['Air Programs']

['Hazardous Air Pollutants']

02/27/2022

...

(a) General. For each emission point, the owner or operator shall meet three stages of compliance, with exceptions specified in this subpart. First, the owner or operator shall conduct a performance test or design evaluation to demonstrate either the performance of the control device or control technology being used or the uncontrolled total organic HAP emissions rate from a continuous process vent. Second, the owner or operator shall meet the requirements for demonstrating initial compliance (e.g., a demonstration that the required percent reduction or emissions limit is achieved). Third, the owner or operator shall meet the requirements for demonstrating continuous compliance through some form of monitoring (e.g., continuous monitoring of operating parameters).

(1) Large control devices and small control devices. A large control device is a control device that controls emission points with total emissions of 10 tons of organic HAP per year or more before control. A small control device is a control device that controls emission points with total emissions less than 10 tons of organic HAP per year before control.

(i) Large control devices. Owners or operators are required to conduct a performance test for a large control device. The establishment of parameter monitoring levels shall be based on data obtained during the required performance test.

(ii) Small control devices. Owners or operators are required to conduct a design evaluation for a small control device. An owner or operator may choose to conduct a performance test for a small control device and such a performance test shall follow the procedures specified in this section, as appropriate. Whenever a small control device becomes a large control device, the owner or operator shall conduct a performance test following the procedures specified in this section, as appropriate. Notification that such a performance test is required, the site-specific test plan, and the results of the performance test shall be provided to the Administrator as specified in �63.1417. Except as provided in �63.1415(a)(2), the parameter monitoring levels for small control devices shall be set based on the design evaluation required by paragraph (a)(3) of this section. Further, when setting the parameter monitoring level(s) based on the design evaluation, the owner or operator shall submit the information specified in �63.1417(d)(7) for review and approval as part of the Precompliance Report.

(iii) Uncontrolled continuous process vents. Owners or operators are required to conduct either a performance test or a design evaluation for continuous process vents that are not controlled through either a large or small control device.

(2) Performance tests. Performance tests shall be conducted under such conditions as the Administrator specifies to the owner or operator based on representative performance of the affected source for the period being tested and in accordance with the General Provisions at �63.7(a)(1), (a)(3), (d), (e)(2), (e)(4), (g), and (h), with the exceptions specified in paragraph (a)(1) of this section. Representative conditions exclude periods of startup and shutdown unless specified by the Administrator or an applicable subpart. The owner or operator may not conduct performance tests during periods of malfunction. The owner or operator must record the process information that is necessary to document operating conditions during the test and include in such record an explanation to support that such conditions represent normal operation. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests. Data shall be reduced in accordance with the EPA approved methods specified in this subpart or, if other test methods are used, the data and methods shall be validated according to the protocol in Method 301 of Appendix A of this part.

(i) Additional control devices not requiring performance tests. An owner or operator is not required to conduct a performance test when using one of the following control devices:

(A) A boiler or process heater with a design heat input capacity of 44 megawatts or greater.

(B) A boiler or process heater into which the vent stream is introduced with the primary fuel or is used as the primary fuel.

(C) A boiler or process heater burning hazardous waste for which the owner or operator:

(1) Has been issued a final permit under 40 CFR part 270 and complies with the requirements of 40 CFR part 266, subpart H; or

(2) Has certified compliance with the interim status requirements of 40 CFR part 266, subpart H.

(D) A hazardous waste incinerator for which the owner or operator has been issued a final permit under 40 CFR part 270 and complies with the requirements of 40 CFR part 264, subpart O, or has certified compliance with the interim status requirements of 40 CFR part 265, subpart O.

(E) A control device for which a performance test was already conducted for determining compliance with another regulation promulgated by the EPA, provided the test was conducted using the same Methods specified in this section, and either no deliberate process changes have been made since the test, or the owner or operator can demonstrate that the results of the performance test, with or without adjustments, reliably demonstrate compliance despite process changes. Parameter monitoring levels established based on such a performance test may be used for purposes of demonstrating continuous compliance with this subpart.

(ii) Exceptions to performance test requirements in the General Provisions. (A) Performance tests shall be conducted at maximum representative operating conditions achievable during either the 6-month period ending 2 months before the Notification of Compliance Status required by �63.1417(e) is due, or during the 6-month period surrounding the date of the performance test (i.e., the period beginning 3 months prior to the performance test and ending 3 months after the performance test). In achieving maximum representative operating conditions, an owner or operator is not required to cause damage to equipment, make a product that does not meet an existing specification for sale to a customer, or make a product in excess of demand.

(B) When �63.7(g) references the Notification of Compliance Status requirements in �63.9(h), the requirements in �63.1417(e) shall apply for purposes of this subpart.

(C) Performance tests shall be performed no later than 150 days after the compliance dates specified in this subpart (i.e., in time for the results to be included in the Notification of Compliance Status), rather than according to the time periods in �63.7(a)(2).

(3) Design evaluations. As provided in paragraph (a) of this section, a design evaluation may be conducted to demonstrate the organic HAP removal efficiency for a control device or control technology, or the uncontrolled total organic HAP emissions rate from a continuous process vent. As applicable, a design evaluation shall address the organic HAP emissions rate from uncontrolled continuous process vents, the composition and organic HAP concentration of the vent stream(s) entering a control device or control technology, the operating parameters of the emission point and any control device or control technology, and other conditions or parameters that reflect the performance of the control device or control technology or the organic HAP emission rate from a continuous process vent. A design evaluation also shall address other vent stream characteristics and control device operating parameters as specified in any one of paragraphs (a)(3)(i) through (vi) of this section, for controlled vent streams, depending on the type of control device that is used. If the vent stream(s) is not the only inlet to the control device, the efficiency demonstration also shall consider all other vapors, gases, and liquids, other than fuels, received by the control device.

