['Air Programs']

['Hazardous Air Pollutants']

09/02/2024

...

(a) For purposes of determining vent stream flow rate, total organic HAP or total organic carbon concentration or TRE index value as applicable, as specified under paragraph (b), (c), or (d) of this section, the sampling site shall be after the last recovery device (if any recovery devices are present) but prior to the inlet of any control device that is present and prior to release to the atmosphere.

(1) Method 1 or 1A of 40 CFR part 60, appendix A, as appropriate, shall be used for selection of the sampling site.

(2) No traverse site selection method is needed for vents smaller than 0.10 meter in diameter.

(b) Except as specified in paragraph (g) of this section, to demonstrate that a vent stream flow rate is less than 0.005 standard cubic meter per minute in accordance with the Group 2 process vent definition of this subpart, the owner or operator shall measure flow rate by the following procedures:

(1) The sampling site shall be selected as specified in paragraph (a) of this section.

(2) The gas volumetric flow rate shall be determined using Method 2, 2A, 2C, or 2D of 40 CFR part 60, appendix A, as appropriate.

(c) Except as specified in paragraph (g) of this section, each owner or operator seeking to demonstrate that a vent stream has an organic HAP concentration below 50 parts per million by volume in accordance with the Group 2 process vent definition of this subpart shall measure either total organic HAP or TOC concentration using the following procedures:

(1) The sampling site shall be selected as specified in paragraph (a) of this section.

(2) Method 18 or Method 25A of 40 CFR part 60, appendix A shall be used to measure concentration; alternatively, any other method or data that has been validated according to the protocol in Method 301 of appendix A of this part may be used.

(3) Where Method 18 of 40 CFR part 60, appendix A is used, the following procedures shall be used to calculate parts per million by volume concentration:

(i) The minimum sampling time for each run shall be 1 hour in which either an integrated sample or four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at approximately equal intervals in time, such as 15 minute intervals during the run.

(ii) The concentration of either TOC (minus methane and ethane) or organic HAP shall be calculated according to paragraph (c)(3)(ii)(A) or (c)(3)(ii)(B) of this section as applicable.

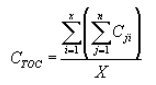

(A) The TOC concentration (CTOC) is the sum of the concentrations of the individual components and shall be computed for each run using the following equation:

where:

CTOC = Concentration of TOC (minus methane and ethane), dry basis, parts per million by volume.

Cji = Concentration of sample component j of the sample i, dry basis, parts per million by volume.

n = Number of components in the sample.

x = Number of samples in the sample run.

(B) The total organic HAP concentration (CHAP) shall be computed according to the equation in paragraph (c)(3)(ii)(A) of this section except that only the organic HAP species shall be summed. The list of organic HAP's is provided in table 2 of subpart F of this part.

(4) Where Method 25A of 40 CFR part 60, appendix A is used, the following procedures shall be used to calculate parts per million by volume TOC concentration:

(i) Method 25A of 40 CFR part 60, appendix A, shall be used only if a single organic HAP compound is greater than 50 percent of total organic HAP, by volume, in the vent stream.

(ii) The vent stream composition may be determined by either process knowledge, test data collected using an appropriate EPA method, or a method or data validated according to the protocol in Method 301 of appendix A of this part. Examples of information that could constitute process knowledge include calculations based on material balances, process stoichiometry, or previous test results provided the results are still relevant to the current vent stream conditions.

(iii) The organic HAP used as the calibration gas for Method 25A of 40 CFR part 60, appendix A shall be the single organic HAP compound present at greater than 50 percent of the total organic HAP by volume.

(iv) The span value for Method 25A of 40 CFR part 60, appendix A shall be 50 parts per million by volume.

(v) Use of Method 25A of 40 CFR part 60, appendix A is acceptable if the response from the high-level calibration gas is at least 20 times the standard deviation of the response from the zero calibration gas when the instrument is zeroed on the most sensitive scale.

(vi) The owner or operator shall demonstrate that the concentration of TOC including methane and ethane measured by Method 25A of 40 CFR part 60, appendix A is below 25 parts per million by volume to be considered a Group 2 vent with an organic HAP concentration below 50 parts per million by volume and to qualify for the low concentration exclusion in §63.113(g) of this subpart.

(d) Except as specified in §63.113(a)(4), to determine the TRE index value, the owner or operator shall conduct a TRE determination and calculate the TRE index value according to the procedures in paragraph (d)(1) or (2) of this section and the TRE equation in paragraph (d)(3) of this section.

