...

(a) For affected facilities for which construction, modification, or reconstruction commenced before May 4, 2011, the applicable PM emissions limit and opacity standard under �60.42Da, SO2 emissions limit under �60.43Da, and NOX emissions limit under �60.44Da apply at all times except during periods of startup, shutdown, or malfunction. For affected facilities for which construction, modification, or reconstruction commenced after May 3, 2011, the applicable SO2 emissions limit under �60.43Da, NOX emissions limit under �60.44Da, and NOX plus CO emissions limit under �60.45Da apply at all times. The applicable PM emissions limit and opacity standard under �60.42Da apply at all times except during periods of startup and shutdown.

(b) After the initial performance test required under �60.8, compliance with the applicable SO2 emissions limit and percentage reduction requirements under �60.43Da, NOX emissions limit under �60.44Da, and NOX plus CO emissions limit under �60.45Da is based on the average emission rate for 30 successive boiler operating days. A separate performance test is completed at the end of each boiler operating day after the initial performance test, and a new 30-boiler operating day rolling average emission rate for both SO2, NOX or NOX plus CO as applicable, and a new percent reduction for SO2 are calculated to demonstrate compliance with the standards.

(c) For the initial performance test required under �60.8, compliance with the applicable SO2 emissions limits and percentage reduction requirements under �60.43Da, the NOX emissions limits under �60.44Da, and the NOX plus CO emissions limits under �60.45Da is based on the average emission rates for SO2, NOX, CO, and percent reduction for SO2 for the first 30 successive boiler operating days. The initial performance test is the only test in which at least 30 days prior notice is required unless otherwise specified by the Administrator. The initial performance test is to be scheduled so that the first boiler operating day of the 30 successive boiler operating days is completed within 60 days after achieving the maximum production rate at which the affected facility will be operated, but not later than 180 days after initial startup of the facility.

(d) For affected facilities for which construction, modification, or reconstruction commenced before May 4, 2011, compliance with applicable 30-boiler operating day rolling average SO2 and NOX emissions limits is determined by calculating the arithmetic average of all hourly emission rates for SO2 and NOX for the 30 successive boiler operating days, except for data obtained during startup, shutdown, or malfunction. For affected facilities for which construction, modification, or reconstruction commenced after May 3, 2011, compliance with applicable 30-boiler operating day rolling average SO2 and NOX emissions limits is determined by dividing the sum of the SO2 and NOX emissions for the 30 successive boiler operating days by the sum of the gross energy output or net energy output, as applicable, for the 30 successive boiler operating days.

(e) For affected facilities for which construction, modification, or reconstruction commenced before May 4, 2011, compliance with applicable SO2 percentage reduction requirements is determined based on the average inlet and outlet SO2 emission rates for the 30 successive boiler operating days. For affected facilities for which construction, modification, or reconstruction commenced after May 3, 2011, compliance with applicable SO2 percentage reduction requirements is determined based on the �as fired� total potential emissions and the total outlet SO2 emissions for the 30 successive boiler operating days.

(f) For affected facilities for which construction, modification, or reconstruction commenced before May 4, 2011, compliance with the applicable daily average PM emissions limit is determined by calculating the arithmetic average of all hourly emission rates each boiler operating day, except for data obtained during startup, shutdown, or malfunction periods. Daily averages are only calculated for boiler operating days that have non-out-of-control data for at least 18 hours of unit operation during which the standard applies. Instead, all of the non-out-of-control hourly emission rates of the operating day(s) not meeting the minimum 18 hours non-out-of-control data daily average requirement are averaged with all of the non-out-of-control hourly emission rates of the next boiler operating day with 18 hours or more of non-out-of-control PM CEMS data to determine compliance. For affected facilities for which construction or reconstruction commenced after May 3, 2011 that elect to demonstrate compliance using PM CEMS, compliance with the applicable PM emissions limit in �60.42Da is determined on a 30-boiler operating day rolling average basis by calculating the arithmetic average of all hourly PM emission rates for the 30 successive boiler operating days, except for data obtained during periods of startup and shutdown.

(g) For affected facilities for which construction, modification, or reconstruction commenced after May 3, 2011, compliance with applicable 30-boiler operating day rolling average NOX plus CO emissions limit is determined by dividing the sum of the NOX plus CO emissions for the 30 successive boiler operating days by the sum of the gross energy output or net energy output, as applicable, for the 30 successive boiler operating days.

(h) If an owner or operator has not obtained the minimum quantity of emission data as required under �60.49Da of this subpart, compliance of the affected facility with the emission requirements under ��60.43Da and 60.44Da of this subpart for the day on which the 30-day period ends may be determined by the Administrator by following the applicable procedures in section 7 of Method 19 of appendix A of this part.

