['Air Programs']

['Hazardous Air Pollutants']

12/23/2024

...

(a) As an alternative to meeting the requirements of §63.7500 for PM (or TSM), HCl, or mercury on a boiler or process heater-specific basis, if you have more than one existing boiler or process heater in any subcategories located at your facility, you may demonstrate compliance by emissions averaging, if your averaged emissions are not more than 90 percent of the applicable emission limit, according to the procedures in this section. You may not include new boilers or process heaters in an emissions average.

(b) For a group of two or more existing boilers or process heaters in the same subcategory that each vent to a separate stack, you may average PM (or TSM), HCl, or mercury emissions among existing units to demonstrate compliance with the limits in Table 2 or 15 to this subpart as specified in paragraphs (b)(1) through (3) of this section, if you satisfy the requirements in paragraphs (c) through (g) of this section.

(1) You may average units using a CEMS or PM CPMS for demonstrating compliance.

(2) For mercury and HCl, averaging is allowed as follows:

(i) You may average among units in any of the solid fuel subcategories.

(ii) You may average among units in any of the liquid fuel subcategories.

(iii) You may average among units in a subcategory of units designed to burn gas 2 (other) fuels.

(iv) You may not average across the units designed to burn liquid, units designed to burn solid fuel, and units designed to burn gas 2 (other) subcategories.

(3) For PM (or TSM), averaging is only allowed between units within each of the following subcategories and you may not average across subcategories:

(i) Units designed to burn coal/solid fossil fuel.

(ii) Stokers/sloped grate/other units designed to burn kiln dried biomass/bio-based solids.

(iii) Stokers/sloped grate/other units designed to burn wet biomass/bio-based solids.

(iv) Fluidized bed units designed to burn biomass/bio-based solid.

(v) Suspension burners designed to burn biomass/bio-based solid.

(vi) Dutch ovens/pile burners designed to burn biomass/bio-based solid.

(vii) Fuel Cells designed to burn biomass/bio-based solid.

(viii) Hybrid suspension/grate burners designed to burn wet biomass/bio-based solid.

(ix) Units designed to burn heavy liquid fuel.

(x) Units designed to burn light liquid fuel.

(xi) Units designed to burn liquid fuel that are non-continental units.

(xii) Units designed to burn gas 2 (other) gases.

(c) For each existing boiler or process heater in the averaging group, the emission rate achieved during the initial compliance test for the HAP being averaged must not exceed the emission level that was being achieved on April 1, 2013 or the control technology employed during the initial compliance test must not be less effective for the HAP being averaged than the control technology employed on April 1, 2013.

(d) The averaged emissions rate from the existing boilers and process heaters participating in the emissions averaging option must not exceed 90 percent of the limits in Table 2 or 15 to this subpart at all times the affected units are subject to numeric emission limits following the compliance date specified in §63.7495.

(e) You must demonstrate initial compliance according to paragraph (e)(1) or (2) of this section using the maximum rated heat input capacity or maximum steam generation capacity of each unit and the results of the initial performance tests or fuel analysis.

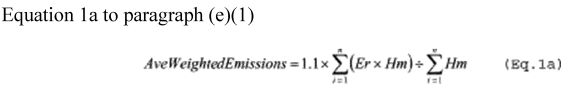

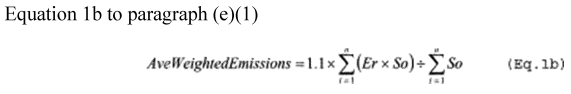

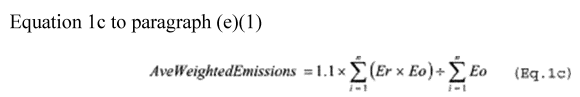

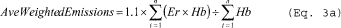

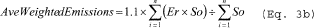

(1) You must use Equation 1a or 1b or 1c to this paragraph (e)(1) to demonstrate that the PM (or TSM), HCl, or mercury emissions from all existing units participating in the emissions averaging option for that pollutant do not exceed the emission limits in Table 2 or 15 to this subpart. Use Equation 1a if you are complying with the emission limits on a heat input basis, use Equation 1b if you are complying with the emission limits on a steam generation (output) basis, and use Equation 1c if you are complying with the emission limits on a electric generation (output) basis.

