['CMV Parts and Maintenance']

['Vehicle maintenance']

04/07/2025

...

S1 Scope and purpose.

(a) Scope. This standard specifies performance requirements for protection of occupants in side impacts.

(b) Purpose. The purpose of this standard is to reduce the risk of serious and fatal injury to occupants of passenger cars, multipurpose passenger vehicles, trucks and buses in side impacts by specifying strength requirements for side doors, limiting the forces, deflections and accelerations measured on anthropomorphic dummies in test crashes, and by other means.

S2 Applicability. This standard applies to passenger cars, and to multipurpose passenger vehicles, trucks designed to carry at least one person and buses with a gross vehicle weight rating (GVWR) of 4,536 kilograms (kg) (10,000 pounds (lb)) or less, except for walk-in vans, or otherwise specified.

S3 Definitions.

Contoured

means, with respect to a door, that the lower portion of its front or rear edge is curved upward, typically to conform to a wheel well.

Double side doors

means a pair of hinged doors with the lock and latch mechanisms located where the door lips overlap.

Limited line manufacturer

means a manufacturer that sells three or fewer carlines, as that term is defined in 49 CFR 583.4, in the United States during a production year.

Lowered floor

means the replacement floor on a motor vehicle whose original floor has been removed, in part or in total, and replaced by a floor that is lower than the original floor.

Modified roof

means the replacement roof on a motor vehicle whose original roof has been removed, in part or in total.

Raised roof

is used as defined in paragraph S4 of 49 CFR 571.216.

Walk-in van

means a special cargo/mail delivery vehicle that has only one designated seating position. That designated seating position must be forward facing and for use only by the driver. The vehicle usually has a thin and light sliding (or folding) side door for easy operation and a high roof clearance that a person of medium stature can enter the passenger compartment area in an up-right position.

S4 Requirements. Subject to the exceptions of S5—

(a) Passenger cars. Passenger cars must meet the requirements set forth in S6 (door crush resistance), S7 (moving deformable barrier test), and S9 (vehicle-to-pole test), subject to the phased-in application of S7 and S9.

(b) Multipurpose passenger vehicles, trucks and buses with a GVWR of 2,722 kg or less (6,000 lb or less). Multipurpose passenger vehicles, trucks and buses with a GVWR of 2,722 kg or less (6,000 lb or less) must meet the requirements set forth in S6 (door crush resistance), S7 (moving deformable barrier test), and S9 (vehicle-to-pole test), subject to the phased-in application of S7 and S9.

(c) Multipurpose passenger vehicles, trucks and buses with a GVWR greater than 2,722 kg (6,000 lb). Multipurpose passenger vehicles, trucks and buses with a GVWR greater than 2,722 kg (6,000 lb) must meet the requirements set forth in S6 (door crush resistance) and S9 (vehicle-to-pole test), subject to the phased-in application of S9.

S5 General exclusions.

(a) Exclusions from S6 (door crush resistance). A vehicle need not meet the requirements of S6 (door crush resistance) for—

(1) Any side door located so that no point on a ten-inch horizontal longitudinal line passing through and bisected by the H-point of a manikin placed in any seat, with the seat adjusted to any position and the seat back adjusted as specified in S8.3, falls within the transverse, horizontal projection of the door's opening,

(2) Any side door located so that no point on a ten-inch horizontal longitudinal line passing through and bisected by the H–point of a manikin placed in any seat recommended by the manufacturer for installation in a location for which seat anchorage hardware is provided, with the seat adjusted to any position and the seat back adjusted as specified in S8.3, falls within the transverse, horizontal projection of the door's opening,

(3) Any side door located so that a portion of a seat, with the seat adjusted to any position and the seat back adjusted as specified in S8.3, falls within the transverse, horizontal projection of the door's opening, but a longitudinal vertical plane tangent to the outboard side of the seat cushion is more than 254 mm (10 inches) from the innermost point on the inside surface of the door at a height between the H–point and shoulder reference point (as shown in Figure 1 of Federal Motor Vehicle Safety Standard No. 210 ( 49 CFR 571.210 )) and longitudinally between the front edge of the cushion with the seat adjusted to its forwardmost position and the rear edge of the cushion with the seat adjusted to its rearmost position.

(4) Any side door that is designed to be easily attached to or removed (e.g., using simple hand tools such as pliers and/or a screwdriver) from a motor vehicle manufactured for operation without doors.

(b) Exclusions from S7 (moving deformable barrier test). The following vehicles are excluded from S7 (moving deformable barrier test):

(1) Motor homes, ambulances and other emergency rescue/medical vehicles (including vehicles with fire-fighting equipment), vehicles equipped with wheelchair lifts, and vehicles which have no doors or exclusively have doors that are designed to be easily attached or removed so the vehicle can be operated without doors.

(2) Passenger cars with a wheelbase greater than 130 inches need not meet the requirements of S7 as applied to the rear seat.

(3) Passenger cars, multipurpose passenger vehicles, trucks and buses need not meet the requirements of S7 (moving deformable barrier test) as applied to the rear seat for side-facing rear seats and for rear seating areas that are so small that a Part 572 Subpart V dummy representing a 5th percentile adult female cannot be accommodated according to the positioning procedure specified in S12.3.4 of this standard. Vehicles that are manufactured before September 1, 2010, and vehicles that manufactured on or after September 1, 2010, that are not part of the percentage of a manufacturer’s production meeting the moving deformable barrier test requirements with advanced test dummies (S7.2 of this section) or are otherwise excluded from the phase-in requirements of S7.2, need not meet the requirements of the moving deformable barrier test as applied to the rear seat for rear seating areas that are so small that a Subpart F dummy (SID) cannot be accommodated according to the positioning procedure specified in S12.1 of this standard.

(4) Multipurpose passenger vehicles, trucks and buses with a GVWR of more than 2,722 kg (6,000 lb) need not meet the requirements of S7 (moving deformable barrier test).

(c) Exclusions from S9 (vehicle-to-pole test). The following vehicles are excluded from S9 (vehicle-to-pole test) (wholly or in limited part, as set forth below):

(1) Motor homes;

(2) Ambulances and other emergency rescue/medical vehicles (including vehicles with fire-fighting equipment) except police cars;

(3) Vehicles with a lowered floor or raised or modified roof and vehicles that have had the original roof rails removed and not replaced;

(4) Vehicles in which the seat for the driver or any front outboard passenger has been removed and wheelchair restraints installed in place of the seat are excluded from meeting the vehicle-to-pole test at that position; and

(5) Vehicles that have no doors, or exclusively have doors that are designed to be easily attached or removed so that the vehicle can be operated without doors.

S6 Door Crush Resistance Requirements. Except as provided in section S5, each vehicle shall be able to meet the requirements of either, at the manufacturer's option, S6.1 or S6.2, when any of its side doors that can be used for occupant egress is tested according to procedures described in S6.3 of this standard (49 CFR 571.214).

S6.1 With any seats that may affect load upon or deflection of the side of the vehicle removed from the vehicle, each vehicle must be able to meet the requirements of S6.1.1 through S6.1.3.

S6.1.1 Initial crush resistance. The initial crush resistance shall not be less than 10,000 N (2,250 lb).

S6.1.2 Intermediate crush resistance. The intermediate crush resistance shall not be less than 15,569 N (3,500 lb). S6.1.3 Peak crush resistance. The peak crush resistance shall not be less than two times the curb weight of the vehicle or 31,138 N (7,000 lb), whichever is less.

S6.1.3 Peak crush resistance. The peak crush resistance shall not be less than two times the curb weight of the vehicle or 31,138 N (7,000 lb), whichever is less.

S6.2 With seats installed in the vehicle, and located in any horizontal or vertical position to which they can be adjusted and at any seat back angle to which they can be adjusted, each vehicle must be able to meet the requirements of S6.2.1 through S6.2.3.

S6.2.1 Initial crush resistance. The initial crush resistance shall not be less than 10,000 N (2,250 lb).

S6.2.2 Intermediate crush resistance. The intermediate crush resistance shall not be less than 19,460 N (4,375 lb).

S6.2.3 Peak crush resistance. The peak crush resistance shall not be less than three and one half times the curb weight of the vehicle or 53,378 N (12,000 lb), whichever is less.

S6.3 Test procedures for door crush resistance. The following procedures apply to determining compliance with S6.1 and S6.2 of S6, Door crush resistance requirements.

(a) Place side windows in their uppermost position and all doors in locked position. Place the sill of the side of the vehicle opposite to the side being tested against a rigid unyielding vertical surface. Fix the vehicle rigidly in position by means of tiedown attachments located at or forward of the front wheel centerline and at or rearward of the rear wheel centerline.

