['Air Programs']

['Hazardous Air Pollutants']

02/25/2022

...

(a) An owner or operator shall determine the total annual benzene quantity from facility waste by the following procedure:

(1) For each waste stream subject to this subpart having a flow-weighted annual average water content greater than 10 percent water, on a volume basis as total water, or is mixed with water or other wastes at any time and the resulting mixture has an annual average water content greater than 10 percent as specified in §61.342(a), the owner or operator shall:

(i) Determine the annual waste quantity for each waste stream using the procedures specified in paragraph (b) of this section.

(ii) Determine the flow-weighted annual average benzene concentration for each waste stream using the procedures specified in paragraph (c) of this section.

(iii) Calculate the annual benzene quantity for each waste stream by multiplying the annual waste quantity of the waste stream times the flow-weighted annual average benzene concentration.

(2) Total annual benzene quantity from facility waste is calculated by adding together the annual benzene quantity for each waste stream generated during the year and the annual benzene quantity for each process unit turnaround waste annualized according to paragraph (b)(4) of this section.

(3) If the total annual benzene quantity from facility waste is equal to or greater than 10 Mg/yr (11 ton/yr), then the owner or operator shall comply with the requirements of §61.342 (c), (d), or (e).

(4) If the total annual benzene quantity from facility waste is less than 10 Mg/yr (11 ton/yr) but is equal to or greater than 1 Mg/yr (1.1 ton/yr), then the owner or operator shall:

(i) Comply with the recordkeeping requirements of §61.356 and reporting requirements of §61.357 of this subpart; and

(ii) Repeat the determination of total annual benzene quantity from facility waste at least once per year and whenever there is a change in the process generating the waste that could cause the total annual benzene quantity from facility waste to increase to 10 Mg/yr (11 ton/yr) or more.

(5) If the total annual benzene quantity from facility waste is less than 1 Mg/yr (1.1 ton/yr), then the owner or operator shall:

(i) Comply with the recordkeeping requirements of §61.356 and reporting requirements of §61.357 of this subpart; and

(ii) Repeat the determination of total annual benzene quantity from facility waste whenever there is a change in the process generating the waste that could cause the total annual benzene quantity from facility waste to increase to 1 Mg/yr (1.1 ton/yr) or more.

(6) The benzene quantity in a waste stream that is generated less than one time per year, except as provided for process unit turnaround waste in paragraph (b)(4) of this section, shall be included in the determination of total annual benzene quantity from facility waste for the year in which the waste is generated unless the waste stream is otherwise excluded from the determination of total annual benzene quantity from facility waste in accordance with paragraphs (a) through (c) of this section. The benzene quantity in this waste stream shall not be annualized or averaged over the time interval between the activities that resulted in generation of the waste, for purposes of determining the total annual benzene quantity from facility waste.

(b) For purposes of the calculation required by paragraph (a) of this section, an owner or operator shall determine the annual waste quantity at the point of waste generation, unless otherwise provided in paragraphs (b) (1), (2), (3), and (4) of this section, by one of the methods given in paragraphs (b) (5) through (7) of this section.

(1) The determination of annual waste quantity for sour water streams that are processed in sour water strippers shall be made at the point that the water exits the sour water stripper.

(2) The determination of annual waste quantity for wastes at coke by-product plants subject to and complying with the control requirements of §61.132, 61.133, 61.134, or 61.139 of subpart L of this part shall be made at the location that the waste stream exits the process unit component or waste management unit controlled by that subpart or at the exit of the ammonia still, provided that the following conditions are met:

(i) The transfer of wastes between units complying with the control requirements of subpart L of this part, process units, and the ammonia still is made through hard piping or other enclosed system.

(ii) The ammonia still meets the definition of a sour water stripper in §61.341.

(3) The determination of annual waste quantity for wastes that are received at hazardous waste treatment, storage, or disposal facilities from offsite shall be made at the point where the waste enters the hazardous waste treatment, storage, or disposal facility.

(4) The determination of annual waste quantity for each process unit turnaround waste generated only at 2 year or greater intervals, may be made by dividing the total quantity of waste generated during the most recent process unit turnaround by the time period (in the nearest tenth of a year) between the turnaround resulting in generation of the waste and the most recent preceding process turnaround for the unit. The resulting annual waste quantity shall be included in the calculation of the annual benzene quantity as provided in paragraph (a)(1)(iii) of this section for the year in which the turnaround occurs and for each subsequent year until the unit undergoes the next process turnaround. For estimates of total annual benzene quantity as specified in the 90-day report, required under §61.357(a)(1), the owner or operator shall estimate the waste quantity generated during the most recent turnaround, and the time period between turnarounds in accordance with good engineering practices. If the owner or operator chooses not to annualize process unit turnaround waste, as specified in this paragraph, then the process unit turnaround waste quantity shall be included in the calculation of the annual benzene quantity for the year in which the turnaround occurs.