(1) Engineering assessment may be used to determine vent stream flow rate, net heating value, TOC emission rate, and total organic HAP emission rate for the representative operating condition expected to yield the lowest TRE index value.

(i) If the TRE value calculated using such engineering assessment and the TRE equation in paragraph (d)(3) of this section is greater than 4.0, then the owner or operator is not required to perform the measurements specified in paragraph (d)(2) of this section.

(ii) If the TRE value calculated using such engineering assessment and the TRE equation in paragraph (d)(3) of this section is less than or equal to 4.0, then the owner or operator is required to perform the measurements specified in paragraph (d)(2) of this section for group determination or consider the process vent a Group 1 vent and comply with the emission reduction specified in §63.113(a) of this subpart.

(iii) Engineering assessment includes, but is not limited to, the following:

(A) Previous test results provided the tests are representative of current operating practices at the process unit.

(B) Bench-scale or pilot-scale test data representative of the process under representative operating conditions.

(C) Maximum flow rate, TOC emission rate, organic HAP emission rate, or net heating value limit specified or implied within a permit limit applicable to the process vent.

(D) Design analysis based on accepted chemical engineering principles, measurable process parameters, or physical or chemical laws or properties. Examples of analytical methods include, but are not limited to:

(1) Use of material balances based on process stoichiometry to estimate maximum organic HAP concentrations,

(2) Estimation of maximum flow rate based on physical equipment design such as pump or blower capacities,

(3) Estimation of TOC or organic HAP concentrations based on saturation conditions,

(4) Estimation of maximum expected net heating value based on the vent stream concentration of each organic compound or, alternatively, as if all TOC in the vent stream were the compound with the highest heating value.

(E) All data, assumptions, and procedures used in the engineering assessment shall be documented.

(2) Except as provided in paragraph (d)(1) of this section, vent stream flow rate, net heating value, TOC emission rate, and total organic HAP emission rate shall be measured and calculated according to the procedures in paragraphs (d)(2)(i) through (v) of this section and used as input to the TRE index value calculation in paragraph (d)(3) of this section.

(i) The vent stream volumetric flow rate (Qs), in standard cubic meters per minute at 20 degrees Celcius, shall be determined using Method 2, 2A, 2C, or 2D of 40 CFR part 60, appendix A, as appropriate. If the vent stream tested passes through a final steam jet ejector and is not condensed, the vent stream volumetric flow shall be corrected to 2.3 percent moisture.

(ii) The molar composition of the vent stream, which is used to calculate net heating value, shall be determined using the following methods:

(A) Method 18 of 40 CFR part 60, appendix A to measure the concentration of each organic compound.

(B) American Society for Testing and Materials D1946-77 to measure the concentration of carbon monoxide and hydrogen.

(C) Method 4 of 40 CFR part 60, appendix A, to measure the moisture content of the vent stream.

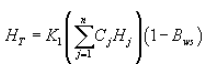

(iii) The net heating value of the vent stream shall be calculated using the following equation:

where:

HT = Net heating value of the sample, megaJoule per standard cubic meter, where the net enthalpy per mole of vent stream is based on combustion at 25°C and 760 millimeters of mercury, but the standard temperature for determining the volume corresponding to one mole is 20°C, as in the definition of Qs (vent stream flow rate).

Kl = Constant, 1.740 × 10−7 (parts per million)−1 (gram-mole per standard cubic meter) (megaJoule per kilocalorie), where standard temperature for (gram-mole per standard cubic meter) is 20°C.

Bws = Water vapor content of the vent stream, proportion by volume; except that if the vent stream passes through a final steam jet and is not condensed, it shall be assumed that Bws = 0.023 in order to correct to 2.3 percent moisture.

Cj = Concentration on a dry basis of compound j in parts per million, as measured for all organic compounds by Method 18 of 40 CFR part 60, appendix A and measured for hydrogen and carbon monoxide by American Society for Testing and Materials D1946-77 as indicated in paragraph (d)(2)(ii) of this section.

Hj = Net heat of combustion of compound j, kilocalorie per gram-mole, based on combustion at 25°C and 760 millimeters mercury. The heats of combustion of vent stream components shall be determined using American Society for Testing and Materials D2382-76 if published values are not available or cannot be calculated.

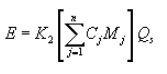

(iv) The emission rate of TOC (minus methane and ethane) (ETOC) and the emission rate of total organic HAP (EHAP) in the vent stream shall both be calculated using the following equation:

where:

E = Emission rate of TOC (minus methane and ethane) or emission rate of total organic HAP in the sample, kilograms per hour.

