['Toxic Substances Control Act - EPA']

['Toxic Substances - EPA', 'Toxic Subtances Control Act - EPA']

12/09/2022

...

(a) Scope�(1) Applicability. This section is intended to meet the testing requirements of the Toxic Substances Control Act (TSCA) (15 U.S.C. 2601).

(a)(2) Source. The source material used in developing this TSCA test guideline is the Office of Pollution Prevention, Pesticides and Toxics (OPPTS) harmonized test guideline 830.7840 (March 1998, revised final guideline). This source is available at the address in paragraph (f) of this section.

(b) Introductory information�(1) Prerequisites. Suitable analytical method, structural formula, vapor pressure curve, dissociation constant, and hydrolysis independence of pH (preliminary test).

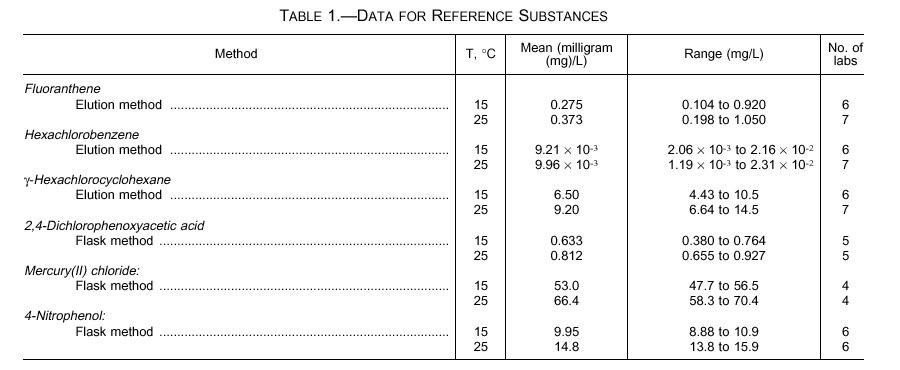

(b)(2) Coefficient of variation. The coefficient of variation on the mean values reported by the participants of the Organization for Economic Cooperation and Development (OECD) Laboratory Intercomparison Testing, Part I, 1979, appeared to be dependent on the chemicals tested and the test temperatures; it ranges from 0.05 to 0.34 for the column elution method, and from 0.03 to 1.12 for the flask method.

(b)(3) Qualifying statements. (i) The method is not applicable to volatile substances. Care should be taken that the substances examined are as pure as possible and stable in water. It must be ascertained that the identity of the substance is not changed during the procedure.

(ii) The column elution method is not suitable for volatile substances. The carrier material used here may not yet be optimal. This method is intended for material with solubilities below approximately 10-2 gram/Liter (g/L).

(iii) The flask method is intended for materials with solubility above 10-2 g/L. It is not applicable to volatile substances; this method may pose difficulties in the case of surface-active materials.

(c) Method�(1) Introduction, purpose, scope, relevance, application, and limits of test. (i) A solution is a homogeneous mixture of different substances in a solvent. The particle sizes of the dispersed substances are of the same magnitude as molecules and ions; therefore, the smallest volumes which can be obtained from a solution are always of uniform composition.

(ii) Solubility in water is a significant parameter because:

(A) The spatial and temporal movement (mobility) of a substance is largely determined by its solubility in water.

(B) Water soluble substances gain ready access to humans and other living organisms.

(C) The knowledge of the solubility in water is a prerequisite for testing biological degradation and bioaccumulation in water and for other tests.

(iii) No single method is available to cover the whole range of solubilities in water, from relatively soluble to very low-soluble chemicals. A general test guideline for the determination of the solubility in water must include methods which cover the whole range of water soluble substances. Therefore, this section includes two methods:

(A) One which applies to substances with low solubilities (<10-2 g/L), referred to as the "column elution method."

(B) The other which applies to substances with higher solubilities (<10-2 g/L), referred to as the "flask method."

(c)(2) Definition. The solubility in water of a substance is specified by the saturation mass concentration of the substance in water and is a function of temperature. The solubility in water is specified in units of weight per volume of solution. The SI-unit is killogram/meter (kg/ m)3; g/L may also be used.

(c)(3) Reference substances. The reference substances need not be employed in all cases when investigating a new substance. They are provided primarily so that calibration of the method may be performed from time to time and to offer the chance to compare the results when another method is applied. The values presented in table 1 of this section are not necessarily representative of the results which can be obtained with this test method as they have been derived from an earlier version of the test method.

(c)(4) Principle of the test methods. The approximate amount of the sample and the time necessary to achieve the saturation mass concentration should be determined in a simple preliminary test.