(5) Select the highest annual quantity of waste managed from historical records representing the most recent 5 years of operation or, if the facility has been in service for less than 5 years but at least 1 year, from historical records representing the total operating life of the facility;

(6) Use the maximum design capacity of the waste management unit; or

(7) Use measurements that are representative of maximum waste generation rates.

(c) For the purposes of the calculation required by §§61.355(a) of this subpart, an owner or operator shall determine the flow-weighted annual average ben- zene concentration in a manner that meets the requirements given in paragraph (c)(1) of this section using either of the methods given in paragraphs (c)(2) and (c)(3) of this section.

(1) The determination of flow-weighted annual average benzene concentration shall meet all of the following criteria:

(i) The determination shall be made at the point of waste generation except for the specific cases given in paragraphs (c)(1)(i)(A) through (D) of this section.

(A) The determination for sour water streams that are processed in sour water strippers shall be made at the point that the water exits the sour water stripper.

(B) The determination for wastes at coke by-product plants subject to and complying with the control requirements of §61.132, 61.133, 61.134, or 61.139 of subpart L of this part shall be made at the location that the waste stream exits the process unit component or waste management unit controlled by that subpart or at the exit of the ammonia still, provided that the following conditions are met:

(1) The transfer of wastes between units complying with the control requirements of subpart L of this part, process units, and the ammonia still is made through hard piping or other enclosed system.

(2) The ammonia still meets the definition of a sour water stripper in §61.341.

(C) The determination for wastes that are received from offsite shall be made at the point where the waste enters the hazardous waste treatment, storage, or disposal facility.

(D) The determination of flow-weighted annual average benzene concentration for process unit turnaround waste shall be made using either of the methods given in paragraph (c)(2) or (c)(3) of this section. The resulting flow-weighted annual average benzene concentration shall be included in the calculation of annual benzene quantity as provided in paragraph (a)(1)(iii) of this section for the year in which the turnaround occurs and for each subsequent year until the unit undergoes the next process unit turnaround.

(ii) Volatilization of the benzene by exposure to air shall not be used in the determination to reduce the benzene concentration.

(iii) Mixing or diluting the waste stream with other wastes or other materials shall not be used in the determination - to reduce the benzene concentration.

(iv) The determination shall be made prior to any treatment of the waste that removes benzene, except as specified in paragraphs (c)(1)(i)(A) through (D) of this section.

(v) For wastes with multiple phases, the determination shall provide the weighted-average benzene concentration based on the benzene concentration in each phase of the waste and the relative proportion of the phases.

(2) Knowledge of the waste. The owner or operator shall provide sufficient information to document the flow-weighted annual average benzene concentration of each waste stream. Examples of information that could constitute knowledge include material balances, records of chemicals purchases, or previous test results provided the results are still relevant to the current waste stream conditions. If test data are used, then the owner or operator shall provide documentation describing the testing protocol and the means by which sampling variability and analytical variability were accounted for in the determination of the flow-weighted annual average benzene concentration for the waste stream. When an owner or operator and the Administrator do not agree on determinations of the flow-weighted annual average benzene concentration based on knowledge of the waste, the procedures under paragraph (c)(3) of this section shall be used to resolve the disagreement.

(3) Measurements of the benzene concentration in the waste stream in accordance with the following procedures:

(i) Collect a minimum of three representative samples from each waste stream. Where feasible, samples shall be taken from an enclosed pipe prior to the waste being exposed to the atmosphere.

(ii) For waste in enclosed pipes, the following procedures shall be used:

(A) Samples shall be collected prior to the waste being exposed to the atmosphere in order to minimize the loss of benzene prior to sampling.

(B) A static mixer shall be installed in the process line or in a by-pass line unless the owner or operator demonstrates that installation of a static mixer in the line is not necessary to accurately determine the benzene concentration of the waste stream.

(C) The sampling tap shall be located within two pipe diameters of the static mixer outlet.

(D) Prior to the initiation of sampling, sample lines and cooling coil shall be purged with at least four volumes of waste.

(E) After purging, the sample flow shall be directed to a sample container and the tip of the sampling tube shall be kept below the surface of the waste during sampling to minimize contact with the atmosphere.

(F) Samples shall be collected at a flow rate such that the cooling coil is able to maintain a waste temperature less than 10°C (50°F).

(G) After filling, the sample container shall be capped immediately (within 5 seconds) to leave a minimum headspace in the container.

(H) The sample containers shall immediately be cooled and maintained at a temperature below 10°C (50°F) for transfer to the laboratory.

(iii) When sampling from an enclosed pipe is not feasible, a minimum of three representative samples shall be collected in a manner to minimize exposure of the sample to the atmosphere and loss of benzene prior to sampling.