(i) Compliance provisions for sources subject to �60.44Da(d)(1), (e)(1), (e)(2)(i), (e)(3)(i), (f), or (g). The owner or operator shall calculate NOX emissions as 1.194 � 10?7 lb/scf-ppm times the average hourly NOX output concentration in ppm (measured according to the provisions of �60.49Da(c)), times the average hourly flow rate (measured in scfh, according to the provisions of �60.49Da(l) or �60.49Da(m)), divided by the average hourly gross energy output (measured according to the provisions of �60.49Da(k)) or the average hourly net energy output, as applicable. Alternatively, for oil-fired and gas-fired units, NOX emissions may be calculated by multiplying the hourly NOX emission rate in lb/MMBtu (measured by the CEMS required under �60.49Da(c) and (d)), by the hourly heat input rate (measured according to the provisions of �60.49Da(n)), and dividing the result by the average gross energy output (measured according to the provisions of �60.49Da(k)) or the average hourly net energy output, as applicable.

(j) Compliance provisions for duct burners subject to �60.44Da(a)(1). To determine compliance with the emissions limits for NOX required by �60.44Da(a) for duct burners used in combined cycle systems, either of the procedures described in paragraph (j)(1) or (2) of this section may be used:

(1) The owner or operator of an affected duct burner shall conduct the performance test required under �60.8 using the appropriate methods in appendix A of this part. Compliance with the emissions limits under �60.44Da(a)(1) is determined on the average of three (nominal 1-hour) runs for the initial and subsequent performance tests. During the performance test, one sampling site shall be located in the exhaust of the turbine prior to the duct burner. A second sampling site shall be located at the outlet from the heat recovery steam generating unit. Measurements shall be taken at both sampling sites during the performance test; or

(2) The owner or operator of an affected duct burner may elect to determine compliance by using the CEMS specified under �60.49Da for measuring NOX and oxygen (O2) (or carbon dioxide (CO2)) and meet the requirements of �60.49Da. Alternatively, data from a NOX emission rate (i.e., NOX-diluent) CEMS certified according to the provisions of �75.20(c) of this chapter and appendix A to part 75 of this chapter, and meeting the quality assurance requirements of �75.21 of this chapter and appendix B to part 75 of this chapter, may be used, with the following caveats. Data used to meet the requirements of �60.51Da shall not include substitute data values derived from the missing data procedures in subpart D of part 75 of this chapter, nor shall the data have been bias adjusted according to the procedures of part 75 of this chapter. The sampling site shall be located at the outlet from the steam generating unit. The NOX emission rate at the outlet from the steam generating unit shall constitute the NOX emission rate from the duct burner of the combined cycle system.

(k) Compliance provisions for duct burners subject to �60.44Da(d)(1) or (e)(1). To determine compliance with the emission limitation for NOX required by �60.44Da(d)(1) or (e)(1) for duct burners used in combined cycle systems, either of the procedures described in paragraphs (k)(1) and (2) of this section may be used:

(1) The owner or operator of an affected duct burner used in combined cycle systems shall determine compliance with the applicable NOX emission limitation in �60.44Da(d)(1) or (e)(1) as follows:

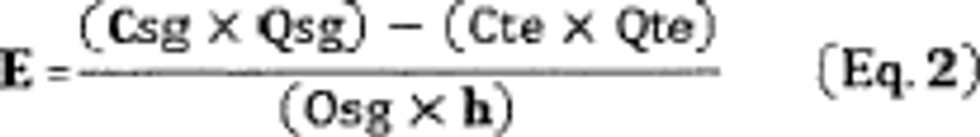

(i) The emission rate (E) of NOX shall be computed using Equation 2 in this section:

Where:

E = Emission rate of NOX from the duct burner, ng/J (lb/MWh) gross energy output;

Csg = Average hourly concentration of NOX exiting the steam generating unit, ng/dscm (lb/dscf);

Cte = Average hourly concentration of NOX in the turbine exhaust upstream from duct burner, ng/dscm (lb/dscf);

Qsg = Average hourly volumetric flow rate of exhaust gas from steam generating unit, dscm/h (dscf/h);

Qte = Average hourly volumetric flow rate of exhaust gas from combustion turbine, dscm/h (dscf/h);

Osg = Average hourly gross energy output from steam generating unit, J/h (MW); and

h = Average hourly fraction of the total heat input to the steam generating unit derived from the combustion of fuel in the affected duct burner.