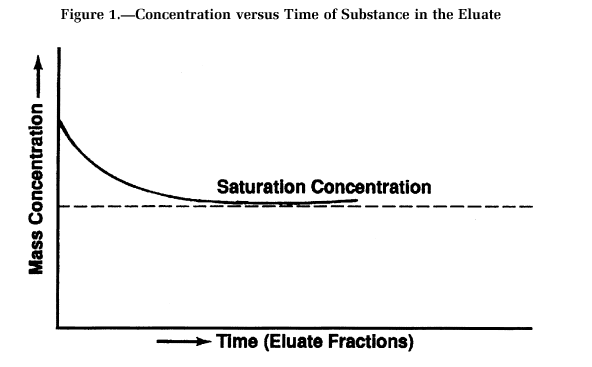

(c)(4)(i) Column elution method. This method is based on the elution of a test substance with water from a microcolumn which is charged with an inert carrier material such as glass beads, silica gel, or sand, and an excess of test substance. The water solubility is determined when the mass concentration of the eluate is constant. This is shown by a concentration plateau as a function of time in the following figure 1:

(c)(4)(ii) Flask method. In this method, the substance (solids must be pulverized) is dissolved in water at a temperature somewhat above the test temperature. When saturation is achieved, the mixture is cooled and kept at the test temperature, stirring as long as necessary to reach equilibrium. Such a procedure is described in the reference listed in paragraph (f)(2) of this section. Subsequently, the mass concentration of the substance in the aqueous solution, which must not contain any undissolved particles, is determined by a suitable analytical method.

(c)(5) Quality criteria�(i) Repeatability. For the column elution method <30% is acceptable; for the flask method <15% should be observed.

(c)(5)(ii) Sensitivity. This depends upon the method of analysis, but mass concentration determinations down to at least 10-6 g/L can be determined.

(c)(5)(iii) Specificity. These methods should only be applied to:

(A) Pure substance.

(B) Substances that are stable in water.

(C) Slightly soluble substances, i.e. <10-2 g/L for the column elution method.

(D) Organic substances for the column elution method.

(c)(5)(iv) Possibility of standardization. These methods can be standardized.

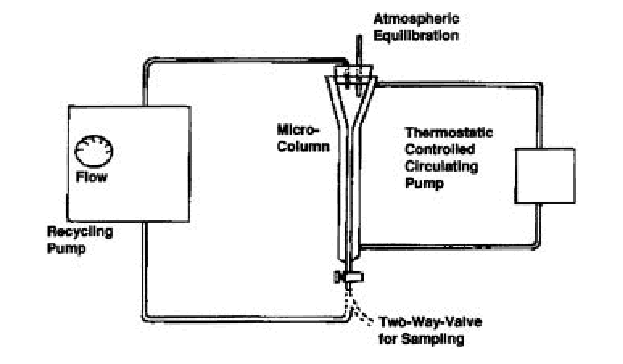

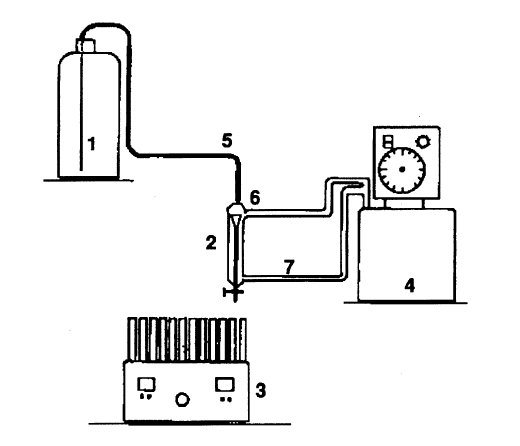

(d) Description of the test procedures�(1) Preparations�(i) Apparatus�(A) Column elution method. (1) The schematic arrangement of the system is presented in the following figure 2:

Figure 2.�Schematic Test Arrangement

(2) Although any size is acceptable, provided it meets the criteria for reproducibility and sensitivity. The column should provide for a head space of at least five bed-volumes of water and a minimum of five samples. Alternatively, the size can be reduced if make-up solvent is employed to replace the initial five bed-volumes removed with impurities. A suitable microcolumn is shown in the following figure 3:

(3) The column should be connected to a recycling pump capable of controlling flows of approximately 25 mL/hours (h). The pump is connected with polytetrafluoroethylene and/or glass connections. The column and pump, when assembled, should have provision for sampling the effluent and equilibrating the head space at atmospheric pressure. The column material is supported with a small (5 millimeter (mm)) plug of glass wool, which must also serve to filter particles.

(B) Flask method. For the flask method, the following material is needed:

(1) Normal laboratory glassware and instrumentation.

(2) A device suitable for the agitation of solutions under controlled constant temperatures.

(3) A centrifuge (preferably thermostatted), if required with emulsions.

(4) Equipment for analytical determinations.

