...

S1. Scope. This standard specifies labeling and performance requirements for motor vehicle brake hose, brake hose assemblies, and brake hose end fittings.

S2. Purpose. The purpose of this standard is to reduce deaths and injuries occurring as a result of brake system failure from pressure or vacuum loss due to hose or hose assembly rupture.

S3. Application. This standard applies to passenger cars, multipurpose passenger vehicles, trucks, buses, trailers, and motorcycles, and to hydraulic, air, and vacuum brake hose, brake hose assemblies, and brake hose end fittings for use in those vehicles.

S4. Definitions.

Armor means protective material installed on a brake hose to increase the resistance of the hose or hose assembly to abrasion or impact damage.

Brake hose means a flexible conduit, other than a vacuum tubing connector, manufactured for use in a brake system to transmit or contain the fluid pressure or vacuum used to apply force to a vehicle’s brakes. For hose, a dimensional description such as “ 1/4 -inch hose” refers to the nominal inside diameter. For tubing, a dimensional description such as “ 1/4 -in tubing” refers to the nominal outside diameter.

Brake hose assembly means a brake hose, with or without armor, equipped with end fittings for use in a brake system, but does not include an air or vacuum assembly prepared by the owner or operator of a used vehicle, by his employee, or by a repair facility, for installation in that used vehicle.

Brake hose end fitting means a coupler, other than a clamp, designed for attachment to the end of a brake hose.

Free length means the linear measurement of hose exposed between the end fittings of a hose assembly in a straight position.

Permanently attached end fitting means an end fitting that is attached by deformation of the fitting about the hose by crimping or swaging, or an end fitting that is attached by use of a sacrificial sleeve or ferrule that requires replacement each time a hose assembly is rebuilt.

Preformed means a brake hose that is manufactured with permanent bends and is shaped to fit a specific vehicle without further bending.

Rupture means any failure that results in separation of a brake hose from its end fitting or in leakage.

Vacuum tubing connector means a flexible conduit of vacuum that (i) connects metal tubing to metal tubing in a brake system, (ii) is attached without end fittings, and (iii) when installed, has an unsupported length less than the total length of those portions that cover the metal tubing.

S5. Requirements—hydraulic brake hose, brake hose assemblies, and brake hose end fittings.

S5.1 Construction. (a) Each hydraulic brake hose assembly shall have permanently attached brake hose end fittings which are attached by deformation of the fitting about the hose by crimping or swaging.

(b) Each hydraulic brake hose assembly that is equipped with a permanent supplemental support integrally attached to the assembly and is manufactured as a replacement for use on a vehicle not equipped, as an integral part of the vehicle’s original design, with a means of attaching the support to the vehicle shall be equipped with a bracket that is integrally attached to the supplemental support and that adapts the vehicle to properly accept this type of brake hose assembly.

S5.2 Labeling.

S5.2.1 Each hydraulic brake hose, except hose sold as part of a motor vehicle, shall have at least two clearly identifiable stripes of at least one-sixteenth of an inch in width, placed on opposite sides of the brake hose parallel to its longitudinal axis. One stripe may be interrupted by the information required by S5.2.2, and the other stripe may be interrupted by additional information at the manufacturer’s option. However, hydraulic brake hose manufactured for use only in an assembly whose end fittings prevent its installation in a twisted orientation in either side of the vehicle, need not meet the requirements of S5.2.1.

S5.2.2 Each hydraulic brake hose shall be labeled, or cut from bulk hose that is labeled, at intervals of not more than 6 inches, measured from the end of one legend to the beginning of the next, in block capital letters and numerals at least one-eighth of an inch high, with the information listed in paragraphs (a) through (e) of this section. The information need not be present on hose that is sold as part of a brake hose assembly or a motor vehicle.

(a) The symbol DOT, constituting a certification by the hose manufacturer that the hose conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the hose, which shall be filed in writing with: Office of Vehicle Safety Compliance, Equipment Division NVS–222, National Highway Traffic Safety Administration, 400 Seventh St. SW., Washington, DC 20590. The marking may consist of a designation other than block capital letters required by S5.2.2.

(c) The month, day, and year, or the month and year, of manufacture, expressed in numerals. For example, 10/1/96 means October 1, 1996.

(d) The nominal inside diameter of the hose expressed in inches or fractions of inches, or in millimeters followed by the abbreviation “mm.”

(e) Either “HR” to indicate that the hose is regular expansion hydraulic hose or “HL” to indicate that the hose is low expansion hydraulic hose.

S5.2.3 Package labeling for brake hose assemblies designed to be used with a supplemental support (a) Each hydraulic brake hose assembly that is equipped with a permanent supplemental support integrally attached to the assembly and is manufactured as a replacement assembly for a vehicle equipped, as an integral part of the vehicle’s original design, with a means of attaching the support to the vehicle shall be sold in a package that is marked or labeled as follows: “FOR USE ON [ insert Manufacturer, Model Name ] ONLY”;

(b) Each hydraulic brake hose assembly that is equipped with a permanent supplemental support integrally attached to the assembly and is manufactured as a replacement for use on a vehicle not equipped, as an integral part of the vehicle’s original design, with a means of attaching the support to the vehicle shall comply with paragraphs (a)(1) and (2) of this section:

(1) Be sold in a package that is marked or labeled as follows: “FOR USE ONLY WITH A SUPPLEMENTAL SUPPORT.”

(2) Be accompanied by clear, detailed instructions explaining the proper installation of the brake hose and the supplemental support bracket to the vehicle and the consequences of not attaching the supplemental support bracket to the vehicle. The instructions shall be printed on or included in the package specified in paragraph (a)(1) of this section.

S5.2.4 Each hydraulic brake hose assembly, except those sold as part of a motor vehicle, shall be labeled by means of a band around the brake hose assembly as specified in this paragraph or, at the option of the manufacturer, by means of labeling as specified in S5.2.4.1. The band may at the manufacturer’s option be attached so as to move freely along the length of the assembly, as long as it is retained by the end fittings. The band shall be etched, embossed, or stamped in block capital letters, numerals or symbols at least one-eighth of an inch high with the following information:

(a) The symbol DOT constituting certification by the hose assembler that the hose assembly conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the hose assembly, which shall be filed in writing with: Office of Vehicle Safety Compliance, Equipment Division NVS–222, National Highway Traffic Safety Administration, 400 Seventh St. SW., Washington, DC 20590. The designation may consist of block capital letters, numerals or a symbol.

S5.2.4.1 At least one end fitting of a hydraulic brake hose assembly shall be etched, stamped or embossed with a designation at least one-sixteenth of an inch high that identifies the manufacturer of the hose assembly and is filed in accordance with S5.2.4(b).

S5.3 Test requirements. A hydraulic brake hose assembly or appropriate part thereof shall be capable of meeting any of the requirements set forth under this heading, when tested under the conditions of S13 and the applicable procedures of S6. However, a particular hose assembly or appropriate part thereof need not meet further requirements after having been subjected to and having met the constriction requirement (S5.3.1) and any one of the requirements specified in S5.3.2 through S5.3.13.

S5.3.1 Constriction. Except for that part of an end fitting which does not contain hose, every inside diameter of any section of a hydraulic brake hose assembly shall be not less than 64 percent of the nominal inside diameter of the brake hose (S6.12).

S5.3.2 Expansion and burst strength. The maximum expansion of a hydraulic brake hose assembly at 1,000 psi, 1,500 psi and 2,900 psi shall not exceed the values specified in Table I (S6.1), except that a brake hose larger than 3/16 inch or 5 mm is not subject to the 2,900 psi expansion test requirements. The hydraulic brake hose assembly shall then withstand water pressure of 4,000 psi for 2 minutes without rupture, and then shall not rupture at less than 7,000 psi for a 1/8 inch, 3 mm, or smaller diameter hose, or at less than 5,000 psi for a hose with a diameter larger than 1/8 inch or 3 mm (S6.2).

| Hydraulic brake hose, inside diameter | Test pressure | |||||

|---|---|---|---|---|---|---|

| 1,000 psi | 1,500 psi | 2,900 psi | ||||

| Regular expansion hose | Low expansion hose | Low expansion hose | Regular expansion hose | Regular expansion hose | Low expansion hose | |

| 1/8 inch, or 3mm, or less | 0.66 | 0.33 | 0.79 | 0.42 | 1.21 | 0.61 |

| > 1/8 inch or 3mm, to 3/16 inch, or 5 mm | 0.86 | 0.55 | 1.02 | 0.72 | 1.67 | 0.91 |

| > 3/16 inch, or 5 | 1.04 | 0.82 | 1.30 | 1.17 | * | * |

S5.3.3 Whip resistance. A hydraulic brake hose assembly shall not rupture when run continuously on a flexing machine for 35 hours (S6.3).

S5.3.4 Tensile strength. A hydraulic brake hose assembly shall withstand a pull of 325 pounds without separation of the hose from its end fittings during a slow pull test, and shall withstand a pull of 370 pounds without separation of the hose from its end fittings during a fast pull test (S6.4).

S5.3.5 Water absorption and burst strength. A hydraulic brake hose assembly, after immersion in water for 70 hours (S6.5), shall withstand water pressure of 4,000 psi for 2 minutes, and then shall not rupture at less than 5,000 psi (S6.2).

S5.3.6 Water absorption and tensile strength. A hydraulic brake hose assembly, after immersion in water for 70 hours (S6.5), shall withstand a pull of 325 pounds without separation of the hose from its end fittings during a slow pull test, and shall withstand a pull of 370 pounds without separation of the hose from its end fittings during a fast pull test (S6.4).

S5.3.7 Water absorption and whip resistance. A hydraulic brake hose assembly, after immersion in water for 70 hours (S6.5), shall not rupture when run continuously on a flexing machine for 35 hours (S6.3).

S5.3.8 Low-temperature resistance. A hydraulic brake hose conditioned at a temperature between minus 49 degrees Fahrenheit (minus 45 degrees Celsius) and minus 54 degrees Fahrenheit (minus 48 degrees Celsius) for 70 hours shall not show cracks visible without magnification when bent around a cylinder as specified in S6.6 (S6.6).