(iv) Each waste sample shall be analyzed using one of the following test methods for determining the benzene concentration in a waste stream:

(A) Method 8020, Aromatic Volatile Organics, in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication No. SW-846 (incorporation by reference as specified in §61.18 of this part);

(B) Method 8021, Volatile Organic Compounds in Water by Purge and Trap Capillary Column Gas Chromatography with Photoionization and Electrolytic Conductivity Detectors in Series in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication No. SW-846 (incorporation by reference as specified in §61.18 of this part);

(C) Method 8240, Gas Chromatography/Mass Spectrometry for Volatile Organics in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication No. SW-846 (incorporation by reference as specified in §61.18 of this part);

(D) Method 8260, Gas Chromatography/Mass Spectrometry for Volatile Organics: Capillary Column Technique in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication No. SW-846 (incorporation by reference as specified in §61.18 of this part);

(E) Method 602, Purgeable Aromatics, as described in 40 CFR part 136, appendix A, Test Procedures for Analysis of Organic Pollutants, for wastewaters for which this is an approved EPA methods; or

(F) Method 624, Purgeables, as described in 40 CFR part 136, appendix A, Test Procedures for Analysis of Organic Pollutants, for wastewaters for which this is an approved EPA method.

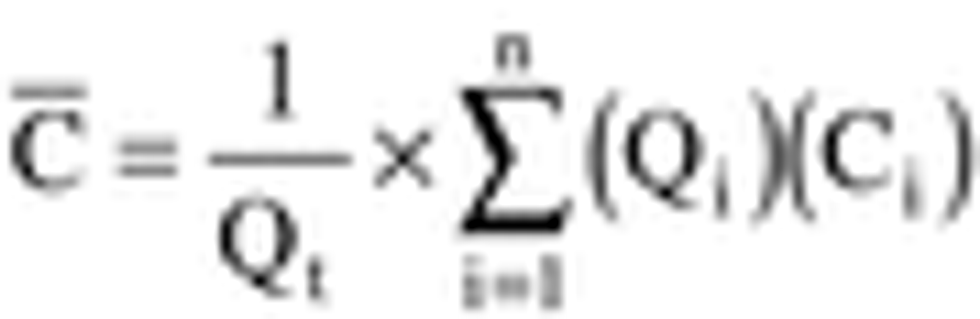

(v) The flow-weighted annual average benzene concentration shall be calculated by averaging the results of the sample analyses as follows:

Where:

C? = Flow-weighted annual average benzene concentration for waste stream, ppmw.

Qt = Total annual waste quantity for waste stream, kg/yr (lb/yr).

n = Number of waste samples (at least 3).

Qi = Annual waste quantity for waste stream represented by Ci, kg/yr (lb/yr).

Ci = Measured concentration of benzene in waste sample i, ppmw.

(d) An owner or operator using performance tests to demonstrate compliance of a treatment process with §61.348 (a)(1)(i) shall measure the flow-weighted annual average benzene concentration of the waste stream exiting the treatment process by collecting and analyzing a minimum of three representative samples of the waste stream using the procedures in paragraph (c)(3) of this section. The test shall be conducted under conditions that exist when the treatment process is operating at the highest inlet waste stream flow rate and benzene content expected to occur. Operations during periods of startup, shutdown, and malfunction shall not constitute representative conditions for the purpose of a test. The owner or operator shall record all process information as is necessary to document the operating conditions during the test.

(e) An owner or operator using performance tests to demonstrate compliance of a treatment process with §61.348(a)(1)(ii) of this subpart shall determine the percent reduction of benzene in the waste stream on a mass basis by the following procedure:

(1) The test shall be conducted under conditions that exist when the treatment process is operating at the highest inlet waste stream flow rate and benzene content expected to occur. Operations during periods of startup, shutdown, and malfunction shall not constitute representative conditions for the purpose of a test. The owner or operator shall record all process information as is necessary to document the operating conditions during the test.

(2) All testing equipment shall be prepared and installed as specified in the appropriate test methods.