(ii) Method 7E of appendix A of this part shall be used to determine the NOX concentrations (Csg and Cte). Method 2, 2F or 2G of appendix A of this part, as appropriate, shall be used to determine the volumetric flow rates (Qsg and Qte) of the exhaust gases. The volumetric flow rate measurements shall be taken at the same time as the concentration measurements.

(iii) The owner or operator shall develop, demonstrate, and provide information satisfactory to the Administrator to determine the average hourly gross energy output from the steam generating unit, and the average hourly percentage of the total heat input to the steam generating unit derived from the combustion of fuel in the affected duct burner.

(iv) Compliance with the applicable NOX emission limitation in �60.44Da(d)(1) or (e)(1) is determined by the three-run average (nominal 1-hour runs) for the initial and subsequent performance tests.

(2) The owner or operator of an affected duct burner used in a combined cycle system may elect to determine compliance with the applicable NOX emission limitation in �60.44Da(d)(1) or (e)(1) on a 30-day rolling average basis as indicated in paragraphs (k)(2)(i) through (iv) of this section.

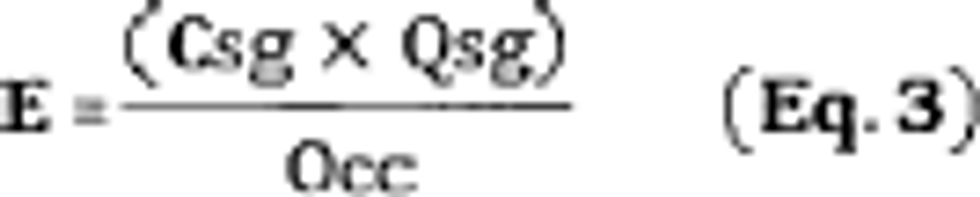

(i) The emission rate (E) of NOX shall be computed using Equation 3 in this section:

Where:

E = Emission rate of NOX from the duct burner, ng/J (lb/MWh) gross energy output;

Csg = Average hourly concentration of NOX exiting the steam generating unit, ng/dscm (lb/dscf);

Qsg = Average hourly volumetric flow rate of exhaust gas from steam generating unit, dscm/h (dscf/h); and

Occ = Average hourly gross energy output from entire combined cycle unit, J/h (MW).

(ii) The CEMS specified under �60.49Da for measuring NOX and O2 (or CO2) shall be used to determine the average hourly NOX concentrations (Csg). The continuous flow monitoring system specified in �60.49Da(l) or �60.49Da(m) shall be used to determine the volumetric flow rate (Qsg) of the exhaust gas. If the option to use the flow monitoring system in �60.49Da(m) is selected, the flow rate data used to meet the requirements of �60.51Da shall not include substitute data values derived from the missing data procedures in subpart D of part 75 of this chapter, nor shall the data have been bias adjusted according to the procedures of part 75 of this chapter. The sampling site shall be located at the outlet from the steam generating unit.

(iii) The continuous monitoring system specified under �60.49Da(k) for measuring and determining gross energy output shall be used to determine the average hourly gross energy output from the entire combined cycle unit (Occ), which is the combined output from the combustion turbine and the steam generating unit.

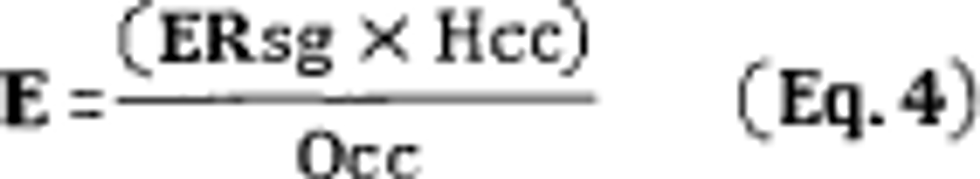

(iv) The owner or operator may, in lieu of installing, operating, and recording data from the continuous flow monitoring system specified in �60.49Da(l), determine the mass rate (lb/h) of NOX emissions by installing, operating, and maintaining continuous fuel flowmeters following the appropriate measurements procedures specified in appendix D of part 75 of this chapter. If this compliance option is selected, the emission rate (E) of NOX shall be computed using Equation 4 in this section:

Where:

E = Emission rate of NOX from the duct burner, ng/J (lb/MWh) gross energy output;

ERsg = Average hourly emission rate of NOX exiting the steam generating unit heat input calculated using appropriate F factor as described in Method 19 of appendix A of this part, ng/J (lb/MMBtu);

Hcc = Average hourly heat input rate of entire combined cycle unit, J/h (MMBtu/h); and

Occ = Average hourly gross energy output from entire combined cycle unit, J/h (MW).

