['CMV Parts and Maintenance']

['Vehicle maintenance']

01/07/2025

...

S1. Scope. This standard specifies requirements for the integrity of compressed natural gas (CNG), motor vehicle fuel containers.

S2. Purpose. The purpose of this standard is to reduce deaths and injuries occurring from fires that result from fuel leakage during and after motor vehicle crashes.

S3. Application. This standard applies to each passenger car, multipurpose passenger vehicle, truck, and bus that uses CNG as a motor fuel and to each container designed to store CNG as motor fuel on-board any motor vehicle.

S4. Definitions.

Brazing

means a group of welding processes wherein coalescence is produced by heating to a suitable temperature above 800 °F and by using a nonferrous filler metal, having a melting point below that to the base metals. The filler metal is distributed between the closely fitted surfaces of the joint by capillary attraction.

Burst pressure

means the highest internal pressure reached in a CNG fuel container during a burst test at a temperature of 21 °C (70 °F).

CNG fuel container

means a container designed to store CNG as motor fuel on-board a motor vehicle.

Fill pressure

means the internal pressure of a CNG fuel container attained at the time of filling. Fill pressure varies according to the gas temperature in the container which is dependent on the charging parameters and the ambient conditions.

Full wrapped

means applying the reinforcement of a filament or resin system over the entire liner, including the domes.

Hoop wrapped

means winding of filament in a substantially circumferential pattern over the cylindrical portion of the liner so that the filament does not transmit any significant stresses in a direction parallel to the cylinder longitudinal axis.

Hydrostatic pressure

means the internal pressure to which a CNG fuel container is taken during testing set forth in S5.4.1.

Liner

means the inner gas tight container or gas cylinder to which the overwrap is applied.

Service pressure

means the internal settled pressure of a CNG fuel container at a uniform gas temperature of 21 °C (70 °F) and full gas content. It is the pressure for which the container has been constructed under normal conditions.

S5 Container and material requirements.

S5.1 Container designations. Container designations are as follows:

S5.1.1 Type 1-Non-composite metallic container means a metal container.

S5.1.2 Type 2-Composite metallic hoop wrapped container means a metal liner reinforced with resin impregnated continuous filament that is “hoop wrapped.”

S5.1.3 Type 3-Composite metallic full wrapped container means a metal liner reinforced with resin impregnated continuous filament that is “full wrapped.”

S5.1.4 Type 4-Composite non-metallic full wrapped container means resin impregnated continuous filament with a non-metallic liner “full wrapped.”

S6 General requirements.

S6.1 Each passenger car, multipurpose passenger vehicle, truck, and bus that uses CNG as a motor fuel shall be equipped with a CNG fuel container that meets the requirements of S7 through S7.4.

S6.2 Each CNG fuel container manufactured on or after March 27, 1995 shall meet the requirements of S7 through S7.4.

S7 Test requirements. Each CNG fuel container shall meet the applicable requirements of S7 through S7.4.

S7.1 Pressure cycling test at ambient temperature. Each CNG fuel container shall not leak when tested in accordance with S8.1.

S7.2 Hydrostatic burst test.

S7.2.1 Each Type 1 CNG fuel container shall not leak when subjected to burst pressure and tested in accordance with S8.2. Burst pressure shall not be less than 2.25 times the service pressure for non-welded containers and shall not be less than 3.5 times the service pressure for welded containers.

S7.2.2 Each Type 2, Type 3, or Type 4 CNG fuel container shall not leak when subjected to burst pressure and tested in accordance with S8.2. Burst pressure shall be not less than 2.25 times the service pressure.

S7.3 Bonfire test. Each CNG fuel container shall be equipped with a pressure relief device. Each CNG fuel container shall completely vent its contents through a pressure relief device or shall not burst while retaining its entire contents when tested in accordance with S8.3.

S7.4 Labeling. Each CNG fuel container shall be permanently labeled with the information specified in paragraphs (a) through (h) of this section. Any label affixed to the container in compliance with this section shall remain in place and be legible for the manufacturer’s recommended service life of the container. The information shall be in English and in letters and numbers that are at least 6.35 mm (1⁄4 inch) high.

(a) The statement: “If there is a question about the proper use, installation, or maintenance of this container, contact__________,” inserting the CNG fuel container manufacturer’s name, address, and telephone number.

(b) The statement: “Manufactured in __________,” inserting the month and year of manufacture of the CNG fuel container.

(c) The statement: “Service pressure _____kPa, (_____psig).”

(d) The symbol DOT, constituting a certification by the CNG container manufacturer that the container complies with all requirements of this standard.

(e) The container designation (e.g., Type 1, 2, 3, 4).

(f) The statement: “CNG Only.”

(g) The statement: “This container should be visually inspected for damage and deterioration after a motor vehicle accident or fire, and either (a) at least every 12 months when installed on a vehicle with a GVWR greater than 4,536 kg, or (b) at least every 36 months or 36,000 miles, whichever comes first, when installed on a vehicle with a GVWR less than or equal to 4,536 kg.”

(h) The statement: “Do Not Use After ______” inserting the month and year that mark the end of the manufacturer’s recommended service life for the container.

S8 Test conditions: fuel container integrity.

S8.1 Pressure cycling test. The requirements of S7.1 shall be met under the conditions of S8.1.1 through S8.1.4.

S8.1.1 Hydrostatically pressurize the CNG container to the service pressure, then to not more than 10 percent of the service pressure, for 13,000 cycles.