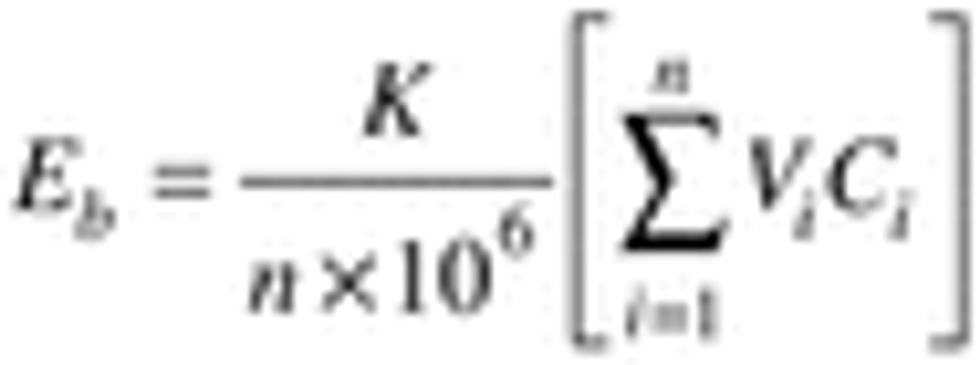

(3) The mass flow rate of benzene entering the treatment process (Eb) shall be determined by computing the product of the flow rate of the waste stream entering the treatment process, as determined by the inlet flow meter, and the benzene concentration of the waste stream, as determined using the sampling and analytical procedures specified in paragraph (c)(2) or (c)(3) of this section. Three grab samples of the waste shall be taken at equally spaced time intervals over a 1-hour period. Each 1-hour period constitutes a run, and the performance test shall consist of a minimum of 3 runs conducted over a 3-hour period. The mass flow rate of benzene entering the treatment process is calculated as follows:

Where:

Eb = Mass flow rate of benzene entering the treatment process, kg/hr (lb/hr).

K = Density of the waste stream, kg/m 3 (lb/ft 3).

Vi = Average volume flow rate of waste entering the treatment process during each run i, m 3/hr (ft 3/hr).

Ci = Average concentration of benzene in the waste stream entering the treatment process during each run i, ppmw.

n = Number of runs.

10 6 = Conversion factor for ppmw.

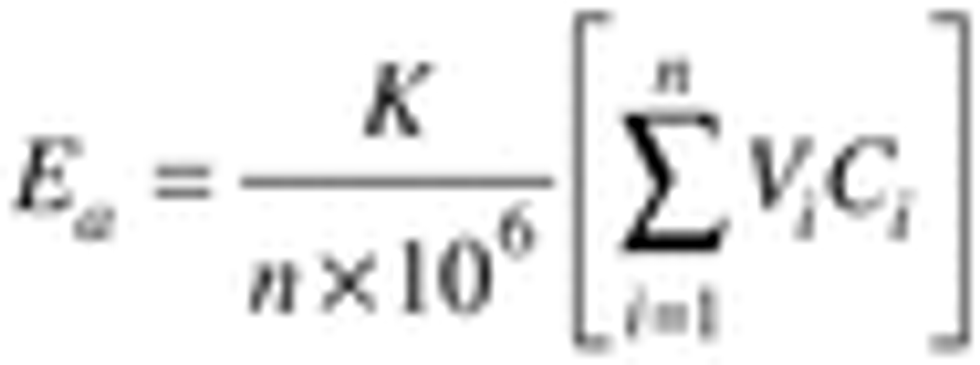

(4) The mass flow rate of benzene exiting the treatment process (Ea) shall be determined by computing the product of the flow rate of the waste stream exiting the treatment process, as determined by the outlet flow meter or the inlet flow meter, and the benzene concentration of the waste stream, as determined using the sampling and analytical procedures specified in paragraph (c)(2) or (c)(3) of this section. Three grab samples of the waste shall be taken at equally spaced time intervals over a 1-hour period. Each 1-hour period constitutes a run, and the performance test shall consist of a minimum of 3 runs conducted over the same 3-hour period at which the mass flow rate of benzene entering the treatment process is determined. The mass flow rate of benzene exiting the treatment process is calculated as follows:

Where:

Ea = Mass flow rate of benzene exiting the treatment process, kg/hr (lb/hr).

K = Density of the waste stream, kg/m 3 (lb/ft 3).

Vi = Average volume flow rate of waste exiting the treatment process during each run i, m 3/hr (ft 3/hr).

Ci = Average concentration of benzene in the waste stream exiting the treatment process during each run i, ppmw.

n = Number of runs.

10 6 = Conversion factor for ppmw.

(f) An owner or operator using performance tests to demonstrate compliance of a treatment process with §61.348(a)(1)(iii) of this subpart shall determine the benzene destruction efficiency for the combustion unit by the following procedure:

(1) The test shall be conducted under conditions that exist when the combustion unit is operating at the highest inlet waste stream flow rate and benzene content expected to occur. Operations during periods of startup, shutdown, and malfunction shall not constitute representative conditions for the purpose of a test. The owner or operator shall record all process information necessary to document the operating conditions during the test.

(2) All testing equipment shall be prepared and installed as specified in the appropriate test methods.