(3) When an affected duct burner steam generating unit utilizes a common steam turbine with one or more affected duct burner steam generating units, the owner or operator shall either:

(i) Determine compliance with the applicable NOX emissions limits by measuring the emissions combined with the emissions from the other unit(s) utilizing the common steam turbine; or

(ii) Develop, demonstrate, and provide information satisfactory to the Administrator on methods for apportioning the combined gross energy output from the steam turbine for each of the affected duct burners. The Administrator may approve such demonstrated substitute methods for apportioning the combined gross energy output measured at the steam turbine whenever the demonstration ensures accurate estimation of emissions regulated under this part.

(l) [Reserved]

(m) Compliance provisions for sources subject to �60.43Da(i)(1)(i), (i)(2)(i), (i)(3)(i), (j)(1)(i), (j)(2)(i), (j)(3)(i), (l)(1)(i), (l)(1)(ii), or (l)(2). The owner or operator shall calculate SO2 emissions as 1.660 � 10?7 lb/scf-ppm times the average hourly SO2 output concentration in ppm (measured according to the provisions of �60.49Da(b)), times the average hourly flow rate (measured according to the provisions of �60.49Da(l) or �60.49Da(m)), divided by the average hourly gross energy output (measured according to the provisions of �60.49Da(k)) or the average hourly net energy output, as applicable. Alternatively, for oil-fired and gas-fired units, SO2 emissions may be calculated by multiplying the hourly SO2 emission rate (in lb/MMBtu), measured by the CEMS required under �60.49Da, by the hourly heat input rate (measured according to the provisions of �60.49Da(n)), and dividing the result by the average gross energy output (measured according to the provisions of �60.49Da(k)) or the average hourly net energy output, as applicable.

(n) Compliance provisions for sources subject to �60.42Da(c)(1) or (e)(1)(i). The owner or operator shall calculate PM emissions by multiplying the average hourly PM output concentration (measured according to the provisions of �60.49Da(t)), by the average hourly flow rate (measured according to the provisions of �60.49Da(l) or �60.49Da(m)), and dividing by the average hourly gross energy output (measured according to the provisions of �60.49Da(k)) or the average hourly net energy output, as applicable.

(o) Compliance provisions for sources subject to �60.42Da(c)(2), (d), or (e)(1)(ii). Except as provided for in paragraph (p) of this section, the owner or operator must demonstrate compliance with each applicable emissions limit according to the requirements in paragraphs (o)(1) through (o)(5) of this section.

(1) You must conduct a performance test to demonstrate initial compliance with the applicable PM emissions limit in �60.42Da by the applicable date specified in �60.8(a). Thereafter, you must conduct each subsequent performance test within 12 calendar months following the date the previous performance test was required to be conducted. You must conduct each performance test according to the requirements in �60.8 using the test methods and procedures in �60.50Da. The owner or operator of an affected facility that has not operated for 60 consecutive calendar days prior to the date that the subsequent performance test would have been required had the unit been operating is not required to perform the subsequent performance test until 30 calendar days after the next boiler operating day. Requests for additional 30 day extensions shall be granted by the relevant air division or office director of the appropriate Regional Office of the U.S. EPA.

(2) You must monitor the performance of each electrostatic precipitator or fabric filter (baghouse) operated to comply with the applicable PM emissions limit in �60.42Da using a continuous opacity monitoring system (COMS) according to the requirements in paragraphs (o)(2)(i) through (vi) unless you elect to comply with one of the alternatives provided in paragraphs (o)(3) and (o)(4) of this section, as applicable to your control device.

(i) Each COMS must meet Performance Specification 1 in 40 CFR part 60, appendix B.

(ii) You must comply with the quality assurance requirements in paragraphs (o)(2)(ii)(A) through (E) of this section.

(A) You must automatically (intrinsic to the opacity monitor) check the zero and upscale (span) calibration drifts at least once daily. For a particular COMS, the acceptable range of zero and upscale calibration materials is as defined in the applicable version of Performance Specification 1 in 40 CFR part 60, appendix B.

(B) You must adjust the zero and span whenever the 24-hour zero drift or 24-hour span drift exceeds 4 percent opacity. The COMS must allow for the amount of excess zero and span drift measured at the 24-hour interval checks to be recorded and quantified. The optical surfaces exposed to the effluent gases must be cleaned prior to performing the zero and span drift adjustments, except for systems using automatic zero adjustments. For systems using automatic zero adjustments, the optical surfaces must be cleaned when the cumulative automatic zero compensation exceeds 4 percent opacity.