(i) For a scrubber, the design evaluation shall consider the vent stream composition, constituent concentrations, liquid-to-vapor ratio, scrubbing liquid flow rate and concentration, temperature, and the reaction kinetics of the constituents with the scrubbing liquid. The design evaluation shall establish the design exhaust vent stream organic compound concentration level and include the additional information in paragraphs (a)(3)(i)(A) and (B) of this section for trays and a packed column scrubber:

(A) Type and total number of theoretical and actual trays; and

(B) Type and total surface area of packing for entire column, and for individual packed sections if column contains more than one packed section.

(ii) For a condenser, the design evaluation shall consider the vent stream flow rate, relative humidity, and temperature and shall establish the design outlet organic HAP compound concentration level, design average temperature of the condenser exhaust vent stream, and the design average temperatures of the coolant fluid at the condenser inlet and outlet. The temperature of the gas stream exiting the condenser shall be measured and used to establish the outlet organic HAP concentration.

(iii) For a carbon adsorption system that regenerates the carbon bed directly onsite in the control device, such as a fixed-bed adsorber, the design evaluation shall consider the vent stream flow rate, relative humidity, and temperature and shall establish the design exhaust vent stream organic compound concentration level, adsorption cycle time, number and capacity of carbon beds, type and working capacity of activated carbon used for carbon beds, design total regeneration stream mass or volumetric flow over the period of each complete carbon bed regeneration cycle, design carbon bed temperature after regeneration, design carbon bed regeneration time, and design service life of carbon. For vacuum desorption, the pressure drop shall be included.

(iv) For a carbon adsorption system that does not regenerate the carbon bed directly onsite in the control device, such as a carbon canister, the design evaluation shall consider the vent stream mass or volumetric flow rate, relative humidity, and temperature and shall establish the design exhaust vent stream organic compound concentration level, capacity of carbon bed, type and working capacity of activated carbon used for carbon bed, and design carbon replacement interval based on the total carbon working capacity of the control device and source operating schedule.

(v) For an enclosed combustion device with a minimum residence time of 0.5 seconds and a minimum temperature of 760 C, the design evaluation shall document that these conditions exist.

(vi) For a combustion control device that does not satisfy the criteria in paragraph (a)(3)(v) of this section, the design evaluation shall address the following characteristics, depending on the type of control device:

(A) For a thermal vapor incinerator, the design evaluation shall consider the autoignition temperature of the organic HAP, shall consider the vent stream flow rate, and shall establish the design minimum and average temperature in the combustion zone and the combustion zone residence time.

(B) For a catalytic vapor incinerator, the design evaluation shall consider the vent stream flow rate and shall establish the design minimum and average temperatures across the catalyst bed inlet and outlet.

(C) For a boiler or process heater, the design evaluation shall consider the vent stream flow rate, shall establish the design minimum and average flame zone temperatures and combustion zone residence time, and shall describe the method and location where the vent stream is introduced into the flame zone.

(4) Establishment of parameter monitoring levels. The owner or operator of a control device that has one or more parameter monitoring level requirements specified under this subpart, or specified under subparts referenced by this subpart, shall establish a maximum or minimum level, as denoted on Table 4 of this subpart, for each measured parameter using the procedures specified in paragraph (a)(4)(i) or (ii) of this section. Except as otherwise provided in this subpart, the owner or operator shall operate control devices such that the hourly average, daily average, batch cycle daily average, or block average of monitored parameters, established as specified in this paragraph, remains above the minimum level or below the maximum level, as appropriate.

(i) Establishment of parameter monitoring levels based on performance tests - (A) Emission points other than batch process vents. During initial compliance testing, the appropriate parameter shall be continuously monitored during the required 1-hour test runs. The monitoring level(s) shall then be established as the average of the maximum (or minimum) point values from the three test runs. The average of the maximum values shall be used when establishing a maximum level, and the average of the minimum values shall be used when establishing a minimum level.

(B) Aggregate batch vent streams. For aggregate batch vent streams the monitoring level shall be established in accordance with paragraph (a)(4)(i)(A) of this section.

(C) Batch process vents. The monitoring level(s) shall be established using the procedures specified in paragraphs (a)(4)(i)(C)(1) or (2) of this section. For batch process vents complying with the percent reduction standards specified in �63.1406 or �63.1407, parameter monitoring levels shall be established by the design evaluation, or during the performance test so that the specified percent reduction from �63.1406 or �63.1407, as appropriate, is met.

(1) If more than one batch emission episode or more than one portion of a batch emission episode has been selected to be controlled, a single level for the batch cycle shall be calculated as follows:

(i) During initial compliance testing, the appropriate parameter shall be monitored continuously and recorded once every 15 minutes at all times when batch emission episodes, or portions thereof, selected to be controlled are vented to the control device. A minimum of three recorded values shall be obtained for each batch emission episode, or portion thereof, regardless of the length of time emissions are occurring.

(ii) The average monitored parameter value shall be calculated for each batch emission episode, or portion thereof, in the batch cycle selected to be controlled. The average shall be based on all values measured during the required performance test.

(iii) If the level to be established is a maximum operating parameter, the level shall be defined as the minimum of the average parameter values from each batch emission episode, or portion thereof, in the batch cycle selected to be controlled (i.e., identify the batch emission episode, or portion thereof, which requires the lowest parameter value in order to assure compliance; the average parameter value that is necessary to assure compliance for that batch emission episode, or portion thereof, shall be the level for all batch emission episodes, or portions thereof, in the batch cycle that are selected to be controlled).