K2 = Constant, 2.494 × 10−6 (parts per million)−1 (gram-mole per standard cubic meter) (kilogram/gram) (minutes/hour), where standard temperature for (gram-mole per standard cubic meter) is 20°C.

Cj = Concentration on a dry basis of organic compound j in parts per million as measured by Method 18 of 40 CFR part 60, appendix A as indicated in paragraph (d)(2)(ii) of this section. If the TOC emission rate is being calculated, Cj includes all organic compounds measured minus methane and ethane; if the total organic HAP emission rate is being calculated, only organic HAP compounds listed in table 2 in subpart F of this part are included.

Mj = Molecular weight of organic compound j, gram/gram-mole.

Qs = Vent stream flow rate, dry standard cubic meter per minute, at a temperature of 20°C.

(v) In order to determine whether a vent stream is halogenated, the mass emission rate of halogen atoms contained in organic compounds shall be calculated.

(A) The vent stream concentration of each organic compound containing halogen atoms (parts per million by volume, by compound) shall be determined based on the following procedures:

(1) Process knowledge that no halogen or hydrogen halides are present in the process, or

(2) Applicable engineering assessment as discussed in paragraph (d)(1)(iii) of this section, or

(3) Concentration of organic compounds containing halogens measured by Method 18 of 40 CFR part 60, appendix A, or

(4) Any other method or data that has been validated according to the applicable procedures in Method 301 of appendix A of this part.

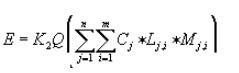

(B) The following equation shall be used to calculate the mass emission rate of halogen atoms:

where:

E = mass of halogen atoms, dry basis, kilogram per hour.

K2 = Constant, 2.494 × 10−6 (parts per million)−1 (kilogram-mole per standard cubic meter) (minute/hour), where standard temperature is 20°C.

Cj = Concentration of halogenated compound j in the gas stream, dry basis, parts per million by volume.

Mji = Molecular weight of halogen atom i in compound j of the gas stream, kilogram per kilogram-mole.

Lji = Number of atoms of halogen i in compound j of the gas stream.

Q = Flow rate of gas stream, dry standard cubic meters per minute, determined according to paragraph (d)(1) or (d)(2)(i) of this section.

j = Halogenated compound j in the gas stream.

i = Halogen atom i in compound j of the gas stream.

n = Number of halogenated compounds j in the gas stream.

m = Number of different halogens i in each compound j of the gas stream.

(3) The owner or operator shall calculate the TRE index value of the vent stream using the equations and procedures in this paragraph.

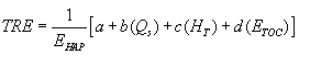

(i) The equation for calculating the TRE index for a vent stream controlled by a flare or incinerator is as follows:

where:

TRE = TRE index value.

EHAP = Hourly emission rate of total organic HAP, kilograms per hour, as calculated in paragraph (d)(1) or (d)(2)(iv) of this section.

Qs = Vent stream flow rate, standard cubic meters per minute, at a standard temperature of 20°C, as calculated in paragraph (d)(1) or (d)(2)(i) of this section.

HT = Vent stream net heating value, megaJoules per standard cubic meter, as calculated in paragraph (d)(1) or (d)(2)(iii) of this section.

ETOC = Emission rate of TOC (minus methane and ethane), kilograms per hour, as calculated in paragraph (d)(1) or (d)(2)(iv) of this section.

a,b,c,d = Coefficients presented in table 1 of this subpart, selected in accordance with paragraphs (d)(3)(ii) and (iii) of this section.

(ii) The owner or operator of a nonhalogenated vent stream shall calculate the TRE index value based on the use of a flare, a thermal incinerator with 0 percent heat recovery, and a thermal incinerator with 70 percent heat recovery and shall select the lowest TRE index value. The owner or operator shall use the applicable coefficients in table 1 of this subpart for nonhalogenated vent streams located within existing sources and the applicable coefficients in table 2 of this subpart for nonhalogenated vent streams located within new sources.

(iii) The owner or operator of a halogenated vent stream shall calculate the TRE index value based on the use of a thermal incinerator with 0 percent heat recovery, and a scrubber. The owner or operator shall use the applicable coefficients in table 1 of this subpart for halogenated vent streams located within existing sources and the applicable coefficients in table 2 of this subpart for halogenated vent streams located within new sources.