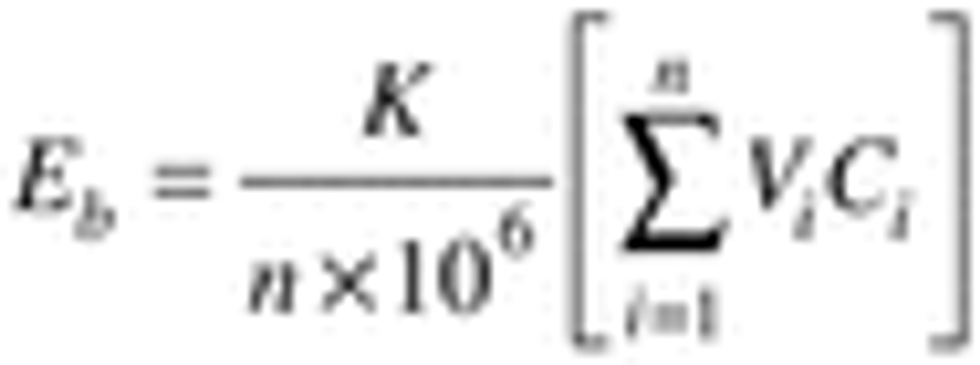

(3) The mass flow rate of benzene entering the combustion unit shall be determined by computing the product of the flow rate of the waste stream entering the combustion unit, as determined by the inlet flow meter, and the benzene concentration of the waste stream, as determined using the sampling procedures in paragraph (c)(2) or (c)(3) of this section. Three grab samples of the waste shall be taken at equally spaced time intervals over a 1-hour period. Each 1-hour period constitutes a run, and the performance test shall consist of a minimum of 3 runs conducted over a 3-hour period. The mass flow rate of benzene into the combustion unit is calculated as follows:

Where:

Eb = Mass flow rate of benzene entering the combustion unit, kg/hr (lb/hr).

K = Density of the waste stream, kg/m 3 (lb/ft 3).

Vi = Average volume flow rate of waste entering the combustion unit during each run i, m 3/hr (ft 3/hr).

Ci = Average concentration of benzene in the waste stream entering the combustion unit during each run i, ppmw.

n = Number of runs.

10 6 = Conversion factor for ppmw.

(4) The mass flow rate of benzene exiting the combustion unit exhaust stack shall be determined as follows:

(i) The time period for the test shall not be less than 3 hours during which at least 3 stack gas samples are collected and be the same time period at which the mass flow rate of benzene entering the treatment process is determined. Each sample shall be collected over a 1-hour period (e.g., in a tedlar bag) to represent a time-integrated composite sample and each 1-hour period shall correspond to the periods when the waste feed is sampled.

(ii) A run shall consist of a 1-hour period during the test. For each run:

(A) The reading from each measurement shall be recorded;

(B) The volume exhausted shall be determined using Method 2, 2A, 2C, or 2D from appendix A of 40 CFR part 60, as appropriate.

(C) The average benzene concentration in the exhaust downstream of the combustion unit shall be determined using Method 18 from appendix A of 40 CFR part 60.

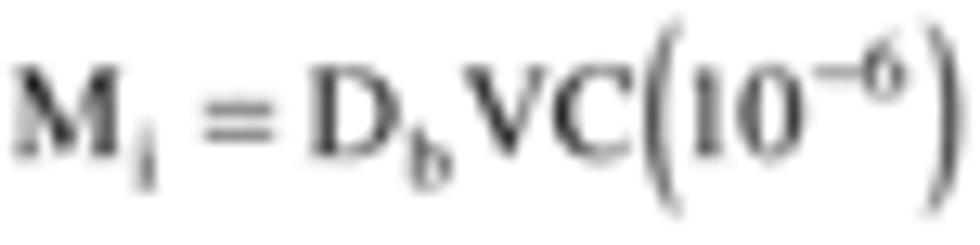

(iii) The mass of benzene emitted during each run shall be calculated as follows:

Where:

Mi = Mass of benzene emitted during run i, kg (lb).

V = Volume of air-vapor mixture exhausted at standard conditions, m 3 (ft 3).

C = Concentration of benzene measured in the exhaust, ppmv.

Db = Density of benzene, 3.24 kg/m 3 (0.202 lb/ft 3).

10 6 = Conversion factor for ppmv.

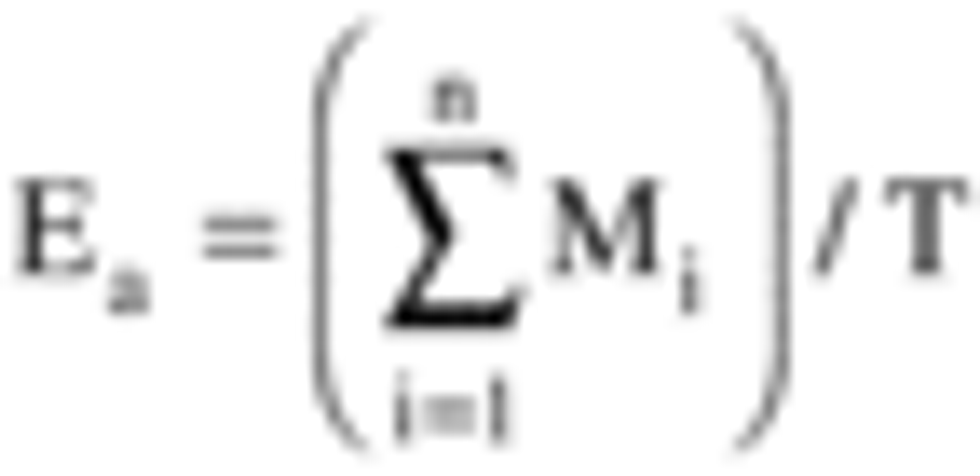

(iv) The benzene mass emission rate in the exhaust shall be calculated as follows:

Where:

Ea = Mass flow rate of benzene emitted from the combustion unit, kg/hr (lb/hr).