(iv) If the level to be established is a minimum operating parameter, the level shall be defined as the maximum of the average parameter values from each batch emission episode, or portion thereof, in the batch cycle selected to be controlled (i.e., identify the batch emission episode, or portion thereof, which requires the highest parameter value in order to assure compliance; the average parameter value that is necessary to assure compliance for that batch emission episode, or portion thereof, shall be the level for all batch emission episodes, or portions thereof, in the batch cycle that are selected to be controlled).

(v) Alternatively, an average monitored parameter value shall be calculated for the entire batch cycle based on all values recorded during each batch emission episode, or portion thereof, selected to be controlled.

(2) Instead of establishing a single level for the batch cycle, as described in paragraph (a)(4)(i)(C)(1) of this section, an owner or operator may establish separate levels for each batch emission episode, or portion thereof, selected to be controlled. Each level shall be determined as specified in paragraphs (a)(4)(i)(C)(1)(i) through (v) of this section.

(3) The batch cycle shall be defined in the Notification of Compliance Status, as specified in �63.1417(e)(2). Said definition shall include an identification of each batch emission episode. The definition of batch cycle shall also include the information required to determine parameter monitoring compliance for partial batch cycles (i.e., when part of a batch cycle is accomplished during 2 different operating days) for those parameters averaged on a batch cycle daily average basis.

(ii) Establishment of parameter monitoring levels based on performance tests, engineering assessments, and/or manufacturer's recommendations. Parameter monitoring levels may be established based on the parameter values measured during the performance test supplemented by engineering assessments and/or manufacturer's recommendations. Performance testing is not required to be conducted over the entire range of expected parameter values. When setting the parameter monitoring level(s) using the procedures specified in this paragraph, the owner or operator shall submit the information specified in �63.1417(d)(7) for review and approval as part of the Precompliance Report.

(b) Initial and continuous compliance for storage vessels. (1) Initial compliance with the percent reduction standard specified in �63.1404(a)(1) shall be demonstrated following the procedures in 40 CFR part 63, subpart SS.

(2) Initial compliance with the work practice standard specified in �63.1404(a)(2) shall be demonstrated following the procedures in 40 CFR part 63, subpart WW.

(3) Continuous compliance with the percent reduction standard specified in �63.1404(a)(1) shall be demonstrated following the procedures in 40 CFR part 63, subpart SS.

(4) Continuous compliance with the work practice standard specified in �63.1404(a)(2) shall be demonstrated following the procedures in 40 CFR part 63, subpart WW.

(5) Initial and continuous compliance with the alternative standard specified in �63.1404(b) shall be demonstrated following the procedures in paragraph (f) of this section.

(c) Initial and continuous compliance for continuous process vents. (1) Initial compliance with the percent reduction standard specified in �63.1405(a)(2) shall be demonstrated following the procedures in 40 CFR part 63, subpart SS.

(2) Initial compliance with �63.1405(a)(1) or (b)(1) (venting of emissions to a flare) shall be demonstrated following the procedures specified in paragraph (g) of this section.

(3) Continuous compliance with the percent reduction standard specified in �63.1405(a)(2) shall be demonstrated following the procedures in 40 CFR part 63, subpart SS.

(4) Continuous compliance with �63.1405(a)(1) or (b)(1) (venting of emissions to a flare) shall be demonstrated following the continuous monitoring procedures specified in �63.1415.

(5) Initial and continuous compliance with the production-based emission limit specified in �63.1405(b)(2)(i) shall be demonstrated following the procedures in paragraph (h)(1) of this section.

(6) Initial and continuous compliance with the emission rate limits specified in �63.1405(b)(2)(ii) and (iii) shall be demonstrated following the procedures of either paragraphs (c)(6)(i) or (ii) of this section.

(i) Continuous process vents meeting the emission rate limit using a closed vent system and a control device or recovery device or by routing emissions to a fuel gas system or process shall follow the procedures in 40 CFR part 63, subpart SS. When complying with the requirements of 40 CFR part 63, subpart SS, the following apply for purposes of this subpart:

(A) The requirements specified in of �63.1405 (a)(2)(i) through (viii).

(B) When 40 CFR part 63, subpart SS refers to meeting a weight-percent emission reduction or ppmv outlet concentration requirement, meeting an emission rate limit in terms of kilograms of total organic HAP per hour shall also apply.

(ii) Continuous process vents meeting the emission rate limit by means other than those specified in paragraph (c)(6)(i) of this section shall follow the procedures specified in paragraph (h)(2) of this section.

(7) Initial and continuous compliance with the alternative standards specified in �63.1405(c) shall be demonstrated following the procedures in paragraph (f) of this section.

(d) Initial and continuous compliance for aggregate batch vent streams. (1) Initial compliance with the percent reduction standard specified in �63.1408(a)(1)(ii) and (2)(ii) shall be demonstrated following the procedures for continuous process vents specified in paragraph (c)(1) of this section.

(2) Initial compliance with �63.1408(a)(1)(i) and (2)(i) (venting of emissions to a flare) shall be demonstrated following the procedures specified in paragraph (g) of this section.

(3) Continuous compliance with the percent reduction standard specified in �63.1408(a)(1)(ii) and (2)(ii) shall be demonstrated following the procedures for continuous process vents specified in paragraph (c)(3) of this section.

(4) Continuous compliance with �63.1408(a)(1)(i) and (a)(2)(i) (venting of emissions to a flare) shall be demonstrated following the continuous monitoring procedures specified in �63.1415.

(5) Initial and continuous compliance with the alternative standard specified in �63.1408(b)(1) shall be demonstrated following the procedures in paragraph (f) of this section.

(6) Initial and continuous compliance with the mass emission limit specified in �63.1408(b)(2) shall be demonstrated following the procedures in paragraph (e)(2) of this section.

