['Air Programs']

['Air Quality']

05/13/2024

...

(a) During performance tests required in �60.8, the owner or operator shall not add gaseous diluent to the effluent gas after the fabric filter in any pressurized fabric collector, unless the amount of dilution is separately determined and considered in the determination of emissions.

(b) When emissions from any EAF(s) are combined with emissions from facilities not subject to the provisions of this subpart but controlled by a common capture system and control device, the owner or operator shall use either or both of the following procedures during a performance test (see also �60.276(b)):

(1) Determine compliance using the combined emissions.

(2) Use a method that is acceptable to the Administrator or delegated authority and that compensates for the emissions from the facilities not subject to the provisions of this subpart.

(3) Any combination of the criteria of paragraphs (b)(1) and (b)(2) of this section.

(c) When emissions from any EAF(s) are combined with emissions from facilities not subject to the provisions of this subpart, compliance with �60.272(a)(3) will be based on emissions from only the affected facility(ies). The owner or operator may use operational knowledge to determine the facilities that are the sources, in whole or in part, of any emissions observed in demonstrations of compliance with �60.272(a)(3).

(1) Determine compliance using the combined emissions.

(2) Shut down operation of facilities not subject to the provisions of this subpart during the performance test.

(d) In conducting the performance tests required in �60.8, the owner or operator shall use as reference methods and procedures the test methods in appendix A of this part or other methods and procedures as specified in this section, except as provided in �60.8(b).

(e) The owner or operator shall determine compliance with the particulate matter standards in �60.272 as follows:

(1) EPA Method 5 (and referenced EPA Methods 1, 2, 3, 3A, 3B, and 4) shall be used for negative-pressure fabric filters and other types of control devices and EPA Method 5D (and referenced EPA Method 5) shall be used for positive-pressure fabric filters to determine the particulate matter concentration and, if applicable, the volumetric flow rate of the effluent gas. The sampling time and sample volume for each run shall be at least 4 hours and 4.5 dscm (160 dscf) and, when a single EAF is sampled, the sampling time shall include an integral number of heats. The manual portions only and not the instrumental portion of the voluntary consensus standard ANSI/ASME PTC 19.10�1981 (incorporated by reference, see �60.17) is an acceptable alternative to EPA Methods 3, 3A, and 3B.

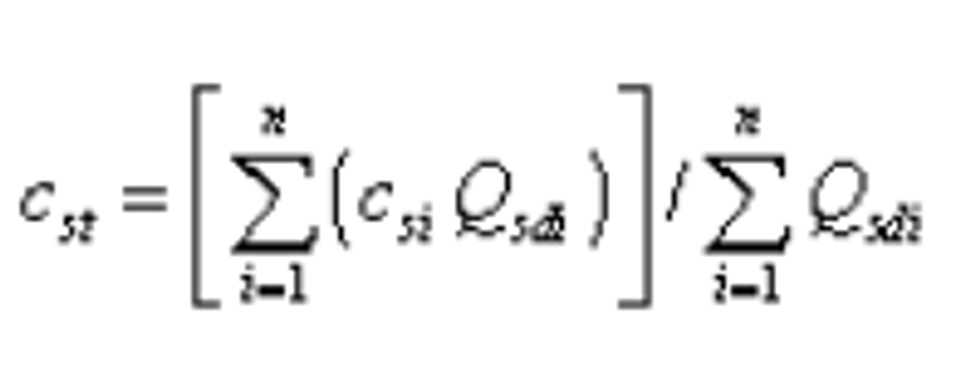

(2) When more than one control device serves the EAF(s) being tested, the concentration of particulate matter shall be determined using the following equation:

where:

cst = average concentration of particulate matter, mg/dscm (gr/dscf).

csi = concentration of particulate matter from control device �i�, mg/dscm (gr/dscf).

n = total number of control devices tested.

Qsdi = volumetric flow rate of stack gas from control device �i�, dscm/hr (dscf/hr).

(3) EPA Method 9 or, as an alternative, ASTM D7520�16 (incorporated by reference, see �60.17), with the caveats described under Shop opacity in �60.271, and the procedures of �60.11 shall be used to determine opacity.

((4) To demonstrate compliance with �60.272(a)(1), (2), and (3), the EPA Method 9 test runs shall be conducted concurrently with the particulate matter test runs, unless inclement weather interferes.

(f) To comply with �60.274 (c), (f), (g), and (i), the owner or operator shall obtain the information in these paragraphs during the particulate matter runs.

(g) Where emissions from any EAF(s) are combined with emissions from facilities not subject to the provisions of this subpart, the owner or operator may use any of the following procedures for demonstrating compliance with �60.272(a)(3), except if the combined emissions are controlled by a common capture system and control device, in which case the owner or operator may use any of the following procedures during an opacity performance test and during shop opacity observations:

(1) Base compliance on control of the combined emissions.

(2) Shut down operation of facilities not subject to the provisions of this subpart.

(3) Any combination of the criteria of paragraphs (g)(1) and (2) of this section.

(h) If visible emissions observations are made in lieu of using a continuous opacity monitoring system, as allowed for by �60.273(c), visible emission observations shall be conducted at least once per day for at least three 6-minute periods when the furnace is operating in the melting and refining period. All visible emissions observations shall be conducted in accordance with EPA Method 9. If visible emissions occur from more than one point, the opacity shall be recorded for any points where visible emissions are observed. Where it is possible to determine that a number of visible emission sites relate to only one incident of the visible emission, only one set of three 6-minute observations will be required. In that case, the EPA Method 9 observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident. Records shall be maintained of any 6-minute average that is in excess of the emission limit specified in �60.272(a).

(i) Unless the presence of inclement weather makes concurrent testing infeasible, the owner or operator shall conduct concurrently the performance tests required under �60.8 to demonstrate compliance with �60.272(a) (1), (2), and (3) of this subpart.

[40 FR 43852, Sept. 23, 1975, as amended at 49 FR 43844, Oct. 31, 1984; 54 FR 6672, Feb. 14, 1989; 54 FR 21344, May 17, 1989; 65 FR 61758, Oct. 17, 2000; 70 FR 8532, Feb. 22, 2005; 88 FR 58478, Aug. 25, 2023]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.