participates in the development and updating of consensus standards through representation on more than 20 consensus standard bodies, and it regularly reviews updated consensus standards to consider their merit for inclusion in the HMR. For this rulemaking, PHMSA evaluated updated international consensus standards pertaining to proper shipping names, hazard classes, packing groups, special provisions, packaging authorizations, air transport quantity limitations, and vessel stowage requirements. It determined that the revised standards provide an enhanced level of safety without imposing significant compliance burdens. These standards have well-established and documented safety histories, and their adoption will maintain the high safety standard currently achieved under the HMR. Therefore, in this final rule, PHMSA is adding and revising the following incorporation by reference materials:

- Paragraph (s)(2) is added, to incorporate the International Atomic Energy Agency Code of Conduct on the Safety and Security of Radioactive Sources. Section 172.800 references the incorporation by reference of this document; however, this entry does not currently appear in §171.7. The addition of this paragraph corrects this oversight. The incorporation of this document in §172.800 provides a list of Category 1 and 2 radioactive sources for which offerors or carriers require a security plan.

- Paragraph (t)(1), which incorporates the International Civil Aviation Organization Technical Instructions for the Safe Transport of Dangerous Goods by Air (ICAO Technical Instructions), 2017-2018 Edition, is revised to incorporate the 2019-2020 Edition. These instructions contain the detailed instructions for the international transport of hazardous materials by air. In a previous rulemaking, [Docket No. PHMSA-2015-0102 (HM-219A); 83 FR 55792], PHMSA added §172.407 to the list of sections in paragraph (t)(1) and (v)(2). The NPRM did not account for this addition, and in this final rule §172.407 has been added to the list in paragraphs (t)(1) and (v)(2) consistent with the earlier published final rule.

- Paragraph (v)(2), which incorporates the International Maritime Organization International Maritime Dangerous Goods Code (IMDG Code), incorporating Amendment 38-16 (English Edition), is revised to incorporate the 39-18 (English Edition), 2018 Edition. This code contains detailed instructions for the international transport of hazardous materials by vessel.

- Paragraph (w), which incorporates various

International Organization for Standardization entries, is revised to incorporate by reference standards for the specification, design, construction, testing, and use of gas cylinders:

- —ISO 11118(E), Gas cylinders—Non-refillable metallic gas cylinders—Specification and test methods is replaced by ISO 11118:2015(E), Gas cylinders—Non-refillable metallic gas cylinders—Specification and test methods in paragraph (w)(53). The purpose of this standard is to provide a specification for the design, manufacture, inspection, and testing of non-refillable metallic gas cylinders for worldwide safe use, handling, and transport. The updated version of ISO 11118 includes, among other edits, clarified requirements for the processing of carbon steel to avoid strain aging and the inclusion of alternative temperatures for artificial aging of carbon steel cylinders prior to burst testing.

- —ISO 11120(E), Gas cylinders—Refillable seamless steel tubes of water capacity between 150 L and 3000 L—Design, construction and testing, First edition, March 1999 is replaced by ISO 11120:2015(E), Gas cylinders—Refillable seamless steel tubes of water capacity between 150 L and 3,000 L—Design, construction and testing in paragraph (w)(62). This standard provides a specification for the design, manufacture, inspection and testing of tubes at the time of manufacture for worldwide usage. The updated version of ISO 11120 includes, among other edits, the modification of ultrasonic provisions for ultrasonic examination in 8.3 to include ultrasonic examination for wall thickness and for imperfections also on the supplied tubing and revision of the provisions for design of tubes for embrittling gases.

- —ISO 11623(E), Transportable gas cylinders—Periodic inspection and testing of composite gas cylinders, First edition, March 2002 is replaced by ISO 11623:2015(E), Gas cylinders—Composite construction—Periodic inspection and testing in paragraph (w)(66). This standard specifies the requirements for periodic inspection and testing and to verify the integrity for further service of hoop-wrapped and fully-wrapped composite transportable gas cylinders, with aluminum-alloy, steel or non-metallic liners or of linerless construction (Types 2, 3, 4, and 5), intended for compressed, liquefied or dissolved gases under pressure, of water capacity from .5 L up to 450 L. The updated version of ISO 11623 includes, among other edits, updated terminology, particularly for the various types of composite cylinders, and moves information regarding intervals between periodic inspection and testing based on cylinder type into the new Annex C (formerly listed in Tables 1 through 4).

- —ISO 14246:2014(E), Gas cylinders—Cylinder valves—Manufacturing tests and examination is added in paragraph (w)(69). This standard covers the function of a cylinder valve as a closure.

- —ISO 16148:2016(E), Gas cylinders—Refillable seamless steel gas cylinders and tubes—Acoustic emission examination (AT) and follow-up ultrasonic examination (UT) for periodic inspection and testing is added in paragraph (w)(71). This International Standard describes two methods of AT, defined as Method A and Method B, and a method of follow-up UT. These non-destructive examination techniques are an alternative to conventional testing procedures for cylinders and tubes.

- —ISO 17871:2015(E) Gas cylinders—Quick-release cylinder valves—Specification and type testing is added in paragraph (w)(72). This standard covers the function of a quick-release cylinder valve as a closure.

- —ISO 21172-1:2015(E), Gas cylinders—Welded steel pressure drums up to 3,000 litres capacity for the transport of gases—Design and construction—Part 1: Capacities up to 1,000 litres is added in paragraph (w)(75). This standard provides a specification for the design, manufacture, inspection, and approval of welded steel gas pressure drums.

- —ISO 22434:2006(E), Transportable gas cylinders—Inspection and maintenance of cylinder valves is added in paragraph (w)(76). This standard specifies the requirements for the inspection and maintenance of cylinder valves, including valves with integrated pressure regulators.

- —ISO/TR 11364:2012(E), Gas cylinders—Compilation of national and international valve stem/gas cylinder neck threads and their identification and marking system is added in paragraph (w)(77). The purpose of this standard is to list all known cylinder/valve threads currently used and also threads used in the past and to specify a harmonized identification code and marking system for both cylinders and valves.