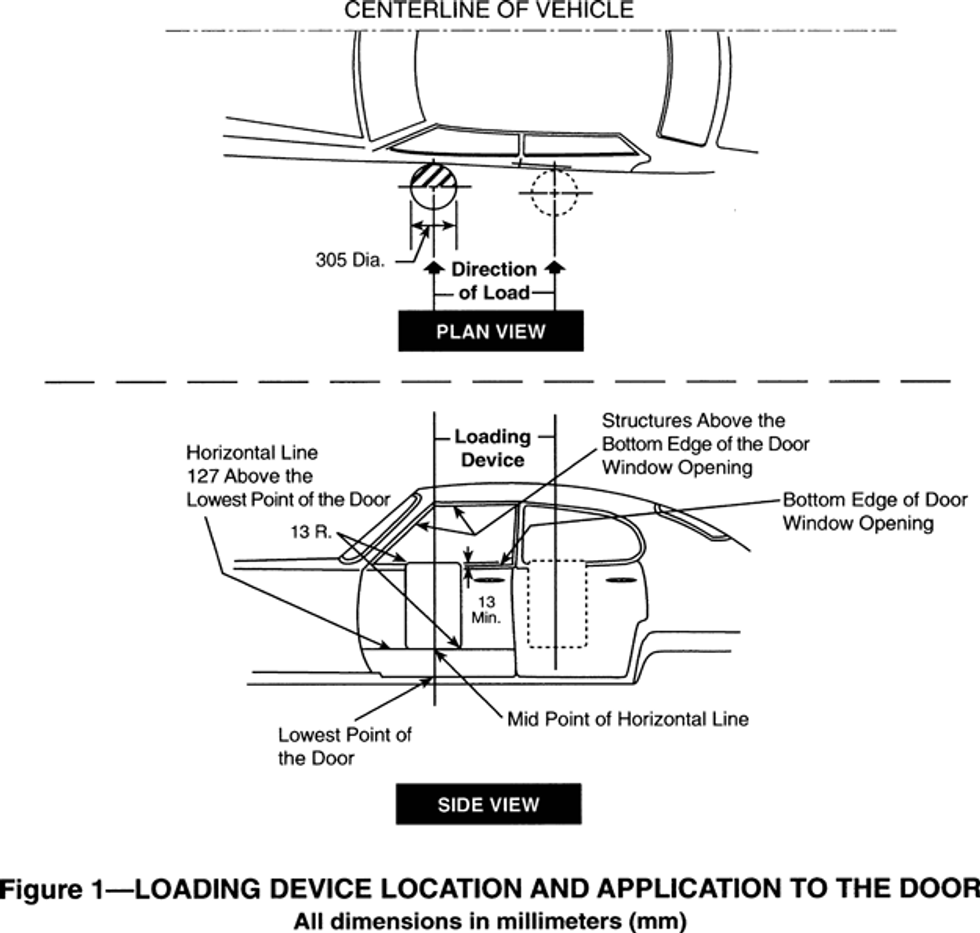

(b) Prepare a loading device consisting of a rigid steel cylinder or semi-cylinder 305 mm (12 inches) in diameter with an edge radius of 13 mm ( 1/2 inch). The length of the loading device shall be such that—

(1) For doors with windows, the top surface of the loading device is at least 13 mm ( 1/2 inch) above the bottom edge of the door window opening but not of a length that will cause contact with any structure above the bottom edge of the door window opening during the test.

(2) For doors without windows, the top surface of the loading device is at the same height above the ground as when the loading device is positioned in accordance with paragraph (b)(1) of this section for purposes of testing a front door with windows on the same vehicle.

(c) Locate the loading device as shown in Figure 1 (side view) of this section so that—

(1) Its longitudinal axis is vertical.

(2) Except as provided in paragraphs (c)(2)(i) and (ii) of this section, its longitudinal axis is laterally opposite the midpoint of a horizontal line drawn across the outer surface of the door 127 mm (5 inches) above the lowest point of the door, exclusive of any decorative or protective molding that is not permanently affixed to the door panel.

(i) For contoured doors on trucks, buses, and multipurpose passenger vehicles with a GVWR of 4,536 kg (10,000 lb) or less, if the length of the horizontal line specified in this paragraph (c)(2) is not equal to or greater than 559 mm (22 inches), the line is moved vertically up the side of the door to the point at which the line is 559 mm (22 inches) long. The longitudinal axis of the loading device is then located laterally opposite the midpoint of that line.

(ii) For double side doors on trucks, buses, and multipurpose passenger vehicles with a GVWR of 4,536 kg (10,000 lb) or less, its longitudinal axis is laterally opposite the midpoint of a horizontal line drawn across the outer surface of the double door span, 127 mm (5 inches) above the lowest point on the doors, exclusive of any decorative or protective molding that is not permanently affixed to the door panel.

(3) Except as provided in paragraphs (c)(3)(i) and (ii) of this section, its bottom surface is in the same horizontal plane as the horizontal line drawn across the outer surface of the door 127 mm (5 inches) above the lowest point of the door, exclusive of any decorative or protective molding that is not permanently affixed to the door panel.

(i) For contoured doors on trucks, buses, and multipurpose passenger vehicles with a GVWR of 4,536 kg (10,000 lb) or less, its bottom surface is in the lowest horizontal plane such that every point on the lateral projection of the bottom surface of the device on the door is at least 127 mm (5 inches), horizontally and vertically, from any edge of the door panel, exclusive of any decorative or protective molding that is not permanently affixed to the door panel.

(ii) For double side doors, its bottom surface is in the same horizontal plane as a horizontal line drawn across the outer surface of the double door span, 127 mm (5 inches) above the lowest point of the doors, exclusive of any decorative or protective molding that is not permanently affixed to the door panel.

(d) Using the loading device, apply a load to the outer surface of the door in an inboard direction normal to a vertical plane along the vehicle's longitudinal centerline. Apply the load continuously such that the loading device travel rate does not exceed 12.7 mm (0.5 inch) per second until the loading device travels 457 mm (18 inches). Guide the loading device to prevent it from being rotated or displaced from its direction of travel. The test is completed within 120 seconds.

(e) Record applied load versus displacement of the loading device, either continuously or in increments of not more than 25.4 mm (1 inch) or 91 kg (200 pounds) for the entire crush distance of 457 mm (18 inches).

(f) Determine the initial crush resistance, intermediate crush resistance, and peak crush resistance as follows:

(1) From the results recorded in paragraph (e) of this section, plot a curve of load versus displacement and obtain the integral of the applied load with respect to the crush distances specified in paragraphs (f)(2) and (3) of this section. These quantities, expressed in mm-kN (inch-pounds) and divided by the specified crush distances, represent the average forces in kN (pounds) required to deflect the door those distances.

(2) The initial crush resistance is the average force required to deform the door over the initial 152 mm (6 inches) of crush.

(3) The intermediate crush resistance is the average force required to deform the door over the initial 305 mm (12 inches) of crush.

(4) The peak crush resistance is the largest force recorded over the entire 457 mm (18-inch) crush distance.

S7 Moving Deformable Barrier (MDB) Requirements. Except as provided in section S5, when tested under the conditions of S8 each vehicle shall meet S7.3 and the following requirements in a 53 ± 1.0 km/h (33.5 mph) impact in which the vehicle is struck on either side by a moving deformable barrier.

S7.1 MDB test with SID. For vehicles manufactured before September 1, 2010, the following requirements must be met. The following requirements also apply to vehicles manufactured on or after September 1, 2010 that are not part of the percentage of a manufacturer's production meeting the MDB test with advanced test dummies (S7.2 of this section) or are otherwise excluded from the phase-in requirements of S7.2. (Vehicles manufactured before September 1, 2010 may meet S7.2, at the manufacturer's option.)

S7.1.1 The test dummy specified in 49 CFR Part 572 Subpart F (SID) is placed in the front and rear outboard seating positions on the struck side of the vehicle, as specified in S11 and S12 of this standard (49 CFR 571.214).

S7.1.2 When using the Part 572 Subpart F dummy (SID), the following performance requirements must be met.

(a) Thorax. The Thoracic Trauma Index (TTI(d)) shall not exceed:

(1) 85 g for a passenger car with four side doors, and for any multipurpose passenger vehicle, truck, or bus; and,

(2) 90 g for a passenger car with two side doors, when calculated in accordance with the following formula:

TI(d) = 1/2 (GR+ GLS)

Where the term “GR” is the greater of the peak accelerations of either the upper or lower rib, expressed in g's and the term “GLS” is the lower spine (T12) peak acceleration, expressed in g's. The peak acceleration values are obtained in accordance with the procedure specified in S11.5.

(b) Pelvis. The peak lateral acceleration of the pelvis, as measured in accordance with S11.5, shall not exceed 130 g's.

S7.2 MDB test with advanced test dummies.

S7.2.1 Vehicles manufactured on or after September 1, 2010 to August 31, 2014.

(a) Except as provided in S7.2.4 of this section, for vehicles manufactured on or after September 1, 2010 to August 31, 2014, a percentage of each manufacturer's production, as specified in S13.1.1, S13.1.2, S13.1.3, and S13.1.4, shall meet the requirements of S7.2.5 and S7.2.6 when tested with the test dummy specified in those sections. Vehicles manufactured before September 1, 2014 may be certified as meeting the requirements of S7.2.5 and S7.2.6.

(b) For vehicles manufactured on or after September 1, 2010 that are not part of the percentage of a manufacturer's production meeting S7.2.1 of this section, the requirements of S7.1 of this section must be met.

(c) Place the Subpart U ES–2re 50th percentile male dummy in the front seat and the Subpart V SID–IIs 5th percentile female test dummy in the rear seat. The test dummies are placed and positioned in the front and rear outboard seating positions on the struck side of the vehicle, as specified in S11 and S12 of this standard (49 CFR 571.214).

S7.2.2 Vehicles manufactured on or after September 1, 2014.

(a) Subject to S7.2.4 of this section, each vehicle manufactured on or after September 1, 2014 must meet the requirements of S7.2.5 and S7.2.6, when tested with the test dummy specified in those sections.

(b) Place the Subpart U ES–2re 50th percentile male dummy in the front seat and the Subpart V SID–IIs 5th percentile female test dummy in the rear seat. The test dummies are placed and positioned in the front and rear outboard seating positions on the struck side of the vehicle, as specified in S11 and S12 of this standard (49 CFR 571.214).

S7.2.3 [Reserved]

S7.2.4 Exceptions from the MDB phase-in; special allowances.

(1) Vehicles that are manufactured by an original vehicle manufacturer that produces or assembles fewer than 5,000 vehicles annually for sale in the United States are not subject to S7.2.1 of this section (but vehicles that will be manufactured on or after September 1, 2014 are subject to S7.2.2);

(2) Vehicles that are manufactured by a limited line manufacturer are not subject to S7.2.1 of this section (but vehicles that will be manufactured on or after September 1, 2014 are subject to S7.2.2).