Where:

AveWeightedEmissions = Average weighted emissions for PM (or TSM), HCl, or mercury, in units of pounds per million Btu of heat input.

Er = Emission rate (as determined during the initial compliance demonstration) of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per million Btu of heat input. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM using the applicable equation in §63.7530(c).

Hm = Maximum rated heat input capacity of unit, i, in units of million Btu per hour.

n = Number of units participating in the emissions averaging option.

1.1 = Required discount factor.

Where:

AveWeightedEmissions = Average weighted emissions for PM (or TSM), HCl, or mercury, in units of pounds per million Btu of steam output.

Er = Emission rate (as determined during the initial compliance demonstration) of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per million Btu of steam output. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM using the applicable equation in §63.7530(c). If you are taking credit for energy conservation measures from a unit according to §63.7533, use the adjusted emission level for that unit, Eadj, determined according to §63.7533 for that unit.

So = Maximum steam output capacity of unit, i, in units of million Btu per hour, as defined in §63.7575.

n = Number of units participating in the emissions averaging option.

1.1 = Required discount factor.

Where:

AveWeightedEmissions = Average weighted emissions for PM (or TSM), HCl, or mercury, in units of pounds per megawatt hour.

Er = Emission rate (as determined during the initial compliance demonstration) of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per megawatt hour. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM using the applicable equation in §63.7530(c). If you are taking credit for energy conservation measures from a unit according to §63.7533, use the adjusted emission level for that unit, Eadj, determined according to §63.7533 for that unit.

Eo = Maximum electric generating output capacity of unit, i, in units of megawatt hour, as defined in §63.7575.

n = Number of units participating in the emissions averaging option.

1.1 = Required discount factor.

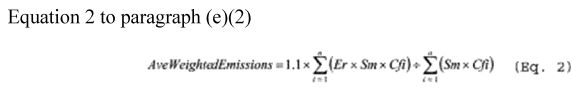

(2) If you are not capable of determining the maximum rated heat input capacity of one or more boilers that generate steam, you may use Equation 2 to this paragraph (e)(2) as an alternative to using Equation 1a of paragraph (e)(1) of this section to demonstrate that the PM (or TSM), HCl, or mercury emissions from all existing units participating in the emissions averaging option do not exceed the emission limits for that pollutant in Table 2 or 15 to this subpart that are in pounds per million Btu of heat input.

Where:

AveWeightedEmissions = Average weighted emission level for PM (or TSM), HCl, or mercury, in units of pounds per million Btu of heat input.

Er = Emission rate (as determined during the most recent compliance demonstration) of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per million Btu of heat input. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM using the applicable equation in §63.7530(c).

Sm = Maximum steam generation capacity by unit, i, in units of pounds per hour.

Cfi = Conversion factor, calculated from the most recent compliance test, in units of million Btu of heat input per pounds of steam generated for unit, i.

1.1 = Required discount factor.

(f) After the initial compliance demonstration described in paragraph (e) of this section, you must demonstrate compliance on a monthly basis determined at the end of every month (12 times per year) according to paragraphs (f)(1) through (3) of this section. The first monthly period begins on the compliance date specified in §63.7495. If the affected source elects to collect monthly data for up the 11 months preceding the first monthly period, these additional data points can be used to compute the 12-month rolling average in paragraph (f)(3) of this section.

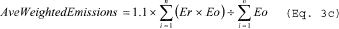

(1) For each calendar month, you must use Equation 3a or 3b or 3c of this section to calculate the average weighted emission rate for that month. Use Equation 3a and the actual heat input for the month for each existing unit participating in the emissions averaging option if you are complying with emission limits on a heat input basis. Use Equation 3b and the actual steam generation for the month if you are complying with the emission limits on a steam generation (output) basis. Use Equation 3c and the actual electrical generation for the month if you are complying with the emission limits on an electrical generation (output) basis.

Where:

AveWeightedEmissions = Average weighted emission level for PM (or TSM), HCl, or mercury, in units of pounds per million Btu of heat input, for that calendar month.