(d)(2) Reagents. The substance to be tested should be as pure as possible, particularly in the flask method where purification is not provided. The carrier material for the column elution method should be inert. Possible materials which can be employed are glass beads and silica. A suitable volatile solvent of analytical reaction quality should be used to apply the test substance to the carrier material. Double distilled water from glass or quartz apparatus should be employed as the eluent or solvent. Water directly from an ion exchanger must not be used.

(d)(3) Test conditions. The test is preferably run at 20 � 0.5 �C (293 �K). If temperature dependence is suspected in the solubility (?3%/ �C), two other temperatures should also be used-both differing from each other and the initially chosen temperature by 10�C. In this case the temperature control should be � 0.1�C. One of these additional temperatures should be below the initial temperature. The chosen temperature(s) should be kept constant in all parts of the equipment (including the leveling vessel).

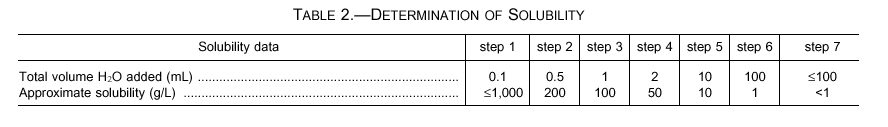

(d)(4) Performance of the tests�(i) Preliminary test. (A) To approximately 0.1 g of the sample (solid substances must be pulverized) in a glass-stoppered 10 milliliter (mL) graduated cylinder, increasing volumes of distilled water at room temperature are added according to the steps shown in Table 2 of this section:

(B) After each addition of water to give the indicated total volume, the mixture is shaken vigorously for 10 min and is visually checked for any undissolved parts of the sample. If, after a total of 10 mL of water has been added (step 5), the sample or parts of it remain undissolved, the contents of the measuring cylinder is transferred to a 100 mL measuring cylinder which is then filled up with water to 100 mL (step 6) and shaken. At lower solubilities the time required to dissolve a substance can be considerably long (24 h should be allowed). The approximate solubility is given in the table under that volume of added water in which complete dissolution of the sample occurs. If the substance is still apparently insoluble, further dilution should be undertaken to ascertain whether the column elution or flask solubility method should be used.

(d)(4)(ii) Column elution�(A) Apparatus. (1) The equipment is arranged as shown in figures 2 and 3 in paragraphs (d)(1)(i)(A)(1) and (d)(1)(i)(A)(2) of this section. Approximately 600 milligrams (mg) of carrier material is weighed and transferred to a 50 mL round-bottom flask. A suitable, weighed amount of test substance is dissolved in the chosen solvent, and an appropriate amount of the test substance solution is added to the carrier material. The solvent must be completely evaporated, e.g. in a rotary evaporator; otherwise water saturation of the carrier is not achieved due to partition effects on the surface of the carrier.

(2) The loading of carrier material may cause problems (erroneous results) if the test substance is deposited as an oil or a different crystal phase. The problem should be examined experimentally.

(3) The loaded carrier material is allowed to soak for about 2 h in approximately 5 mL of water, and then the suspension is added to the microcolumn. Alternatively, dry loaded carrier material may be poured in the microcolumn, which has been filled with water and then equilibrated for approximately 2 h.

(B) Test procedure. The elution of the substance from the carrier material can be carried out in two different ways: Leveling vessel or circulating pump. The two principles should be used alternatively.

(1) Leveling vessel, see figure 3 in paragraph (d)(1)(i)(A)(2) and figure 4 in paragraph (d)(4)(iii) of this section.

(i) The connection to the leveling vessel is made by using a ground glass joint which is connected by teflon tubing. It is recommended that a flow rate of approximately 25 mL/h be used. Successive eluate fractions should be collected and analyzed by the chosen method.

(ii) Fractions from the middle eluate range where the concentrations are constant (� 30%) in at least five consecutive fractions are used to determine the solubility in water.

(iii) A second run is to be performed at half the flow rate of the first. If the results of the two runs are in agreement, the test is satisfactory; if there is a higher apparent solubility with the lower flow rate, then the halving of the flow rate must continue until two successive runs give the same solubility.

(2) Circulating pump, see figures 2 and 3 in paragraphs (d)(1)(i)(A)(1) and (d)(1)(i)(A)(2) of this section.

(i) With this apparatus, the microcolumn must be modified. A stopcock with 2-way action must be used, see figure 3 in paragraph (d)(1)(i)(A)(2) of this section). The circulating pump can be, e.g. a peristaltic pump (be careful that no contamination and/or adsorption occurs with the tube material) or a membrane pump.

(ii) The flow through the column is started. It is recommended that a flow rate of approximately 25 mL/h be used (approximately 10 bed volumes per h for the described column). The first five-bed volumes (minimum) are discarded to remove water soluble impurities.