(3) Convertibles manufactured before September 1, 2015, are not subject to S7.2.1 or S7.2.2 of this section. These vehicles may be voluntarily certified to meet the MDB test requirements prior to September 1, 2015. Vehicles manufactured on or after September 1, 2015 are subject to S7 and S7.2.2.

(b) Vehicles that are altered (within the meaning of 49 CFR 567.7) before September 1, 2016 after having been previously certified in accordance with part 567 of this chapter, and vehicles manufactured in two or more stages before September 1, 2016, are not subject to S7.2.1. Vehicles that are altered on or after September 1, 2016, and vehicles that are manufactured in two or more stages on or after September 1, 2016, must meet the requirements of S7.2.5 and S7.2.6, when tested with the test dummy specified in those sections. Place the Subpart U ES–2re 50th percentile male dummy in the front seat and the Subpart V SID-IIs 5th percentile female test dummy in the rear seat. The test dummies are placed and positioned in the front and rear outboard seating positions on the struck side of the vehicle, as specified in S11 and S12 of this standard (49 CFR 571.214).

S7.2.5 Dynamic performance requirements using the Part 572 Subpart U dummy (ES–2re 50th percentile male) dummy. Use the 49 CFR Part 572 Subpart U ES–2re dummy specified in S11 with measurements in accordance with S11.5. The following criteria shall be met:

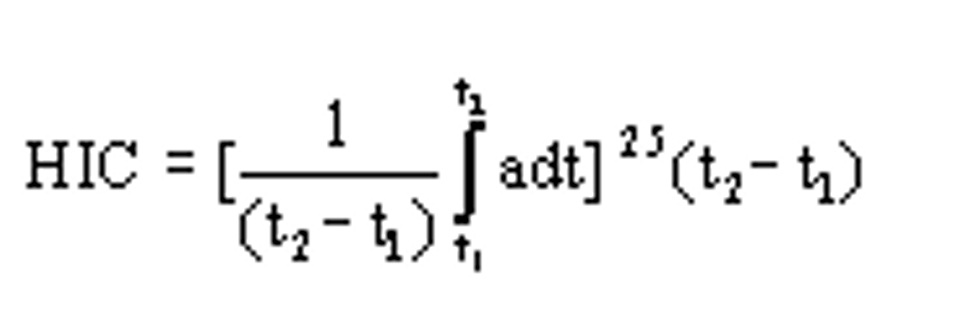

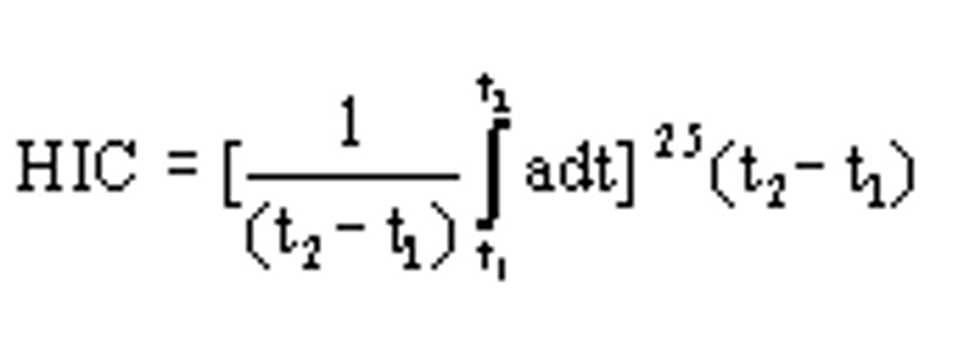

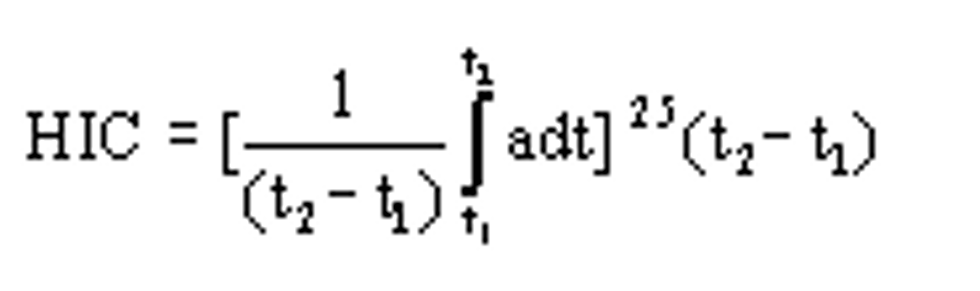

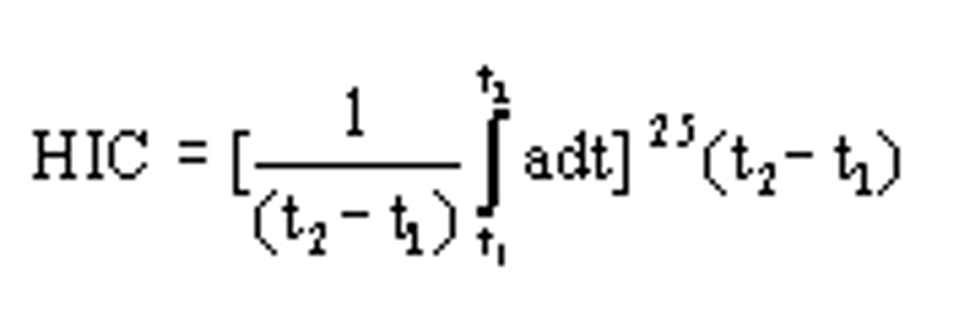

(a) The HIC shall not exceed 1000 when calculated in accordance with the following formula:

Where the term a is the resultant head acceleration at the center of gravity of the dummy head expressed as a multiple of g (the acceleration of gravity), and t1 and t2 are any two points in time during the impact which are separated by not more than a 36 millisecond time interval and where t1 is less than t2.

(b) Thorax. The deflection of any of the upper, middle, and lower ribs, shall not exceed 44 mm (1.73 inches).

(c) Force measurements.

(1) The sum of the front, middle and rear abdominal forces, shall not exceed 2,500 N (562 lb).

(2) The pubic symphysis force shall not exceed 6,000 N (1,350 pounds).

S7.2.6 Dynamic performance requirements using the Part 572 Subpart V SID–IIs (5th percentile female) dummy. Use the 49 CFR Part 572 Subpart V SID–IIs 5th percentile female dummy specified in S11 with measurements in accordance with S11.5. The following criteria shall be met:

(a) The HIC shall not exceed 1000 when calculated in accordance with the following formula:

Where the term a is the resultant head acceleration expressed as a multiple of g (the acceleration of gravity), and t1 and t2 are any two points in time during the impact which are separated by not more than a 36 millisecond time interval.

(b) The resultant lower spine acceleration shall not exceed 82 g.

(c) The sum of the acetabular and iliac pelvic forces shall not exceed 5,525 N.

S7.3 Door opening.

(a) Any side door that is struck by the moving deformable barrier shall not separate totally from the vehicle.

(b) Any door (including a rear hatchback or tailgate) that is not struck by the moving deformable barrier shall meet the following requirements:

(1) The door shall not disengage from the latched position;

(2) The latch shall not separate from the striker, and the hinge components shall not separate from each other or from their attachment to the vehicle.

(3) Neither the latch nor the hinge systems of the door shall pull out of their anchorages.

S8 Test conditions for determining compliance with moving deformable barrier requirements. General test conditions for determining compliance with the moving deformable barrier test are specified below. Additional specifications may also be found in S12 of this standard (49 CFR 571.214).

S8.1 Test weight. Each vehicle is loaded to its unloaded vehicle weight, plus 136 kg (300 pounds) or its rated cargo and luggage capacity (whichever is less), secured in the luggage or load-carrying area, plus the weight of the necessary anthropomorphic test dummies. Any added test equipment is located away from impact areas in secure places in the vehicle. The vehicle's fuel system is filled in accordance with the following procedure. With the test vehicle on a level surface, pump the fuel from the vehicle's fuel tank and then operate the engine until it stops. Then, add Stoddard solvent to the test vehicle's fuel tank in an amount that is equal to not less than 92 percent and not more than 94 percent of the fuel tank's usable capacity stated by the vehicle's manufacturer. In addition, add the amount of Stoddard solvent needed to fill the entire fuel system from the fuel tank through the engine's induction system.

S8.2 Vehicle test attitude. Determine the distance between a level surface and a standard reference point on the test vehicle's body, directly above each wheel opening, when the vehicle is in its fully loaded condition at the test site, with all tires inflated to the manufacturer's specifications listed on the vehicle's tire placard, and with the vehicle filled to 100 percent of all fluid capacities. The “fully loaded condition” is the test vehicle loaded in accordance with S8.1 of this standard (49 CFR 571.214). The load placed in the cargo area is centered over the longitudinal centerline of the vehicle. The pretest vehicle attitude is equal to the fully loaded attitude ± 10 mm.

S8.3 Adjustable seats.

S8.3.1 50th Percentile Male ES–2re Dummy (49 CFR Part 572 Subpart U) In Front Seats

S8.3.1.1 Lumbar support adjustment. Position adjustable lumbar supports so that the lumbar support is in its lowest, retracted or deflated adjustment position.

S8.3.1.2 Other seat adjustments. Position any adjustable parts of the seat that provide additional support so that they are in the lowest or non-deployed adjustment position. Position any adjustable head restraint in the highest and most forward position. Place adjustable seat backs in the manufacturer's nominal design riding position in the manner specified by the manufacturer. If the position is not specified, set the seat back at the first detent rearward of 25° from the vertical.

S8.3.1.3 Seat position adjustment. If the driver and any front outboard passenger seats do not adjust independently of each other, the struck side seat shall control the final position of the non-struck side seat. If the driver and any front outboard passenger seats adjust independently of each other, adjust both the struck and non-struck side seats in the manner specified in S8.3.1.