Mi = Mass of benzene emitted from the combustion unit during run i, kg (lb).

T = Total time of all runs, hr.

n = Number of runs.

(5) The benzene destruction efficiency for the combustion unit shall be calculated as follows:

Where:

R = Benzene destruction efficiency for the combustion unit, percent.

Eb = Mass flow rate of benzene entering the combustion unit, kg/hr (lb/hr).

Ea = Mass flow rate of benzene emitted from the combustion unit, kg/hr (lb/hr).

(g) An owner or operator using performance tests to demonstrate compliance of a wastewater treatment system unit with §61.348(b) shall measure the flow-weighted annual average benzene concentration of the wastewater stream where the waste stream enters an exempt waste management unit by collecting and analyzing a minimum of three representative samples of the waste stream using the procedures in paragraph (c)(3) of this section. The test shall be conducted under conditions that exist when the wastewater treatment system is operating at the highest inlet wastewater stream flow rate and benzene content expected to occur. Operations during periods of startup, shutdown, and malfunction shall not constitute representative conditions for the purpose of a test. The owner or operator shall record all process information as is necessary to document the operating conditions during the test.

(h) An owner or operator shall test equipment for compliance with no detectable emissions as required in §§61.343 through 61.347, and §61.349 of this subpart in accordance with the following requirements:

(1) Monitoring shall comply with Method 21 from appendix A of 40 CFR part 60.

(2) The detection instrument shall meet the performance criteria of Method 21.

(3) The instrument shall be calibrated before use on each day of its use by the procedures specified in Method 21.

(4) Calibration gases shall be:

(i) Zero air (less than 10 ppm of hydrocarbon in air); and

(ii) A mixture of methane or n-hexane and air at a concentration of approximately, but less than, 10,000 ppm methane or n-hexane.

(5) The background level shall be determined as set forth in Method 21.

(6) The instrument probe shall be traversed around all potential leak interfaces as close as possible to the interface as described in Method 21.

(7) The arithmetic difference between the maximum concentration indicated by the instrument and the background level is compared to 500 ppm for determining compliance.

(i) An owner or operator using a performance test to demonstrate compliance of a control device with either the organic reduction efficiency requirement or the benzene reduction efficiency requirement specified under §61.349(a)(2) shall use the following procedures:

(1) The test shall be conducted under conditions that exist when the waste management unit vented to the control device is operating at the highest load or capacity level expected to occur. Operations during periods of startup, shutdown, and malfunction shall not constitute representative conditions for the purpose of a test. The owner or operator shall record all process information necessary to document the operating conditions during the test.

(2) Sampling sites shall be selected using Method 1 or 1A from appendix A of 40 CFR part 60, as appropriate.

(3) The mass flow rate of either the organics or benzene entering and exiting the control device shall be determined as follows:

(i) The time period for the test shall not be less than 3 hours during which at least 3 stack gas samples are collected. Samples of the vent stream entering and exiting the control device shall be collected during the same time period. Each sample shall be collected over a 1-hour period (e.g., in a tedlar bag) to represent a time-integrated composite sample.

(ii) A run shall consist of a 1-hour period during the test. For each run:

(A) The reading from each measurement shall be recorded;

(B) The volume exhausted shall be determined using Method 2, 2A, 2C, or 2D from appendix A of 40 CFR part 60, as appropriate;

(C) The organic concentration or the benzene concentration, as appropriate, in the vent stream entering and exiting the control shall be determined using Method 18 from appendix A of 40 CFR part 60.

