['Air Programs']

['Air Quality']

06/23/2023

...

(a) Compliance schedule. (1) The owner or operator shall comply with this section no later than the implementation date specified in �65.1(f).

(2) The use of monitoring data generated before the regulated source became subject to the referencing subpart to qualify initially for less frequent monitoring is governed by the provisions of �65.104(b)(6).

(b) Leak detection. Unless otherwise specified in �65.102(b) or paragraph (e) of this section, the owner or operator shall monitor all valves at the intervals specified in paragraphs (b)(3) and/or (b)(4) of this section and shall comply with all other provisions of this section.

(1) Monitoring method. The valves shall be monitored to detect leaks by the method specified in �65.104(b) and (c).

(2) Instrument reading that defines a leak. The instrument reading that defines a leak is 500 parts per million or greater.

(3) Monitoring frequency. The owner or operator shall monitor valves for leaks at the intervals specified in paragraphs (b)(3)(i) through (v) of this section and shall keep the record specified in paragraph (b)(3)(vi) of this section.

(i) If at least the greater of two valves or 2 percent of the valves in a process unit leak, as calculated according to paragraph (c) of this section, the owner or operator shall monitor each valve once per month.

(ii) At process units with less than the greater of two leaking valves or 2 percent leaking valves, the owner or operator shall monitor each valve once each quarter except as provided in paragraphs (b)(3)(iii) through (v) of this section. Monitoring data generated before the regulated source became subject to the referencing subpart and meeting the criteria of either �65.104(b)(1) through (5) or �65.104(b)(6) may be used to qualify initially for less frequent monitoring under paragraphs (b)(3)(iii) through (v) of this section.

(iii) At process units with less than 1 percent leaking valves, the owner or operator may elect to monitor each valve once every 2 quarters.

(iv) At process units with less than 0.5 percent leaking valves, the owner or operator may elect to monitor each valve once every 4 quarters.

(v) At process units with less than 0.25 percent leaking valves, the owner or operator may elect to monitor each valve once every 2 years.

(vi) The owner or operator shall keep a record of the monitoring schedule for each process unit.

(4) Valve subgrouping. For a process unit or a group of process units to which this subpart applies, an owner or operator may choose to subdivide the valves in the applicable process unit or group of process units and apply the provisions of paragraph (b)(3) of this section to each subgroup. If the owner or operator elects to subdivide the valves in the applicable process unit or group of process units, then the provisions of paragraphs (b)(4)(i) through (viii) of this section apply.

(i) The overall performance of total valves in the applicable process unit or group of process units to be subdivided shall be less than 2 percent leaking valves, as detected according to paragraphs (b)(1) and (2) of this section and as calculated according to paragraphs (c)(1)(ii) and (c)(2) of this section.

(ii) The initial assignment or subsequent reassignment of valves to subgroups shall be governed by the following provisions:

(A) The owner or operator shall determine which valves are assigned to each subgroup. Valves with less than 1 year of monitoring data or valves not monitored within the last 12 months must be placed initially into the most frequently monitored subgroup until at least 1 year of monitoring data have been obtained.

(B) Any valve or group of valves can be reassigned from a less frequently monitored subgroup to a more frequently monitored subgroup provided that the valves to be reassigned were monitored during the most recent monitoring period for the less frequently monitored subgroup. The monitoring results must be included with that less frequently monitored subgroup's associated percent leaking valves calculation for that monitoring event.

(C) Any valve or group of valves can be reassigned from a more frequently monitored subgroup to a less frequently monitored subgroup provided that the valves to be reassigned have not leaked for the period of the less frequently monitored subgroup (for example, for the last 12 months, if the valve or group of valves is to be reassigned to a subgroup being monitored annually). Nonrepairable valves may not be reassigned to a less frequently monitored subgroup.