S8.3.1.3.1 Using only the controls that primarily move the seat and seat cushion independent of the seat back in the fore and aft directions, move the seat cushion reference point (SCRP) to the rearmost position. Using any part of any control, other than those just used, determine the full range of angles of the seat cushion reference line and set the seat cushion reference line to the middle of the range. Using any part of any control other than those that primarily move the seat or seat cushion fore and aft, while maintaining the seat cushion reference line angle, place the SCRP to its lowest position.

S8.3.1.3.2 Using only the control that primarily moves the seat fore and aft, move the seat cushion reference point to the mid travel position. If an adjustment position does not exist midway between the forwardmost and rearmost positions, the closest adjustment position to the rear of the midpoint is used.

S8.3.1.3.3 If the seat or seat cushion height is adjustable, other than by the controls that primarily move the seat or seat cushion fore and aft, set the height of the seat cushion reference point to the minimum height, with the seat cushion reference line angle set as closely as possible to the angle determined in S8.3.1.3.1. Mark location of the seat for future reference.

S8.3.2 50th Percentile Male SID Dummy (49 CFR Part 572 Subpart F) in Front and Rear Seats

S8.3.2.1 Adjustable seats. Adjustable seats are placed in the adjustment position midway between the forward most and rearmost positions, and if separately adjustable in a vertical direction, are at the lowest position. If an adjustment position does not exist midway between the forward most and rearmost positions, the closest adjustment position to the rear of the mid-point is used.

S8.3.2.2 Adjustable seat back placement. Place adjustable seat backs in the manufacturer's nominal design riding position in the manner specified by the manufacturer. If the position is not specified, set the seat back at the first detent rearward of 25° from the vertical. Place each adjustable head restraint in its highest adjustment position. Position adjustable lumbar supports so that they are set in their released, i.e., full back position.

S8.3.3 5th Percentile Female Dummy in Second Row Seat.

S8.3.3.1 Lumbar support adjustment. Position adjustable lumbar supports so that the lumbar support is in its lowest, retracted or deflated adjustment position.

S8.3.3.2 Other seat adjustments. Position any adjustable parts of the seat that provide additional support so that they are in the lowest or non-deployed adjustment position. Position any adjustable head restraint in the lowest and most forward in-use position. If it is possible to achieve a position lower than the effective detent range, the head restraint should be set to its lowest possible position. A non-use position as specified by S4.4 of FMVSS No. 202a, is excluded from being considered as the lowest possible position.

S8.3.3.3 Seat position adjustment. Using only the controls that primarily move the seat and seat cushion independent of the seat back in the fore and aft directions, move the seat cushion reference point (SCRP) to the rearmost position. Using any part of any control, other than those just used, determine the full range of angles of the seat cushion reference line and set the seat cushion reference line to the middle of the range. Using any part of any control other than those that primarily move the seat or seat cushion fore and aft, while maintaining the seat cushion reference line angle, place the SCRP to its lowest position. Mark location of the seat for future reference. If the non-struck side seat adjusts independently of the struck side seat, adjust the seat in the manner specified in this section.

S8.4 Adjustable steering controls. Adjustable steering controls are adjusted so that the steering control hub is at the geometric center of the locus it describes when it is moved through its full range of driving positions. If there is no setting detent in the mid-position, lower the steering control to the detent just below the mid-position. If the steering column is telescoping, place the steering column in the mid-position. If there is no mid-position, move the steering control rearward one position from the mid-position.

S8.5 Windows and sunroofs. Movable vehicle windows and vents are placed in the fully closed position on the struck side of the vehicle. Any sunroof shall be placed in the fully closed position.

S8.6 Convertible tops. Convertibles and open-body type vehicles have the top, if any, in place in the closed passenger compartment configuration.

S8.7 Doors. Doors, including any rear hatchback or tailgate, are fully closed and latched but not locked.

S8.8 Transmission and brake engagement. For a vehicle equipped with a manual transmission, the transmission is placed in second gear. For a vehicle equipped with an automatic transmission, the transmission is placed in neutral. For all vehicles, the parking brake is engaged.

S8.9 Moving deformable barrier. The moving deformable barrier conforms to the dimensions shown in Figure 2 and specified in 49 CFR Part 587.

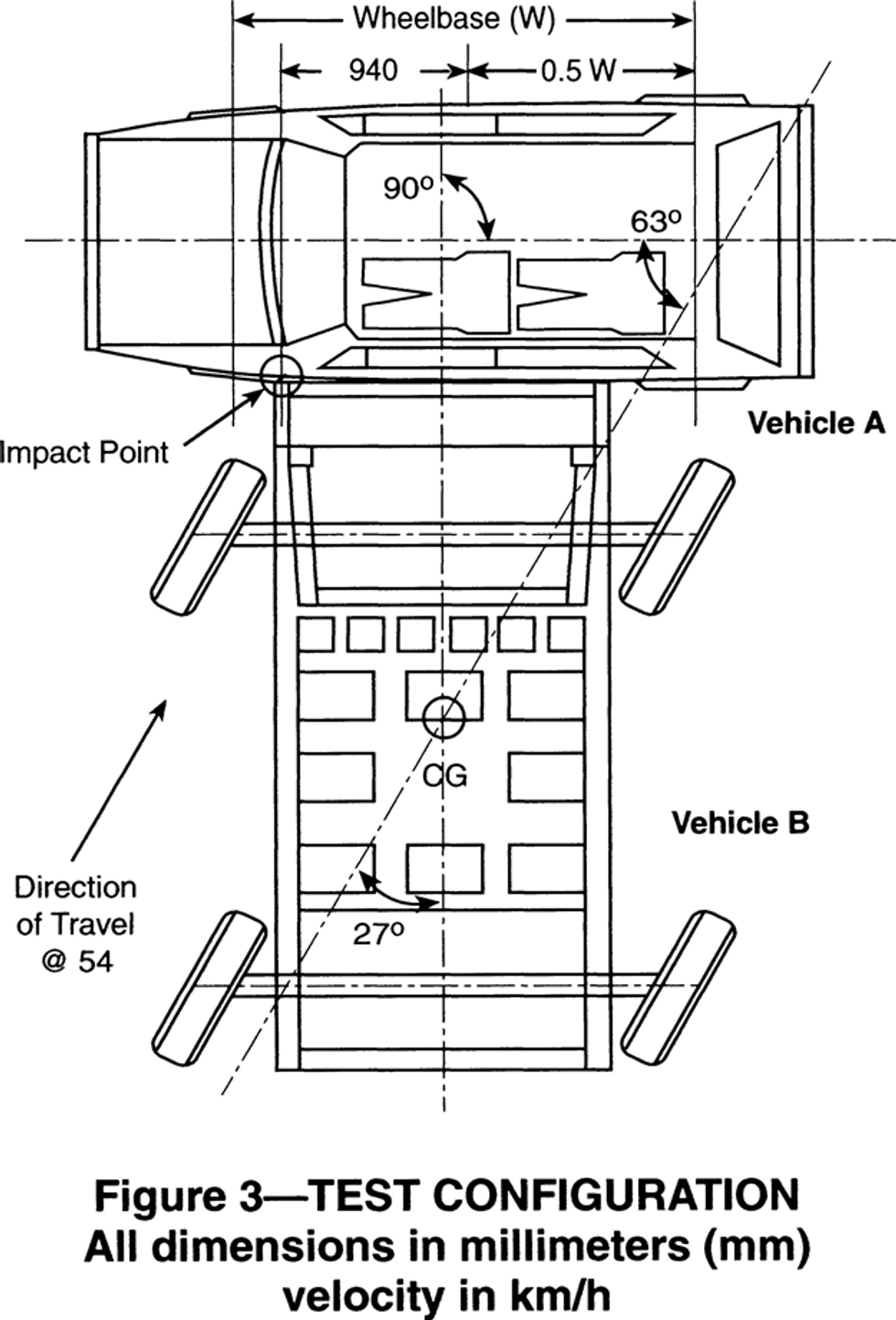

S8.10 Impact configuration. The test vehicle (vehicle A in Figure 3) is stationary. The line of forward motion of the moving deformable barrier (vehicle B in Figure 3) forms an angle of 63 degrees with the centerline of the test vehicle. The longitudinal centerline of the moving deformable barrier is perpendicular to the longitudinal centerline of the test vehicle when the barrier strikes the test vehicle. In a test in which the test vehicle is to be struck on its left (right) side: All wheels of the moving deformable barrier are positioned at an angle of 27 ± 1 degrees to the right (left) of the centerline of the moving deformable barrier; and the left (right) forward edge of the moving deformable barrier is aligned so that a longitudinal plane tangent to that side passes through the impact reference line within a tolerance of ± 51 mm (2 inches) when the barrier strikes the test vehicle.

S8.11 Impact reference line. Place a vertical reference line at the location described below on the side of the vehicle that will be struck by the moving deformable barrier.

S8.11.1 Passenger cars.

(a) For vehicles with a wheelbase of 2,896 mm (114 inches) or less, 940 mm (37 inches) forward of the center of the vehicle's wheelbase.

(b) For vehicles with a wheelbase greater than 2,896 mm (114 inches), 508 mm (20 inches) rearward of the centerline of the vehicle's front axle.

S8.11.2 Multipurpose passenger vehicles, trucks and buses.

(a) For vehicles with a wheelbase of 2,489 mm (98 inches) or less, 305 mm (12 inches) rearward of the centerline of the vehicle's front axle, except as otherwise specified in paragraph (d) of this section.

(b) For vehicles with a wheelbase of greater than 2,489 mm (98 inches) but not greater than 2,896 mm (114 inches), 940 mm (37 inches) forward of the center of the vehicle's wheelbase, except as otherwise specified in paragraph (d) of this section.

(c) For vehicles with a wheelbase greater than 2,896 mm (114 inches), 508 mm (20 inches) rearward of the centerline of the vehicle's front axle, except as otherwise specified in paragraph (d) of this section.