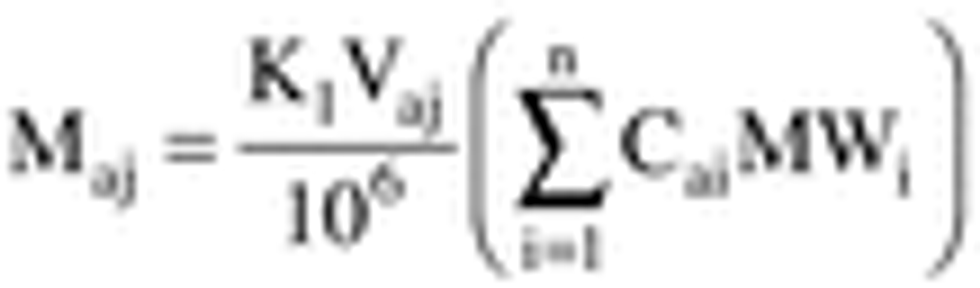

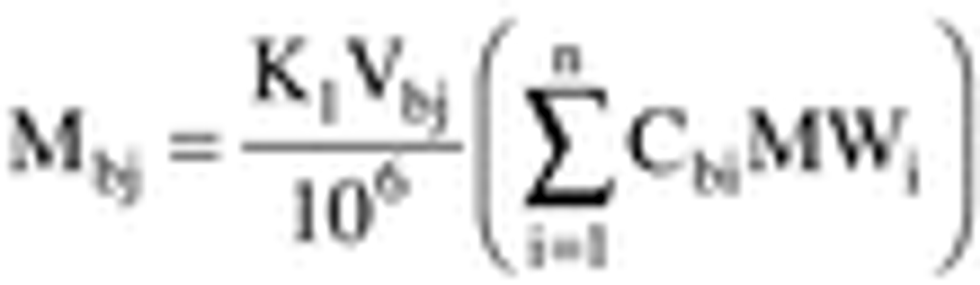

(iii) The mass of organics or benzene entering and exiting the control device during each run shall be calculated as follows:

Maj = Mass of organics or benzene in the vent stream entering the control device during run j, kg (lb).

Mbj = Mass of organics or benzene in the vent stream exiting the control device during run j, kg (lb).

Vaj = Volume of vent stream entering the control device during run j, at standard conditions, m 3 (ft 3).

Vbj = Volume of vent stream exiting the control device during run j, at standard conditions, m 3 (ft 3).

Cai = Organic concentration of compound i or the benzene concentration measured in the vent stream entering the control device as determined by Method 18, ppm by volume on a dry basis.

Cbi = Organic concentration of compound i or the benzene concentration measured in the vent stream exiting the control device as determined by Method 18, ppm by volume on a dry basis.

MWi = Molecular weight of organic compound i in the vent stream, or the molecular weight of benzene, kg/kg-mol (lb/lb-mole).

n = Number of organic compounds in the vent stream; if benzene reduction efficiency is being demonstrated, then n = 1.

K1 = Conversion factor for molar volume at standard conditions (293 K and 760 mm Hg (527 R and 14.7 psia))

= 0.0416 kg-mol/m 3 (0.00118 lb-mol/ft 3)

10?6 = Conversion factor for ppmv.

(iv) The mass flow rate of organics or benzene entering and exiting the control device shall be calculated as follows:

Where:

Ea = Mass flow rate of organics or benzene entering the control device, kg/hr (lb/hr).

Eb = Mass flow rate of organics or benzene exiting the control device, kg/hr (lb/hr).

Maj = Mass of organics or benzene in the vent stream entering the control device during run j, kg (lb).

M bj = Mass of organics or benzene in the vent stream exiting the control device during run j, kg (lb).

T = Total time of all runs, hr.

n = Number of runs.

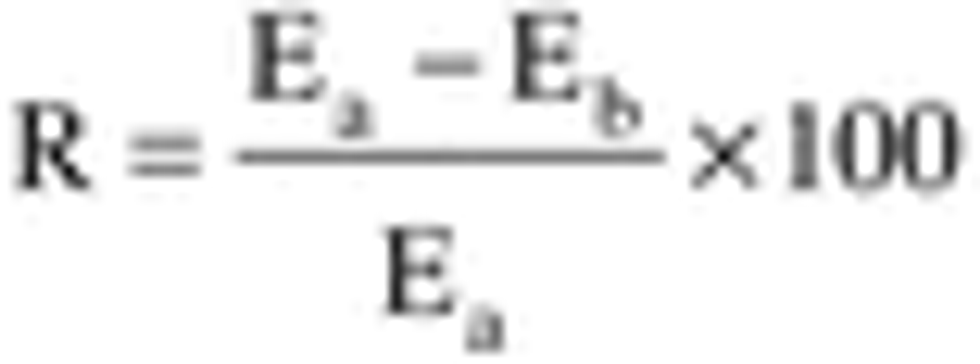

(4) The organic reduction efficiency or the benzene reduction efficiency for the control device shall be calculated as follows:

Where:

R = Total organic reduction of efficiency or benzene reduction efficiency for the control device, percent.

Eb = Mass flow rate of organics or benzene entering the control device, kg/hr (lb/hr).

Ea = Mass flow rate of organic or benzene emitted from the control device, kg/hr (lb/hr).

(j) An owner or operator shall determine the benzene quantity for the purposes of the calculation required by §61.342 (c)(3)(ii)(B) according to the provisions of paragraph (a) of this section, except that the procedures in paragraph (a) of this section shall also apply to wastes with a water content of 10 percent or less.