(e) Initial and continuous compliance for batch process vents - (1) Compliance with percent reduction standards. Owners or operators opting to comply with the percent reduction standards specified in �63.1406(a)(1)(ii) and (a)(2)(ii) or �63.1407(a)(2)(ii) and (a)(3)(ii) shall select portions of the batch process vent emissions (i.e., select batch emission episodes or portions of batch emission episodes) to be controlled such that the specified percent reduction is achieved for the batch cycle. Paragraphs (e)(1)(i) and (ii) of this section specify how the performance of a control device or control technology is to be determined. Paragraph (e)(1)(iii) of this section specifies how to demonstrate that the required percent emission reduction is achieved for the batch cycle.

(i) Design evaluation. The design evaluation shall comply with the provisions in paragraph (a)(3) of this section. The design evaluation shall include the value(s) and basis for the parameter monitoring level(s) required by �63.1415. The design evaluation shall determine either of the following:

(A) Each batch emission episode. The control device efficiency for each batch emission episode that the owner or operator selects to control.

(B) One or more representative batch emission episodes. The control device efficiency for one or more batch emission episodes provided that the owner or operator demonstrates that the control device achieves the same or higher efficiency for all other batch emission episodes that the owner or operator selects to control.

(ii) Performance test. An owner or operator shall conduct performance tests following the procedures in paragraph (e)(1)(ii)(A) of this section, the procedures in paragraph (e)(1)(ii)(B) of this section, or a combination of the two procedures. Under paragraph (e)(1)(ii)(A) of this section, a performance test is conducted for each batch emission episode selected for control. Under paragraph (e)(1)(ii)(B) of this section, an owner or operator groups together several batch emission episodes and conducts a single performance test for the batch emission episode that is the most challenging, in terms of achieving emission reductions, for the control device or control technology; thereby demonstrating that the achieved emission reduction for the tested batch emission episode is the minimum control device or control technology performance expected for each batch emission episode in the group. An owner or operator may use the concept provided by paragraph (e)(1)(ii)(B) of this section for several different groups of batch emission episodes.

(A) Testing each batch emission episode. A performance test shall be performed for each batch emission episode, or portion thereof, that the owner or operator selects to control. Performance tests shall be conducted using the testing procedures specified in �63.1414(a) and (b) and the following procedures:

(1) Only one test (i.e., only one run) is required for each batch emission episode selected by the owner or operator for control.

(2) Except as specified in paragraph (e)(1)(ii)(A)(3) of this section, the performance test shall be conducted over the entire period of emissions selected by the owner or operator for control.

(3) An owner or operator may choose to test only those periods of the batch emission episode during which the emission rate for the entire batch emission episode can be determined or during which the organic HAP emissions are greater than the average emission rate of the batch emission episode. The owner or operator choosing either of these options shall develop an emission profile illustrating the emission rate (kilogram per unit time) over the entire batch emission episode, based on either process knowledge or test data, to demonstrate that test periods are representative. Examples of information that could constitute process knowledge include calculations based on material balances and process stoichiometry. Previous test results may be used to develop the emission profile provided the results are still relevant to the current batch process vent conditions. The emission profile shall be included in the site-specific test plan required by �63.1417(h)(2).

(4) When choosing sampling sites using the methods specified in �63.1414(a)(1), inlet sampling sites shall be located as specified in paragraphs (e)(1)(ii)(A)(4)(i) and (ii) of this section. Outlet sampling sites shall be located at the outlet of the control device prior to release to the atmosphere.

(i) The control device inlet sampling site shall be located at the exit from the batch unit operation after any condensers operating as process condensers and before any control device.

(ii) If a batch process vent is introduced with the combustion air or as a secondary fuel into a boiler or process heater with a design capacity less than 44 megawatts, selection of the location of the inlet sampling sites shall ensure the measurement of total organic HAP concentrations in all batch process vents and primary and secondary fuels introduced into the boiler or process heater.

(B) Testing only the most challenging batch emission episode. Under this paragraph, an owner or operator groups together several batch emission episodes and conducts a single performance test for the batch emission episode that is the most challenging, in terms of achieving emission reductions, for the control device or control technology; thereby demonstrating that the achieved emission reduction for the tested batch emission episode is the minimum control device or control technology performance expected for each batch emission episode in the group. The owner or operator shall use the control device efficiency determined from the performance test for all the other batch emission episodes in that group for purposes of paragraph (e)(2)(iii) of this section. Performance tests shall be conducted using the testing procedures specified in �63.1414(a) and (b) and the following procedures:

(1) The procedures specified in paragraphs (e)(2)(ii)(A)(2) through (4) of this section.

(2) Develop an emission profile illustrating the emission rate (kilogram/unit time) for each period of emissions to be addressed by the performance test. The emission profile shall be based on either process knowledge or test data. Examples of information that could constitute process knowledge include calculations based on material balances and process stoichiometry. Previous test results may be used to develop the emission profile provided the results are still relevant to the current batch process vent conditions. The emission profile shall be included in the site-specific test plan required by �63.1417(h)(2).

(3) Provide rationale for why the control device efficiency for all the other batch emission episodes in the group will be greater than or equal to the control device efficiency achieved during the tested period of the most challenging batch emission episode in the group, as specified in the Notification of Compliance Status Report required by �63.1417(e).