(d) At the manufacturer's option, for different wheelbase versions of the same model vehicle, the impact reference line may be located by the following:

(1) Select the shortest wheelbase vehicle of the different wheelbase versions of the same model and locate on it the impact reference line at the location described in (a), (b) or (c) of this section, as appropriate;

(2) Measure the distance between the seating reference point (SgRP) and the impact reference line;

(3) Maintain the same distance between the SgRP and the impact reference line for the version being tested as that between the SgRP and the impact reference line for the shortest wheelbase version of the model.

(e) For the compliance test, the impact reference line will be located using the procedure used by the manufacturer as the basis for its certification of compliance with the requirements of this standard. If the manufacturer did not use any of the procedures in this section, or does not specify a procedure when asked by the agency, the agency may locate the impact reference line using either procedure.

S8.12

Anthropomorphic test dummies. The anthropomorphic test dummies used to evaluate a vehicle's performance in the moving deformable barrier test conform to the requirements of S11 and are positioned as described in S12 of this standard (49 CFR 571.214).

S9. Vehicle-To-Pole Requirements.

S9.1 Except as provided in S5, when tested under the conditions of S10:

S9.1.1 Except as provided in S9.1.3 of this section, for vehicles manufactured on or after September 1, 2010 to August 31, 2014, a percentage of each manufacturer's production, as specified in S13.1.1, S13.1.2, S13.1.3, and S13.1.4 shall meet the requirements of S9.2.1, S9.2.2, and S9.2.3 when tested under the conditions of S10 into a fixed, rigid pole of 254 mm (10 inches) in diameter, at any velocity between 26 km/h to 32 km/h (16 to 20 mph) inclusive. Vehicles manufactured before September 1, 2014 that are not subject to the phase-in may be certified as meeting the requirements specified in this section.

S9.1.2 Except as provided in S9.1.3 of this section, each vehicle manufactured on or after September 1, 2014, must meet the requirements of S9.2.1, S9.2.2 and S9.2.3, when tested under the conditions specified in S10 into a fixed, rigid pole of 254 mm (10 inches) in diameter, at any speed up to and including 32 km/h (20 mph). All vehicles manufactured on or after September 1, 2014 must meet S9.1.2 without the use of advance credits.

S9.1.3 Exceptions from the phase-in; special allowances.

(a)(1) Vehicles that are manufactured by an original vehicle manufacturer that produces or assembles fewer than 5,000 vehicles annually for sale in the United States are not subject to S9.1.1 of this section (but vehicles manufactured on or after September 1, 2014 by these manufacturers are subject to S9.1.2);

(2) Vehicles that are manufactured by a limited line manufacturer are not subject to S9.1.1 of this section (but vehicles manufactured on or after September 1, 2014 by these manufacturers are subject to S9.1.2).

(b) Vehicles that are altered (within the meaning of 49 CFR 567.7) before September 1, 2016 after having been previously certified in accordance with part 567 of this chapter, and vehicles manufactured in two or more stages before September 1, 2016, are not subject to S9.1.1. Vehicles that are altered on or after September 1, 2016, and vehicles that are manufactured in two or more stages on or after September 1, 2016, must meet the requirements of S9.1.2, when tested under the conditions specified in S10 into a fixed, rigid pole of 254 mm (10 inches) in diameter, at any speed up to and including 32 km/h (20 mph).

(c) Vehicles with a gross vehicle weight rating greater than 3,855 kg (8,500 lb) manufactured before September 1, 2015 are not subject to S9.1.1 or S9.1.2 of this section. These vehicles may be voluntarily certified to meet the pole test requirements prior to September 1, 2015. Vehicles with a gross vehicle weight rating greater than 3,855 kg (8,500 lb) manufactured on or after September 1, 2015 must meet the requirements of S9.2.1, S9.2.2 and S9.2.3, when tested under the conditions specified in S10 into a fixed, rigid pole of 254 mm (10 inches) in diameter, at any speed up to and including 32 km/h (20 mph).

(d)(1) Convertibles manufactured before September 1, 2015 are not subject to S9.1.1 or S9.1.2 of this section. These vehicles may be voluntarily certified to meet the pole test requirements prior to September 1, 2015.

(2) Convertibles manufactured on or after September 1, 2015 must meet the requirements of S9.2.1, S9.2.2 and S9.2.3, when tested under the conditions specified in S10 into a fixed, rigid pole of 254 mm (10 inches) in diameter, at any speed up to and including 32 km/h (20 mph).

S9.2 Requirements. Each vehicle shall meet these vehicle-to-pole test requirements when tested under the conditions of S10 of this standard. At NHTSA's option, either the 50th percentile adult male test dummy (ES–2re dummy, 49 CFR Part 572 Subpart U) or the 5th percentile adult female test dummy (SID–IIs, 49 CFR Part 572 Subpart V) shall be used in the test. At NHTSA's option, either front outboard seating position shall be tested. The vehicle shall meet the specific requirements at all front outboard seating positions.

S9.2.1 Dynamic performance requirements using the Part 572 Subpart U (ES–2re 50th percentile male) dummy. When using the ES–2re Part 572 Subpart U dummy, use the specifications of S11 of this standard (49 CFR 571.214). When using the dummy, the following performance requirements must be met using measurements in accordance with S11.5.

(a) The HIC shall not exceed 1000 when calculated in accordance with the following formula:

Where the term a is the resultant head acceleration at the center of gravity of the dummy head expressed as a multiple of g (the acceleration of gravity), and t1 and t2 are any two points in time during the impact which are separated by not more than a 36 millisecond time interval and where t1 is less than t2.

(b) Thorax. The deflection of any of the upper, middle, and lower ribs, shall not exceed 44 mm (1.73 inches).

(c) Force measurements.

(1) The sum of the front, middle and rear abdominal forces, shall not exceed 2,500 N (562 pounds).

(2) The pubic symphysis force shall not exceed 6,000 N (1,350 pounds).

S9.2.2 Dynamic performance requirements using the Part 572 Subpart V SID–IIs (5th percentile female) dummy. When using the SID–IIs Part 572 Subpart V dummy, use the specifications of S11 of this standard (49 CFR 571.214). When using the dummy, the following performance requirements must be met.

(a) The HIC shall not exceed 1000 when calculated in accordance with the following formula:

Where the term a is the resultant head acceleration at the center of gravity of the dummy head expressed as a multiple of g (the acceleration of gravity), and t1 and t2 are any two points in time during the impact which are separated by not more than a 36 millisecond time interval and where t1 is less than t2.

(b) Resultant lower spine acceleration must not exceed 82 g.

(c) The sum of the acetabular and iliac pelvic forces must not exceed 5,525 N.

S9.2.3 Door opening.

(a) Any side door that is struck by the pole shall not separate totally from the vehicle.

(b) Any door (including a rear hatchback or tailgate) that is not struck by the pole shall meet the following requirements:

(1) The door shall not disengage from the latched position; and

(2) The latch shall not separate from the striker, and the hinge components shall not separate from each other or from their attachment to the vehicle.

(3) Neither the latch nor the hinge systems of the door shall pull out of their anchorages.

S10. General test conditions for determining compliance with vehicle-to-pole requirements. General test conditions for determining compliance with the vehicle-to-pole test are specified below and in S12 of this standard (49 CFR 571.214).

S10.1 Test weight. Each vehicle is loaded as specified in S8.1 of this standard (49 CFR 571.214).

S10.2 Vehicle test attitude. When the vehicle is in its “as delivered,” “fully loaded” and “as tested” condition, locate the vehicle on a flat, horizontal surface to determine the vehicle attitude. Use the same level surface or reference plane and the same standard points on the test vehicle when determining the “as delivered,” “fully loaded” and “as tested” conditions. Measure the angles relative to a horizontal plane, front-to-rear and from left-to-right for the “as delivered,” “fully loaded,” and “as tested” conditions. The front-to-rear angle (pitch) is measured along a fixed reference on the left and right front occupant's door sills. Mark where the angles are taken on the door sills. The left to right angle (roll) is measured along a fixed reference point at the front and rear of the vehicle at the vehicle longitudinal center plane. Mark where the angles are measured. The “as delivered” condition is the vehicle as received at the test site, with 100 percent of all fluid capacities and all tires inflated to the manufacturer's specifications listed on the vehicle's tire placard. When the vehicle is in its “fully loaded” condition, measure the angle between the left front occupant's door sill and the horizontal, at the same place the “as delivered” angle was measured. The “fully loaded condition” is the test vehicle loaded in accordance with S8.1 of this standard (49 CFR 571.214). The load placed in the cargo area is centered over the longitudinal centerline of the vehicle. The vehicle “as tested” pitch and roll angles are between the “as delivered” and “fully loaded” condition, inclusive.

S10.3 Adjustable seats.

S10.3.1 Driver and front outboard passenger seat set-up for 50th percentile male dummy. The driver and front outboard passenger seats are set up as specified in S8.3.1 of this standard, 49 CFR 571.214.

S10.3.2. Driver and front outboard passenger seat set-up for 49 CFR part 572 Subpart V 5th percentile female dummy.

S10.3.2.1 Lumbar support adjustment. Position adjustable lumbar supports so that the lumbar support is in its lowest, retracted or deflated adjustment position.

S10.3.2.2 Other seat adjustments. Position any adjustable parts of the seat that provide additional support so that they are in the lowest or non-deployed adjustment position. Position any adjustable head restraint in the lowest and most forward in-use position. If it is possible to achieve a position lower than the effective detent range, the head restraint should be set to its lowest possible position. A non-use position as specified by S4.4 of FMVSS No. 202a, is excluded from being considered as the lowest possible position.

S10.3.2.3 Seat position adjustment. If the driver and any front outboard passenger seats do not adjust independently of each other, the struck side seat shall control the final position of the non-struck side seat. If the driver and any front outboard passenger seats adjust independently of each other, adjust both the struck and non-struck side seats in the manner specified in S10.3.2.