Er = Emission rate (as determined during the most recent compliance demonstration) of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per million Btu of heat input. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM according to Table 6 to this subpart.

Hb = The heat input for that calendar month to unit, i, in units of million Btu.

n = Number of units participating in the emissions averaging option.

1.1 = Required discount factor.

Where:

AveWeightedEmissions = Average weighted emission level for PM (or TSM), HCl, or mercury, in units of pounds per million Btu of steam output, for that calendar month.

Er = Emission rate (as determined during the most recent compliance demonstration) of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per million Btu of steam output. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM according to Table 6 to this subpart. If you are taking credit for energy conservation measures from a unit according to §63.7533, use the adjusted emission level for that unit, Eadj, determined according to §63.7533 for that unit.

So = The steam output for that calendar month from unit, i, in units of million Btu, as defined in §63.7575.

n = Number of units participating in the emissions averaging option.

1.1 = Required discount factor.

Where:

AveWeightedEmissions = Average weighted emission level for PM (or TSM), HCl, or mercury, in units of pounds per megawatt hour, for that calendar month.

Er = Emission rate (as determined during the most recent compliance demonstration) of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per megawatt hour. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM according to Table 6 to this subpart. If you are taking credit for energy conservation measures from a unit according to §63.7533, use the adjusted emission level for that unit, Eadj, determined according to §63.7533 for that unit.

Eo = The electric generating output for that calendar month from unit, i, in units of megawatt hour, as defined in §63.7575.

n = Number of units participating in the emissions averaging option.

1.1 = Required discount factor.

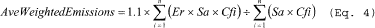

(2) If you are not capable of monitoring heat input, you may use Equation 4 of this section as an alternative to using Equation 3a of this section to calculate the average weighted emission rate using the actual steam generation from the boilers participating in the emissions averaging option.

Where:

AveWeightedEmissions = average weighted emission level for PM (or TSM), HCl, or mercury, in units of pounds per million Btu of heat input for that calendar month.

Er = Emission rate (as determined during the most recent compliance demonstration of PM (or TSM), HCl, or mercury from unit, i, in units of pounds per million Btu of heat input. Determine the emission rate for PM (or TSM), HCl, or mercury by performance testing according to Table 5 to this subpart, or by fuel analysis for HCl or mercury or TSM according to Table 6 to this subpart.

Sa = Actual steam generation for that calendar month by boiler, i, in units of pounds.

Cfi = Conversion factor, as calculated during the most recent compliance test, in units of million Btu of heat input per pounds of steam generated for boiler, i.

1.1 = Required discount factor.

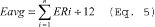

(3) Until 12 monthly weighted average emission rates have been accumulated, calculate and report only the average weighted emission rate determined under paragraph (f)(1) or (2) of this section for each calendar month. After 12 monthly weighted average emission rates have been accumulated, for each subsequent calendar month, use Equation 5 of this section to calculate the 12-month rolling average of the monthly weighted average emission rates for the current calendar month and the previous 11 calendar months.

Where:

Eavg = 12-month rolling average emission rate, (pounds per million Btu heat input)

ERi = Monthly weighted average, for calendar month “i” (pounds per million Btu heat input), as calculated by paragraph (f)(1) or (2) of this section.

(g) You must develop, and submit upon request to the applicable Administrator for review and approval, an implementation plan for emission averaging according to the following procedures and requirements in paragraphs (g)(1) through (4) of this section.

(1) If requested, you must submit the implementation plan no later than 180 days before the date that the facility intends to demonstrate compliance using the emission averaging option.