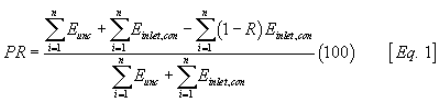

(iii) Batch cycle percent reduction. The percent reduction for the batch cycle for an individual reactor batch process vent and the overall percent reduction for the collection of non-reactor batch process vents within the affected source shall be determined using Equation 1 of this section and the control device efficiencies specified in paragraphs (e)(1)(iii)(A) through (C) of this section. All information used to calculate the batch cycle percent reduction for an individual reactor batch process vent, including a definition of the batch cycle identifying all batch emission episodes, shall be recorded as specified in �63.1416 (d)(1)(ii). All information used to calculate the overall percent reduction for the collection of non-reactor batch process vents within the affected source, including a list of all batch emission episodes from the collection of non-reactor batch process vents within the affected source, shall be recorded as specified in �63.1416 (d)(1)(ii). This information shall include identification of those batch emission episodes, or portions thereof, selected for control. This information shall include estimates of uncontrolled organic HAP emissions for those batch emission episodes, or portions thereof, that are not selected for control, determined as specified in paragraph (e)(2)(iii)(D) or (E) of this section.

Where:

PR = Percent reduction.

Eunc = Mass rate of total organic HAP for uncontrolled batch emission episode i, kg/hr.

Einlet, con = Mass rate of total organic HAP for controlled batch emission episode i at the inlet to the control device, kg/hr.

R = Control efficiency of control device as specified in paragraphs (e)(1)(iii)(A) through (e)(1)(iii)(C) of this section. The value of R may vary between batch emission episodes.

n = Number of uncontrolled batch emission episodes, controlled batch emission episodes, and control devices. The value of n is not necessarily the same for these three items.

(A) When conducting a performance test, the control efficiency of the control device shall be determined following the procedures in �63.1414(b)(4).

(B) For combustion control devices listed in paragraphs (a)(2)(i)(A) and (B) of this section and for flares, the control efficiency in Equation 1 of this section shall be 98 percent.

(C) If a performance test is not required, the control efficiency shall be based on the design evaluation specified in paragraph (e)(1)(i) of this section.

(D) For batch process vents estimated through engineering assessment, as described in �63.1414(f)(6), to emit less than 10 tons per year of uncontrolled organic HAP emissions, the owner or operator may use in Equation 1 of this section the emissions determined using engineering assessment or may determine organic HAP emissions using any of the procedures specified in �63.1414(d).

(E) For batch process vents estimated through engineering assessment, as described in �63.1414(d)(6), to emit 10 tons per year or greater of uncontrolled organic HAP emissions, organic HAP emissions shall be estimated following the procedures specified in �63.1414(d).

(F) Owners or operators designating a condenser, sometimes operated as a process condenser, as a control device shall conduct inprocess recycling and follow the recordkeeping requirements specified in �63.1416(d)(1)(vi).

(iv) Initial compliance with percent reduction standards. Initial compliance with the percent reduction standards specified in �63.1406(a)(1)(ii) and (2)(ii) and �63.1407(a)(2)(ii) and (3)(ii) is achieved when the owner or operator demonstrates, following the procedures in paragraphs (e)(1)(i) through (iii) of this section, that the required percent reduction is achieved.

(v) Continuous compliance with percent reduction standards. Continuous compliance with the percent reduction standards specified in �63.1406(a)(1)(ii) and (2)(ii) and �63.1407(a)(2)(ii) and (3)(ii) shall be demonstrated following the continuous monitoring procedures specified in �63.1415.

(2) Compliance with mass emission limit standards. Each owner or operator shall determine initial and continuous compliance with the mass emission limits specified in �63.1406 (a)(1)(iii) and (a)(2)(iii), according to the following procedures, as appropriate:

(i) If production at an affected source is exclusively non-solvent-based amino/phenolic resin or is exclusively solvent-based amino/phenolic resin, or an owner or operator chooses to meet the non-solvent-based emission limit, the owner or operator shall demonstrate initial and continuous compliance as follows:

(A) Initial compliance. Initial compliance shall be based on the average of the first 6 monthly average emission rate data points. The 6-month average shall be compared to the mass emission limit specified in �63.1406 (a)(1)(iii) and (a)(2)(iii), as appropriate.

(B) Continuous compliance. For the first year of compliance, continuous compliance shall be based on a cumulative average monthly emission rate calculated each month based on the available monthly emission rate data points (e.g., 7 data points after 7 months of operation, 8 data points after 8 months of operation) beginning the first month after initial compliance is demonstrated. The first continuous compliance cumulative average monthly emission rate shall be calculated using the first 7 monthly average emission rate data points. After the first year of compliance, a 12-month rolling average monthly emission rate shall be calculated each month based on the previous 12 monthly emission rate data points. Continuous compliance shall be determined by comparing the cumulative average monthly emission rate or the 12-month rolling average monthly emission rate to the mass emission limit specified in �63.1406 (a)(1)(iii) and (a)(2)(iii), as appropriate.

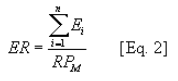

(C) Procedures to determine the monthly emission rate. The monthly emission rate, kilograms of organic HAP per megagram of product, shall be determined at the end of each month using Equation 2 of this section:

Where:

ER = Emission rate of organic HAP from reactor batch process vents, kg of HAP/Mg product.

Ei = Emission rate of organic HAP from reactor batch process vent i as determined using the procedures specified in paragraph (e)(2)(i)(C)(1) of this section, kg/month.

RPm = Amount of resin produced in one month as determined using the procedures specified in paragraph (e)(2)(i)(C)(4) of this section, Mg/month.

n = Number of batch process vents.

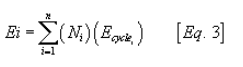

(1) The monthly emission rate of organic HAP, in kilograms per month, from an individual batch process vent (Ei) shall be determined using Equation 3 of this section. Once organic HAP emissions for a batch cycle (Ecyclei) have been estimated, as specified in either paragraph (e)(2)(i)(C)(2) or (3) of this section, the owner or operator may use the estimated organic HAP emissions (Ecyclei) to determine Ei using Equation 3 of this section until the estimated organic HAP emissions (Ecyclei) are no longer representative due to a process change or other reasons known to the owner or operator. If organic HAP emissions for a batch cycle (Ecyclei) are determined to no longer be representative, the owner or operator shall redetermine organic HAP emissions for the batch cycle (Ecyclei) following the procedures in paragraph (e)(2)(i)(C)(2) or (3) of this section, as appropriate.