S5.3.9 Brake fluid compatibility, constriction, and burst strength. Except for brake hose assemblies designed for use with mineral or petroleum-based brake fluids, a hydraulic brake hose assembly shall meet the constriction requirement of S5.3.1 after having been subjected to a temperature of 248 degrees Fahrenheit (120 degrees Celsius) for 70 hours while filled with SAE RM-66-04 “Compatibility Fluid,” as described in Appendix B of SAE Standard J1703 JAN95 (incorporated by reference, see §571.5 ). It shall then withstand water pressure of 4,000 psi for 2 minutes and thereafter shall not rupture at less than 5,000 psi (S6.2 except all sizes of hose are tested at 5,000 psi).

S5.3.10 Ozone resistance. A hydraulic brake hose shall not show cracks visible under 7-power magnification after exposure to ozone for 70 hours at 104° F. (S6.8).

S5.3.11 Dynamic Ozone Test. A hydraulic brake hose shall not show cracks visible without magnification after having been subjected to a 48-hour dynamic ozone test (S6.9).

S5.3.12 High temperature impulse test. A brake hose assembly tested under the conditions in S6.10:

(a) Shall withstand pressure cycling for 150 cycles, at 295 degrees Fahrenheit (146 degrees Celsius) without leakage;

(b) Shall not rupture during a 2- minute, 4,000 psi pressure hold test, and;

(c) Shall not burst at a pressure less than 5,000 psi.

S5.3.13 End fitting corrosion resistance. After 24 hours of exposure to salt spray, a hydraulic brake hose end fitting shall show no base metal corrosion on the end fitting surface except where crimping or the application of labeling information has caused displacement of the protective coating (S6.11).

S6. Test procedures—Hydraulic brake hose, brake hose assemblies, and brake hose end fittings.

S6.1. Expansion test.

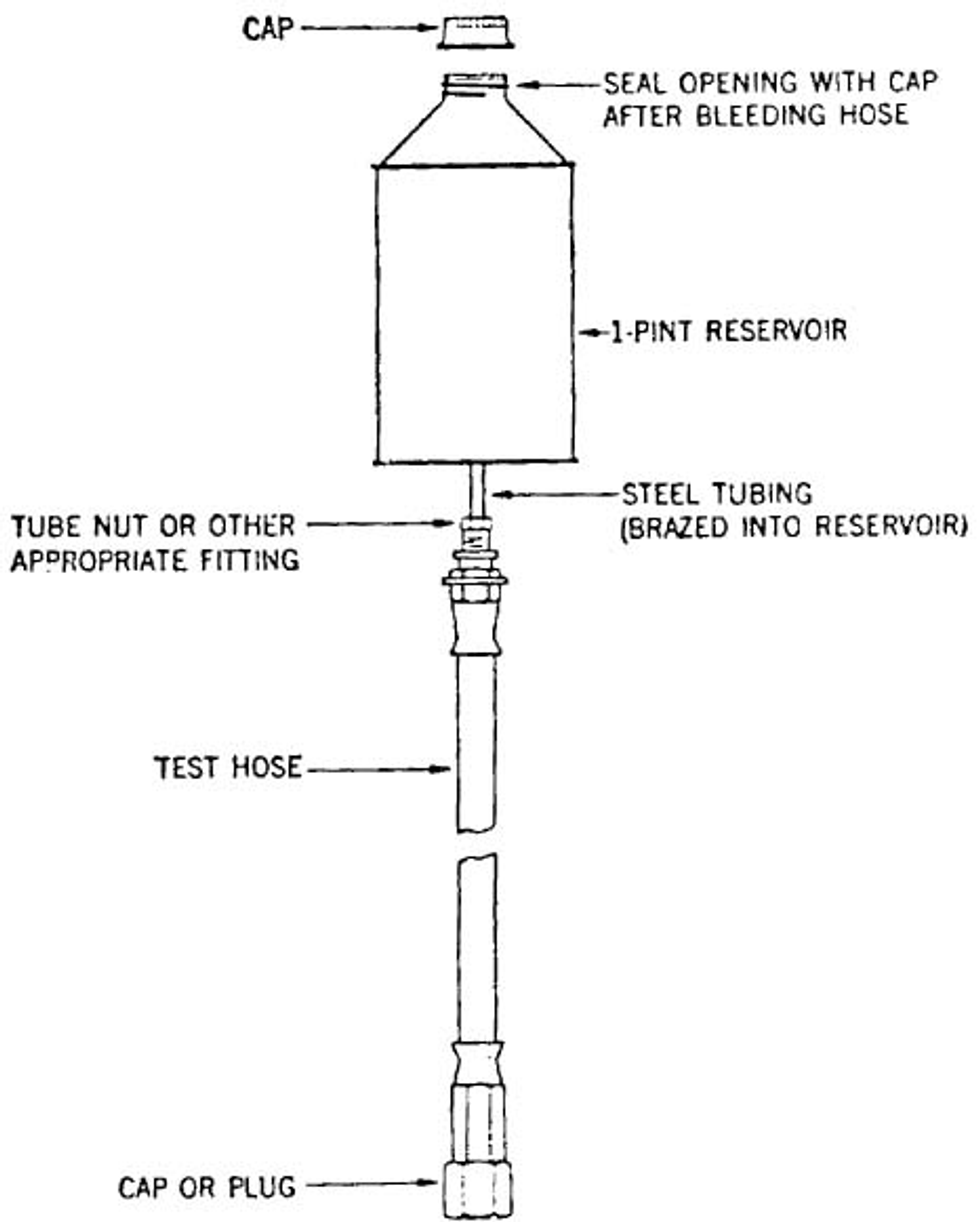

S6.1.1 Apparatus. Utilize a test apparatus (as shown in Figure 1) which consists of:

(a) Source for required fluid pressure;

(b) Test fluid of water without any additives and free of gases;

(c) Reservoir for test fluid;

(d) Pressure gauges;

(e) Brake hose end fittings in which to mount the hose vertically; and

(f) Graduate burette with 0.05 cc increments.

|

| Fig. 1. Expansion Test Apparatus |

S6.1.2 Preparation.

(a) Measure the free length of the hose assembly.

(b) Mount the hose so that it is in a vertical straight position without tension when pressure is applied.

(c) fill the hose with test fluid and bleed all gases from the system.

(d) Close the valve to the burette and apply 1,500 psi for 10 seconds; then release pressure.

S6.1.3 Calculation of expansion at 1,000, 1,500 psi, and 2,900 psi.

(a) Adjust the fluid level in the burette to zero.

(b) Close the valve to the burette, apply pressure at the rate of 15,000 psi per minute, and seal 1,000 psi in the hose (1,500 psi in the second series, and 2,900 psi in the third series).

(c) After 3 seconds open the valve to the burette for 10 seconds and allow the fluid in the expanded hose to rise into the burette.

(d) Repeat the procedure in steps (b) and (c) twice. Measure the amount of test fluid which has accumulated in the burette as a result of the three applications of pressure.

(e) Calculate the volumetric expansion per foot by dividing the total accumulated test fluid by 3 and further dividing by the free length of the hose in feet.

S6.2 Burst strength test.

(a) Connect the brake hose to a pressure system and fill it completely with water, allowing all gases to escape.

(b) Apply water pressure of 4,000 psi at a rate of 15,000 psi per minute.

(c) After 2 minutes at 4,000 psi, increase the pressure at the rate of 15,000 psi per minute until the pressure exceeds 5,000 psi for a brake hose larger than 1/8 inch or 3 mm diameter, or until the pressure exceeds 7,000 psi for a brake hose of 1/8 inch, 3 mm, or smaller diameter.

S6.3 Whip resistance test.

S6.3.1 Apparatus. Utilize test apparatus that is dynamically balanced and includes:

(a) A movable header consisting of a horizontal bar equipped with capped end fittings and mounted through bearings at each end to points 4 inches from the center of two vertically rotating disks whose edges are in the same vertical plane;

(b) An adjustable stationary header parallel to the movable header in the same horizontal plane as the centers of the disks, and fitted with open end fittings;

(c) An elapsed time indicator; and

(d) A source of water pressure connected to the open end fittings.

S6.3.2 Preparation.

(a) Except for the supplemental support specified in S6.3.2(d), remove all external appendages including, but not limited to, hose armor, chafing collars, mounting brackets, date band and spring guards.

(b) Measure the hose free length.

(c) Mount the hose in the whip test machine, introducing slack as specified in Table II for the size hose tested, measuring the projected length parallel to the axis of the rotating disks. The manufacturer may, at his option, adapt the fitting attachment points to permit mounting hose assemblies equipped with angled or other special fittings in the same orientation as hose assemblies equipped with straight fittings.

(d) In the case of a brake hose assembly equipped with a permanent supplemental support integrally attached to the assembly, the assembly may be mounted using the supplemental support and associated means of simulating its attachment to the vehicle. Mount the supplemental support in the same vertical and horizontal planes as the stationary header end of the whip test fixture described in S6.3.1(b). Mount or attach the supplemental support so that it is positioned in accordance with the recommendation of the assembly manufacturer for attaching the supplemental support on a vehicle.

| Free length between end fittings, inches | Slack, inches | |

|---|---|---|

| 1/8 inch or 3 mm hose or less | More than 1/8 inch or 3 mm hose | |

| 8 to 15- 1/2, inclusive | 1.750 | |

| 10 to 15- 1/2, inclusive | 1,000 | |

| Over 15- 1/2 to 19 inclusive | 1.250 | |

| Over 19 to 24, inclusive | 0.750 | |

S6.3.3 Operation.

(a) Apply 235 psi water pressure and bleed all gases from the system.

(b) Drive the movable head at 800 rpm.

S6.4 Tensile strength test. Utilize a tension testing machine conforming to the requirements of ASTM E4-03 (incorporated by reference, see §571.5 ) and provided with a recording device to measure the force applied.

S6.4.1 Preparation. Mount the hose assembly to ensure straight, evenly distributed machine pull.