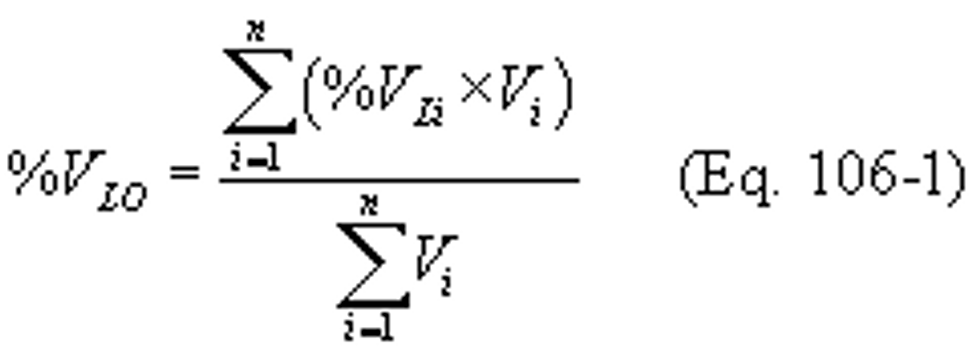

(iii) The owner or operator shall determine every 6 months if the overall performance of total valves in the applicable process unit or group of process units is less than 2 percent leaking valves and so indicate the performance in the next periodic report. If the overall performance of total valves in the applicable process unit or group of process units is 2 percent leaking valves or greater, the owner or operator shall no longer subgroup and shall revert to the program required in paragraphs (b)(1) through (3) of this section for that applicable process unit or group of process units. An owner or operator can again elect to comply with the valve subgrouping procedures of paragraph (b)(4) of this section if future overall performance of total valves in the process unit or group of process units is again less than 2 percent. The overall performance of total valves in the applicable process unit or group of process units shall be calculated as a weighted average of the percent leaking valves of each subgroup according to Equation 106-1 of this section:

Where:

%VLO = Overall performance of total valves in the applicable process unit or group of process units.

%VLi = Percent leaking valves in subgroup i, most recent value calculated according to the procedures in paragraphs (c)(1)(ii) and (c)(2) of this section.

Vi = Number of valves in subgroup i.

n = Number of subgroups.

(iv) The owner or operator shall maintain the following records:

(A) Which valves are assigned to each subgroup;

(B) Monitoring results and calculations made for each subgroup for each monitoring period;

(C) Which valves are reassigned, the last monitoring result prior to reassignment, and when they were reassigned; and

(D) The results of the semiannual overall performance calculation required in paragraph (b)(4)(iii) of this section.

(v) The owner or operator shall notify the Administrator no later than 30 days prior to the beginning of the next monitoring period of the decision to begin or end subgrouping valves. The notification shall identify the participating process units and the number of valves assigned to each subgroup, if applicable. The notification may be included in a periodic report if the periodic report is submitted no later than 30 days prior to the beginning of the next monitoring period.

(vi) The owner or operator shall submit in the periodic reports the following information:

(A) Total number of valves in each subgroup; and

(B) Results of the semiannual overall performance calculation required by paragraph (b)(4)(iii) of this section.

(vii) To determine the monitoring frequency for each subgroup, the calculation procedures of paragraph (c)(2) of this section shall be used.

(viii) Except for the overall performance calculations required by paragraphs (b)(4)(i) and (iii) of this section, each subgroup shall be treated as if it were a separate process unit for the purposes of applying the provisions of this section.

(c) Percent leaking valves calculation�(1) Calculation basis and procedures. (i) The owner or operator shall decide no later than the implementation date of this part or upon revision of an operating permit whether to calculate percent leaking valves on a process unit or group of process units basis. Once the owner or operator has decided, all subsequent percentage calculations shall be made on the same basis, and this shall be the basis used for comparison with the subgrouping criteria specified in paragraph (b)(4)(i) of this section.

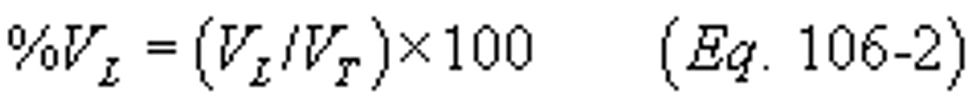

(ii) The percent leaking valves for each monitoring period for each process unit or valve subgroup, as provided in paragraph (b)(4) of this section, shall be calculated using Equation 106-2 of this section:

Where:

%VL = Percent leaking valves.