(C) You must apply a method for producing a simulated zero opacity condition and an upscale (span) opacity condition using a certified neutral density filter or other related technique to produce a known obscuration of the light beam. All procedures applied must provide a system check of the analyzer internal optical surfaces and all electronic circuitry including the lamp and photodetector assembly.

(D) Except during periods of system breakdowns, repairs, calibration checks, and zero and span adjustments, the COMS must be in continuous operation and must complete a minimum of one cycle of sampling and analyzing for each successive 10 second period and one cycle of data recording for each successive 6-minute period.

(E) You must reduce all data from the COMS to 6-minute averages. Six-minute opacity averages must be calculated from 36 or more data points equally spaced over each 6-minute period. Data recorded during periods of system breakdowns, repairs, calibration checks, and zero and span adjustments must not be included in the data averages. An arithmetic or integrated average of all data may be used.

(iii) During each performance test conducted according to paragraph (o)(1) of this section, you must establish an opacity baseline level. The value of the opacity baseline level is determined by averaging all of the 6-minute average opacity values (reported to the nearest 0.1 percent opacity) from the COMS measurements recorded during each of the test run intervals conducted for the performance test, and then adding 2.5 percent opacity to your calculated average opacity value for all of the test runs. If your opacity baseline level is less than 5.0 percent, then the opacity baseline level is set at 5.0 percent.

(iv) You must evaluate the preceding 24-hour average opacity level measured by the COMS each boiler operating day excluding periods of affected facility startup, shutdown, or malfunction. If the measured 24-hour average opacity emission level is greater than the baseline opacity level determined in paragraph (o)(2)(iii) of this section, you must initiate investigation of the relevant equipment and control systems within 24 hours of the first discovery of the high opacity incident and take the appropriate corrective action as soon as practicable to adjust control settings or repair equipment to reduce the measured 24-hour average opacity to a level below the baseline opacity level. In cases when a wet scrubber is used in combination with another PM control device that serves as the primary PM control device, the wet scrubber must be maintained and operated.

(v) You must record the opacity measurements, calculations performed, and any corrective actions taken. The record of corrective action taken must include the date and time during which the measured 24-hour average opacity was greater than baseline opacity level, and the date, time, and description of the corrective action.

(vi) If the measured 24-hour average opacity for your affected facility remains at a level greater than the opacity baseline level after 7 boiler operating days, then you must conduct a new PM performance test according to paragraph (o)(1) of this section and establish a new opacity baseline value according to paragraph (o)(2) of this section. This new performance test must be conducted within 60 days of the date that the measured 24-hour average opacity was first determined to exceed the baseline opacity level unless a waiver is granted by the permitting authority.

(3) As an alternative to complying with the requirements of paragraph (o)(2) of this section, an owner or operator may elect to monitor the performance of an electrostatic precipitator (ESP) operated to comply with the applicable PM emissions limit in �60.42Da using an ESP predictive model developed in accordance with the requirements in paragraphs (o)(3)(i) through (v) of this section.

(i) You must calibrate the ESP predictive model with each PM control device used to comply with the applicable PM emissions limit in �60.42Da operating under normal conditions. In cases when a wet scrubber is used in combination with an ESP to comply with the PM emissions limit, the wet scrubber must be maintained and operated.

(ii) You must develop a site-specific monitoring plan that includes a description of the ESP predictive model used, the model input parameters, and the procedures and criteria for establishing monitoring parameter baseline levels indicative of compliance with the PM emissions limit. You must submit the site-specific monitoring plan for approval by the permitting authority. For reference purposes in preparing the monitoring plan, see the OAQPS �Compliance Assurance Monitoring (CAM) Protocol for an Electrostatic Precipitator (ESP) Controlling Particulate Matter (PM) Emissions from a Coal-Fired Boiler.� This document is available from the U.S. Environmental Protection Agency (U.S. EPA); Office of Air Quality Planning and Standards; Sector Policies and Programs Division; Measurement Policy Group (D243-02), Research Triangle Park, NC 27711. This document is also available on the Technology Transfer Network (TTN) under Emission Measurement Center Continuous Emission Monitoring.

(iii) You must run the ESP predictive model using the applicable input data each boiler operating day and evaluate the model output for the preceding boiler operating day excluding periods of affected facility startup, shutdown, or malfunction. If the values for one or more of the model parameters exceed the applicable baseline levels determined according to your approved site-specific monitoring plan, you must initiate investigation of the relevant equipment and control systems within 24 hours of the first discovery of a model parameter deviation and, take the appropriate corrective action as soon as practicable to adjust control settings or repair equipment to return the model output to within the applicable baseline levels.