- Paragraphs (aa)(1)-(4), which updates four (4) existing Organization for Economic Cooperation and Development (OECD) guidelines concerning corrosivity testing (Nos. 404, 430, 431, & 435). The references to these standards are updated to the 2015 versions of the standards. Updated OECD Guideline 404 and OECD Guideline 435 contain minor variations in the types of information to be recorded as a part of the test report. Updated OECD Guideline 430 and OECD Guideline 431 include references to a developed document on integrated approaches to testing and assessment.

- Paragraph (bb)(1), which incorporates the Transport Canada Transportation of Dangerous Goods Regulations, adds subparagraphs (xx), (xxi), and (xxii), to include SOR/2016-95 published June 1, 2016; SOR/2017-137 published July 12, 2017; and SOR/2017-253 published December 13, 2017, respectively. These additions are to incorporate changes to the Transport Canada Transportation of Dangerous Goods Regulations. SOR/2016-95 contains amendments concerning reporting requirements and international restrictions on lithium batteries. SOR/2017-137 contains amendments related to international harmonization. SOR/2017-253 containes amendments related to marine transportation.

- Paragraph (bb)(2) is added to incorporate by reference Containers for Transport of Dangerous Goods by Rail, a Transport Canada standard that was published in 2013. The standard applies to the design, manufacture, maintenance and qualification of tank cars and ton containers and the selection and use of large containers or transport units used in the handling, offering for transport, or transporting of dangerous goods by rail.

- Paragraph (dd)(1), which incorporates the United Nations Recommendations on the Transport of Dangerous Goods—Model Regulations, 19th Revised Edition (2015), Volumes I and II, is revised to incorporate the 20th Revised Edition (2017), Volumes I and II. This standard presents a basic scheme of provisions that allow uniform development of national and international regulations governing the various modes of transport. In a previous rulemaking, [Docket No. PHMSA-2015-0102 (HM-219A); 83 FR 55792], PHMSA added §172.519 to the list of sections in paragraph (dd)(1). The NPRM did not account for this addition and in this final rule, §172.519 has been added to the list in paragraph (dd)(1) consistent with the earlier published final rule.

- Paragraph (dd)(2)(ii) is added to incorporate the United Nations Recommendations on the Transport of Dangerous Goods, Manual of Tests and Criteria, 6th Revised Edition, Amendment 1. This standard contains criteria, test methods, and procedures to be used for the classification of hazardous materials according to the UN Model Regulations.

- Paragraph (dd)(3), which incorporates the United Nations Recommendations on the Transport of Dangerous Goods, Globally Harmonized System of Classification and Labelling of Chemicals Sixth revised edition (2015), is revised to incorporate the United Nations Recommendations on the Transport of Dangerous Goods, Globally Harmonized System of Classification and Labelling of Chemicals (GHS), Seventh revised edition (2017). This standard helps identify the intrinsic hazards found in substances and mixtures and to convey information about these hazards.

Section 171.8 Definitions and Abbreviations

Section 171.8 defines terms generally used throughout the HMR that have broad or multi-modal applicability. In this final rule, PHMSA is amending the definition of “UN pressure receptacle” to include pressure drums. Additionally, PHMSA is adding a definition for “UN Pressure drum” to mean a welded transportable pressure receptacle of a water capacity exceeding 150 L and not more than 1,000 L (e.g., cylindrical receptacles equipped with rolling hoops, spheres on skids). These amendments provide defining terms related to pressure drums for which ISO 21172-1:2015(E) Gas cylinders—Welded steel pressure drums up to 3,000 litres capacity for the transport of gases—Design and construction—Part 1: Capacities up to 1,000 litres is incorporated in §178.71.

Section 171.12 North American Shipments

Section 171.12 prescribes requirements for the use of the Transport Canada TDG Regulations. In a March 30, 2017, final rule [HM-215N; 82 FR 15796], PHMSA amended the HMR to expand recognition of cylinders and pressure receptacles, cargo tank repair facilities, and certificates of equivalency (an authorization to conduct an activity in compliance with the conditions of that authorization instead of the standard requirements) in accordance with the TDG Regulations. The goal of these amendments is to promote flexibility and permit the use of advanced technology for the requalification and use of pressure receptacles; doing so will provide for a broader selection of authorized pressure receptacles, reduce the need for special permits, and to facilitate cross-border transportation of these cylinders. In this final rule, PHMSA is clarifying the recognition of certificates of equivalency issued by Transport Canada. Transport Canada issues equivalency certificates as both a competent authority approval and for an alternative means of compliance with TDG Regulations. PHMSA provides reciprocity for equivalency certificates that are issued by Transport Canada as an alternative to the TDG Regulations; PHMSA does not provide recognition to Canada's competent authority approvals. In this final rule, PHMSA is amending paragraph (a)(1) to clarify the extent of reciprocity regarding certificates of equivalency.

Additionally, PHMSA is amending paragraph (a)(3)(v) to update the standard incorporated by reference to which Canadian rail cars must conform. The existing reference to the Canadian General Standards Board standard 43.147 is replaced with Containers for Transport of Dangerous Goods by Rail (2013).

PHMSA received comments of general support from the Dow and DGAC. Dow specifically mentioned support for the incorporation by reference of the Containers for Transport of Dangerous Goods by Rail and clarification of the certificates of equivalency.

PHMSA received a comment from Transport Canada suggesting that the terms “pressure drum” and “pressure receptacle” addressed in §171.8 of this final rule, also be included in §171.12 in a manner that promotes reciprocity between the United States and Canada. We agree with the commenter and in this final rule are adding the terms “pressure drum” and “UN pressure receptacle” to §171.12 and authorizing use of these packages when marked with the letters “CAN.”

Part 172—Hazardous Materials Table, Special Provisions, Hazardous Materials Communications, Emergency Response Information, Training Requirements, and Security Plans

Section 172.101 Purpose and Use of Hazardous Materials Table

Section 172.101 contains the HMT and provides instructions for its use. In this final rule, PHMSA is revising the instructional text that precedes the HMT for paragraph (e) of this section.