S6.4.2 Operation. (a) Conduct the slow pull test by applying tension at a rate of 1 inch per minute travel of the moving head until separation occurs.

(b) Conduct the fast pull test by applying tension at a rate of 2 inches per minute travel of the moving head until separation occurs.

S6.5 Water absorption sequence tests. (a) Prepare three brake hose assemblies and measure the free length of the hose assemblies.

(b) Immerse the brake hose assemblies in distilled water at 185 degrees Fahrenheit (85 degrees Celsius) for 70 hours. Remove the brake hose assemblies from the water and condition in air at room temperature for 30 minutes.

(c) Conduct the tests in S6.2, S6.3, and S6.4, using a different hose for each sequence.

S6.6 Low temperature resistance test.

S6.6.1 Preparation.

(a) Remove hose armor, if any, and condition the hose in a straight position in air at a temperature between minus 49 degrees Fahrenheit and minus 54 degrees Fahrenheit (minus 45 degrees Celsius and minus 48 degrees Celsius) for 70 hours.

(b) Condition a cylinder in air at a temperature between minus 49 degrees Fahrenheit and minus 54 degrees Fahrenheit (minus 45 degrees Celsius and minus 48 degrees Celsius) for 70 hours, using a cylinder of 2 1/2 inches in diameter for tests of hose less than 1/8 inch or 3mm, 3 inches in diameter for tests of 1/8 inch or 3 mm hose, 3½ inches in diameter for tests of 3/16 to 1/4 inch hose or 4 mm to 6 mm hose, and 4 inches in diameter for tests of hose greater than 1/4 inch or 6 mm in diameter.

S6.6.2 Flexibility testing. Bend the conditioned hose 180 degrees around the conditioned cylinder at a steady rate in a period of 3 to 5 seconds. Examine without magnification for cracks.

S6.7 Brake fluid compatibility test.

S6.7.1 Preparation.

(a) Attach a hose assembly below a 1-pint reservoir filled with 100 ml. of SAE RM-66-04 Compatibility Fluid as shown in Figure 2.

(b) Fill the hose assembly with brake fluid, seal the lower end, and place the test assembly in an oven in a vertical position.

|

| Fig. 2. Brake Fluid Compatability Apparatus |

S6.7.2 Oven treatment. (a) Condition the hose assembly at 200° F. for 70 hours.

(b) Cool the hose assembly at room temperature for 30 minutes.

(c) Drain the brake hose assembly, immediately determine that every inside diameter of any section of the hose assembly, except for that part of an end fitting which does not contain hose, is not less than 64 percent of the nominal inside diameter of the hose, and conduct the test specified in S6.2.

S6.8 Ozone resistance test. Utilize a cylinder with a diameter eight times the nominal outside diameter of the brake hose excluding armor.

S6.8.1 Preparation. After removing any armor, bind a hydraulic brake hose 360 around the cylinder. In the case of hose shorter than the circumference of the cylinder, bend the hose so that as much of its length as possible is in contact.

S6.8.2 Exposure to ozone.

(a) Condition the hose on the cylinder in air at room temperature for 24 hours.

(b) Immediately thereafter, condition the hose on the cylinder for 70 hours in an exposure chamber having an ambient air temperature of 104 degrees Fahrenheit (40 degrees Celsius) during the test and containing air mixed with ozone in the proportion of 100 parts of ozone per 100 million parts of air by volume.

(c) Examine the hose for cracks under 7-power magnification, ignoring areas immediately adjacent to or within the area covered by binding.

S6.9 Dynamic Ozone Test.

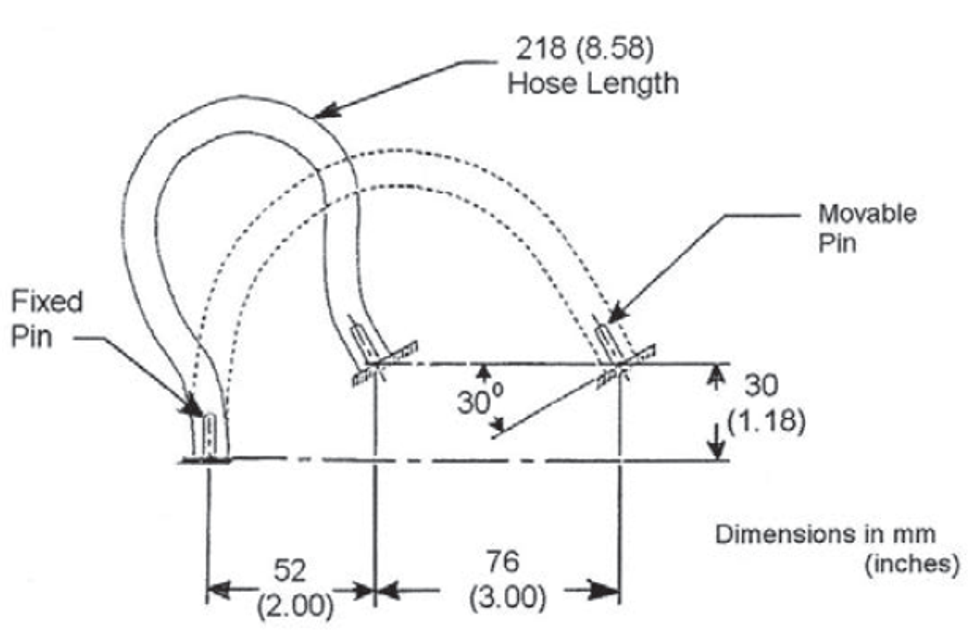

S6.9.1 Apparatus. Utilize a test apparatus shown in Figure 3 which is constructed so that:

(a) It has a fixed pin with a vertical orientation over which one end of the brake hose is installed.

(b) It has a movable pin that is oriented 30 degrees from vertical, with the top of the movable pin angled towards the fixed pin. The moveable pin maintains its orientation to the fixed pin throughout its travel in the horizontal plane. The other end of the brake hose is installed on the movable pin.

|

| Figure 3. Dynamic Ozone Test Apparatus |

S6.9.2 Preparation. (a) Precondition the hose assembly by laying it on a flat surface in an unstressed condition, at room temperature, for 24 hours.

(b) Cut the brake hose assembly to a length of 8.6 inches (218 mm), such that no end fittings remain on the cut hose.

(c) Mount the brake hose onto the test fixture by fully inserting the fixture pins into each end of the hose. Secure the hose to the fixture pins using a band clamp at each end of the hose.

(d) Place the test fixture into an ozone chamber

(e) Stabilize the atmosphere in the ozone chamber so that the ambient temperature is 104°F (40 degrees Celsius) and the air mixture contains air mixed with ozone in the proportion of 100 parts of ozone per 100 million parts of air by volume. This atmosphere is to remain stable throughout the remainder of the test.

(f) Begin cycling the movable pin at a rate of 0.3 Hz. Continue the cycling for 48 hours.

(g) At the completion of 48 hours of cycling, remove the test fixture from the ozone chamber. Without removing the hose from the test fixture, visually examine the hose for cracks without magnification, ignoring areas immediately adjacent to or within the area covered by the band clamps. Examine the hose with the movable pin at any point along its travel.

S6.10 High temperature impulse test.

S6.10.1 Apparatus. (a) A pressure cycling machine to which one end of the brake hose assembly can be attached, with the entire hose assembly installed vertically inside of a circulating air oven. The machine shall be capable of increasing the pressure in the hose from zero psi to 1600 psi, and decreasing the pressure in the hose from 1600 psi to zero psi, within 2 seconds.

(b) A circulating air oven that can reach a temperature of 295 degrees Fahrenheit (146 degrees Celsius) within 30 minutes, and that can maintain a constant 295 degrees F (146 degrees Celsius) thereafter, with the brake hose assembly inside of the oven and attached to the pressure cycling machine.

(c) A burst test apparatus to conduct testing specified in S6.2

S6.10.2 Preparation. (a) Connect one end of the hose assembly to the pressure cycling machine and plug the other end of the hose. Fill the pressure cycling machine and hose assembly with SAE RM-66-04 “Compatibility Fluid,” as described in Appendix B of SAE Standard J1703 JAN95 (incorporated by reference, see §571.5 ) and bleed all gases from the system.

(b) Place the brake hose assembly inside of the circulating air oven in a vertical position. Increase the oven temperature to 295 degrees F (146 degrees Celsius) and maintain this temperature throughout the pressure cycling test.

(c) During each pressure cycle, the pressure in the hose is increased from zero psi to 1600 psi and held constant for 1 minute, then the pressure is decreased from 1600 psi to zero psi and held constant for 1 minute. Perform 150 pressure cycles on the brake hose assembly.

(d) Remove the brake hose assembly from the oven, disconnect it from the pressure cycling machine, and drain the fluid from the hose. Cool the brake hose assembly at room temperature for 45 minutes.

(e) Wipe the brake hose using acetone to remove residual Compatibility Fluid. Conduct the burst strength test in S6.2, except all sizes of hose are tested at 5,000 psi.

S6.11 End fitting corrosion test. Utilize the apparatus described in ASTM B117-03 (incorporated by reference, see §571.5 ).

S6.11.1 Construction. Construct the salt spray chamber so that:

(a) The construction material does not affect the corrosiveness of the fog.

(b) The hose assembly is supported or suspended 30 degrees from the vertical and parallel to the principal direction of the horizontal flow of fog through the chamber.

(c) The hose assembly does not contact any metallic material or any material capable of acting as a wick

(d) Condensation which falls from the assembly does not return to the solution reservoir for respraying.

(e) Condensation from any source does not fall on the brake hose assemblies or the solution collectors.

(f) Spray from the nozzles is not directed onto the hose assembly.

S6.11.2 Preparation. (a) Plug each end of the hose assembly.

(b) Mix a salt solution five parts by weight of sodium chloride to 95 parts of distilled water, using sodium chloride substantially free of nickel and copper, and containing on a dry basis not more than 0.1 percent of sodium iodide and not more than 0.3 percent total impurities. Ensure that the solution is free of suspended solids before the solution is atomized.