Where:

Ei = Monthly emissions from a batch process vent, kg/month.

Ni = Number of type i batch cycles performed monthly, cycles/month.

Ecyclei = Emissions from the batch process vent associated with a single type i batch cycle, as determined using the procedures specified in either paragraph (e)(2)(i)(C)(2) or (3) of this section, kg/batch cycle.

n = Number of different types of batch cycles that cause the emission of organic HAP from the batch process vent.

(2) For reactor batch process vents estimated through engineering assessment, as described in �63.1414(d)(6), to emit less than 10 tons per year of uncontrolled organic HAP emissions, the owner or operator may use the emissions determined using engineering assessment in Equation 3 of this section or may determine organic HAP emissions using any of the procedures specified in �63.1414(d). For reactor batch process vents estimated through engineering assessment, as described in �63.1414(d)(6), to emit 10 tons per year or greater of uncontrolled organic HAP emissions, uncontrolled organic HAP emissions from the batch emission episodes making up the batch cycle shall be estimated following the procedures specified in �63.1414(d).

(3) For reactor batch process vents vented to a control device or control technology, controlled organic HAP emissions shall be determined as follows:

(i) Uncontrolled organic HAP emissions shall be determined following the procedures in paragraph (e)(2)(i)(C)(2) of this section.

(ii) Control device or control technology efficiency shall be determined using the procedures in paragraph (e)(1)(i) of this section for small control devices or the procedures in paragraph (e)(1)(ii) of this section for large control devices.

(iii) Controlled organic HAP emissions shall be determined by applying the control device or control technology efficiency, determined in paragraph (e)(2)(i)(C)(3)(ii) of this section, to the uncontrolled organic HAP emissions, determined in paragraph (e)(2)(i)(C)(3)(i) of this section.

(4) The rate of resin produced, RPM (Mg/month), shall be determined based on production records certified by the owner or operator to represent actual production for the month. A sample of the records selected by the owner or operator for this purpose shall be provided to the Administrator in the Precompliance Report as required by �63.1417(d).

(ii) If production at an affected source reflects a mix of solvent-based and non-solvent-based resin and the owner or operator does not choose to meet the non-solvent-based emission limit specified in �63.1406 (a)(1)(iii) or (a)(2)(iii), as applicable, the owner or operator shall demonstrate initial and continuous compliance as follows:

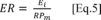

(A) Procedures for determining a site-specific emission limit. A site-specific emission limit shall be determined using Equation 4 of this section.

Where:

SSEL = Site specific emission limit, kg of organic HAP/Mg of product.

MGs = Megagrams of solvent-based resin product produced, megagrams.

MGns = Megagrams of non-solvent-based resin product produced, megagrams.

ELs = Emission limit for solvent-based resin product, kg organic HAP/Mg solvent-based resin product.

ELns = Emission limit for non-solvent-based resin product, kg organic HAP/Mg non-solvent-based resin product.

(B) Initial compliance. For purposes of determining initial compliance, the site-specific emission limit shall be based on production for the first 6 months beginning January 20, 2000 or the first 6 months after initial start-up, whichever is later. Using the site-specific emission limit, initial compliance shall be demonstrated using the procedures in paragraph (e)(2)(i)(A) of this section, as appropriate.

(C) Continuous compliance. For purposes of determining continuous compliance for the period of operation starting at the beginning of the 7th month and ending after the 12th month, the site-specific emission limit shall be determined each month based on production for the cumulative period. For purposes of determining continuous compliance after the first year of production, the site-specific emission limit shall be determined each month based on production for a 12-month rolling period. Using the site-specific emission limit, continuous compliance shall be demonstrated using the procedures in paragraph (e)(2)(i)(B) of this section, as appropriate.

(3) Compliance by venting to a flare. Initial compliance with the standards specified in �63.1406(a)(1)(i) and (a)(2)(i) and �63.1407(a)(2)(i) and (a)(3)(i) shall be demonstrated following the procedures specified in paragraph (g) of this section. Continuous compliance with these standards shall be demonstrated following the continuous monitoring procedures specified in �63.1415.

(4) Compliance with alternative standard. Initial and continuous compliance with the alternative standard specified in ��63.1406(b) and 63.1407(b)(1) shall be demonstrated following the procedures in paragraph (f) of this section.

(f) Compliance with alternative standard. Initial and continuous compliance with the alternative standards in ��63.1404(b), 63.1405(c), 63.1406(b), 63.1407(b)(1), and 63.1408(b)(1) are demonstrated when the daily average outlet organic HAP concentration is 20 ppmv or less when using a combustion control device or 50 ppmv or less when using a non-combustion control device. To demonstrate initial and continuous compliance, the owner or operator shall follow the test method specified in �63.1414(a)(6) and shall be in compliance with the monitoring provisions in �63.1415(e) no later than the initial compliance date and on each day thereafter.

(g) Flare compliance demonstrations. Notwithstanding any other provision of this subpart, if an owner or operator of an affected source uses a flare to comply with any of the requirements of this subpart, the owner or operator shall comply with paragraphs (g)(1) through (3) of this section. When using a flare to comply, the owner or operator is not required to conduct a performance test to determine percent emission reduction or outlet organic HAP concentration. If a compliance demonstration has been conducted previously for a flare, using the techniques specified in paragraphs (g)(1) through (3) of this section, that compliance demonstration may be used to satisfy the requirements of this paragraph if either no deliberate process changes have been made since the compliance demonstration, or the results of the compliance demonstration reliably demonstrate compliance despite process changes.