Paragraph (e) of §172.101 provides instructions for the use of column (4) of the HMT. Column (4) lists the identification number assigned to each proper shipping name. Most identification numbers are preceded by the letters “UN” and are associated with proper shipping names, which may be used for both domestic and international transportation. Some proper shipping names are assigned “NA” or “North American” numbers. In the NPRM, PHMSA proposed a revision to paragraph (e) to indicate that NA numbers are only recognized for use in the United States. In the NPRM, PHMSA stated that NA numbers are not authorized in Canada because the TDG limit the use of NA numbers to materials classified as “Consumer commodity,” and do not allow for the use of other NA numbers. Transport Canada made this amendment in August 15, 2001 with SOR 2001-186.9 The TDG, Part 9.1 Transporting Dangerous Goods from the United States into or through Canada state that the HMR may be followed as an alternative to the TDG if certain conditions are met, including that “the classification in Schedule 1 or in the UN Recommendations, for dangerous goods that have the letter “D” assigned to them in column 1 of the table to section 172.101 of 49 CFR, except for dangerous goods with the shipping name 'Consumer commodity'.” The letter “D” is assigned to NA numbers. Therefore, NA numbers are not recognized for shipments from a place in the United States to a place in Canada or from a place in the United States through Canada to a place outside Canada. As such, PHMSA is revising the HMR to be consistent with Canada's national regulations. PHMSA received comments from DGAC on the use of NA numbers in §172.101(e), North American Shipments. Specifically, DGAC stated this change will eliminate mutual recognition of NA numbers between the United States and Canada. Although the text in §172.101(e), stating that NA numbers are not recognized for international transportation, except to and from Canada, was not previously amended to align with the TDG, the mutual recognition of NA numbers has not been permitted under the TDG since the August 15, 2001 publication. NA numbers will continue to be recognized for shipments within the United States.

9http://www.gazette.gc.ca/rp-pr/p2/2001/2001-08-15-s/pdf/g2-135s1.pdf.