(c) After atomization at 95 degrees Fahrenheit (35 degrees Celsius), ensure that the collected solution is in the PH range of 6.5 to 7.2. Make the PH measurements at 77 degrees Fahrenheit (28 degrees Celsius).

(d) Maintain a compressed air supply to the nozzle or nozzles free of oil and dirt and between 10 and 25 psi.

S6.11.3 Operation. Subject the brake hose assembly to the salt spray continuously for 24 hours.

(a) Regulate the mixture so that each collector will collect from 1 to 2 milliliters of solution per hour for each 80 square centimeters of horizontal collecting area.

(b) Maintain exposure zone temperature at 95 degrees Fahrenheit (35 degrees Celsius).

(c) Upon completion, remove the salt deposit from the surface of the hose by washing gently or dipping in clean running water not warmer than 100 degrees Fahrenheit (38 degrees Celsius) and then drying immediately.

S6.12 Constriction test. Brake hose constriction test requirements shall be met using at least one of the methods specified in S6.12.1, S6.12.2, or S6.12.3.

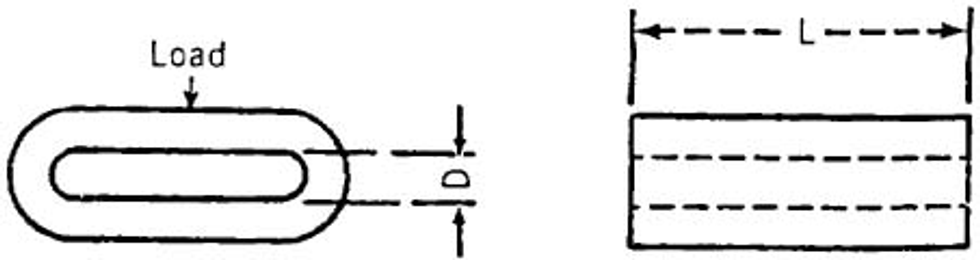

S6.12.1 Plug gauge. (a) Utilize a plug gauge as shown in Figure 4. Diameter “A” is equal to 64 percent of the nominal inside diameter of the hydraulic brake hose being tested.

(b) Brake hose assemblies that are to be used for additional testing have constriction testing only at each end fitting. Other brake hose assemblies may be cut into 3-inch lengths to permit constriction testing of the entire assembly. Hose assemblies with end fittings that do not permit entry of the gauge ( e.g., restrictive orifice or banjo fitting) are cut 3 inches from the point at which the hose terminates in the end fitting and then tested from the cut end.

(c) Hold the brake hose in a straight position and vertical orientation.

(d) Place the spherical end of the plug gauge just inside the hose or end fitting. If the spherical end will not enter the hose or end fitting using no more force than gravity acting on the plug gauge, this constitutes failure of the constriction test.

(e) Release the plug gauge. Within 3 seconds, the plug gauge shall fall under the force of gravity alone up to the handle of the gauge. If the plug gauge does not fully enter the hose up to the handle of the gauge within three seconds, this constitutes failure of the constriction test.

S6.12.2 Extended plug gauge. (a) The test in 6.12.1 may be conducted with an extended plug gauge to enable testing of the entire brake hose from one end fitting, without cutting the brake hose. The extended plug gauge weight and spherical diameter specifications are as shown in Figure 4, but the handle portion of the gauge may be deleted and the gauge length may be greater than 3 inches.

(b) The required performance of the extended plug gauge in S6.12.1(e) is that after the plug gauge is released, the extended plug gauge shall fall under the force of gravity alone at an average rate of 1 inch per second until the spherical diameter of the extended gauge passes through all portions of the brake hose assembly containing hose. If the extended plug gauge does not pass through all portions of the brake hose assembly containing hose at an average rate of 1 inch per second, this constitutes failure of the constriction test.

|

| Figure 4. Constriction Test Plug Guage |

S6.12.3 Drop ball test. (a) Utilize a rigid spherical ball with a diameter equal to 64 percent of the nominal inside diameter of the hydraulic brake hose being tested. The weight of the spherical ball shall not exceed 2 ounces (57 grams).

(b) Hold the brake hose in a straight position and vertical orientation.

(c) Hold the ball just above the end fitting.

(d) Release the ball. The ball shall fall under the force of gravity alone completely through all portions of the brake hose assembly containing hose, at an average rate of 1 inch per second. Failure of the ball to pass completely through all portions of the brake hose assembly containing hose, at an average rate of 1 inch per second, constitutes failure of the constriction test.

S7. Requirements—Air brake hose, brake hose assemblies, and brake hose end fittings.

S7.1 Construction. Each air brake hose assembly shall be equipped with permanently attached brake hose end fittings or reusable brake hose end fittings. Each air brake hose constructed of synthetic or natural elastomeric rubber shall conform to the dimensional requirements specified in Table III, except for brake hose manufactured in metric sizes.

| Type A—Hose Size—Nominal Inside Diameter | ||||||

| 1/4 | 5/16 | 3/8 | 7/16 | 1/2 SP (1) | 5/8 | |

| Min. I.D. | 0.227 (5.8) | 0.289 (7.3) | 0.352 (8.9) | 0.407 (10.3) | 0.469 (11.9) | 0.594 (15.1) |

| Max. I.D. | 0.273 (6.9) | 0.335 (8.5) | 0.398 (10.1) | 0.469 (11.9) | 0.531 (13.5) | 0.656 (16.7) |

| Min. O.D. | 0.594 (15.1) | 0.656 (16.7) | 0.719 (18.3) | 0.781 (19.8) | 0.844 (21.4) | 1.031 (26.2) |

| Max. O.D. | 0.656 (16.7) | 0.719 (18.3) | 0.781 (19.8) | 0.843 (21.4) | 0.906 (23.0) | 1.094 (27.8) |

| Type AI (2) —Hose Size—Nominal Inside Diameter | ||||||

| 3/16 | 1/4 | 5/16 | 13/32 | 1/2 | 5/8 | |

| Min. I.D. | 0.188 (4.8) | 0.250 (6.4) | 0.312 (7.9) | 0.406 (10.3) | 0.500 (12.7) | 0.625 (15.9) |

| Max. I.D. | 0.214 (5.4) | 0.281 (7.1) | 0.343 (8.7) | 0.437 (11.1) | 0.539 (13.7) | 0.667 (16.9) |

| Min. O.D. | 0.472 (12.0) | 0.535 (13.6) | 0.598 (15.1) | 0.714 (18.1) | 0.808 (20.5) | 0.933 (23.7) |

| Max. O.D. | 0.510 (13.0) | 0.573 (14.6) | 0.636 (16.2) | 0.760 (19.3) | 0.854 (21.7) | 0.979 (24.9) |

| Type AII (2) —Hose Size—Nominal Inside Diameter | ||||||

| 3/16 | 1/4 | 5/16 | 13/32 | 1/2 | 5/8 | |

| Min. I.D. | 0.188 (4.8) | 0.250 (6.4) | 0.312 (7.9) | 0.406 (10.3) | 0.500 (12.7) | 0.625 (15.9) |

| Max. I.D. | 0.214 (5.4) | 0.281 (7.1) | 0.343 (8.7) | 0.437 (11.1) | 0.539 (13.7) | 0.667 (16.9) |

| Min. O.D. | 0.500 (12.7) | 0.562 (14.3) | 0.656 (16.7) | 0.742 (18.8) | 0.898 (22.8) | 1.054 (26.8) |

| Max. O.D. | 0.539 (13.7) | 0.602 (15.3) | 0.695 (17.7) | 0.789 (20.1) | 0.945 (24.0) | 1.101 (27.9) |

| (1) Notes: Type A, sizes 3/8, 7/16, and 1/2 Special can be assembled with reusable end fittings. All sizes can be assembled using permanently-attached (crimped) end fittings. | ||||||

| (2) Types AI and AII, all sizes, can be assembled with reusable or permanently-attached (crimped) end fittings. | ||||||

S7.2 Labeling

S7.2.1 Hose. Each air brake hose shall be labeled, or cut from bulk hose that is labeled, at intervals of not more than 6 inches, measured from the end of one legend to the beginning of the next, in block capital letters and numerals at least one-eighth of an inch high, with the information listed in paragraphs (a) through (e) of this section. The information need not be present on hose that is sold as part of a brake hose assembly or a motor vehicle.

(a) The symbol DOT, constituting a certification by the hose manufacturer that the hose conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the hose, which shall be filed in writing with: Office of Vehicle Safety Compliance, Equipment Division NVS–222, National Highway Traffic Safety Administration, 400 Seventh St. SW., Washington, DC 20590. The designation may consist of block capital letters, numerals, or a symbol.

(c) The month, day, and year, or the month and year, of manufacture, expressed in numerals. For example, 10/1/96 means October 1, 1996.

(d) The nominal inside diameter of the hose expressed in inches or fractions of inches or in millimeters. The abbreviation “mm” shall follow hose sizes that are expressed in millimeters. (Examples: 3/8, 1/2 ( 1/2 SP in the case of 1/2 inch special air brake hose), 4mm, 6mm.)

(e) The type designation corresponding to the brake hose dimensions in Table III. Type A shall be labeled with the letter “A”, Type AI shall be labeled with the letters “AI”, and type AII shall be labeled with the letters “AII”. Metric air brake hose shall be labeled with the letter “A.”

S7.2.2 End fittings. Except for an end fitting that is attached by deformation of the fitting about a hose by crimping or swaging, at least one component of each air brake hose fitting shall be etched, embossed, or stamped in block capital letters and numerals at least one-sixteenth of an inch high with the following information:

(a) The symbol DOT, constituting a certification by the manufacturer of that component that the component conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of that component of the fitting, which shall be filed in writing with: Office of Vehicle Safety Compliance, Equipment Division NVS–222, National Highway Traffic Safety Administration, 400 Seventh St. S.W., Washington, DC 20590. The designation may consist of block capital letters, numerals, or a symbol.

(c) The letter “A” shall indicate intended use in air brake systems. In the case of an end fitting intended for use in a reusable assembly with brake hose subject to Table III, “AI” or “AII” shall indicate use with Type I or Type II hose, respectively.