(e) Except as specified in §63.113(a)(4), the owner or operator of a Group 2 process vent shall recalculate the TRE index value, flow, or organic hazardous air pollutants concentration for each process vent, as necessary to determine whether the vent is Group 1 or Group 2, whenever process changes are made that could reasonably be expected to change the vent to a Group 1 vent. Examples of process changes include, but are not limited to, changes in production capacity, production rate, feedstock type, or catalyst type, or whenever there is replacement, removal, or addition of recovery equipment. For purposes of this paragraph, process changes do not include: Process upsets; unintentional, temporary process changes; and changes that are within the range on which the original TRE calculation was based.

(1) The TRE index value, flow rate, or organic HAP concentration shall be recalculated based on measurements of vent stream flow rate, TOC, and organic HAP concentrations, and heating values as specified in §63.115 (a), (b), (c), and (d) of this subpart, as applicable, or on best engineering assessment of the effects of the change. Engineering assessments shall meet the specifications in paragraph (d)(1) of this section.

(2) Where the recalculated TRE index value is less than or equal to 1.0, or less than or equal to 4.0 but greater than 1.0, the recalculated flow rate is greater than or equal to 0.005 standard cubic meter per minute, or the recalculated concentration is greater than or equal to 50 parts per million by volume, the owner or operator shall submit a report as specified in §63.118 (g), (h), (i), or (j) of this subpart and shall comply with the appropriate provisions in §63.113 of this subpart by the dates specified in §63.100 of subpart F of this part.

(f) Except as specified in §63.113(a)(4), notwithstanding any other provisions of this subpart, in any case where a process vent includes one or more gas streams that are not from a source subject to this subpart (hereafter called “non-HON streams” for purposes of this paragraph), and one or more gas streams that meet the criteria in §63.107(b) through (h) or the criteria in §63.107(i) (hereafter called “HON streams” for purposes of this paragraph), the owner or operator may elect to comply with paragraphs (f)(1) through (3) of this section.

(1) The owner or operator may determine the characteristics (flow rate, total organic HAP concentration, and TRE index value) for each HON stream, or combination of HON streams, at a representative point as near as practical to, but before, the point at which it is combined with one or more non-HON streams.

(2) If one or more of the HON streams, or combinations of HON streams, has the characteristics (determined at the location specified in paragraph (f)(1) of this section) associated with a Group 1 process vent, the combined vent stream is a Group 1 process vent. Except as specified in paragraph (f)(3) of this section, if none of the HON streams, or combinations of HON streams, when determined at the location specified in paragraph (f)(1) of this section, has the characteristics associated with a Group 1 process vent, the combined vent stream is a Group 2 process vent regardless of the TRE index value determined at the location specified in §63.115(a). If the combined vent stream is a Group 2 process vent as determined by the previous sentence, but one or more of the HON streams, or combinations of HON streams, has a TRE index value greater than 1 but less than or equal to 4, the combined vent stream is a process vent with a TRE index value greater than 1 but less than or equal to 4. In this case, the owner or operator shall monitor the combined vent stream as required by §63.114(b).

(3) Paragraphs (f)(1) and (2) of this section are not intended to apply instead of any other subpart of this part. If another subpart of this part applies to one or more of the non-HON streams contributing to the combined vent stream, that subpart may impose emission control requirements such as, but not limited to, requiring the combined vent stream to be classified and controlled as a Group 1 process vent.

(g) For each source as defined in §63.101, beginning no later than the compliance dates specified in §63.100(k)(10), paragraphs (b) and (c) of this section no longer apply. Instead, to demonstrate that a vent stream total organic HAP mass flow rate is less than 1.0 pound per hour in accordance with the Group 2 process vent definition of this subpart, the owner or operator must use the following procedures:

(1) The sampling site must be selected as specified in paragraph (a) of this section.

(2) Method 18 or Method 25A of appendices A-6 and A-7 to 40 CFR part 60 of this chapter, respectively, or Method 320 of appendix A to this part must be used to measure concentration. ASTM D6420-18 (incorporated by reference, see §63.14) may also be used in lieu of Method 18 or Method 320, if the target compounds are all known and are all listed in section 1.1 of ASTM D6420-18 as measurable; ASTM D6420-18 must not be used for methane and ethane; and ASTM D6420-18 may not be used as a total VOC method.

(3) Where Method 18 of appendix A-6 to part 60 of this chapter, Method 320 of appendix A to this part, or ASTM D6420-18 is used, the following procedures must be used to calculate the total organic HAP mass flow rate:

(i) The minimum sampling time for each run must be 1 hour in which either an integrated sample or four grab samples must be taken. If grab sampling is used, then the samples must be taken at approximately equal intervals in time, such as 15 minute intervals during the run.