S10.3.2.3.1 Using only the controls that primarily move the seat and seat cushion independent of the seat back in the fore and aft directions, move the seat cushion reference point (SCRP) to the rearmost position. Using any part of any control, other than those just used, determine the full range of angles of the seat cushion reference line and set the seat cushion reference line to the middle of the range. Using any part of any control other than those that primarily move the seat or seat cushion fore and aft, while maintaining the seat cushion reference line angle, place the SCRP to its lowest position.

S10.3.2.3.2 Using only the control that primarily moves the seat fore and aft, move the seat reference point to the most forward position.

S10.3.2.3.3 If the seat or seat cushion height is adjustable, other than by the controls that primarily move the seat or seat cushion fore and aft, set the seat reference point to the midpoint height, with the seat cushion reference line angle set as close as possible to the angle determined in S10.3.2.3.1. Mark location of the seat for future reference.

S10.4 Positioning dummies for the vehicle-to-pole test.

(a) 50th percentile male test dummy (49 CFR Part 572 Subpart U ES–2re dummy). The 50th percentile male test dummy is positioned in the front outboard seating position on the struck side of the vehicle in accordance with the provisions of S12.2 of this standard, 49 CFR 571.214.

(b) 5th percentile female test dummy (49 CFR Part 572 Subpart V SID–IIs dummy). The 5th percentile female test dummy is positioned in the front outboard seating positions on the struck side of the vehicle in accordance with the provisions of S12.3 of this standard, 49 CFR 571.214.

S10.5 Adjustable steering controls. Adjustable steering controls are adjusted so that the steering control hub is at the geometric center of the locus it describes when it is moved through its full range of driving positions. If there is no setting detent in the mid-position, lower the steering control to the detent just below the mid-position. If the steering column is telescoping, place the steering column in the mid-position. If there is no mid-position, move the steering control rearward one position from the mid-position.

S10.6 Windows and sunroofs. Movable vehicle windows and vents are placed in the fully closed position on the struck side of the vehicle. Any sunroof is placed in the fully closed position.

S10.7 Convertible tops. Convertibles and open-body type vehicles have the top, if any, in place in the closed passenger compartment configuration.

S10.8 Doors. Doors, including any rear hatchback or tailgate, are fully closed and latched but not locked.

S10.9 Transmission and brake engagement. For a vehicle equipped with a manual transmission, the transmission is placed in second gear. For a vehicle equipped with an automatic transmission, the transmission is placed in neutral. For all vehicles, the parking brake is engaged.

S10.10 Rigid pole. The rigid pole is a vertical metal structure beginning no more than 102 millimeters (4 inches) above the lowest point of the tires on the striking side of the test vehicle when the vehicle is loaded as specified in S8.1 and extending above the highest point of the roof of the test vehicle. The pole is 254 mm (10 inches) ± 6 mm (0.25 in) in diameter and set off from any mounting surface, such as a barrier or other structure, so that the test vehicle will not contact such a mount or support at any time within 100 milliseconds of the initiation of vehicle to pole contact.

S10.11 Impact reference line. The impact reference line is located on the striking side of the vehicle at the intersection of the vehicle exterior and a vertical plane passing through the center of gravity of the head of the dummy seated in accordance with S12 in the front outboard designated seating position. The vertical plane forms an angle of 285 (or 75) degrees with the vehicle's longitudinal centerline for the right (or left) side impact test. The angle is measured counterclockwise from the vehicle's positive X-axis as defined in S10.13.

S10.12 Impact configuration.

S10.12.1 The rigid pole is stationary.

S10.12.2 The test vehicle is propelled sideways so that its line of forward motion forms an angle of 285 (or 75) degrees (±3 degrees) for the right (or left) side impact with the vehicle's longitudinal centerline. The angle is measured counterclockwise from the vehicle's positive X-axis as defined in S10.13. The impact reference line is aligned with the center line of the rigid pole surface, as viewed in the direction of vehicle motion, so that, when the vehicle-to-pole contact occurs, the center line contacts the vehicle area bounded by two vertical planes parallel to and 38 mm (1.5 inches) forward and aft of the impact reference line.

S10.13 Vehicle reference coordinate system. The vehicle reference coordinate system is an orthogonal coordinate system consisting of three axes, a longitudinal axis (X), a transverse axis (Y), and a vertical axis (Z). X and Y are in the same horizontal plane and Z passes through the intersection of X and Y. The origin of the system is at the center of gravity of the vehicle. The X-axis is parallel to the longitudinal centerline of the vehicle and is positive to the vehicle front end and negative to the rear end. The Y-axis is positive to the left side of the vehicle and negative to the right side. The Z-axis is positive above the X-Y plane and negative below it.

S11 Anthropomorphic test dummies. The anthropomorphic test dummies used to evaluate a vehicle's performance in the moving deformable barrier and vehicle-to-pole tests are specified in 49 CFR part 572. In a test in which the test vehicle is to be struck on its left side, each dummy is to be configured and instrumented to be struck on its left side, in accordance with part 572. In a test in which the test vehicle is to be struck on its right side, each dummy is to be configured and instrumented to be struck on its right side, in accordance with part 572.

S11.1 Clothing.

(a) 50th percentile male. Each test dummy representing a 50th percentile male is clothed in formfitting cotton stretch garments with short sleeves and midcalf length pants. Each foot of the test dummy is equipped with a size 11EEE shoe, which meets the configuration size, sole, and heel thickness specifications of MIL-S-13192 (incorporated by reference, see §571.5 ) and weighs 0.68 ± 0.09 kilograms (1.25 ± 0.2 lb).

(b) 5th percentile female. The 49 CFR Part 572 Subpart V test dummy representing a 5th percentile female is clothed in formfitting cotton stretch garments with short sleeves and about the knee length pants. Each foot has on a size 7.5W shoe that meets the configuration and size specifications of MIL-S-21711E (incorporated by reference, see §571.5 ) or its equivalent.

S11.2 Limb joints.

(a) For the 50th percentile male dummy, set the limb joints at between 1 and 2 g. Adjust the leg joints with the torso in the supine position. Adjust the knee and ankle joints so that they just support the lower leg and the foot when extended horizontally (1 to 2 g adjustment).

(b) For the 49 CFR Part 572 Subpart V 5th percentile female dummy, set the limb joints at slightly above 1 g, barely restraining the weight of the limb when extended horizontally. The force needed to move a limb segment does not exceed 2 g throughout the range of limb motion. Adjust the leg joints with the torso in the supine position.

S11.3 The stabilized temperature of the test dummy at the time of the test is at any temperature between 20.6 degrees C and 22.2 degrees C.

S11.4 Acceleration data. Accelerometers are installed on the head, rib, spine and pelvis components of various dummies as required to meet the injury criteria of the standard. Accelerations measured from different dummy components may use different filters and processing methods.

S11.5 Processing Data.

(a) Subpart F (SID) test dummy.

(1) Process the acceleration data from the accelerometers mounted on the ribs, spine and pelvis of the Subpart F dummy with the FIR100 software specified in 49 CFR 572.44(d). Process the data in the following manner:

(i) Filter the data with a 300 Hz, SAE Class 180 filter;

(ii) Subsample the data to a 1600 Hz sampling rate;

(iii) Remove the bias from the subsampled data; and

(iv) Filter the data with the FIR100 software specified in 49 CFR 572.44(d), which has the following characteristics—

(A) Passband frequency 100 Hz.

(B) Stopband frequency 189 Hz.

(C) Stopband gain −50 db.

(D) Passband ripple 0.0225 db.

(2) [Reserved]

(b) Subpart U (ES–2re 50th percentile male) test dummy.

(1) The rib deflection data are filtered at channel frequency class 180 Hz. Abdominal and pubic force data are filtered at channel frequency class of 600 Hz.

(2) The acceleration data from the accelerometers installed inside the skull cavity of the ES–2re test dummy are filtered at channel frequency class of 1000 Hz.

(c) Subpart V (SID–IIs 5th percentile female) test dummy.

(1) The acceleration data from the accelerometers installed inside the skull cavity of the SID–IIs test dummy are filtered at channel frequency class of 1000 Hz.

(2) The acceleration data from the accelerometers installed on the lower spine of the SID–IIs test dummy are filtered at channel frequency class of 180 Hz.

(3) The iliac and acetabular forces from load cells installed in the pelvis of the SID–IIs are filtered at channel frequency class of 600 Hz.

S12 Positioning procedures for the anthropomorphic test dummies.

S12.1 50th percentile male test dummy—49 CFR Part 572 Subpart F (SID). Position a correctly configured test dummy, conforming to the applicable requirements of part 572 Subpart F of this chapter, in the front outboard seating position on the side of the test vehicle to be struck by the moving deformable barrier and, if the vehicle has a second seat, position another conforming test dummy in the second seat outboard position on the same side of the vehicle, as specified in S12.1.3. Each test dummy is restrained using all available belt systems in all seating positions where such belt restraints are provided. Place any adjustable anchorages at the manufacturer's nominal design position for a 50th percentile adult male occupant. In addition, any folding armrest is retracted. Additional positioning procedures are specified below.

S12.1.1 Positioning a Part 572 Subpart F (SID) dummy in the driver's seating position.

(a) Torso. Hold the dummy's head in place and push laterally on the non-impacted side of the upper torso in a single stroke with a force of 66.7–89.0 N (15–20 lb) towards the impacted side.

(1) For a bench seat. The upper torso of the test dummy rests against the seat back. The midsagittal plane of the test dummy is vertical and parallel to the vehicle's longitudinal centerline, and passes through the center of the steering control.

(2) For a bucket seat. The upper torso of the test dummy rests against the seat back. The midsagittal plane of the test dummy is vertical and parallel to the vehicle's longitudinal centerline, and coincides with the longitudinal centerline of the bucket seat.

(b) Pelvis.