(2) You must include the information contained in paragraphs (g)(2)(i) through (vii) of this section in your implementation plan for all emission sources included in an emissions average:

(i) The identification of all existing boilers and process heaters in the averaging group, including for each either the applicable HAP emission level or the control technology installed as of January 31, 2013 and the date on which you are requesting emission averaging to commence;

(ii) The process parameter (heat input or steam generated) that will be monitored for each averaging group;

(iii) The specific control technology or pollution prevention measure to be used for each emission boiler or process heater in the averaging group and the date of its installation or application. If the pollution prevention measure reduces or eliminates emissions from multiple boilers or process heaters, the owner or operator must identify each boiler or process heater;

(iv) The test plan for the measurement of PM (or TSM), HCl, or mercury emissions in accordance with the requirements in §63.7520;

(v) The operating parameters to be monitored for each control system or device consistent with §63.7500 and Table 4, and a description of how the operating limits will be determined;

(vi) If you request to monitor an alternative operating parameter pursuant to §63.7525, you must also include:

(A) A description of the parameter(s) to be monitored and an explanation of the criteria used to select the parameter(s); and

(B) A description of the methods and procedures that will be used to demonstrate that the parameter indicates proper operation of the control device; the frequency and content of monitoring, reporting, and recordkeeping requirements; and a demonstration, to the satisfaction of the Administrator, that the proposed monitoring frequency is sufficient to represent control device operating conditions; and

(vii) A demonstration that compliance with each of the applicable emission limit(s) will be achieved under representative operating load conditions. Following each compliance demonstration and until the next compliance demonstration, you must comply with the operating limit for operating load conditions specified in Table 4 to this subpart.

(3) If submitted upon request, the Administrator shall review and approve or disapprove the plan according to the following criteria:

(i) Whether the content of the plan includes all of the information specified in paragraph (g)(2) of this section; and

(ii) Whether the plan presents sufficient information to determine that compliance will be achieved and maintained.

(4) The applicable Administrator shall not approve an emission averaging implementation plan containing any of the following provisions:

(i) Any averaging between emissions of differing pollutants or between differing sources; or

(ii) The inclusion of any emission source other than an existing unit in the same subcategories.

(h) For a group of two or more existing affected units, each of which vents through a single common stack, you may average PM (or TSM), HCl, or mercury emissions to demonstrate compliance with the limits for that pollutant in Table 2 or 15 to this subpart if you satisfy the requirements in paragraph (i) or (j) of this section.

(i) For a group of two or more existing units in the same subcategory, each of which vents through a common emissions control system to a common stack, that does not receive emissions from units in other subcategories or categories, you may treat such averaging group as a single existing unit for purposes of this subpart and comply with the requirements of this subpart as if the group were a single unit.

(j) For all other groups of units subject to the common stack requirements of paragraph (h) of this section, including situations where the exhaust of affected units are each individually controlled and then sent to a common stack, the owner or operator may elect to:

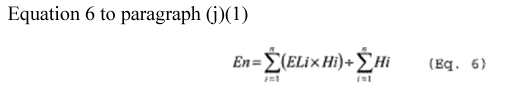

(1) Conduct performance tests according to procedures specified in §63.7520 in the common stack if affected units from other subcategories vent to the common stack. The emission limits that the group must comply with are determined by the use of Equation 6 to this paragraph (j)(1).

Where:

En = HAP emission limit, pounds per million British thermal units (lb/MMBtu) or parts per million (ppm).

ELi = Appropriate emission limit from Table 2 or 15 to this subpart for unit i, in units of lb/MMBtu or ppm.

Hi = Heat input from unit i, MMBtu.

(2) Conduct performance tests according to procedures specified in §63.7520 in the common stack. If affected units and non-affected units vent to the common stack, the non-affected units must be shut down or vented to a different stack during the performance test unless the facility determines to demonstrate compliance with the non-affected units venting to the stack; and

(3) Meet the applicable operating limit specified in §63.7540 and Table 8 to this subpart for each emissions control system (except that, if each unit venting to the common stack has an applicable opacity operating limit, then a single continuous opacity monitoring system may be located in the common stack instead of in each duct to the common stack).

(k) The common stack of a group of two or more existing boilers or process heaters in the same subcategories subject to paragraph (h) of this section may be treated as a separate stack for purposes of paragraph (b) of this section and included in an emissions averaging group subject to paragraph (b) of this section.

[76 FR 15664, Mar. 21, 2011, as amended at 78 FR 7168, Jan. 31, 2013; 80 FR 72809, Nov. 20, 2015; 87 FR 60843, Oct. 6, 2022]

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.