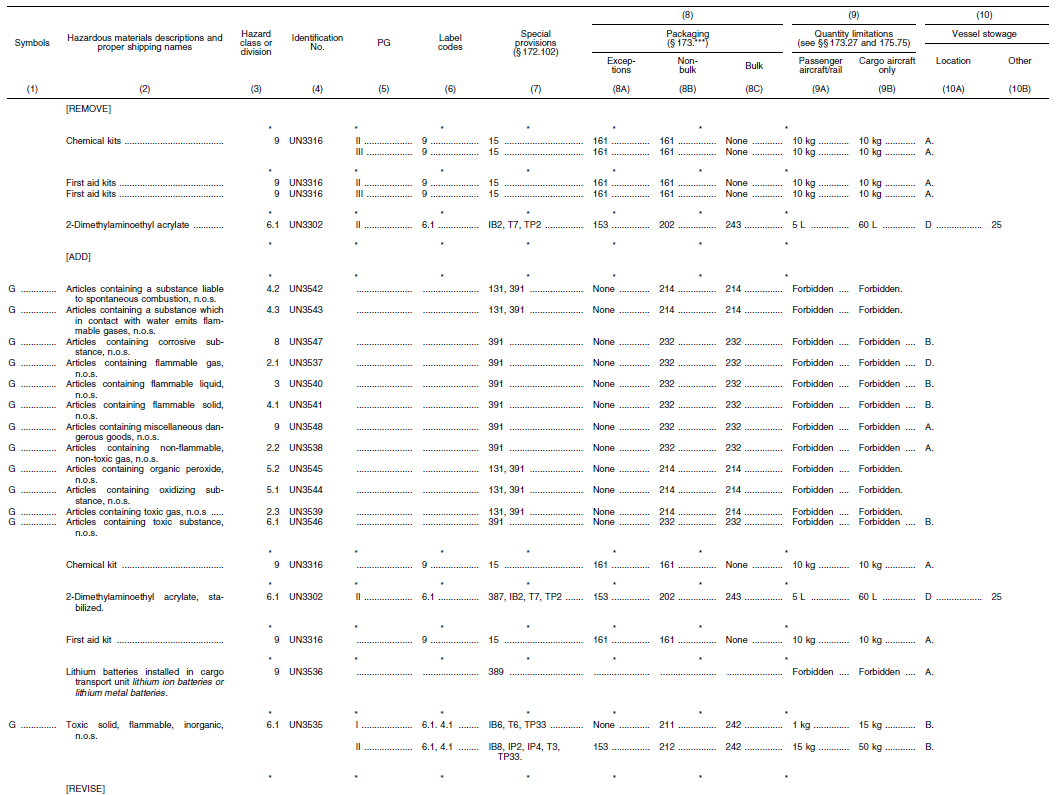

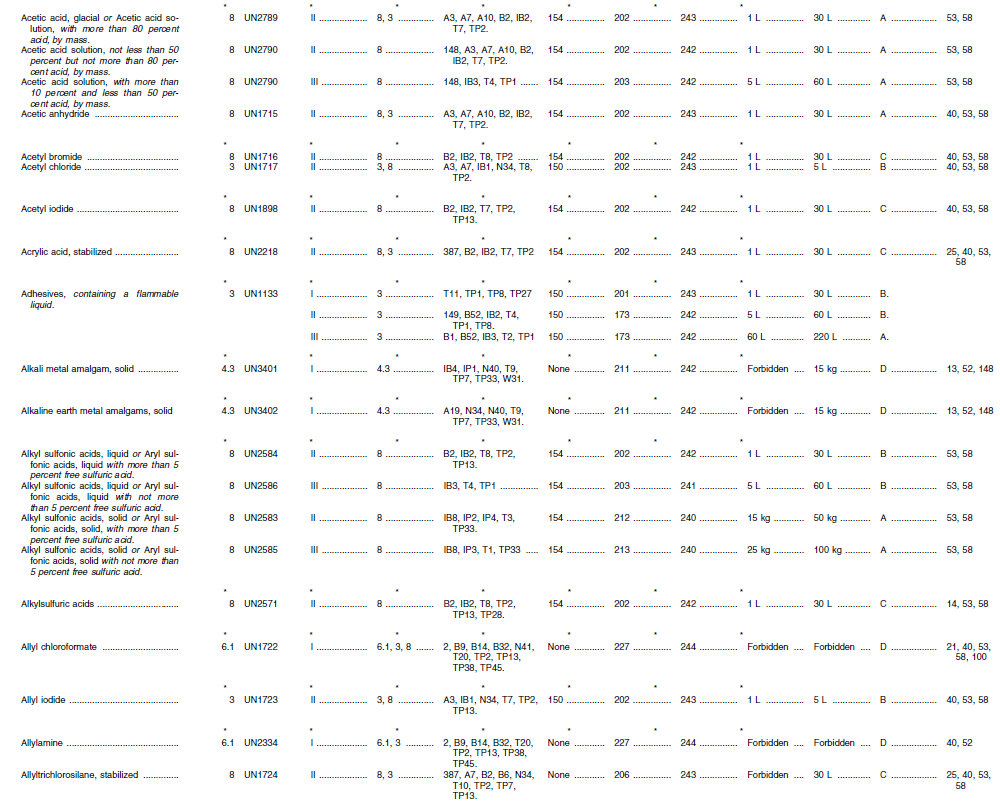

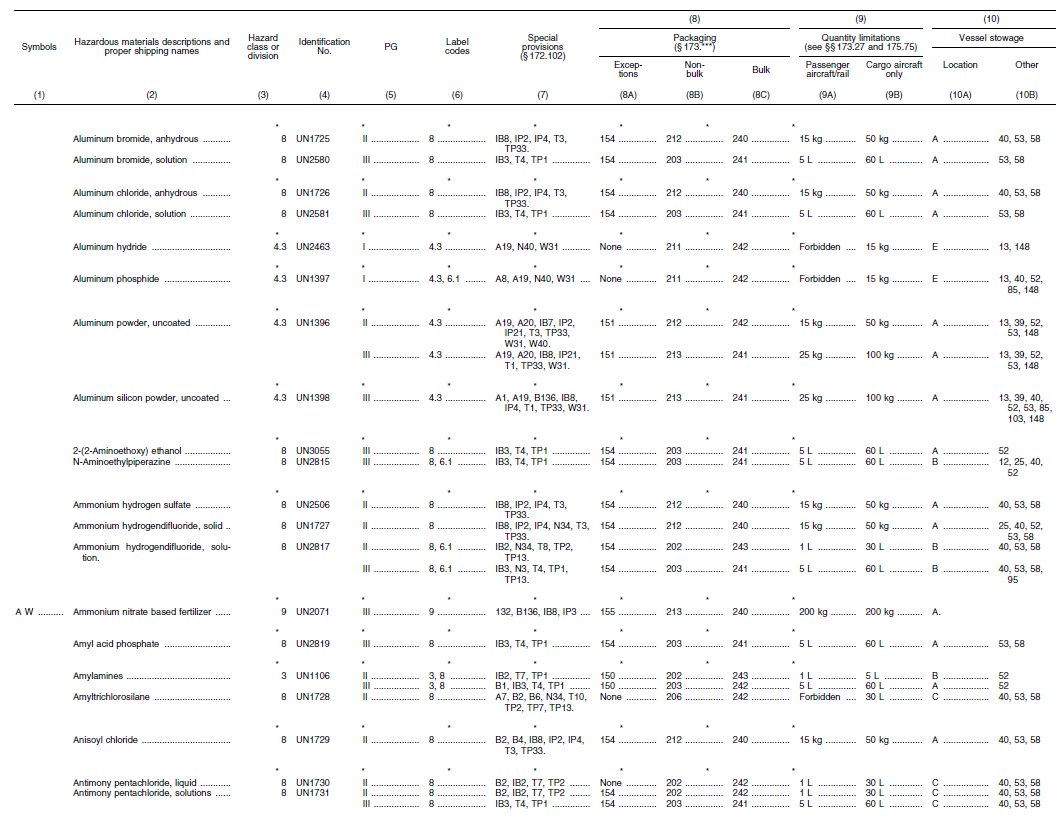

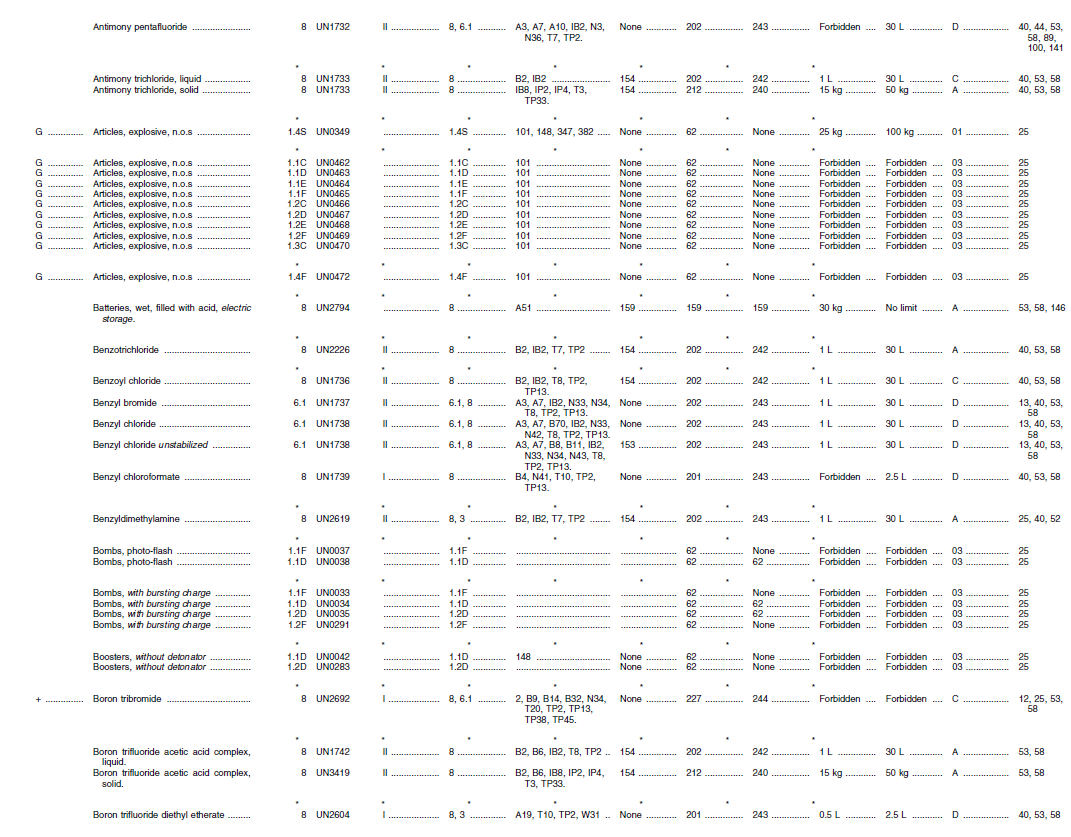

1. Hazardous Materials Table (HMT)

In this final rule, PHMSA is amending the HMT. Readers should review all changes for a complete understanding of the amendments. For purposes of the U.S. Government Printing Office's typesetting procedures, proposed changes to the HMT appear under three sections of the Table, “remove,” “add,” and “revise.” Certain entries in the HMT, such as those with revisions to the proper shipping names, appear as a “remove” and “add.” The amendments to the HMT include the following:

2. New HMT Entries

- UN3537 Articles containing flammable gas, n.o.s.

- UN3538 Articles containing non-flammable, non-toxic gas, n.o.s.

- UN3539 Articles containing toxic gas, n.o.s.

- UN3540 Articles containing flammable liquid, n.o.s.

- UN3541 Articles containing flammable solid, n.o.s.

- UN3542 Articles containing a substance liable to spontaneous combustion, n.o.s.

- UN3543 Articles containing a substance which in contact with water emits flammable gases, n.o.s.

- UN3544 Articles containing oxidizing substance, n.o.s.

- UN3545 Articles containing organic peroxide, n.o.s.

- UN3546 Articles containing toxic substance, n.o.s.

- UN3547 Articles containing corrosive substance, n.o.s.

- UN3548 Articles containing miscellaneous dangerous goods, n.o.s.

PHMSA is adding a classification scheme for articles containing hazardous materials not otherwise specified by name in the HMR that contain hazardous materials of various hazard classes and divisions. This addresses transportation scenarios where various hazardous materials or hazardous materials residues are present in articles above the quantities currently authorized for dangerous goods in machinery or apparatus. This authorizes safe and secure methods to transport articles that may be too large to fit into typical packagings. Absent provisions to package and transport these materials safely, such articles may be offered for transport under provisions that do not adequately account for the physical and chemical properties of the substances or mode of transport and may require the issuance of an approval by the Associate Administrator for Hazardous Materials Safety. - UN3535 Toxic solid, flammable, inorganic, n.o.s.

Consistent with the 20th Revised Edition of the UN Model Regulations, this new generic entry addresses toxic solids with a flammable subsidiary risk in Packing Groups (PG) I and II. - UN3536 Lithium batteries installed in cargo transport unit

lithium ion batteries or lithium metal batteries

This new HMT entry addresses lithium metal and lithium ion batteries that are installed in a cargo transport unit and designed only to provide power external to the cargo transport unit. The lithium batteries must meet the requirements of §173.185 and contain the necessary systems to prevent overcharge and over discharge between the batteries. Such units are forbidden for transport on aircraft. PHMSA received one comment on the proposed changes to §172.101 from PRBA supporting the new entry of UN3536 in the table.

3. Amendments to Column (2) Hazardous Materials Descriptions and Proper Shipping Names

Section 172.101(c) describes column (2) of the HMT and the requirements for hazardous materials descriptions and proper shipping names. For the entry “2-Dimethylaminoethyl acrylate,” the word “stabilized” is added to the end, as the substance has been determined to polymerize in certain conditions.

4. Amendments to Column (5) Packing Group

The HMT entries for articles “UN3316, Chemical kit” and “UN3316, First aid kit” are revised to remove Packing Group II and III assignments. This revision reverts the entries to a single row with the packing group column left blank as they existed prior to adding the Packing Group II and III assignments in a final rule published on January 8, 2015 [Docket No. PHMSA-2013-0260 (HM-215M); 80 FR 1075]. This revision addresses situations where materials in the kits are not assigned to a packing group or have Packing Group I assigned, as permitted by §173.161.

5. Amendments to Column (7) Special Provisions

Section 172.101(h) describes column (7) of the HMT, which contains special provisions for each entry in the table. Section 172.102(c) prescribes the special provisions assigned to specific entries in the HMT. The modifications to the entries in the HMT are discussed below.

In an October 18, 2018, final rule, entitled “Notification of the Pilot-in-Command and Response to Air Related Petitions for Rulemaking” [(HM-259); 83 FR 52878], PHMSA removed special provision A6 from UN numbers 2789, 2790, 1715, 1717, 1723, 1732, 1739, 1758, 2240, 3264, 3265, 1764, 1765, 1768, 1775, 1776, 1778, 1777, 1782, 1786, 1790, 2031, 2308, 1808, 2258, 2879, 1818, 2564, 2699, 2502, 2443, and 2444. However, the HM-215O NPRM incorrectly showed special provision A6 as still being applicable to these entries. Therefore, in this final rule, A6 is not assigned to these HMT entries consistent with the previously published HM-259 final rule.

Similarly, in the HM-259 final rule, PHMSA removed special provision A3 from UN numbers 1739, 2604, 1758, 2240, 1183, 1777, 1242, 1798, 1873, 2879, 1828, 1831, 2699, and 2444. However, the HM-215O NPRM incorrectly showed special provision A3 as still being applicable to these entries. Therefore, in this final rule, A3 is not assigned to these HMT entries consistent with the previously published HM-259 final rule.

Finally, in a March 6, 2019, interim final rule (IFR) [(HM-224I); 84 FR 8006], PHMSA removed special provision A51 from UN3480 and added special provision A100 to UN 3480. However, the HM-215O NPRM did not account for this action and in this final rule, A51 is removed from UN3480 and A100 is added to UN 3480 consistent with the previously published HM-224I IFR.

See “Section 172.102 special provisions” below for a detailed discussion of the additions, revisions, and deletions to the special provisions addressed in this final rule.