(1) H-point. The H-points of each test dummy coincide within 12.7 mm ( 1/2 inch) in the vertical dimension and 12.7 mm ( 1/2 inch) in the horizontal dimension of a point that is located 6.4 mm ( 1/4 inch) below the position of the H-point determined by using the equipment for the 50th percentile and procedures specified in SAE Standard J826-1980 (incorporated by reference, see §571.5 ), except that Table 1 of SAE Standard J826-1980 is not applicable. The length of the lower leg and thigh segments of the H-point machine are adjusted to 414 and 401 mm (16.3 and 15.8 inches), respectively.

(2) Pelvic angle. As determined using the pelvic angle gauge (GM drawing 78051–532 incorporated by reference in part 572, Subpart E of this chapter) which is inserted into the H–point gauging hole of the dummy, the angle of the plane of the surface on the lumbar-pelvic adaptor on which the lumbar spine attaches is 23 to 25 degrees from the horizontal, sloping upward toward the front of the vehicle.

(3) Legs. The upper legs of each test dummy rest against the seat cushion to the extent permitted by placement of the feet. The left knee of the dummy is positioned such that the distance from the outer surface of the knee pivot bolt to the dummy's midsagittal plane is 152.4 mm (6.0 inches). To the extent practicable, the left leg of the test dummy is in a vertical longitudinal plane.

(4) Feet. The right foot of the test dummy rests on the undepressed accelerator with the heel resting as far forward as possible on the floorpan. The left foot is set perpendicular to the lower leg with the heel resting on the floorpan in the same lateral line as the right heel.

S12.1.2 Positioning a Part 572 Subpart F (SID) dummy in any front outboard passenger seating position.

(a) Torso. Hold the dummy's head in place and push laterally on the non-impacted side of the upper torso in a single stroke with a force of 66.7–89.0 N (15–20 lb) towards the impacted side.

(1) For a bench seat. The upper torso of the test dummy rests against the seat back. The midsagittal plane of the test dummy is vertical and parallel to the vehicle's longitudinal centerline. For vehicles with manually operated driving controls the midsagittal plane of the test dummy is the same distance from the vehicle's longitudinal centerline as would be the midsagittal plane of a test dummy positioned in the driver's seating position under S12.1.1(a)(1). For vehicles without manually operated driving controls the midsagittal plane of the test dummy shall be vertical and parallel to the vehicle's longitudinal centerline, and passes through any front outboard passenger seat's SgRP.

(2) For a bucket seat. The upper torso of the test dummy rests against the seat back. The midsagittal plane of the test dummy is vertical and parallel to the vehicle's longitudinal centerline, and coincides with the longitudinal centerline of the bucket seat.

(b) Pelvis.

(1) H-point. The H-points of each test dummy coincide within 12.7 mm ( 1/2 inch) in the vertical dimension and 12.7 mm ( 1/2 inch) in the horizontal dimension of a point that is located 6.4 mm ( 1/4 inch) below the position of the H-point determined by using the equipment for the 50th percentile and procedures specified in SAE Standard J826-1980 (incorporated by reference, see §571.5 ), except that Table 1 of SAE J826-1980 is not applicable. The length of the lower leg and thigh segments of the H-point machine are adjusted to 414 and 401 mm (16.3 and 15.8 inches), respectively.

(2) Pelvic angle. As determined using the pelvic angle gauge (GM drawing 78051–532 incorporated by reference in part 572, Subpart E of this chapter) which is inserted into the H–point gauging hole of the dummy, the angle of the plane of the surface on the lumbar-pelvic adaptor on which the lumbar spine attaches is 23 to 25 degrees from the horizontal, sloping upward toward the front of the vehicle.

(c) Legs. The upper legs of each test dummy rest against the seat cushion to the extent permitted by placement of the feet. The initial distance between the outboard knee clevis flange surfaces is 292 mm (11.5 inches). To the extent practicable, both legs of the test dummies in outboard passenger positions are in vertical longitudinal planes. Final adjustment to accommodate placement of feet in accordance with S12.1.2(d) for various passenger compartment configurations is permitted.

(d) Feet. The feet of the test dummy are placed on the vehicle's toeboard with the heels resting on the floorpan as close as possible to the intersection of the toeboard and floorpan. If the feet cannot be placed flat on the toeboard, they are set perpendicular to the lower legs and placed as far forward as possible so that the heels rest on the floorpan.

S12.1.3 Positioning a Part 572 Subpart F (SID) dummy in the rear outboard seating positions.

(a) Torso. Hold the dummy's head in place and push laterally on the non-impacted side of the upper torso in a single stroke with a force of 66.7–89.0 N (15–20 lb) towards the impacted side.

(1) For a bench seat. The upper torso of the test dummy rests against the seat back. The midsagittal plane of the test dummy is vertical and parallel to the vehicle's longitudinal centerline, and, if possible, the same distance from the vehicle's longitudinal centerline as the midsagittal plane of a test dummy positioned in the driver's seating position under S12.1.1(a)(1) or left front passenger seating positioned under S12.1.2(a)(1) in vehicles without manually operated driving controls. If it is not possible to position the test dummy so that its midsagittal plane is parallel to the vehicle longitudinal centerline and is at this distance from the vehicle's longitudinal centerline, the test dummy is positioned so that some portion of the test dummy just touches, at or above the seat level, the side surface of the vehicle, such as the upper quarter panel, an armrest, or any interior trim (i.e., either the broad trim panel surface or a smaller, localized trim feature).

(2) For a bucket or contoured seat. The upper torso of the test dummy rests against the seat back. The midsagittal plane of the test dummy is vertical and parallel to the vehicle's longitudinal centerline, and coincides with the longitudinal centerline of the bucket or contoured seat.

(b) Pelvis.

(1) H-point. The H-points of each test dummy coincide within 12.7 mm ( 1/2 inch) in the vertical dimension and 12.7 mm ( 1/2 inch) in the horizontal dimension of a point that is located 6.4 mm ( 1/4 inch) below the position of the H-point determined by using the equipment for the 50th percentile and procedures specified in SAE Standard J826-1980 (incorporated by reference, see §571.5 ), except that Table 1 of SAE J826-1980 is not applicable. The length of the lower leg and thigh segments of the H-point machine are adjusted to 414 and 401 mm (16.3 and 15.8 inches), respectively.

(2) Pelvic angle. As determined using the pelvic angle gauge (GM drawing 78051–532 incorporated by reference in part 572, Subpart E of this chapter) which is inserted into the H–point gauging hole of the dummy, the angle of the plane of the surface on the lumbar-pelvic adaptor on which the lumbar spine attaches is 23 to 25 degrees from the horizontal, sloping upward toward the front of the vehicle.

(c) Legs. Rest the upper legs of each test dummy against the seat cushion to the extent permitted by placement of the feet. The initial distance between the outboard knee clevis flange surfaces is 292 mm (11.5 inches). To the extent practicable, both legs of the test dummies in outboard passenger positions are in vertical longitudinal planes. Final adjustment to accommodate placement of feet in accordance with S12.1.3(d) for various passenger compartment configurations is permitted.

(d) Feet. Place the feet of the test dummy flat on the floorpan and beneath the front seat as far as possible without front seat interference. If necessary, the distance between the knees may be changed in order to place the feet beneath the seat.

S12.2 50th percentile male test dummy—49 CFR Part 572 Subpart U (ES–2re).

S12.2.1 Positioning an ES–2re dummy in all seating positions. Position a correctly configured ES-2re test dummy, conforming to the applicable requirements of part 572 of this chapter, in the front outboard seating position on the side of the test vehicle to be struck by the moving deformable barrier or pole. Restrain the test dummy using all available belt systems in the seating positions where the belt restraints are provided. Place any adjustable anchorages at the manufacturer's nominal design position for a 50th percentile adult male occupant. Retract any folding armrest.

(a) Upper torso.

(1) The plane of symmetry of the dummy coincides with the vertical median plane of the specified seating position.

(2) Bend the upper torso forward and then lay it back against the seat back. Set the shoulders of the dummy fully rearward.

(b) Pelvis. Position the pelvis of the dummy according to the following:

(1) Position the pelvis of the dummy such that a lateral line passing through the dummy H-points is perpendicular to the longitudinal center plane of the seat. The line through the dummy H-points is horizontal with a maximum inclination of ± 2 degrees. The dummy may be equipped with tilt sensors in the thorax and the pelvis. These instruments can help to obtain the desired position.

(2) The correct position of the dummy pelvis may be checked relative to the H-point of the H-point Manikin by using the M3 holes in the H-point back plates at each side of the ES-2re pelvis. Position the dummy such that the M3 holes are located within a circle of radius 10 mm (0.39 in.) around the H-point of the H-point Manikin.

(c) Arms. Place the dummy's upper arms such that the angle between the projection of the arm centerline on the mid-sagittal plane of the dummy and the torso reference line is 40° ±5°. The torso reference line is defined as the thoracic spine centerline. The shoulder-arm joint allows for discrete arm positions at 0, 40, and 90 degree settings forward of the spine.

(d) Legs and Feet. Position the legs and feet of the dummy according to the following:

(1) For the driver's seating position, without inducing pelvis or torso movement, place the right foot of the dummy on the un-pressed accelerator pedal with the heel resting as far forward as possible on the floor pan. Set the left foot perpendicular to the lower leg with the heel resting on the floor pan in the same lateral line as the right heel. Set the knees of the dummy such that their outside surfaces are 150 ± 10 mm (5.9 ± 0.4 inches) from the plane of symmetry of the dummy. If possible within these constraints, place the thighs of the dummy in contact with the seat cushion.

(2) For other seating positions, without inducing pelvis or torso movement, place the heels of the dummy as far forward as possible on the floor pan without compressing the seat cushion more than the compression due to the weight of the leg. Set the knees of the dummy such that their outside surfaces are 150 ± 10 mm (5.9 ± 0.4 inches) from the plane of symmetry of the dummy.