(iv) You must record the ESP predictive model inputs and outputs and any corrective actions taken. The record of corrective action taken must include the date and time during which the model output values exceeded the applicable baseline levels, and the date, time, and description of the corrective action.

(v) If after 7 consecutive days a model parameter continues to exceed the applicable baseline level, then you must conduct a new PM performance test according to paragraph (o)(1) of this section. This new performance test must be conducted within 60 calendar days of the date that the model parameter was first determined to exceed its baseline level unless a waiver is granted by the permitting authority.

(4) As an alternative to complying with the requirements of paragraph (o)(2) of this section, an owner or operator may elect to monitor the performance of a fabric filter (baghouse) operated to comply with the applicable PM emissions limit in �60.42Da by using a bag leak detection system according to the requirements in paragraphs (o)(4)(i) through (v) of this section.

(i) Each bag leak detection system must meet the specifications and requirements in paragraphs (o)(4)(i)(A) through (H) of this section.

(A) The bag leak detection system must be certified by the manufacturer to be capable of detecting PM emissions at concentrations of 1 milligram per actual cubic meter (0.00044 grains per actual cubic foot) or less.

(B) The bag leak detection system sensor must provide output of relative PM loadings. The owner or operator must continuously record the output from the bag leak detection system using electronic or other means (e.g., using a strip chart recorder or a data logger.)

(C) The bag leak detection system must be equipped with an alarm system that will react when the system detects an increase in relative particulate loading over the alarm set point established according to paragraph (o)(4)(i)(D) of this section, and the alarm must be located such that it can be noticed by the appropriate plant personnel.

(D) In the initial adjustment of the bag leak detection system, you must establish, at a minimum, the baseline output by adjusting the sensitivity (range) and the averaging period of the device, the alarm set points, and the alarm delay time.

(E) Following initial adjustment, you must not adjust the averaging period, alarm set point, or alarm delay time without approval from the permitting authority except as provided in paragraph (d)(1)(vi) of this section.

(F) Once per quarter, you may adjust the sensitivity of the bag leak detection system to account for seasonal effects, including temperature and humidity, according to the procedures identified in the site-specific monitoring plan required by paragraph (o)(4)(ii) of this section.

(G) You must install the bag leak detection sensor downstream of the fabric filter and upstream of any wet scrubber.

(H) Where multiple detectors are required, the system's instrumentation and alarm may be shared among detectors.

(ii) You must develop and submit to the permitting authority for approval a site-specific monitoring plan for each bag leak detection system. You must operate and maintain the bag leak detection system according to the site-specific monitoring plan at all times. Each monitoring plan must describe the items in paragraphs (o)(4)(ii)(A) through (F) of this section.

(A) Installation of the bag leak detection system;

(B) Initial and periodic adjustment of the bag leak detection system, including how the alarm set-point will be established;

(C) Operation of the bag leak detection system, including quality assurance procedures;

(D) How the bag leak detection system will be maintained, including a routine maintenance schedule and spare parts inventory list;

(E) How the bag leak detection system output will be recorded and stored; and

(F) Corrective action procedures as specified in paragraph (o)(4)(iii) of this section. In approving the site-specific monitoring plan, the permitting authority may allow owners and operators more than 3 hours to alleviate a specific condition that causes an alarm if the owner or operator identifies in the monitoring plan this specific condition as one that could lead to an alarm, adequately explains why it is not feasible to alleviate this condition within 3 hours of the time the alarm occurs, and demonstrates that the requested time will ensure alleviation of this condition as expeditiously as practicable.

(iii) For each bag leak detection system, you must initiate procedures to determine the cause of every alarm within 1 hour of the alarm. Except as provided in paragraph (o)(4)(ii)(F) of this section, you must alleviate the cause of the alarm within 3 hours of the alarm by taking whatever corrective action(s) are necessary. Corrective actions may include, but are not limited to the following:

(A) Inspecting the fabric filter for air leaks, torn or broken bags or filter media, or any other condition that may cause an increase in particulate emissions;

(B) Sealing off defective bags or filter media;

(C) Replacing defective bags or filter media or otherwise repairing the control device;

(D) Sealing off a defective fabric filter compartment;

(E) Cleaning the bag leak detection system probe or otherwise repairing the bag leak detection system; or

(F) Shutting down the process producing the particulate emissions.

(iv) You must maintain records of the information specified in paragraphs (o)(4)(iv)(A) through (C) of this section for each bag leak detection system.