(1) Conduct a visible emission test using the techniques specified in �63.11(b)(4).

(2) Determine the net heating value of the gas being combusted using the techniques specified in �63.11(b)(6).

(3) Determine the exit velocity using the techniques specified in either �63.11(b)(7)(i) (and �63.11(b)(7)(iii), where applicable) or �63.11(b)(8), as appropriate.

(h) Continuous process vent compliance at existing sources. (1) Each owner or operator complying with the mass emission limit specified in �63.1405(b)(2)(i) shall determine initial compliance as specified in paragraph (h)(1)(i) of this section and continuous compliance as specified in paragraph (h)(1)(ii) of this section.

(i) Initial compliance. Initial compliance shall be determined by comparing the results of the performance test or design evaluation, as specified in paragraph (a)(1) of this section, to the mass emission limit specified in �63.1405(b)(2)(i).

(ii) Continuous compliance. Continuous compliance shall be based on the daily average emission rate calculated for each operating day. The first continuous compliance average daily emission rate shall be calculated using the first 24-hour period or otherwise-specified operating day after the compliance date. Continuous compliance shall be determined by comparing the daily average emission rate to the mass emission limit specified in �63.1405(b)(2)(i).

(2) As required by paragraph (c)(6)(ii) of this section, each owner or operator complying with the emission rate limits specified in �63.1405(b)(2)(ii) and (iii), as applicable, by means other than those specified in paragraph (c)(6)(i) of this section, shall determine initial compliance as specified in paragraph (h)(2)(i) of this section and continuous compliance as specified in paragraph (h)(2)(ii) of this section.

(i) Initial compliance. Initial compliance shall be determined by comparing the results of the performance test or design evaluation, as specified in paragraph (a)(1) of this section, to the emission rate limits specified in �63.1405(b)(2)(ii) and (iii), as applicable.

(ii) Continuous compliance. Continuous compliance shall be based on the hourly average emission rate calculated for each operating day. The first continuous compliance average hourly emission rate shall be calculated using the first 24-hour period or otherwise-specified operating day after the compliance date. Continuous compliance shall be determined by comparing the average hourly emission rate to the emission rate limit specified in �63.1405(b)(2)(ii) or (iii), as applicable.

(3) Procedures to determine continuous compliance with the mass emission limit specified in �63.1405(b)(2)(i).

(i) The daily emission rate, kilograms of organic HAP per megagram of product, shall be determined for each operating day using Equation 5 of this section:

Where:

ER = Emission rate of organic HAP from continuous process vent, kg of HAP/Mg product.

Ei = Emission rate of organic HAP from continuous process vent i as determined using the procedures specified in paragraph (h)(3)(ii) of this section, kg/day.

RPm = Amount of resin produced in one month as determined using the procedures specified in paragraph (h)(3)(iii) of this section, Mg/day.

(ii) The daily emission rate of organic HAP, in kilograms per day, from an individual continuous process vent (Ei) shall be determined. Once organic HAP emissions have been estimated, as specified in paragraph (h)(3)(ii)(A) of this section for uncontrolled continuous process vents or paragraphs (h)(3)(ii)(A) and (B) of this section for continuous process vents vented to a control device or control technology, the owner or operator may use the estimated organic HAP emissions (Ei) until the estimated organic HAP emissions are no longer representative due to a process change or other reason known to the owner or operator. If organic HAP emissions (Ei) are determined to no longer be representative, the owner or operator shall redetermine organic HAP emissions for the continuous process vent following the procedures in paragraph (h)(3)(ii)(A) of this section for uncontrolled continuous process vents or paragraphs (h)(3)(ii)(A) and (B) of this section for continuous process vents vented to a control device or control technology.

(A) For continuous process vents estimated through engineering assessment, as described in �63.1414(d)(10), to emit less than 10 tons per year of uncontrolled organic HAP emissions, the owner or operator may use the emissions determined using engineering assessment in Equation 5 of this section or may determine organic HAP emissions using the procedures specified in paragraph (a)(1)(i) of this section. For continuous process vents estimated through engineering assessment, as described in �63.1414(d)(10), to emit 10 tons per year or greater of uncontrolled organic HAP emissions, uncontrolled organic HAP emissions shall be estimated following the procedures specified in paragraph (a)(1)(i) of this section.

(B) For continuous process vents vented to a control device or control technology, controlled organic HAP emissions shall be determined as follows:

(1) Uncontrolled organic HAP emissions shall be determined following the procedures in paragraph (h)(3)(ii)(A) of this section.

(2) Control device or control technology efficiency shall be determined using the procedures in paragraph (a)(1)(i) of this section for large control devices or the procedures in paragraph (a)(1)(ii) of this section for small control devices.

(3) Controlled organic HAP emissions shall be determined by applying the control device or control technology efficiency, determined in paragraph (h)(3)(ii)(B)(2) of this section, to the uncontrolled organic HAP emissions, determined in paragraph (h)(3)(ii)(B)(1) of this section.

(iii) The rate of resin produced, RPM (Mg/day), shall be determined based on production records certified by the owner or operator to represent actual production for the day. A sample of the records selected by the owner or operator for this purpose shall be provided to the Administrator in the Precompliance Report as required by �63.1417(d).

(4) Procedures to determine continuous compliance with the emission rate limit specified in �63.1405(b)(2)(ii) or (iii).

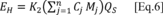

(i) The hourly emission rate, kilograms of organic HAP per hour, shall be determined for each hour during the operating day using Equation 6 of this section:

Where:

EH = Hourly emission rate of organic HAP in the sample, kilograms per hour.