(d) The nominal inside diameter of the hose to which the fitting is properly attached expressed in inches or fractions of inches or in millimeters. (See examples in S7.2.1 (d).) The abbreviation “mm” shall follow hose sizes that are expressed in millimeters.

S7.2.3 Assemblies. Each air brake hose assembly made with end fittings that are attached by crimping or swaging, except those sold as part of a motor vehicle, shall be labeled by means of a band around the brake hose assembly as specified in this paragraph or, at the option of the manufacturer, by means of labeling as specified in S7.2.3.1. The band may at the manufacturer’s option be attached so as to move freely along the length of the assembly, as long as it is retained by the end fittings. The band shall be etched, embossed, or stamped in block capital letters, numerals or symbols at least one-eighth of an inch high, with the following information:

(a) The symbol DOT, constituting certification by the hose assembler that the hose assembly conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the hose assembly, which shall be filed in writing with: Office of Crash Avoidance Standards, Vehicle Dynamics Division, National Highway Traffic Safety Administration, 400 Seventh Street SW., Washington, DC 20590. The designation may consist of block capital letters, numerals or a symbol.

S7.2.3.1 At least one end fitting of an air brake hose assembly made with end fittings that are attached by crimping or swaging shall be etched, stamped or embossed with a designation at least one-sixteenth of an inch high that identifies the manufacturer of the hose assembly and is filed in accordance with S7.2.3(b).

S7.3 Test requirements. Each air brake hose assembly or appropriate part thereof shall be capable of meeting any of the requirements set forth under this heading, when tested under the conditions of S13 and the applicable procedures of S8. However, a particular hose assembly or appropriate part thereof need not meet further requirements after having met the constriction requirement (S7.3.1) and then having been subjected to any one of the requirements specified in S7.3.2 through S7.3.13.

S7.3.1 Constriction. Every inside diameter of any section of an air brake hose assembly shall not be less than 66 percent of the nominal inside diameter of the brake hose. (S8.14)

S7.3.2 High temperature resistance. An air brake hose shall not show external or internal cracks, charring, or disintegration visible without magnification when straightened after being bent for 70 hours at 212 degrees Fahrenheit (100 degrees Celsius) over a small test cylinder having the radius specified in Table IV for the size of hose tested. (S8.1)

S7.3.3 Low temperature resistance. The inside and outside surfaces of an air brake hose shall not show cracks as a result of conditioning at minus 40 degrees Fahrenheit (minus 40 degrees Celsius) for 70 hours when bent around a large test cylinder having the radius specified in Table IV for the size of hose tested (S8.2).

| Nominal hose inside diameter, inches 1 | 3/16 | 1/4 | 5/16 | 3/8 | 13/32 | 7/16, 1/2 | 5/8 |

| Nominal hose inside diameter, millimeters 1 | 4, 5 | 6 | 8 | 10 | 12 | 16 | |

| Small test cylinder, radius in inches (millimeters) 2 | 1 (25) | 1 1/2 (38) | 1 3/4 (45) | 1 3/4 (45) | 1 7/8 (48) | 2 (51) | 2 1/2 (64) |

| Large test cylinder, radius in inches (millimeters) 3 | 2 (51) | 2 1/2 (64) | 3 (76) | 3 1/2 (89) | 3 1/2 (89) | 4 (102) | 4 1/2 (114) |

| Notes: | |||||||

| 1 These sizes are listed to provide test cylinder radii for brake hoses manufactured in these sizes. They do not represent conversions. | |||||||

| 2 Small test cylinders are used for the high temperature resistance test. | |||||||

| 3 Large test cylinders are used for the low temperature resistance, ozone resistance, and adhesion of wire-reinforced hose tests. | |||||||

S7.3.4 Oil resistance. After immersion in ASTM No. 3 oil for 70 hours at 212°F. the volume of a specimen prepared from the inner tube and cover of an air brake hose shall not increase more than 100 percent (S8.3).

S7.3.5 Ozone resistance. An air brake hose assembly shall not show cracks visible under 7-power magnification after exposure to ozone for 70 hours at 104 degrees Fahrenheit (40 degrees Celsius) when bent around a test cylinder of the radius specified in Table IV for the size of hose tested (S8.4).

S7.3.6 Length change. An air brake hose shall not contract in length more than 7 percent nor elongate more than 5 percent when subjected to air pressure of 200 psi (S8.5).

S7.3.7 Adhesion. (a) Except for hose reinforced by wire, an air brake hose shall withstand a tensile force of 8 pounds per inch of length before separation of adjacent layers (S8.6).

(b) An air brake hose reinforced by wire shall permit a steel ball to roll freely along the entire length of the inside of the hose when the hose is subjected to a vacuum of 25 inches of Hg and bent around a test cylinder (S8.13).

S7.3.8 Flex strength and air pressure. An air brake hose assembly of the length specified in the table accompanying Figure 5, when subjected to a flex test and internal pressure cycling, shall be capable of having its internal pressure increased from zero to 140 psi within 2 minutes with pressurized air supplied through an orifice (S8.7).

S7.3.9 Corrosion resistance and burst strength. An air brake hose assembly exposed to salt spray shall not rupture when exposed to hydrostatic pressure of 900 psi (S8.8).

S7.3.10 Tensile strength. An air brake hose assembly designed for use between a frame and axle or between a towed and towing vehicle shall withstand, without separation of the hose from its end fittings, a pull of 250 pounds if it is 1/4 inch, 6 mm, or less in nominal inside diameter, or a pull of 325 pounds if it is larger than 1/4 inch or 6 mm in nominal inside diameter. An air brake hose assembly designed for use in any other application shall withstand, without separation of the hose from its end fittings, a pull of 50 pounds if it is 1/4 inch, 6 mm, or less in nominal inside diameter, 150 pounds if it is larger than 1/4 inch or 6 mm and equal to or smaller than 1/2 inch or 12 mm in nominal inside diameter, or 325 pounds if it is larger than 1/2 inch or 12 mm in nominal inside diameter (S8.9).

S7.3.11 Water absorption and tensile strength. After immersion in distilled water for 70 hours, an air brake hose assembly designed for use between a frame and axle or between a towed and a towing vehicle shall withstand, without separation of the hose from its end fittings, a pull of 250 pounds if it is 1/4 inch or less or 6 mm or less in nominal inside diameter, or a pull of 325 pounds if it is larger than 1/4 inch or 6 mm in nominal inside diameter. After immersion in distilled water for 70 hours, an air brake hose assembly designed for use in any other application shall withstand, without separation of the hose from its end fittings, a pull of 50 pounds if it is 1/4 inch or 6 mm or less in nominal inside diameter, 150 pounds if it is larger than 1/4 inch or 6 mm and equal to or smaller than 1/2 inch or 12 mm in nominal inside diameter, or 325 pounds if it is larger than 1/2 inch or 12 mm in nominal inside diameter. (S8.10)

S7.3.12 Zinc chloride resistance. The outer cover of an air brake hose shall not show cracks visible under 7-power magnification after immersion in a 50 percent zinc chloride aqueous solution for 200 hours (S8.11).

S7.3.13 End fitting corrosion resistance. After 24 hours of exposure to salt spray, air brake hose end fittings shall show no base metal corrosion on the end fitting surface except where crimping or the application of labeling information causes a displacement of the protective coating.

S8. Test procedures—Air brake hose, brake hose assemblies, and brake hose end fittings.

S8.1 High temperature resistance test.

(a) Utilize a small test cylinder with a radius specified in Table IV for the size of hose tested.

(b) Bind the hose around the cylinder and condition it in an air oven for 70 hours at 212 degrees Fahrenheit (100 degrees Celsius).

(c) Cool the hose to room temperature, remove it from the cylinder and straighten it.

(d) Without magnification, examine the hose externally and cut the hose lengthwise and examine the inner tube.

S8.2 Low temperature resistance test.

(a) Utilize a large test cylinder with a radius specified in Table IV for the size of hose tested.

(b) Condition the cylinder and the brake hose, in a straight position, in a cold box at minus 40° F. for 70 hours.

(c) With the hose and cylinder at minus 40 degrees Fahrenheit (minus 40 degrees Celsius), bend the hose 180 degrees around the cylinder at a steady rate in a period of 3 to 5 seconds. Remove the hose from the test cylinder and visibly examine the exterior of the hose for cracks without magnification.

(d) Allow the hose to warm at room temperature for 2 hours. All reusable end fittings are removed from the hose. All permanently-attached end fittings are cut away from the hose. Cut through one wall of the hose longitudinally along its entire length. Unfold the hose to permit examination of the interior surface. Visibly examine the interior of the hose for cracks without magnification.

S8.3 Oil resistance test. Utilize three test specimens and average the results.

S8.3.1 Preparation. Fashion a test specimen by cutting a rectangular block 2 inches long and not less than one-third of an inch in width, having a thickness of not more than one-sixteenth inch, from the brake hose and buff the specimen on both faces to ensure smooth surfaces.

S8.3.2 Measurement.

(a) Weigh each specimen to the nearest milligram in air (W 1 ) and in distilled water (W 2 ) at room temperature. If wetting is necessary to remove air bubbles, dip the specimen in acetone and thoroughly rinse it with distilled water.

(b) Immerse each specimen in ASTM IRM 903 oil for 70 hours at 212 degrees Fahrenheit (100 degrees Celsius) and then cool in ASTM IRM 903 oil at room temperature for 30 to 60 minutes.

(c) Dip the specimen quickly in acetone and blot it lightly with filter paper.

(d) Weigh each specimen in a tared weighing bottle (W 3 ) and in distilled water (W 4 ) within five minutes of removal from the cooling liquid.

(e) Calculate the percentage increase in volume follows:

Percent of increase = [(W 3 - W 4 ) - (W 1 -W 2 )]/(W 1 - W 2 ) x 100

S8.4 Ozone resistance test. Conduct the test specified in S6.8, using air brake hose, except use the large test cylinder specified in Table IV for the size of hose tested.