(A) Records of the bag leak detection system output;

(B) Records of bag leak detection system adjustments, including the date and time of the adjustment, the initial bag leak detection system settings, and the final bag leak detection system settings; and

(C) The date and time of all bag leak detection system alarms, the time that procedures to determine the cause of the alarm were initiated, if procedures were initiated within 1 hour of the alarm, the cause of the alarm, an explanation of the actions taken, the date and time the cause of the alarm was alleviated, and if the alarm was alleviated within 3 hours of the alarm.

(v) If after any period composed of 30 boiler operating days during which the alarm rate exceeds 5 percent of the process operating time (excluding control device or process startup, shutdown, and malfunction), then you must conduct a new PM performance test according to paragraph (o)(1) of this section. This new performance test must be conducted within 60 calendar days of the date that the alarm rate was first determined to exceed 5 percent limit unless a waiver is granted by the permitting authority.

(5) An owner or operator of a modified affected facility electing to meet the emission limitations in �60.42Da(d) shall determine the percent reduction in PM by using the emission rate for PM determined by the performance test conducted according to the requirements in paragraph (o)(1) of this section and the ash content on a mass basis of the fuel burned during each performance test run as determined by analysis of the fuel as fired.

(p) As an alternative to meeting the compliance provisions specified in paragraph (o) of this section, an owner or operator may elect to install, evaluate, maintain, and operate a CEMS measuring PM emissions discharged from the affected facility to the atmosphere and record the output of the system as specified in paragraphs (p)(1) through (p)(8) of this section.

(1) The owner or operator shall submit a written notification to the Administrator of intent to demonstrate compliance with this subpart by using a CEMS measuring PM. This notification shall be sent at least 30 calendar days before the initial startup of the monitor for compliance determination purposes. The owner or operator may discontinue operation of the monitor and instead return to demonstration of compliance with this subpart according to the requirements in paragraph (o) of this section by submitting written notification to the Administrator of such intent at least 30 calendar days before shutdown of the monitor for compliance determination purposes.

(2) Each CEMS shall be installed, evaluated, operated, and maintained according to the requirements in �60.49Da(v).

(3) The initial performance evaluation shall be completed no later than 180 days after the date of initial startup of the affected facility, as specified under �60.8 of subpart A of this part or within 180 days of the date of notification to the Administrator required under paragraph (p)(1) of this section, whichever is later.

(4) Compliance with the applicable emissions limit shall be determined based on the 24-hour daily (block) average of the hourly arithmetic average emissions concentrations using the continuous monitoring system outlet data. The 24-hour block arithmetic average emission concentration shall be calculated using EPA Reference Method 19 of appendix A of this part, section 4.1.

(5) At a minimum, non-out-of-control CEMS hourly averages shall be obtained for 75 percent of all operating hours on a 30-boiler operating day rolling average basis. Beginning on January 1, 2012, non-out-of-control CEMS hourly averages shall be obtained for 90 percent of all operating hours on a 30-boiler operating day rolling average basis.

(i) At least two data points per hour shall be used to calculate each 1-hour arithmetic average.

(ii) [Reserved]

(6) The 1-hour arithmetic averages required shall be expressed in ng/J, MMBtu/hr, or lb/MWh and shall be used to calculate the boiler operating day daily arithmetic average emission concentrations. The 1-hour arithmetic averages shall be calculated using the data points required under �60.13(e)(2) of subpart A of this part.

(7) All non-out-of-control CEMS data shall be used in calculating average emission concentrations even if the minimum CEMS data requirements of paragraph (j)(5) of this section are not met.

(8) When PM emissions data are not obtained because of CEMS breakdowns, repairs, calibration checks, and zero and span adjustments, emissions data shall be obtained by using other monitoring systems as approved by the Administrator or EPA Reference Method 19 of appendix A of this part to provide, as necessary, non-out-of-control emissions data for a minimum of 90 percent (only 75 percent is required prior to January 1, 2012) of all operating hours per 30-boiler operating day rolling average.

(q) Compliance provisions for sources subject to �60.42Da(b). An owner or operator of an affected facility subject to the opacity standard in �60.42Da(b) shall monitor the opacity of emissions discharged from the affected facility to the atmosphere according to the requirements in �60.49Da(a), as applicable to the affected facility.

(r) Compliance provisions for sources subject to �60.45Da. To determine compliance with the NOX plus CO emissions limit, the owner or operator shall use the procedures specified in paragraphs (r)(1) through (3) of this section.