K2 = Constant, 2.494 � 10?6 (parts per million)?1 (gram-mole per standard cubic meter) (kilogram/gram) (minutes/hour), where standard temperature for (gram-mole per standard cubic meter) is 20�C.

n = Number of components in the sample.

CJ = Organic HAP concentration on a dry basis of organic compound j in parts per million as determined by the methods specified in paragraph (h)(4)(ii) of this section.

Mj = Molecular weight of organic compound j, gram/gram-mole.

QS = Continuous process vent flow rate, dry standard cubic meters per minute, at a temperature of 20�C, as determined by the methods specified in paragraph (h)(4)(ii) of this section.

(ii) The average hourly emission rate, kilograms of organic HAP per hour, shall be determined for each operating day using Equation 7 of this section:

Where:

AE = Average hourly emission rate per operating day, kilograms per hour.

n = Number of hours in the operating day.

(ii) Continuous process vent flow rate and organic HAP concentration shall be determined using the procedures specified in �63.1414(a), or by using the engineering assessment procedures in paragraph (h)(4)(iii) of this section.

(iii) Engineering assessment. For the purposes of determining continuous compliance with the emission rate limit specified in �63.1405(b)(2)(ii) or (iii) using Equations 6 and 7, engineering assessments may be used to determine continuous process vent flow rate and organic HAP concentration. An engineering assessment includes, but is not limited to, the following examples:

(A) Previous test results, provided the tests are representative of current operating practices.

(B) Bench-scale or pilot-scale test data representative of the process under representative operating conditions.

(C) Maximum volumetric flow rate or organic HAP concentration specified or implied within a permit limit applicable to the continuous process vent.

(D) Design analysis based on accepted chemical engineering principles, measurable process parameters, or physical or chemical laws or properties. Examples of analytical methods include, but are not limited to, the following:

(1) Estimation of maximum organic HAP concentrations based on process stoichiometry material balances or saturation conditions; and

(2) Estimation of maximum volumetric flow rate based on physical equipment design, such as pump or blower capacities.

(i) Deviations. Paragraphs (i)(1) through (4) of this section describe deviations from the emission limits, the operating limits, the work practice standards, and the emission standard, respectively. Paragraph (i)(5) of this section describes situations that are not deviations. Paragraph (i)(6) of this section describes periods that are excluded from compliance determinations.

(1) Deviations from the emission limit. The following are deviations from the emission limit:

(i) Exceedance of the condenser outlet gas temperature limit (i.e., having an average value higher than the established maximum level) monitored according to the provisions of �63.1415(b)(3);

(ii) Exceedance of the outlet concentration (i.e., having an average value higher than the established maximum level) monitored according to the provisions of �63.1415(b)(8);

(iii) Exceedance of the mass emission limit (i.e., having an average value higher than the specified limit) monitored according to the provisions of paragraph (e)(2) of this section for batch process vents and according to the provisions of paragraph (h)(1) of this section for continuous process vents;

(iv) Exceedance of the organic HAP outlet concentration limit (i.e., having an average value higher than the specified limit) monitored according to the provisions of �63.1415(e); and

(v) Exceedance of the emission rate limit (i.e., having an average value higher than the specified limit) determined according to the provisions of paragraph (h)(2) of this section.

(2) Deviations from the operating limit. Exceedance of the parameters monitored according to �63.1415(b)(1), (b)(2), and (b)(4) through (7) are considered deviations from the operating limit. An exceedance of the monitored parameter has occurred if:

(i) The parameter, averaged over the operating day or block, is below a minimum value established during the initial compliance demonstration; or (ii) The parameter, averaged over the operating day or block, is above the maximum value established during the initial compliance demonstration.

(3) Deviations from the work practice standard. If all flames at the pilot light of a flare are absent, there has been a deviation from the work practice standard.

(4) Deviation from the emission standard. If monitoring data are insufficient, as described in paragraphs (i)(4)(i) through (iii) of this section, there has been a deviation from the emission standard.

(i) The period of control device or control technology operation is 4 hours or greater in an operating day, and monitoring data are insufficient to constitute a valid hour of data, as defined in paragraph (i)(4)(iii) of this section, for at least 75 percent of the operating hours;

(ii) The period of control device or control technology operation is less than 4 hours in an operating day, and more than one of the hours during the period of operation does not constitute a valid hour of data due to insufficient monitoring data; and

(iii) Monitoring data are insufficient to constitute a valid hour of data, as used in paragraphs (i)(4)(i) and (ii) of this section, if measured values are unavailable for any of the 15-minute periods within the hour. For data compression systems approved under �63.1417(k)(3), monitoring data are insufficient to calculate a valid hour of data if there are less than four data measurements made during the hour.

(5) Situations that are not deviations. If any of the situations listed in paragraphs (i)(5)(i) or (ii) of this section occur, such situations shall not be considered to be deviations.

(i) Monitoring data cannot be collected during monitoring device calibration check or monitoring device malfunction; or

(ii) Monitoring data are not collected during periods of nonoperation of the affected source or portion thereof (resulting in cessation of the emissions to which the monitoring applies).

(6) Periods not considered to be part of the period of control or recovery device operation. The periods listed in paragraphs (i)(6)(i) and (ii) of this section are not considered to be part of the period of control or recovery device operation for purposes of determining averages or periods of control device or control technology operation.

(i) Monitoring system breakdowns, repairs, calibration checks, and zero (low-level) and high-level adjustments; or

(ii) Periods of nonoperation of the affected source (or portion thereof), resulting in cessation of the emissions to which the monitoring applies.

[65 FR 3290, Jan. 20, 2000, as amended at 65 FR 8768, Feb. 22, 2000; 71 FR 20460, Apr. 20, 2006; 79 FR 60931, Oct. 8, 2014; 83 FR 51853, Oct. 15, 2018]

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.