S8.5 Length change test.

(a) Position a test hose in a straight, horizontal position, and apply air pressure of 10 psi thereto.

(b) Measure the hose to determine original free length.

(c) Without releasing the 10 psi, raise the air pressure to the test hose to 200 psi.

(d) Measure the hose under 200 psi to determine final free length. An elongation or contraction is an increase or decrease, respectively, in the final free length from the original free length of the hose.

S8.6 Adhesion test for air brake hose not reinforced by wire.

S8.6.1 Apparatus. A tension testing machine that is power-driven and that applies a constant rate of extension is used for measuring the force required to separate the layers of the test specimen. The apparatus is constructed so that:

(a) The recording head includes a freely rotating form with an outside diameter substantially the same as the inside diameter of the hose specimen to be placed on it.

(b) The freely rotating form is mounted so that its axis of rotation is in the plane of the ply being separated from the specimen and so that the applied force is perpendicular to the tangent of the specimen circumference at the line of separation.

(c) The rate of travel of the power-actuated grip is a uniform one inch per minute and the capacity of the machine is such that maximum applied tension during the test is not more than 85 percent nor less than 15 percent of the machine’s rated capacity.

(d) The machine produces a chart with separation as one coordinate and applied tension as the other.

S8.6.2 Preparation.

(a) Cut a test specimen of 1 inch or more in length from the hose to be tested and cut the layer to be tested of that test specimen longitudinally along its entire length to the level of contact with the adjacent layer.

(b) Peel the layer to be tested from the adjacent layer to create a flap large enough to permit attachment of the power-actuated clamp of the apparatus.

(c) Mount the test specimen on the freely rotating form with the separated layer attached to the power-actuated clamp.

S8.6.3 [Reserved]

S8.6.4 Calculations.

(a) The adhesion value shall be the minimum force recorded on the chart excluding that portion of the chart which corresponds to the initial and final 20 percent portion along the displacement axis.

(b) Express the force in pounds per inch of length.

S8.7 Flex strength and air pressure test.

S8.7.1 Apparatus. A flex testing machine with a fixed hose assembly attachment point and a movable hose assembly attachment point, which meets the dimensional requirements of Figure 5 for the size of hose being tested. The attachment points connect to the end fittings on the hose assembly without leakage and, after the hose assembly has been installed for the flex test, are restrained from rotation. The movable end has a linear travel of 6 inches and a cycle rate of 100 cycles per minute. The machine is capable of increasing the air pressure in the hose assembly from zero to 150 psi within 2 seconds, and decreasing the air pressure in the hose assembly from 150 to zero psi within 2 seconds.

|

| Figure 5. Flex Test Apparatus |

| Free hose length | Nominal hose inside diameter | Dimensions | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Position “1” | Position “2” | ||||||||

| A | B | C | R (1) | A | B | C | R (1) | ||

| 10.00 (254) | 3/16, 1/4 | 3.00 (76) | 2.75 (70) | 3.75 (95) | 1.40 (34) | 3.00 (76) | 2.75 (70) | 3.75 (95) | 1.20 (30) |

| 11.00 (279) | 5/16, 3/8, 13/32 | 3.00 (76) | 3.50 (89) | 4.50 (114) | 1.70 (43) | 3.00 (76) | 3.50 (89) | 4.50 (114) | 1.30 (33) |

| 14.00 (355) | 7/16, 1/2, 5/8 | 3.00 (76) | 4.00 (102) | 5.00 (127) | 2.20 (56) | 3.00 (76) | 4.00 (102) | 5.00 (127) | 1.80 (46) |

| Note (1): This is an approximate average radius. | |||||||||

S8.7.2 Preparation. (a) Lay the hose material on a flat surface in an unstressed condition. Apply a permanent marking line along the centerline of the hose on the uppermost surface.

(b) Prepare the hose assembly with a free length as shown in the table accompanying Figure 5. The end fittings shall be attached according to the end fitting manufacturer’s instructions.

(c) Plug the ends of the hose assembly and conduct the salt spray test in S6.11 using an air brake hose assembly. Remove the plugs from the end fittings.

(d) Within 168 hours of completion of the salt spray test, expose the hose assembly to an air temperature of 212 degrees Fahrenheit (100 degrees Celsius) for 70 hours, with the hose in a straight position. Remove the hose and cool it at room temperature for 2 hours. Within 166 hours, subject the hose to the flexure test in S8.7.2(e).

(e) Install the hose assembly on the flex testing machine as follows. With the movable hose attachment point at the mid point of its travel, attach one end of the hose to the movable attachment point with the marked line on the hose in the uppermost position. Attach the other end of the hose to the fixed attachment point allowing the hose to follow its natural curvature.

(f) Cycle the air pressure in the hose by increasing the pressure in the hose from zero psi to 150 psi and holding constant for one minute, then decreasing the pressure from 150 psi to zero psi and holding constant for one minute. Continue the pressure cycling for the duration of the flex testing. Begin the flex testing by cycling the movable attachment point through 6 inches of travel at a rate of 100 cycles per minute. Stop the flex testing and pressure cycling after one million flex cycles have been completed.

(g) Install an orifice with a hole diameter of 0.0625 inches and a thickness of 0.032 inches in the air pressure supply line to the hose assembly. Provide a gauge or other means to measure air pressure in the hose assembly. Regulate the supply air pressure to the orifice to 150 psi.

(h) Apply 150 psi air pressure to the orifice. After 2 minutes have elapsed, measure the air pressure in the brake hose assembly, while pressurized air continues to be supplied through the orifice.

S8.8 Corrosion resistance and burst strength test.

(a) Conduct the test specified in S6.11 using an air brake hose assembly. Remove the plugs from the ends of the hose assembly.

(b) Fill the hose assembly with water, allowing all gases to escape. Apply water pressure at a uniform rate of increase of approximately 1,000 psi per minute until the hose ruptures.

S8.9 Tensile strength test. Utilize a tension testing machine conforming to the requirements of ASTM E4-03 (incorporated by reference, see §571.5 ) and provided with a recording device to measure the force applied.

(a) Attach an air brake hose assembly to the testing machine to permit straight, even, machine pull on the hose. Use adapters to mount hose assemblies equipped with angled end fittings so that the hose is in a straight position when installed on the machine.

(b) Apply tension at a rate of 1 inch per minute travel of the moving head until separation occurs.

S8.10 Water Absorption and tensile strength test. Immerse an air brake hose assembly in distilled water at room temperature for 70 hours. Thirty minutes after removal from the water, conduct the test specified in S8.9.

S8.11 Zinc chloride resistance test. Immerse an air brake hose in a 50 percent zinc chloride aqueous solution at room temperature for 200 hours. Remove it from the solution and examine it under 7-power magnification for cracks.

S8.12 End fitting corrosion resistance test. Conduct the test specified in S6.11 using an air brake hose assembly.

S8.13 Adhesion test for air brake hose reinforced by wire. (a) Place a steel ball with a diameter equal to 73 percent of the nominal inside diameter of the hose being tested inside of the hose. Plug one end of the hose. Attach the other end of the hose to a source of vacuum.

(b) Subject the hose to a vacuum of 25 inches of Hg for five minutes. With the vacuum still applied to the hose, bend the hose 180 degrees around a large test cylinder with a radius specified in Table IV for the size of hose tested. At the location of this bend, bend the hose 180 degrees around the test cylinder in the opposite direction.

(c) With the vacuum still applied to the hose, return the hose to a straight position. Attempt to roll the ball inside the hose using gravity from one end of the hose to the other end.

S8.14 Constriction test. Perform the constriction test in S6.12 using an air brake hose, except that the spherical diameter “A” of the plug gauge in Figure 4, or the diameter of the rigid spherical ball in S6.12.3(a), shall be 66 percent of the nominal inside diameter of the air brake hose being tested.

S9. Requirements—vacuum brake hose, brake hose assemblies, and brake hose end fittings.

S9.1 Labeling.

S9.1.1 Hose. Each vacuum brake hose shall be labeled, or cut from bulk hose that is labeled, at intervals of not more than 6 inches, measured from the end of one legend to the beginning of the next, in block capital letters and numerals at least one-eighth of an inch high, with the information listed in paragraphs (a) through (e) of this section. The information need not be present on hose that is sold as part of a brake hose assembly or a motor vehicle.

(a) The symbol DOT, constituting a certification by the hose manufacturer that the hose conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the hose, which shall be filed in writing with: Office of Crash Avoidance Standards, Vehicle Dynamics Division, National Highway Traffic Safety Administration, 400 Seventh Street, SW., Washington, DC 20590. The designation may consist of block capital letters, numerals or a symbol.

(c) The month, day, and year, or the month and year, of manufacture, expressed in numerals. For example, 10/1/96 means October 1, 1996.

(d) The nominal inside diameter of the hose expressed in inches or fractions of inches or in millimeters, or the nominal outside diameter of plastic tubing expressed in inches or fractions of inches or in millimeters followed by the letters OD. The abbreviation “mm” shall follow hose sizes that are expressed in millimeters. (Example of inside diameter: 7/32, 1/4, 4 mm. Example of outside diameter: 1/4 OD, 12 mm OD.)

(e) The letters “VL” or “VH” shall indicate that the component is a light-duty vacuum brake hose or heavy-duty vacuum brake hose, respectively.

S9.1.2 End fittings. Except for an end fitting that is attached by heat shrinking or by interference fit with plastic vacuum hose or that is attached by deformation of the fitting about a hose by crimping or swaging, at least one component of each vacuum brake hose fitting shall be etched, embossed, or stamped in block capital letters and numerals at least one-sixteenth of an inch high with the following information:

(a) The symbol DOT, constituting a certification by the manufacturer of that component that the component conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of that component of the fitting, which shall be filed in writing with: Office of Crash Avoidance Standards, Vehicle Dynamics Division, National Highway Traffic Safety Administration, 400 Seventh Street, SW., Washington, DC 20590. The designation may consist of block capital letters, numerals or a symbol.