S8.1.2 After being pressurized as specified in S8.1.1, hydrostatically pressurize the CNG container to 125 percent of the service pressure, then to not more than 10 percent of the service pressure, for 5,000 cycles.

S8.1.3 The cycling rate for S8.1.1 and S8.1.2 shall be any value up to and including 10 cycles per minute.

S8.1.4 The cycling is conducted at ambient temperature.

S8.2 Hydrostatic burst test. The requirements of S7.2 shall be met under the conditions of S8.2.1 through S8.2.2.

S8.2.1 Hydrostatically pressurize the CNG fuel container, as follows: The pressure is increased up to the minimum prescribed burst pressure determined in S7.2.1 or S7.2.2, and held constant at the minimum burst pressure for 10 seconds.

S8.2.2 The pressurization rate throughout the test shall be any value up to and including 1,379 kPa (200 psi) per second.

S8.3 Bonfire test. The requirements of S7.3 shall be met under the conditions of S8.3.1 through S8.3.7.

S8.3.1 Fill the CNG fuel container with compressed natural gas and test it at:

(a) 100 percent of service pressure; and

(b) 25 percent of service pressure.

S8.3.2 Container positioning.

(a) Position the CNG fuel container in accordance with paragraphs (b) and (c) of S8.3.2.

(b) Position the CNG fuel container so that its longitudinal axis is horizontal and its bottom is 100 mm (4 inches) above the fire source.

(c)(1) Position a CNG fuel container that is 1.65 meters (65 inches) in length or less and is fitted with one pressure relief device so that the center of the container is over the center of the fire source.

(2) Position a CNG fuel container that is greater than 1.65 meters (65 inches) in length and is fitted with one pressure relief device at one end of the container so that the center of the fire source is 0.825 meters (32.5 inches) from the other end of the container, measured horizontally along a line parallel to the longitudinal axis of the container.

(3) Position a CNG fuel container that is fitted with pressure relief devices at more than one location along its length so that the portion of container over the center of the fire source is the portion midway between the two pressure relief devices that are separated by the greatest distance, measured horizontally along a line parallel to the longitudinal axis of the container.

(4) Test a CNG fuel container that is greater than 1.65 meters (65 inches) in length, is protected by thermal insulation, and does not have pressure relief devices, twice at 100 percent of service pressure. In one test, position the center of the container over the center of the fire source. In another test, position one end of the container so that the fire source is centered 0.825 meters (32.5 inches) from one end of the container, measured horizontally along a line parallel to the longitudinal axis of the container.

S8.3.3 Number and placement of thermocouples. To monitor flame temperature, place three thermocouples so that they are suspended 25 mm (one inch) below the bottom of the CNG fuel container. Position thermocouples so that they are equally spaced over the length of the fire source or length of the container, whichever is shorter.

S8.3.4 Shielding.

(a) Use shielding to prevent the flame from directly contacting the CNG fuel container valves, fittings, or pressure relief devices.

(b) To provide the shielding, use steel with 0.6 mm (.025 in) minimum nominal thickness.

(c) Position the shielding so that it does not directly contact the CNG fuel container valves, fittings, or pressure relief devices.

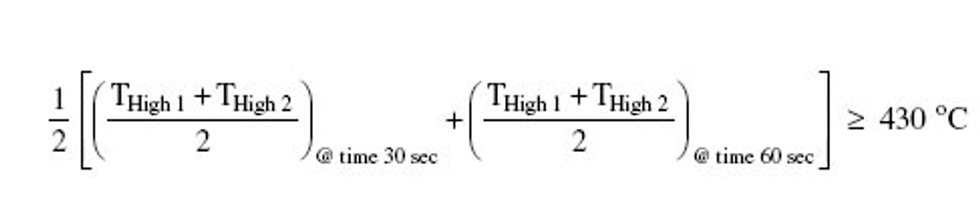

S8.3.5 Fire source. Use a uniform fire source that is 1.65 meters long (65 inches). Beginning five minutes after the fire is ignited, maintain an average flame temperature of not less than 430 degrees Celsius (800 degrees Fahrenheit) as determined by the average of the two thermocouples recording the highest temperatures over a 60 second interval:

If the pressure relief device releases before the end of the fifth minute after ignition, then the minimum temperature requirement does not apply.

S8.3.6 Recording data. Record time, temperature, and pressure readings at 30 second intervals, beginning when the fire is ignited and continuing until the pressure release device releases.

S8.3.7 Duration of exposure to fire source. The CNG fuel container is exposed to the fire source for 20 minutes after ignition or until the pressure release device releases, whichever period is shorter.

S8.3.8 Number of tests per container. A single CNG fuel container is not subjected to more than one bonfire test.

S8.3.9 Wind velocity. The average ambient wind velocity at the CNG fuel container during the period specified in S8.3.6 of this standard is not to exceed 24 meters/second (5 mph).

S8.3.10 The average wind velocity at the container is any velocity up to and including 2.24 meters/second (5 mph).

[59 FR 49021, Sept. 26, 1994; 59 FR 66776, Dec. 28, 1994; 60 FR 37843, July 24, 1995; 60 FR 57948, Nov. 24, 1995; 61 FR 19204, May 1, 1996; 61 FR 47089, Sept. 6, 1996; 63 FR 66765, Dec. 3, 1998; 65 FR 51772, Aug. 25, 2000; 65 FR 64626, Oct. 30, 2000; 87 FR 7964, Feb. 11, 2022]

['CMV Parts and Maintenance']

['Vehicle maintenance']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.