- Special provision 325. Special provision 325 is added to the following HMT entries:

- UN2912 Radioactive material, low specific activity (LSA-I) non-fissile or fissile-excepted

- UN2913 Radioactive material, surface contaminated objects (SCO-I or SCO-II) non-fissile or fissile-excepted

- UN2915 Radioactive material, Type A package non-special form, non-fissile or fissile-excepted

- UN2916 Radioactive material, Type B(U) package non-fissile or fissile-excepted

- UN2917 Radioactive material, Type B(M) package non-fissile or fissile-excepted

- UN2919 Radioactive material, transported under special arrangement, non-fissile or fissile-excepted

- UN3321 Radioactive material, low specific activity (LSA-II) non-fissile or fissile-excepted

- UN3322 Radioactive material, low specific activity (LSA-III) non-fissile or fissile-excepted

- Special provision 347. Special provision 347 restricts the use of certain HMT entries classed as Division 1.4S explosive materials to those articles successfully passing Test Series 6(d) of Part I of the UN Manual of Tests and Criteria. The 6(d) test is a test on a single package to determine if there are hazardous effects outside the package arising from accidental ignition or initiation of the contents. A Division 1.4 explosive is defined as an explosive that presents a minor explosion hazard such that hazardous effects are confined to a package and no projection of fragments of appreciable size or range are expected; and that an external fire must not cause virtually instantaneous explosion of almost the entire contents of a package containing a Division 1.4 explosive. Explosive articles or substances are assigned to Division 1.4, Compatibility Group S (1.4S) if hazardous effects are confined within a package or the blast and projection effects do not significantly hinder emergency response efforts.

Special provision 347 is presently assigned to eight (8) Division 1.4S entries in the HMT including shaped charges, detonators, power device cartridges, detonator assemblies, and plastic bonded bursting charges. Following a review of other Division 1.4S entries, the UN Working Group on Explosives supported applying special provision 347 to entries for Division 1.4S articles and substances that are generic or “not otherwise specified” (n.o.s.), and to UN 0367 (Fuzes, detonating) that are normally package dependent. The UN Working Group noted that generic entries normally warrant more systematic testing. In the NPRM, PHMSA requested comment on whether this provision is likely to have net benefits. PHMSA received one comment from IME stating that the “addition of the special provision will benefit transportation safety and that the additional costs are, accordingly justified.” Therefore, in this final rule, consistent with the UN Model Regulations, PHMSA is adding special provision 347 to the following entries:- UN0349 Articles, explosives, n.o.s.

- UN0367 Fuzes, detonating

- UN0384 Components, explosive train, n.o.s.

- UN0481 Substances, explosive, n.o.s.

- Special provision 368. Special provision 368 prescribes requirements for non-fissile or fissile-excepted uranium hexafluoride that must be described as UN3507 or UN2978, as appropriate. Based on an informal working paper submitted at the 50th session of the UN Sub-Committee of Experts (SCOE) on the Transport of Dangerous Goods that highlighted potential errors in the 19th revised edition of the Model Regulations, it was agreed that special provision 368 should have been assigned to “UN 2908, Radioactive material, excepted package—empty packaging” because empty uncleaned packagings containing residues of non-fissile or fissile-excepted uranium hexafluoride should be classified under UN3507 or UN2978 as appropriate. Therefore, in this final rule, PHMSA is assigning special provision 368 to the following entry to aid shippers:

- UN2908 Radioactive material, excepted package—empty packaging.

- Special provision 369. Special provision 369 is revised for clarity and is applicable to the following HMT entry:

- UN3507 Uranium hexafluoride, radioactive material, excepted package, less than 0.1 kg per package, non-fissile or fissile-excepted

- Special provision 383. Consistent with the deletion of this special provision in section 172.102, special provision 383 is removed from the following PG II HMT entries:

- UN1133 Adhesives, containing a flammable liquid

- UN1263 Paint related material including paint thinning, drying, removing, or reducing compound

- UN1263 Paint including paint, lacquer, enamel, stain, shellac solutions, varnish, polish, liquid filler and liquid lacquer base

- UN1210 Printing ink, flammable or Printing ink related material (including printing ink thinning or reducing compound), flammable

- UN1866 Resin Solution, flammable

- Special provision 388. New special provision 388 is added to the following HMT entries:

- UN3090 Lithium metal batteries including lithium alloy batteries

- UN3091 Lithium metal batteries contained in equipment including lithium alloy batteries

- UN3091 Lithium metal batteries packed with equipment including lithium alloy batteries

- UN3480 Lithium ion batteries including lithium ion polymer batteries

- UN3481 Lithium ion batteries contained in equipment including lithium ion polymer batteries

- UN3481 Lithium ion batteries packed with equipment including lithium ion polymer batteries

- Special provision 389. New special provision 389 providing applicable transport conditions is added to the following new HMT entry:

- UN3536 Lithium batteries installed in cargo transport unit lithium ion batteries or lithium metal batteries

- Special provision 391. New special provision 391 is added to the following new HMT entries:

- UN3537 Articles containing flammable gas, n.o.s.

- UN3538 Articles containing non-flammable, non-toxic gas, n.o.s.

- UN3539 Articles containing toxic gas, n.o.s.

- UN3540 Articles containing flammable liquid, n.o.s.

- UN3541 Articles containing flammable solid, n.o.s.

- UN3542 Articles containing a substance liable to spontaneous combustion, n.o.s.

- UN3543Articles containing a substance which in contact with water emits flammable gases, n.o.s.

- UN3544 Articles containing oxidizing substance, n.o.s.

- UN3545 Articles containing organic peroxide, n.o.s.

- UN3546 Articles containing toxic substance, n.o.s.

- UN3547 Articles containing corrosive substance, n.o.s.

- UN3548 Articles containing miscellaneous dangerous goods, n.o.s.