(c) The letters “VL” or “VH” shall indicate that the end fitting is intended for use in a light-duty or heavy-duty vacuum brake system, respectively.

(d) The nominal inside diameter of the hose to which the fitting is properly attached expressed in inches or fractions of inches or in millimeters, or the outside diameter of the plastic tubing to which the fitting is properly attached expressed in inches or fraction of inches or in millimeters followed by the letter OD (See examples in S9.1.1(d)). The abbreviation “mm” shall follow hose sizes that are expressed in millimeters.

S9.1.3 Assemblies. Each vacuum brake hose assembly made with end fittings that are attached by crimping or swaging and each plastic tube assembly made with end fittings that are attached by heat shrinking or dimensional interference fit, except those sold as part of a motor vehicle, shall be labeled by means of a band around the brake hose assembly as specified in this paragraph or, at the option of the manufacturer, by means of labeling as specified in S9.1.3.1. The band may at the manufacturer’s option be attached so as to move freely along the length of the assembly, as long as it is retained by the end fittings. The band shall be etched, embossed, or stamped, in block capital letters, numerals or symbols at least one-eighth of an inch high, with the following information:

(a) The symbol DOT, constituting certification by the hose assembler that the hose assembly conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the hose assembly, which shall be filed in writing with: Office of Crash Avoidance Standards, Vehicle Dynamics Division, National Highway Traffic Safety Administration, 400 Seventh Street SW., Washington, DC 20590. The designation may consist of block capital letters, numerals or a symbol.

S9.1.3.1 At least one end fitting of a vacuum brake hose assembly made with end fittings that are attached by crimping or swaging, or of a plastic tubing assembly made with end fittings that are attached by heat shrinking or dimensional interference fit shall be etched, stamped or embossed with a designation at least one-sixteenth of an inch high that identifies the manufacturer of the hose assembly and is filed in accordance with S9.1.3(b).

S9.2 Test requirements. Each vacuum brake hose assembly or appropriate part thereof shall be capable of meeting any of the requirements set forth under this heading, when tested under the conditions of S13 and the applicable procedures of S10. However, a particular hose assembly or appropriate part thereof need not meet further requirements after having met the constriction requirement (S9.2.1) and then having been subjected to any one of the requirements specified in S9.2.2 through S9.2.10.

S9.2.1 Constriction. Except for that part of an end fitting which does not contain hose, every inside diameter of any section of a vacuum brake hose assembly shall not be less than 75 percent of the nominal inside diameter of the hose if for heavy duty, or 70 percent of the nominal inside diameter of the hose if for light duty (S10.10).

S9.2.2 High temperature resistance. A vacuum brake hose tested under the conditions specified in S10.1:

(a) Shall not have collapse of the outside diameter exceeding 10 percent of the initial outside diameter for a heavy-duty vacuum brake hose, or exceeding 15 percent of the initial outside diameter for a light-duty vacuum brake hose;

(b) Shall not show external cracks, charring, or disintegration visible without magnification, and;

(c) Shall not leak when subjected to a hydrostatic pressure test.

S9.2.3 Low temperature resistance. A vacuum brake hose tested under the conditions specified in S10.2 shall:

(a) Not show cracks visible without magnification after conditioning at minus 40 degrees Fahrenheit (minus 40 degrees Celsius) for 70 hours when bent around a cylinder having the radius specified in Table V for the size hose tested; and

(b) Not leak when subjected to a hydrostatic pressure test (S10.1(e)).

S9.2.4 Ozone resistance. A vacuum brake hose shall not show cracks visible under 7-power magnification after exposure to ozone for 70 hours (S10.3).

S9.2.5 Burst strength. A vacuum brake hose shall not rupture under hydrostatic pressure of 350 psi (S10.4).

S9.2.6 Vacuum. The collapse of the outside diameter of a vacuum brake hose under internal vacuum of 26 inches of Hg. for five minutes shall not exceed one-sixteenth of an inch (S10.5).

S9.2.7 Bend. The collapse of the outside diameter of a vacuum brake hose, other than a preformed vacuum brake hose, at the middle point of the test length when bent until the ends touch shall not exceed the values given in Table V for the size of hose tested (S10.6).

| Hose inside diameter* | High temperature resistance | Low temperature resistance | Bend | Deformation—collapsed inside diameter (dimension D), inches | ||||

|---|---|---|---|---|---|---|---|---|

| Inches | Millimeters | Hose length, inches | Radius of cylinder, inches | Hose length, inches | Radius of cylinder, | Hose length, inches | Maximum collapse of outside inches | |

| 7/32 | 5 | 8 | 1- 1/2 | 17- 1/2 | 3 | 7 | 11/64 | 3/64 |

| 1/4 | 6 | 9 | 1- 1/2 | 17- 1/2 | 3 | 8 | 3/32 | 1/16 |

| 9/32 | 9 | 1- 3/4 | 19 | 3- 1/2 | 9 | 12/64 | 4/64 | |

| 11/32 | 8 | 9 | 1- 3/4 | 19 | 3- 1/2 | 11 | 13/64 | 5/64 |

| 3/8 | 10 | 10 | 1- 3/4 | 19 | 3- 1/2 | 12 | 5/32 | 3/32 |

| 7/16 | 11 | 2 | 20- 1/2 | 4 | 14 | 17/64 | 5/64 | |

| 15/32 | 11 | 2 | 20- 1/2 | 4 | 14 | 17/64 | 5/64 | |

| 1/2 | 12 | 11 | 2 | 20- 1/2 | 4 | 16 | 7/32 | 1/8 |

| 5/8 | 16 | 12 | 2- 1/4 | 22 | 4- 1/2 | 22 | 7/32 | 5/32 |

| 3/4 | 14 | 2- 1/2 | 24 | 5 | 28 | 7/32 | 3/16 | |

| 1 | 16 | 3- 1/4 | 28- 1/2 | 6- 1/2 | 36 | 9/32 | 1/4 | |

| *These sizes are listed to provide test values for brake hosesmanufactured in these sizes. They do not represent conversions. | ||||||||

S9.2.8 Swell and adhesion. Following exposure to Reference Fuel B (as described in ASTM D471-98 (incorporated by reference, see §571.5 ), every inside diameter of any section of a vacuum brake hose shall not be less than 75 percent of the nominal inside diameter of the hose if for heavy duty, or 70 percent of the nominal inside diameter of the hose if for light duty. The vacuum brake hose shall show no leakage in a vacuum test of 26 inches of Hg for 10 minutes. A vacuum hose that is constructed of two or more layers shall withstand a force of 6 pounds per inch of length before separation of adjacent layers. (S10.7).

S9.2.9 Deformation. A vacuum brake hose shall return to 90 percent of its original outside diameter within 60 seconds after five applications of force as specified in S10.8, except that a wirereinforced hose need only return to 85 percent of its original outside diameter. In the case of a heavy duty hose, the first application of force shall not exceed a peak value of 70 pounds, and the fifth application of force shall reach a peak value of at least 40 pounds. In the case of light duty hose the first application of force shall not exceed a peak value of 50 pounds, and the fifth application of force shall reach a peak value of at least 20 pounds (S10.9).

S9.2.10 End fitting corrosion resistance. After 24 hours of exposure to salt spray, vacuum brake hose end fittings shall show no base metal corrosion of the end fitting surface except where crimping or the application of labeling information has caused displacement of the protective coating. (S10.10).

S10. Test procedures—Vacuum brake hose, brake hose assemblies, and brake hose end fittings.

S10.1 High temperature resistance test. (a) Measure the initial outside diameter of the hose.

(b) Subject the hose to an internal vacuum of 26 inches of Hg at an ambient temperature of 257 degrees Fahrenheit (125 degrees Celsius) for a period of 96 hours. Remove the hose to room temperature and atmospheric pressure.

(c) Within 5 minutes of completion of the conditioning in S10.1(b), measure the outside diameter at the point of greatest collapse and calculate the percentage collapse based on the initial outside diameter.

(d) Cool the hose at room temperature for 5 hours. Bend the hose around a mandrel with a diameter equal to five times the initial outside diameter of the hose. Examine the exterior of the hose for cracks, charring, or disintegration visible without magnification. Remove the hose from the mandrel.

(e) Fill the hose assembly with water, allowing all gases to escape. Apply water pressure in the hose of 175 psi within 10 seconds. Maintain an internal hydrostatic pressure of 175 psi for one minute and examine the hose for visible leakage.

S10.2 Low temperature resistance test. (a) Conduct the test specified in S8.2(a) through (c) using vacuum brake hose with the cylinder radius specified in Table V for the size of hose tested.

(b) Remove the hose from the test cylinder, warm the hose at room temperature for 5 hours, and conduct the hydrostatic pressure test in S10.1(e).

S10.3 Ozone resistance test. Conduct the test specified in S6.8 using vacuum brake hose.

S10.4 Burst strength test. Conduct the test specified in S8.8 using vacuum brake hose.

S10.5 Vacuum test. Utilize a 12-inch vacuum brake hose assembly sealed at one end.

(a) Measure the hose outside diameter.

(b) Attach the hose to a source of vacuum and subject it to a vacuum of 26 inches of Hg for 5 minutes.

(c) Measure the hose to determine the minimum outside diameter while the hose is still subject to vacuum.

S10.6 Bend test.

(a) Bend a vacuum brake hose, of the length prescribed in Table V, in the direction of its normal curvature until the ends just touch as shown in Figure 6.

(b) Measure the outside diameter of the specimen at point A before and after bending.

(c) The difference between the two measurements is the collapse of the hose outside diameter on bending.

|

| Fig. 6—Bend Test of Vacuum Brake Hose. |

S10.7 Swell and adhesion test. (a) Fill a specimen of vacuum brake hose 12 inches long with ASTM Reference Fuel B as described in ASTM D471-98 (incorporated by reference, see §571.5 ).

(b) Maintain reference fuel in the hose under atmospheric pressure at room temperature for 48 hours.

(c) Remove fuel and conduct the constriction test in S10.10.

(d) Attach the hose to a source of vacuum and subject it to a vacuum of 26 inches of Hg for 10 minutes. Remove the hose from the vacuum source.