VL = Number of valves found leaking, including those valves found leaking pursuant to paragraphs (d)(2)(iii)(A) and (d)(2)(iii)(B) of this section and excluding nonrepairable valves as provided in paragraph (c)(3) of this section.

VT = The sum of the total number of valves monitored.

(2) Calculation for monitoring frequency. When determining monitoring frequency for each process unit or valve subgroup subject to monthly, quarterly, or semiannual monitoring frequencies, the percent leaking valves shall be the arithmetic average of the percent leaking valves from the last two monitoring periods. When determining monitoring frequency for each process unit or valve subgroup subject to annual or biennial (once every 2 years) monitoring frequencies, the percent leaking valves shall be the arithmetic average of the percent leaking valves from the last three monitoring periods.

(3) Nonrepairable valves. (i) Nonrepairable valves shall be included in the calculation of percent leaking valves the first time the valve is identified as leaking and nonrepairable and as required to comply with paragraph (c)(3)(ii) of this section. Otherwise, a number of nonrepairable valves (identified and included in the percent leaking valves calculation in a previous period) up to a maximum of 1 percent of the total number of valves in regulated material service at a process unit may be excluded from calculation of percent leaking valves for subsequent monitoring periods.

(ii) If the number of nonrepairable valves exceeds 1 percent of the total number of valves in regulated material service at a process unit, the number of nonrepairable valves exceeding 1 percent of the total number of valves in regulated material service shall be included in the calculation of percent leaking valves.

(d) Leak repair. (1) If a leak is determined pursuant to paragraph (b), (e)(1), or (e)(2) of this section, then the leak shall be repaired using the procedures in �65.105, as applicable.

(2) After a leak determined under paragraph (b) or (e)(2) of this section has been repaired, the valve shall be monitored at least once within the first 3 months after its repair. The monitoring required by paragraph (d) of this section is in addition to the monitoring required to satisfy the definition of repair.

(i) The monitoring shall be conducted as specified in �65.104(b) and (c), as appropriate, to determine whether the valve has resumed leaking.

(ii) Periodic monitoring required by paragraph (b) of this section may be used to satisfy the requirements of paragraph (d) of this section if the timing of the monitoring period coincides with the time specified in paragraph (d) of this section. Alternatively, other monitoring may be performed to satisfy the requirements of paragraph (d) of this section regardless of whether the timing of the monitoring period for periodic monitoring coincides with the time specified in paragraph (d) of this section.

(iii) If a leak is detected by monitoring that is conducted under paragraph (d)(2) of this section, the owner or operator shall comply with the following provisions to determine whether that valve must be counted as a leaking valve for purposes of paragraph (c)(1)(ii) of this section:

(A) If the owner or operator elected to use periodic monitoring required by paragraph (b) of this section to satisfy the requirements of paragraph (d)(2) of this section, then the valve shall be counted as a leaking valve.

(B) If the owner or operator elected to use other monitoring, prior to the periodic monitoring required by paragraph (b) of this section, to satisfy the requirements of paragraph (d)(2) of this section, then the valve shall be counted as a leaking valve unless it is repaired and shown by periodic monitoring not to be leaking.

(e) Special provisions for valves � (1) Unsafe-to-monitor valves. Any valve that is designated as described in �65.103(c)(1) as an unsafe-to-monitor valve is exempt from the requirements of paragraph (b) and (d)(2) of this section, and the owner or operator shall monitor the valve according to the written plan specified in �65.103(c)(4).

(2) Difficult-to-monitor valves. Any valve that is designated as described in �65.103(c)(2) as a difficult-to-monitor valve is exempt from the requirements of paragraph (b) of this section, and the owner or operator shall monitor the valve according to the written plan specified in �65.103(c)(4).

(3) Less than 250 valves. Any equipment located at a plant site with fewer than 250 valves in regulated material service is exempt from the requirements for monthly monitoring specified in paragraph (b)(3)(i) of this section. Instead, the owner or operator shall monitor each valve in regulated material service for leaks once each quarter or comply with paragraph (b)(3)(iii), (iv), or (v) of this section except as provided in paragraphs (e)(1) and (2) of this section.

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.