S12.3 5th percentile female test dummy—49 CFR Part 572 Subpart V (SID–IIs). Position a correctly configured 5th percentile female Part 572 Subpart V (SID–IIs) test dummy, conforming to the applicable requirements of part 572 of this chapter, in the front outboard seating position on the side of the test vehicle to be struck by the pole and, for the moving deformable barrier, if the vehicle has a second seat, position a conforming test dummy in the second seat outboard position on the same side of the vehicle (side to be struck) as specified in S12.3.4. Retract any folding armrest. Additional procedures are specified below.

S12.3.1 General provisions and definitions.

(a) Measure all angles with respect to the horizontal plane unless otherwise stated.

(b) Adjust the SID–IIs dummy's neck bracket to align the zero degree index marks.

(c) Other seat adjustments. The longitudinal centerline of a bucket seat cushion passes through the SgRP and is parallel to the longitudinal centerline of the vehicle.

(d) Driver and any front outboard passenger dummy manual belt adjustment. Use all available belt systems. Place adjustable belt anchorages at the nominal position for a 5th percentile adult female suggested by the vehicle manufacturer.

(e) Definitions.

(1) The term “midsagittal plane”

refers to the vertical plane that separates the dummy into equal left and right halves.

(2) The term “vertical longitudinal plane”

refers to a vertical plane parallel to the vehicle's longitudinal centerline.

(3) The term “vertical plane”

refers to a vertical plane, not necessarily parallel to the vehicle's longitudinal centerline.

(4) The term “transverse instrumentation platform”

refers to the transverse instrumentation surface inside the dummy's skull casting to which the neck load cell mounts. This surface is perpendicular to the skull cap's machined inferior-superior mounting surface.

(5) The term “thigh”

refers to the femur between, but not including, the knee and the pelvis.

(6) The term “leg”

refers to the lower part of the entire leg including the knee.

(7) The term “foot”

refers to the foot, including the ankle.

(8) For leg and thigh angles,

use the following references:

(i) Thigh—a straight line on the thigh skin between the center of the 1/2-13 UNC–2B tapped hole in the upper leg femur clamp and the knee pivot shoulder bolt.

(ii) Leg—a straight line on the leg skin between the center of the ankle shell and the knee pivot shoulder bolt.

(9) The term “seat cushion reference point” (SCRP)

means a point placed on the outboard side of the seat cushion at a horizontal distance between 150 mm (5.9 in) and 250 mm (9.8 in) from the front edge of the seat used as a guide in positioning the seat.

(10) The term “seat cushion reference line”

means a line on the side of the seat cushion, passing through the seat cushion reference point, whose projection in the vehicle vertical longitudinal plane is straight and has a known angle with respect to the horizontal.

S12.3.2 5th percentile female driver dummy positioning.

(a) Driver torso/head/seat back angle positioning.

(1) With the seat in the position determined in S10.3.2, use only the control that moves the seat fore and aft to place the seat in the rearmost position. If the seat cushion reference line angle automatically changes as the seat is moved from the full forward position, maintain, as closely as possible, the seat cushion reference line angle determined in S10.3.2.3.3, for the final forward position when measuring the pelvic angle as specified in S12.3.2(a)(11). The seat cushion reference line angle position may be achieved through the use of any seat or seat cushion adjustments other than that which primarily moves the seat or seat cushion fore-aft.

(2) Fully recline the seat back, if adjustable. Install the dummy into the driver's seat, such that when the legs are positioned 120 degrees to the thighs, the calves of the legs are not touching the seat cushion.

(3) Bucket seats. Center the dummy on the seat cushion so that its midsagittal plane is vertical and passes through the SgRP within ±10 mm (±0.4 in).

(4) Bench seats. Position the midsagittal plane of the dummy vertical and parallel to the vehicle's longitudinal centerline and aligned within ±10 mm (±0.4 in) of the center of the steering control rim.

(5) Hold the dummy's thighs down and push rearward on the upper torso to maximize the dummy's pelvic angle.

(6) Place the legs at 120 degrees to the thighs. Set the initial transverse distance between the longitudinal centerlines at the front of the dummy's knees at 160 to 170 mm (6.3 to 6.7 in), with the thighs and legs of the dummy in vertical planes. Push rearward on the dummy's knees to force the pelvis into the seat so there is no gap between the pelvis and the seat back or until contact occurs between the back of the dummy's calves and the front of the seat cushion.

(7) Gently rock the upper torso relative to the lower torso laterally in a side to side motion three times through a ± 5 degree arc (approximately 51 mm (2 in) side to side).

(8) If needed, extend the legs slightly so that the feet are not in contact with the floor pan. Let the thighs rest on the seat cushion to the extent permitted by the foot movement. Keeping the leg and the thigh in a vertical plane, place the foot in the vertical longitudinal plane that passes through the centerline of the accelerator pedal. Rotate the left thigh outboard about the hip until the center of the knee is the same distance from the midsagittal plane of the dummy as the right knee ±5 mm (±0.2 in). Using only the control that moves the seat fore and aft, attempt to return the seat to the full forward position. If either of the dummy's legs first contacts the steering control, then adjust the steering control, if adjustable, upward until contact with the steering control is avoided. If the steering control is not adjustable, separate the knees enough to avoid steering control contact. Proceed with moving the seat forward until either the leg contacts the vehicle interior or the seat reaches the full forward position. (The right foot may contact and depress the accelerator and/or change the angle of the foot with respect to the leg during seat movement.) If necessary to avoid contact with the vehicle's brake or clutch pedal, rotate the test dummy's left foot about the leg. If there is still interference, rotate the left thigh outboard about the hip the minimum distance necessary to avoid pedal interference. If a dummy leg contacts the vehicle interior before the full forward position is attained, position the seat at the next detent where there is no contact. If the seat is a power seat, move the seat fore and aft to avoid contact while assuring that there is a maximum of 5 mm (0.2 in) distance between the vehicle interior and the point on the dummy that would first contact the vehicle interior. If the steering control was moved, return it to the position described in S10.5. If the steering control contacts the dummy's leg(s) prior to attaining this position, adjust it to the next higher detent, or if infinitely adjustable, until there is 5 mm (0.2 in) clearance between the control and the dummy's leg(s).

(9) Head leveling.

(i) Vehicles with fixed seat backs. Adjust the lower neck bracket to level the transverse instrumentation platform angle of the head to within ± 0.5 degrees. If it is not possible to level the transverse instrumentation platform to within ± 0.5 degrees, select the neck bracket adjustment position that minimizes the difference between the transverse instrumentation platform angle and level.

(ii) Vehicles with adjustable seat backs. While holding the thighs in place, rotate the seat back forward until the transverse instrumentation platform angle of the head is level to within ±0.5 degrees, making sure that the pelvis does not interfere with the seat bight. (If the torso contacts the steering control, use S12.3.2(a)(10) before proceeding with the remaining portion of this paragraph.) If it is not possible to level the transverse instrumentation platform to within ±0.5 degrees, select the seat back adjustment position that minimizes the difference between the transverse instrumentation platform angle and level, then adjust the neck bracket to level the transverse instrumentation platform angle to within ±0.5 degrees if possible. If it is still not possible to level the transverse instrumentation platform to within ±0.5 degrees, select the neck bracket angle position that minimizes the difference between the transverse instrumentation platform angle and level.

(10) If the torso contacts the steering control, adjust the steering control in the following order until there is no contact: Telescoping adjustment, lowering adjustment, raising adjustment. If the vehicle has no adjustments or contact with the steering control cannot be eliminated by adjustment, position the seat at the next detent where there is no contact with the steering control as adjusted in S10.5. If the seat is a power seat, position the seat to avoid contact while assuring that there is a maximum of 5 mm (0.2 in) distance between the steering control as adjusted in S10.5 and the point of contact on the dummy.

(11) Measure and set the dummy's pelvic angle using the pelvic angle gage. The angle is set to 20.0 degrees ± 2.5 degrees. If this is not possible, adjust the pelvic angle as close to 20.0 degrees as possible while keeping the transverse instrumentation platform of the head as level as possible by adjustments specified in S12.3.2(a)(9).

(12) If the dummy is contacting the vehicle interior after these adjustments, move the seat rearward until there is a maximum of 5 mm (0.2 in) between the contact point of the dummy and the interior of the vehicle or if it has a manual seat adjustment, to the next rearward detent position. If after these adjustments, the dummy contact point is more than 5 mm (0.2 in) from the vehicle interior and the seat is still not in its forwardmost position, move the seat forward until the contact point is 5 mm (0.2 in) or less from the vehicle interior, or if it has a manual seat adjustment, move the seat to the closest detent position without making contact, or until the seat reaches its forwardmost position, whichever occurs first.

(b) Driver foot positioning.

(1) If the vehicle has an adjustable accelerator pedal, adjust it to the full forward position. If the heel of the right foot can contact the floor pan, follow the positioning procedure in S12.3.2(b)(1)(i). If not, follow the positioning procedure in S12.3.2(b)(1)(ii).

(i) Rest the right foot of the test dummy on the un-depressed accelerator pedal with the rearmost point of the heel on the floor pan in the plane of the pedal. If the foot cannot be placed on the accelerator pedal, set it initially perpendicular to the leg and then place it as far forward as possible in the direction of the pedal centerline with the rearmost point of the heel resting on the floor pan. If the vehicle has an adjustable accelerator pedal and the right foot is not touching the accelerator pedal when positioned as above, move the pedal rearward until it touches the right foot. If the accelerator pedal in the full rearward position still does not touch the foot, leave the pedal in that position.

(ii) Extend the foot and lower leg by decreasing the knee flexion angle until any part of the foot contacts the un-depressed accelerator pedal or the highest part of the foot is at the same height as the highest part of the pedal. If the vehicle has an adjustable accelerator pedal and the right foot is not touching the accelerator pedal when positioned as above, move the pedal rearward until it touches the right foot.