(e) For a vacuum brake hose constructed of two or more layers, conduct the test specified in S8.6 using the vacuum brake hose.

S10.8 [Reserved]

S10.9 Deformation test. Table VI specifies the test specimen dimensions.

S10.9.1 Apparatus. Utilize a compression device, equipped to measure force of at least 100 pounds, and feeler gages of sufficient length to be passed completely through the test specimen.

S10.9.2 Operation.

(a) Position the test specimen longitudinally in the compression device with the fabric laps not in the line of the applied pressure.

| Hose inside diameter* | Specimen dimentions (see Fig. 7) | Feeler gage dimensions | |||

|---|---|---|---|---|---|

| in. | mm | Depth (inch) | Length (inch) | Width (inch) | Thickness (inch) |

| 7/32 | 5 | 3/64 | 1 | 1/8 | 3/64 |

| 1/4 | 6 | 1/16 | 1 | 1/8 | 1/16 |

| 9/32 | 1/16 | 1 | 1/8 | 1/16 | |

| 11/32 | 8 | 5/64 | 1 | 3/16 | 5/64 |

| 3/8 | 10 | 3/32 | 1 | 3/16 | 3/32 |

| 7/16 | 5/64 | 1 | 1/4 | 5/64 | |

| 15/32 | 5/64 | 1 | 1/4 | 5/64 | |

| 1/2 | 12 | 1/8 | 1 | 1/4 | 1/8 |

| 5/8 | 16 | 5/32 | 1 | 1/4 | 5/32 |

| 3/4 | 3/16 | 1 | 1/4 | 3/16 | |

| 1 | 1/4 | 1 | 1/4 | 1/4 | |

| *These sizes are listed to provide test values for brake hoses manufactured in these sizes. They do not represent conversions. | |||||

(b) Apply gradually increasing force to the test specimen to compress its inside diameter to that specified in Table VI (dimension D of Figure 7) for the size of hose tested.

|

| Fig. 7. Deformed Specimen of Vacuum Brake Hose |

(c) After 5 seconds release the force and record the peak load applied.

(d) Repeat the procedure four times permitting a 10-second recovery period between load applications.

S10.10 End fitting corrosion resistance test. Conduct the test specified in S6.11 using a vacuum brake hose assembly.

S10.11 Constriction test. Perform the constriction test in S6.12 using a vacuum brake hose, except that the spherical diameter “A” of the plug gauge in Figure 4, or the diameter of the rigid spherical ball in S6.12.3(a), shall be 75 percent of the nominal inside diameter of the vacuum brake hose if it is heavy duty, or 70 percent of the nominal inside diameter of the vacuum brake hose if it is light duty.

S11. Requirements—Plastic air brake tubing, plastic air brake tubing assemblies, and plastic air brake tubing end fittings.

S11.1 Construction. Each plastic air brake tubing assembly shall be equipped with permanently attached end fittings or reusable end fittings. Plastic air brake tubing shall conform to the dimensional requirements specified in Table VII. (S12.1)

| Nominal tubing outside diameter | Maximum outside diameter | Minimum outside diameter | Nominal inside diameter | Nominal wall thickness | Wall thickness tolerance | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| mm | inches | mm | inches | mm | inches | mm | inches | mm | inches | |

| 1/8 inch | 3.25 | 0.128 | 3010 | 0.122 | 2.01 | 0.079 | 0.58 | 0.023 | 0.08 | 0.003 |

| 5/32 inch | 4.04 | 0.159 | 3.89 | 0.153 | 2.34 | 0.092 | 0.81 | 0.032 | 0.08 | 0.003 |

| 3/16 inch | 4.83 | 0.190 | 4.67 | 0.184 | 2.97 | 0.117 | 0.89 | 0.035 | 0.08 | 0.003 |

| 1/4 inch | 6.43 | 0.253 | 6.27 | 0.247 | 4.32 | 0.170 | 1.02 | 0.040 | 0.08 | 0.003 |

| 5/16 inch | 8.03 | 0.316 | 7.82 | 0.308 | 5.89 | 0.232 | 1.02 | 0.040 | 0.10 | 0.004 |

| 3/8 inch | 9.63 | 0.379 | 9.42 | 0.371 | 6.38 | 0.251 | 1.57 | 0.062 | 0.10 | 0.004 |

| 1/2 inch | 12.83 | 0.505 | 12.57 | 0.495 | 9.55 | 0.376 | 1.57 | 0.062 | 0.10 | 0.004 |

| 5/8 inch | 16.00 | 0.630 | 15.75 | 0.620 | 11.20 | 0.441 | 2.34 | 0.092 | 0.13 | 0.005 |

| 3/4 inch | 19.18 | 0.755 | 18.92 | 0.745 | 14.38 | 0.566 | 2.34 | 0.092 | 0.13 | 0.005 |

| 6 mm | 6.10 | 0.240 | 5.90 | 0.232 | 4.00 | 0.157 | 1.00 | 0.039 | 0.10 | 0.004 |

| 8 mm | 8.10 | 0.319 | 7.90 | 0.311 | 6.00 | 0.236 | 1.00 | 0.039 | 0.10 | 0.004 |

| 10 mm | 10.13 | 0.399 | 9.87 | 0.389 | 7.00 | 0.276 | 1.50 | 0.059 | 0.10 | 0.004 |

| 12 mm | 12.13 | 0.478 | 11.87 | 0.467 | 9.00 | 0.354 | 1.50 | 0.059 | 0.10 | 0.004 |

| 16 mm | 16.13 | 0.635 | 15.87 | 0.625 | 12.00 | 0.472 | 2.00 | 0.079 | 0.13 | 0.005 |

S11.2 Labeling.

S11.2.1 Plastic air brake tubing. Plastic air brake tubing shall be labeled, or cut from bulk tubing that is labeled, at intervals of not more than 6 inches, measured from the end of one legend to the beginning of the next, in block capital letters and numerals at least oneeighth of an inch high, with the information listed in paragraphs (a) through (e) of this section. The information need not be present on tubing that is sold as part of a motor vehicle.

(a) The symbol DOT, constituting a certification by the hose manufacturer that the hose conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the tubing, which shall be filed in writing with: Office of Vehicle Safety Compliance, Equipment Division NVS–222, National Highway Traffic Safety Administration, 400 Seventh St. SW., Washington, DC 20590. The designation may consist of block capital letters, numerals, or a symbol.

(c) The month, day, and year, or the month and year, of manufacture, expressed in numerals. For example, 10/1/96 means October 1, 1996.

(d) The nominal outside diameter expressed in inches or fractions of inches or in millimeters followed by the letters OD. The abbreviation “mm” shall follow tubing sizes that are expressed in millimeters. (Examples: 3/8 OD, 6 mm OD.)

(e) The letter “A” shall indicate intended use in air brake systems.

S11.2.2 End fittings. Except for an end fitting that is attached by deformation of the fitting about the tubing by crimping or swaging, at least one component of each plastic air brake tubing end fitting shall be etched, embossed, or stamped in block capital letters and numerals at least onesixteenth of an inch high with the following information:

(a) The symbol DOT, constituting a certification by the manufacturer that the end fitting conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the end fitting, which shall be filed in writing with: Office of Vehicle Safety Compliance, Equipment Division NVS–222, National Highway Traffic Safety Administration, 400 Seventh St. SW., Washington, DC 20590. The designation may consist of block capital letters, numerals, or a symbol.

(c) The letter “A” shall indicate intended use in air brake systems.

(d) The nominal outside diameter of the plastic tubing to which the fitting is properly attached expressed in inches or fractions of inches or in millimeters followed by the letters OD. The abbreviation “mm” shall follow tubing sizes that are expressed in millimeters. (Examples: 3/8 OD, 6 mm OD)

S11.2.3. Assemblies. Each plastic air brake tubing assembly made with end fittings that are attached by crimping or swaging, except those sold as part of a motor vehicle, shall be labeled by means of a band around the brake tubing assembly as specified in this paragraph or, at the option of the manufacturer, by means of labeling as specified in S11.2.3.1. The band may at the manufacturer’s option be attached so as to move freely along the length of the assembly, as long as it is retained by the end fittings. The band shall be etched, embossed, or stamped in block capital letters, numerals or symbols at least one-eighth of an inch high, with the following information:

(a) The symbol DOT, constituting certification by the tubing assembler that the tubing assembly conforms to all applicable motor vehicle safety standards.

(b) A designation that identifies the manufacturer of the hose assembly, which shall be filed in writing with: Office of Vehicle Safety Compliance, Equipment Division NVS–222, National Highway Traffic Safety Administration, 400 Seventh St. SW., Washington, DC 20590. The designation may consist of block capital letters, numerals, or a symbol.

S11.2.3.1 At least one end fitting of a plastic air brake tubing assembly made with end fittings that are attached by crimping or swaging shall be etched, stamped, or embossed with a designation at least one-sixteenth of an inch high that identifies the manufacturer of the tubing assembly and is filed in accordance with S11.2.3(b).

S11.3 Test requirements. Each plastic air brake tubing assembly or appropriate part thereof shall be capable of meeting any of the requirements set forth under this heading, when tested under the conditions of S13 and the applicable procedures of S12. However, a particular tubing assembly or appropriate part thereof need not meet further requirements after having met the constriction requirement (S11.3.1) and then having been subjected to any one of the requirements specified in S11.3.2 through S11.3.24. Unless otherwise specified, testing is conducted on a sample of tubing 12 inches in length.

S11.3.1 Constriction. Every inside diameter of any section of a plastic air brake tubing assembly shall not be less than 66 percent of the nominal inside diameter of the brake tubing. (S12.2)

S11.3.2 High temperature conditioning and dimensional stability. Plastic air brake tubing shall conform to the dimensions in Table VII after conditioning in air at 230 degrees Fahrenheit (110 degrees Celsius) for four hours. (S12.3)

S11.3.3 Boiling water conditioning and dimensional stability. Plastic air brake tubing shall conform to the dimensions in Table VII after conditioning in boiling water for two hours. (S12.4)