(1) Calculate NOX emissions as 1.194 � 10?7 lb/scf-ppm times the average hourly NOX output concentration in ppm (measured according to the provisions of �60.49Da(c)), times the average hourly flow rate (measured in scfh, according to the provisions of �60.49Da(l) or �60.49Da(m)), divided by the average hourly gross energy output (measured according to the provisions of �60.49Da(k)) or the average hourly net energy output, as applicable.

(2) Calculate CO emissions by multiplying the average hourly CO output concentration (measured according to the provisions of �60.49Da(u), by the average hourly flow rate (measured according to the provisions of �60.49Da(l) or �60.49Da(m)), and dividing by the average hourly gross energy output (measured according to the provisions of �60.49Da(k)) or the average hourly net energy output, as applicable.

(3) Calculate NOX plus CO emissions by summing the NOX emissions results from paragraph (r)(1) of this section plus the CO emissions results from paragraph (r)(2) of this section.

(s) Affirmative defense for exceedance of emissions limit during malfunction. In response to an action to enforce the standards set forth in paragraph ��60.42Da, 60.43Da, 60.44Da, and 60.45Da, you may assert an affirmative defense to a claim for civil penalties for exceedances of such standards that are caused by malfunction, as defined at 40 CFR 60.2. Appropriate penalties may be assessed, however, if you fail to meet your burden of proving all of the requirements in the affirmative defense as specified in paragraphs (s)(1) and (2) of this section. The affirmative defense shall not be available for claims for injunctive relief.

(1) To establish the affirmative defense in any action to enforce such a limit, you must timely meet the notification requirements in paragraph (s)(2) of this section, and must prove by a preponderance of evidence that:

(i) The excess emissions:

(A) Were caused by a sudden, infrequent, and unavoidable failure of air pollution control and monitoring equipment, process equipment, or a process to operate in a normal or usual manner; and

(B) Could not have been prevented through careful planning, proper design, or better operation and maintenance practices; and

(C) Did not stem from any activity or event that could have been foreseen and avoided, or planned for; and

(D) Were not part of a recurring pattern indicative of inadequate design, operation, or maintenance; and

(ii) Repairs were made as expeditiously as possible when the applicable emissions limits were being exceeded. Off-shift and overtime labor were used, to the extent practicable to make these repairs; and

(iii) The frequency, amount, and duration of the excess emissions (including any bypass) were minimized to the maximum extent practicable during periods of such emissions; and

(iv) If the excess emissions resulted from a bypass of control equipment or a process, then the bypass was unavoidable to prevent loss of life, personal injury, or severe property damage; and

(v) All possible steps were taken to minimize the impact of the excess emissions on ambient air quality, the environment, and human health; and

(vi) All emissions monitoring and control systems were kept in operation if at all possible, consistent with safety and good air pollution control practices; and

(vii) All of the actions in response to the excess emissions were documented by properly signed, contemporaneous operating logs; and

(viii) At all times, the facility was operated in a manner consistent with good practices for minimizing emissions; and

(ix) A written root cause analysis has been prepared, the purpose of which is to determine, correct, and eliminate the primary causes of the malfunction and the excess emissions resulting from the malfunction event at issue. The analysis shall also specify, using best monitoring methods and engineering judgment, the amount of excess emissions that were the result of the malfunction.

(2) Notification. The owner or operator of the affected source experiencing an exceedance of its emission limit(s) during a malfunction shall notify the Administrator by telephone or facsimile (FAX) transmission as soon as possible, but no later than two business days after the initial occurrence of the malfunction or, if it is not possible to determine within two business days whether the malfunction caused or contributed to an exceedance, no later than two business days after the owner or operator knew or should have known that the malfunction caused or contributed to an exceedance, but, in no event later than two business days after the end of the averaging period, if it wishes to avail itself of an affirmative defense to civil penalties for that malfunction. The owner or operator seeking to assert an affirmative defense shall also submit a written report to the Administrator within 45 days of the initial occurrence of the exceedance of the standard in �63.9991 to demonstrate, with all necessary supporting documentation, that it has met the requirements set forth in paragraph (s)(1) of this section. The owner or operator may seek an extension of this deadline for up to 30 additional days by submitting a written request to the Administrator before the expiration of the 45 day period. Until a request for an extension has been approved by the Administrator, the owner or operator is subject to the requirement to submit such report within 45 days of the initial occurrence of the exceedance.

[72 FR 32722, June 13, 2007, as amended at 74 FR 5079, Jan. 28, 2009; 76 FR 3522, Jan. 20, 2011; 77 FR 9454, Feb. 16, 2012; 78 FR 24083, Apr. 24, 2013; 81 FR 20180, Apr. 6, 2016]