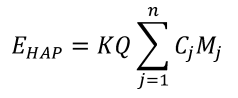

(ii) The mass rate of total organic HAP for each run must be computed using the following equation:

Equation 6 to Paragraph (g)(3)(ii)

Where:

E HAP = Emission rate of total organic HAP, lb/hr.

K = 1.675 × 10 -7 (parts per million) -1 (lb-mole per standard cubic feet) (minutes per hour), where standard temperature is 68 °F (20 °C).

Q = Flowrate of gas stream, dry standard cubic feet per minute), where standard temperature is 68 °F (20 °C), determined using Method 2, 2A, 2C, or 2D of 40 CFR part 60, appendix A, as appropriate. The flowrate may be based solely on an engineering assessment if measurements cannot be made with EPA reference methods.

C j = Concentration of organic compound j in the gas stream as measured by Method 18 of appendix A-6 to 40 CFR part 60, Method 320 of appendix A to this part, or ASTM D6420-18 (incorporated by reference, see §63.14), ppmv dry basis. The concentration may be based solely on an engineering assessment if measurements cannot be made with EPA reference methods.

M i = Molecular weight of organic compound j, lb/lb-mole.

j = Individual organic HAP compound in the gas stream. The list of organic HAPs is provided in table 2 of subpart F of this part.

n = Number of organic HAP compounds j in the gas stream.

(iii) The owner or operator must demonstrate that the emission rate of total organic HAP is less than 1.0 pound per hour for the vent stream to be considered a Group 2 process vent.

(4) Where Method 25A of appendix A-7 to part 60 of this chapter is used, the following procedures must be used to calculate parts per million by volume TOC concentration:

(i) Method 25A of appendix A-7 to part 60 of this chapter must be used only if a single organic HAP compound is greater than 50 percent of total organic HAP, by volume, in the vent stream.

(A) This organic HAP must be used as the calibration gas for Method 25A of appendix A-7 to part 60 of this chapter.

(B) Use of Method 25A of appendix A-7 to part 60 of this chapter is acceptable if the response from the high-level calibration gas is at least 20 times the standard deviation of the response from the zero calibration gas when the instrument is zeroed on the most sensitive scale.

(ii) The span value for Method 25A of appendix A-7 to part 60 of this chapter must be equal to approximately twice the expected concentration of TOC in the gas stream.

(iii) The minimum sampling time for each run must be 1 hour. The results must be corrected to a dry basis. You must use Method 4 of appendix A-3 to part 60 of this chapter to convert the Method 25A results to a dry basis.

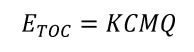

(iv) The mass rate of TOC for each run must be computed using the following equation:

Equation 7 to Paragraph (g)(4)(iv)

Where:

E TOC = Emission rate of TOC, lb/hr.

K = 1.675 × 10 -7 (parts per million) -1 (lb-mole per standard cubic feet) (minutes per hour), where standard temperature is 68 °F (20 °C).

C = Concentration of TOC in the gas stream as measured by Method 25A of appendix A to part 60 of this chapter ppmv dry basis. The concentration may be based solely on an engineering assessment if measurements cannot be made with EPA reference methods.

M = Molecular weight of the organic HAP used as the calibration gas, lb/lb-mole.

Q = Flowrate of gas stream, dry standard cubic feet per minute), where standard temperature is 68 °F (20 °C), determined using Method 2, 2A, 2C, or 2D of appendix A-1 to part 60 of this chapter, as appropriate. The flowrate may be based solely on an engineering assessment if measurements cannot be made with EPA reference methods.

(v) The owner or operator must demonstrate that the emission rate of TOC is less than 1.0 pound per hour for the vent stream to be considered a Group 2 process vent.

(5) The requirements specified in paragraphs (g)(1) through (4) of this section for an initial measurement or initial performance test do not apply if the conditions specified in paragraphs (g)(5)(i) through (iv) of this section are met for a previously conducted measurement or performance test.

(i) No changes have been made to the process since the time of the measurement or performance test;

(ii) The operating conditions and test methods used during measurement or performance test conform to the requirements in paragraphs (g)(1) through (4) of this section;

(iii) The control device and process parameter values established during the previously conducted measurement or performance test are used to demonstrate continuous compliance with the related requirements of this subpart, if applicable; and

(iv) The previously conducted measurement or performance test was completed within the last 60 months.

[59 FR 19468, Apr. 22, 1994, as amended at 62 FR 2746, Jan. 17, 1997; 66 FR 6931, Jan. 22, 2001; 89 FR 43067, May 16, 2024]

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.