- Special provision B136. PHMSA is adding new special provision B136 to the following HMT entries:

- UN1363 Copra

- UN1386 Seed cake, containing vegetable oil solvent extractions and expelled seeds, with not more than 10 percent of oil and when the amount of moisture is higher than 11 percent, with not more than 20 percent of oil and moisture combined

- UN1386 Seed cake with more than 1.5 percent oil and not more than 11 percent moisture

- UN1398 Aluminum silicon powder, uncoated

- UN1435 Zinc ashes

- UN2071 Ammonium nitrate based fertilizer

- UN2216 Fish meal, stabilized or Fish scrap, stabilized

- UN2217 Seed cake with not more than 1.5 percent oil and not more than 11 percent moisture

- UN2793 Ferrous metal borings or Ferrous metal shavings or Ferrous metal turnings or Ferrous metal cuttings in a form liable to self-heating

- Special provisions W31 and W32. Special provision W32 is removed from the following PG I HMT entries (unless otherwise noted in Table 1) and replaced with special provision W31:

| Proper shipping name | UN No. |

|---|---|

| Calcium phosphide | UN1360 |

| Aluminum phosphide | UN1397 |

| Calcium carbide | UN1402 |

| Calcium hydride | UN1404 |

| Cesium or Caesium | UN1407 |

| Metal hydrides, water reactive, n.o.s | UN1409 |

| Lithium aluminum hydride | UN1410 |

| Lithium borohydride | UN1413 |

| Lithium hydride | UN1414 |

| Lithium | UN1415 |

| Magnesium, powder or Magnesium alloys, powder | UN1418 |

| Magnesium aluminum phosphide | UN1419 |

| Rubidium | UN1423 |

| Sodium borohydride | UN1426 |

| Sodium hydride | UN1427 |

| Sodium | UN1428 |

| Sodium phosphide | UN1432 |

| Stannic phosphide | UN1433 |

| Zinc phosphide | UN1714 |

| Potassium borohydride | UN1870 |

| Magnesium hydride | UN2010 |

| Magnesium phosphide | UN2011 |

| Potassium phosphide | UN2012 |

| Strontium phosphide | UN2013 |

| Potassium | UN2257 |

| Aluminum hydride | UN2463 |

| Lithium nitride | UN2806 |

| Water-reactive solid, n.o.s | UN2813 |

| Metallic substance, water-reactive, n.o.s | UN3208 |

| Metallic substance, water-reactive, self-heating, n.o.s | UN3209 (All PGs) |

| Alkali metal amalgam, solid | UN3401 |

| Alkaline earth metal amalgams, solid | UN3402 |

| Potassium, metal alloys, solid | UN3403 |

| Potassium sodium alloys, solid | UN3404 |

- Special provision W40. Special provision W40 prohibits the use of non-bulk bags. This requirement typically applies to solid substances in Packing Group II. Consistent with changes made in Amendment 39-18 of the IMDG Code, special provision W40 is removed from the following HMT entries:

- UN1396 Aluminum powder, uncoated (PG III)

- UN1398 Aluminum silicon powder, uncoated

- UN1403 Calcium cyanamide with more than 0.1 percent of calcium carbide

- UN1405 Calcium silicide (PG III)

- U3208 Metallic substance, water-reactive, n.o.s. (PG III)

Additionally, PHMSA is adding special provision W40 to the following HMT entry:

UN3208 Metallic substance, water-reactive, n.o.s. (PG II)

6. Amendments to Column (10) Vessel Stowage Requirements

Section 172.101(k) explains the purpose of column (10) of the HMT and prescribes the vessel stowage and segregation requirements for specific entries. Column (10) is divided into two columns: Column (10A) [Vessel stowage] specifies the authorized stowage locations on board cargo and passenger vessels, and column (10B) [Other provisions] specifies special stowage and segregation provisions. The meaning of each code in column (10B) is set forth in §176.84.

In the NPRM, PHMSA proposed to amend various vessel stowage codes assigned to explosives articles to allow under deck stowage of these articles when not in closed cargo transport units (CCTUs). PHMSA received a comment from IME noting support for the changes, but indicating that the commercial ports used by their industry in the United States require commercial explosives to be containerized regardless of whether they are shipped on deck or under deck. PHMSA reiterates that these changes also allow the shipment of large and robust articles that while generally contained in some manner (e.g. a custom built crate, cradle, or box) may not fit in a traditional CCTU. The changes made in this final rule authorize such transport when not in a traditional CCTU. While these changes do not authorize the break bulk stowage of explosive substances, they do facilitate the movement of larger explosive articles.

The following table addresses this issue through modification of the stowage categories for individual UN numbers for which under deck stowage was previously permitted prior to Amendment 36-12 of the IMDG Code. Table 2 contains the changes listed in numerical order by UN identification number and additionally lists the proper shipping name, the previous column (10A) entry, and the adopted column (10A) entry.

| Proper shipping name | UN No. | Previous code column (10A) | Adopted code column (10A) |

|---|---|---|---|

| Cartridges for weapons, with bursting charge | 0005 | 05 | 03 |

| Cartridges for weapons, with bursting charge | 0006 | 04 | 03 |

| Cartridges for weapons, with bursting charge | 0007 | 05 | 03 |

| Bombs, with bursting charge | 0033 | 05 | 03 |

| Bombs, with bursting charge | 0034 | 04 | 03 |

| Bombs, with bursting charge | 0035 | 04 | 03 |

| Bombs, photo-flash | 0037 | 05 | 03 |

| Bombs, photo-flash | 0038 | 04 | 03 |

| Boosters, without detonator | 0042 | 04 | 03 |

| Bursters, explosive | 0043 | 04 | 03 |

| Charges, demolition | 0048 | 04 | 03 |

| Charges, depth | 0056 | 04 | 03 |

| Charges, shaped, without detonator | 0059 | 04 | 03 |

| Charges, supplementary explosive | 0060 | 04 | 03 |

| Cord, detonating, flexible | 0065 | 04 | 03 |

| Fracturing devices, explosive, without detonators for oil wells | 0099 | 04 | 03 |