(iii) Following this, the recycling pump is connected and the apparatus allowed to run until equilibration is established, as defined by five successive samples whose concentrations do not differ by more than 30% in a random fashion (see paragraph (f)(2) of this section). These samples should be separated from each other by time intervals corresponding to the passage of at least 10 bed-volumes of the eluent.

(3) In both cases (using a circulation pump or a leveling vessel) the fractions should be checked for the presence of colloidal matter by examination for the Tyndall effect (light scattering). Presence of such particles invalidates the results, and the test should be repeated with improvements in the filtering action of the column. The pH of each sample should be recorded. A second run should be performed at the same temperature.

(d)(4)(iii) Flask method: Test procedure. The quantity of material necessary to saturate the desired volume of water is estimated from the preliminary test. The volume of water required will depend on the analytical method and the solubility range. About five times the quantity of material determined in paragraph (d)(4)(i)(A) of this section is weighed into each of three glass vessels fitted with glass stoppers (e.g. centrifuge tubes, flasks). The chosen volume of water is added to each vessel, and the vessels are tightly stoppered. The closed vessels are then agitated at 30�C. (A shaking or stirring device capable of operating at constant temperature should be used, e.g. magnetic stirring in a thermostatically controlled water bath.) After 1 day, one of the vessels is removed and re-equilibrated for 24 h at the test temperature with occasional shaking. The contents of the vessel are then centrifuged at the test temperature, and the concentration of compound in the clear aqueous phase is determined by a suitable analytical method. The other two flasks are treated similarly after initial equilibration at 30�C for 2 and 3 days, respectively. If the concentration results from at least the last two vessels agree with the required reproducibility, the test is satisfactory. The whole test should be repeated, using longer equilibration times if the results from vessels one, two, and three show a tendency to increasing values. The arrangement of the apparatus is shown in the following figure 4:

Figure 4.�Test Arrangement for the Determination of Solubility in Water of Slightly Soluble, Low Volatility Organic Substances

1 = Leveling vessel (e.g. 2.5 L chemical flask)

2 = Column (see figure 3 in paragraph (d)(1)(i)(A)(2) of this section)

3 = Fraction accumulator

4 = Thermostat

5 = Teflon tubing

6 = Glass stopper

7 = Water line (between thermostat and column, inner diameter: approximately 8 mm)

(d)(4)(iv) Analysis. A substance-specific analytical method is required for these determinations, since small amounts of soluble impurities can cause large errors in the measured solubility. Examples of such methods are gas or liquid chromatography, titration methods, photometric methods, and polarographic methods.

(e) Data and reporting�(1) Column elution method�(i) Treatment of results. The mean value from at least five consecutive samples taken from the saturation plateau (figure 1 in paragraph (c)(4)(i) of this section) should be determined for each run, as should the standard deviation. A comparison should be made between the two means to ensure that they agree with a repeatability of less than 30%.

(e)(1)(ii) Test report. The report should contain an indication of the results of the preliminary test plus the following information:

(A) The individual concentrations, flow rates and pHs of each samples.

(B) The means and standard deviations from at least five samples from the saturation plateau of each run.

(C) The average of the two successive, acceptable runs.

(D) The temperature of the runs.

(E) The method of analysis employed.

(F) The nature of the carrier material employed.

(G) Loading of carrier material.

(H) Solvent used.

(I) Statement that the identity of the substance in the saturated solution has been proved.

(e)(2) Flask method�(i) Treatment of results. The individual results should be given for each of the three flasks and those results deemed to be constant (repeatability <15%) should be averaged and given in units of mass per volume of solution. This may require the conversion of mass units to volume units, using the density when the solubility is very high (100 g/L).

(e)(2)(ii) Test report. The report should include the following information:

(A) The individual analytical determinations and the average where more than one value was determined for each flask.

(B) The average of the value for the different flasks which were in agreement.

(C) The test temperature.

(D) The analytical method employed.

(f) References. For additional information on this test guideline, the following references should be consulted. These references are available at the addresses in �700.17(b)(1) and (2) of this chapter.

(1) Veith, G.D. and V.M. Comstock. Apparatus for continuously saturating water with hydrophobic organic chemicals. Journal of the Fishing Research Board of Canada 32:1849-1851 (1975).

(2) Organization for Economic Cooperation and Development, Guidelines for The Testing of Chemicals, OECD 105, Water Solubility (Column Elution Method�Shake Flask Method), OECD, Paris, France (1981).

[65 FR 78760, Dec. 15, 2000; 77 FR 46293, Aug. 3, 2012]

['Toxic Substances Control Act - EPA']

['Toxic Substances - EPA', 'Toxic Subtances Control Act - EPA']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.