(k) An owner or operator shall determine the benzene quantity for the purposes of the calculation required by §61.342(e)(2) by the following procedure:

(1) For each waste stream that is not controlled forair emissions in accordance with §61.343. 61.344, 61.345, 61.346, 61.347, or 61.348(a), as applicable to the waste management unit that manages the waste, the benzene quantity shall be determined as specified in paragraph (a) of this section, except that paragraph (b)(4) of this section shall not apply, i.e., the waste quantity for process unit turnaround waste is not annualized but shall be included in the determination of benzene quantity for the year in which the waste is generated for the purposes of the calculation required by §61.342(e)(2).

(2) For each waste stream that is controlled for air emissions in accordance with §61.343. 61.344, 61.345, 61.346, 61.347, or 61.348(a), as applicable to the waste management unit that manages the waste, the determination of annual waste quantity and flow-weighted annual average benzene concentration shall be made at the first applicable location as described in paragraphs (k)(2)(i), (k)(2)(ii), and (k)(2)(iii) of this section and prior to any reduction of benzene concentration through volatilization of the benzene, using the methods given in (k)(2)(iv) and (k)(2)(v) of this section.

(i) Where the waste stream enters the first waste management unit not complying with §§61.343, 61.344, 61.345, 61.346, 61.347, and 61.348(a) that are applicable to the waste management unit,

(ii) For each waste stream that is managed or treated only in compliance with §§61.343 through 61.348(a) up to the point of final direct discharge from the facility, the determination of benzene quantity shall be prior to any reduction of benzene concentration through volatilization of the benzene, or

(iii) For wastes managed in units controlled for air emissions in accordance with §§61.343, 61.344, 61.345, 61.346, 61.347, and 61.348(a), and then transferred offsite, facilities shall use the first applicable offsite location as described in paragraphs (k)(2)(i) and (k)(2)(ii) of this section if they have documentation from the offsite facility of the benzene quantity at this location. Facilities without this documentation for offsite wastes shall use the benzene quantity determined at the point where the transferred waste leaves the facility.

(iv) Annual waste quantity shall be determined using the procedures in paragraphs (b)(5), (6), or (7) of this section, and

(v) The flow-weighted annual average benzene concentration shall be determined using the procedures in paragraphs (c)(2) or (3) of this section.

(3) The benzene quantity in a waste stream that is generated less than one time per year, including process unit turnaround waste, shall be included in the determination of benzene quantity as determined in paragraph (k)(6) of this section for the year in which the waste is generated. The benzene quantity in this waste stream shall not be annualized or averaged over the time interval between the activities that resulted in generation of the waste for purposes of determining benzene quantity as determined in paragraph (k)(6) of this section.

(4) The benzene in waste entering an enhanced biodegradation unit, as defined in §61.348(b)(2)(ii)(B), shall not be included in the determination of benzene quantity, determined in paragraph (k)(6) of this section, if the following conditions are met:

(i) The benzene concentration for each waste stream entering the enhanced biodegradation unit is less than 10 ppmw on a flow-weighted annual average basis, and

(ii) All prior waste management units managing the waste comply with §§61.343, 61.344, 61.345, 61.346, 61.347 and 61.348(a).

(5) The benzene quantity for each waste stream in paragraph (k)(2) of this section shall be determined by multiplying the annual waste quantity of each waste stream times its flow-weighted annual average benzene concentration.

(6) The total benzene quantity for the purposes of the calculation required by §61.342(e)(2) shall be determined by adding together the benzene quantities determined in paragraphs (k)(1) and (k)(5) of this section for each applicable waste stream.

(7) If the benzene quantity determined in paragraph (6) of this section exceeds 6.0 Mg/yr (6.6 ton/yr) only because of multiple counting of the benzene quantity for a waste stream, the owner or operator may use the following procedures for the purposes of the calculation required by §61.342(e)(2):

(i) Determine which waste management units are involved in the multiple counting of benzene;

(ii) Determine the quantity of benzene that is emitted, recovered, or removed from the affected units identified in paragraph (k)(7)(i) of this section, or destroyed in the units if applicable, using either direct measurements or the best available estimation techniques developed or approved by the Administrator.

(iii) Adjust the benzene quantity to eliminate the multiple counting of benzene based on the results from paragraph (k)(7)(ii) of this section and determine the total benzene quantity for the purposes of the calculation required by §61.342(e)(2).

(iv) Submit in the annual report required under §61.357(a) a description of the methods used and the resulting calculations for the alternative procedure under paragraph (k)(7) of this section, the benzene quantity determination from paragraph (k)(6) of this section, and the adjusted benzene quantity determination from paragraph (k)(7)(iii) of this section.

[55 FR 8346, Mar. 7, 1990; 55 FR 12444, Apr. 3, 1990, as amended at 55 FR 37231, Sept. 10, 1990; 58 FR 3099, Jan. 7, 1993; 65 FR 62160, Oct. 17, 2000]

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.