| Cord, detonating or Fuze, detonating metal clad | 0102 | 04 | 03 |

| Jet perforating guns, charged oil well without detonator | 0124 | 04 | 03 |

| Mines with bursting charge | 0136 | 05 | 03 |

| Mines with bursting charge | 0137 | 04 | 03 |

| Mines with bursting charge | 0138 | 04 | 03 |

| Projectiles, with bursting charge | 0167 | 05 | 03 |

| Projectiles, with bursting charge | 0168 | 04 | 03 |

| Projectiles, with bursting charge | 0169 | 04 | 03 |

| Rockets, with bursting charge | 0180 | 05 | 03 |

| Rockets, with bursting charge | 0181 | 04 | 03 |

| Rockets, with bursting charge | 0182 | 04 | 03 |

| Rockets, with inert head | 0183 | 04 | 03 |

| Rocket motors | 0186 | 04 | 03 |

| Sounding devices, explosive | 0204 | 05 | 03 |

| Warheads, torpedo with bursting charge | 0221 | 04 | 03 |

| Charges, propelling, for cannon | 0242 | 04 | 03 |

| Charges, propelling | 0271 | 04 | 03 |

| Charges, propelling | 0272 | 04 | 03 |

| Cartridges, power device | 0275 | 04 | 03 |

| Cartridges, oil well | 0277 | 04 | 03 |

| Charges, propelling, for cannon | 0279 | 04 | 03 |

| Rocket motors | 0280 | 04 | 03 |

| Boosters, without detonator | 0283 | 04 | 03 |

| Grenades, hand or rifle, with bursting charge | 0284 | 04 | 03 |

| Grenades, hand or rifle, with bursting charge | 0285 | 04 | 03 |

| Warheads, rocket with bursting charge | 0286 | 04 | 03 |

| Warheads, rocket with bursting charge | 0287 | 04 | 03 |

| Cord, detonating or Fuze, detonating metal clad | 0290 | 04 | 03 |

| Bombs, with bursting charge | 0291 | 05 | 03 |

| Grenades, hand or rifle, with bursting charge | 0292 | 05 | 03 |

| Grenades, hand or rifle, with bursting charge | 0293 | 05 | 03 |

| Mines with bursting charge | 0294 | 05 | 03 |

| Rockets, with bursting charge | 0295 | 05 | 03 |

| Sounding devices, explosive | 0296 | 05 | 03 |

| Cartridges for weapons, with bursting charge | 0321 | 04 | 03 |

| Projectiles, with bursting charge | 0324 | 05 | 03 |

| Cartridges for weapons, blank | 0326 | 04 | 03 |

| Cartridges for weapons, blank or Cartridges, small arms, blank | 0327 | 04 | 03 |

| Cartridges for weapons, inert projectile | 0328 | 04 | 03 |

| Torpedoes with bursting charge | 0329 | 04 | 03 |

| Torpedoes with bursting charge | 0330 | 05 | 03 |

| Projectiles, with burster or expelling charge | 0346 | 04 | 03 |

| Cartridges for weapons, with bursting charge | 0348 | 05 | 03 |

| Warheads, rocket with bursting charge | 0369 | 05 | 03 |

| Warheads, rocket with burster or expelling charge | 0371 | 05 | 03 |

| Sounding devices, explosive | 0374 | 04 | 03 |

| Sounding devices, explosive | 0375 | 04 | 03 |

| Cartridges, power device | 0381 | 04 | 03 |

| Fuzes, detonating, with protective features | 0408 | 04 | 03 |

| Fuzes, detonating, with protective features | 0409 | 04 | 03 |

| Cartridges for weapons, blank | 0413 | 04 | 03 |

| Charges, propelling, for cannon | 0414 | 04 | 03 |

| Charges, propelling | 0415 | 04 | 03 |

| Cartridges for weapons, inert projectile or Cartridges, small arms | 0417 | 04 | 03 |

| Projectiles, with burster or expelling charge | 0426 | 05 | 03 |

| Projectiles, with burster or expelling charge | 0427 | 05 | 03 |

| Rockets, with expelling charge | 0436 | 04 | 03 |

| Rockets, with expelling charge | 0437 | 04 | 03 |

| Charges, shaped, without detonator | 0439 | 04 | 03 |

| Charges, explosive, commercial without detonator | 0442 | 04 | 03 |

| Charges, explosive, commercial without detonator | 0443 | 04 | 03 |

| Cases, combustible, empty, without primer | 0447 | 04 | 03 |

| Torpedoes with bursting charge | 0451 | 04 | 03 |

| Charges, bursting, plastics bonded | 0457 | 04 | 03 |

| Charges, bursting, plastics bonded | 0458 | 04 | 03 |

| Articles, explosive, n.o.s | 0462 | 04 | 03 |

| Articles, explosive, n.o.s | 0463 | 04 | 03 |

| Articles, explosive, n.o.s | 0464 | 04 | 03 |

| Articles, explosive, n.o.s | 0465 | 05 | 03 |

| Articles, explosive, n.o.s | 0466 | 04 | 03 |

| Articles, explosive, n.o.s | 0467 | 04 | 03 |

| Articles, explosive, n.o.s | 0468 | 04 | 03 |

| Articles, explosive, n.o.s | 0469 | 05 | 03 |

| Articles, explosive, n.o.s | 0470 | 04 | 03 |

| Articles, explosive, n.o.s | 0472 | 05 | 03 |

| Rockets, with inert head | 0502 | 02 | 03 |

Consistent with changes to Amendment 39-18 of the IMDG Code, PHMSA is making numerous changes to the special stowage and segregation provisions [Other provisions] indicated in column (10B) of the HMT.

Amendment 39-18 of the IMDG Code amended multiple entries to ensure proper segregation between acids and both amines and cyanides. Amines react dangerously with acids, evolving heat, and the heat of reaction has the potential to generate corrosive vapors. Cyanides react with acids to generate toxic vapors. However, current vessel segregation requirements are inconsistent. Therefore, PHMSA is applying stowage codes 52, 53, and 58—which require stowage “separated from acids,” “separated from alkaline compounds”, and “separated from cyanides,” respectively—to column 10B of the HMT, as shown in Table 3, below.

Consistent with changes adopted in Amendment 39-18 of the IMDG Code, PHMSA is adding existing stowage codes 12 and 25 to entries in the HMT. Vessel stowage code 12 requires keeping the cargo as cool as reasonably practicable. Vessel stowage code 25 requires protecting shipments from sources of heat. PHMSA is adding codes 12 and 25 to Nitrocellulose with alcohol with not less than 25 percent alcohol by mass, and with not more than 12.6 percent nitrogen, by dry mass, UN 2556. The addition of these two vessel stowage codes will help ensure that nitrocellulose is stowed so as to keep it as cool as practicable during transportation and to avoid possible loss of stabilization material in packages. Additionally, PHMSA is adding stowage code 25 to Dipropylamine, UN 2383 consistent with changes adopted in Amendment 39-18 of the IMDG Code.