['CMV Parts and Maintenance']

['Vehicle maintenance']

04/07/2025

...

S1. Purpose and scope. This standard establishes requirements for seat belt assembly anchorages to insure their proper location for effective occupant restraint and to reduce the likelihood of their failure.

S2. Application. This standard applies to passenger cars, multipurpose passenger vehicles, trucks, and buses.

S3. Definitions.

Actuator

means the device used to apply the load in performing testing.

Bridged pull yoke

means the yoke that bridges the torso and pelvis on the FAD1 or FAD2 and is used for testing Type 1 seat belt assemblies.

FAD

means the force application device, either the FAD1 or the FAD2, a one-piece device consisting of an upper torso portion and a pelvic portion hinged together.

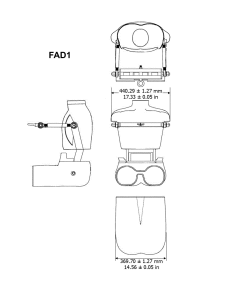

FAD1

means the larger version of the force application device specified in drawings NHTSA221-210-01, “Drawing Package for the Force Application Device 1 (FAD1),” April 9, 2024 (incorporated by reference, see §571.5). FAD1 is depicted in figure 7 to this standard (figure provided for illustration purposes).

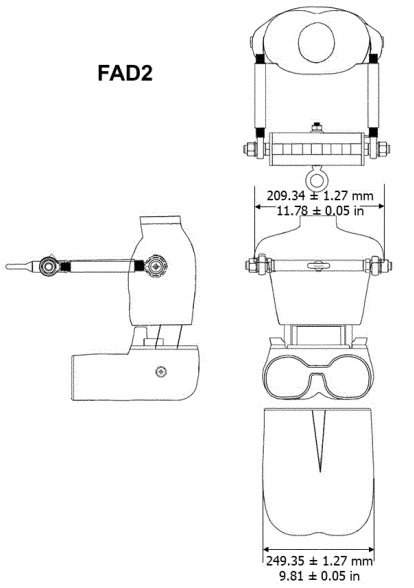

FAD2

means the smaller version of the force application device specified in drawings NHTSA221-210-01J, “Drawing Package for the Force Application Device 2 (FAD2),” April 9, 2024 (incorporated by reference; see §571.5). FAD2 is depicted in figure 8 to this standard (figure provided for illustration purposes).

Midsagittal plane

means the vertical plane that separates the FAD into equal left and right halves.

School bus torso belt adjusted height

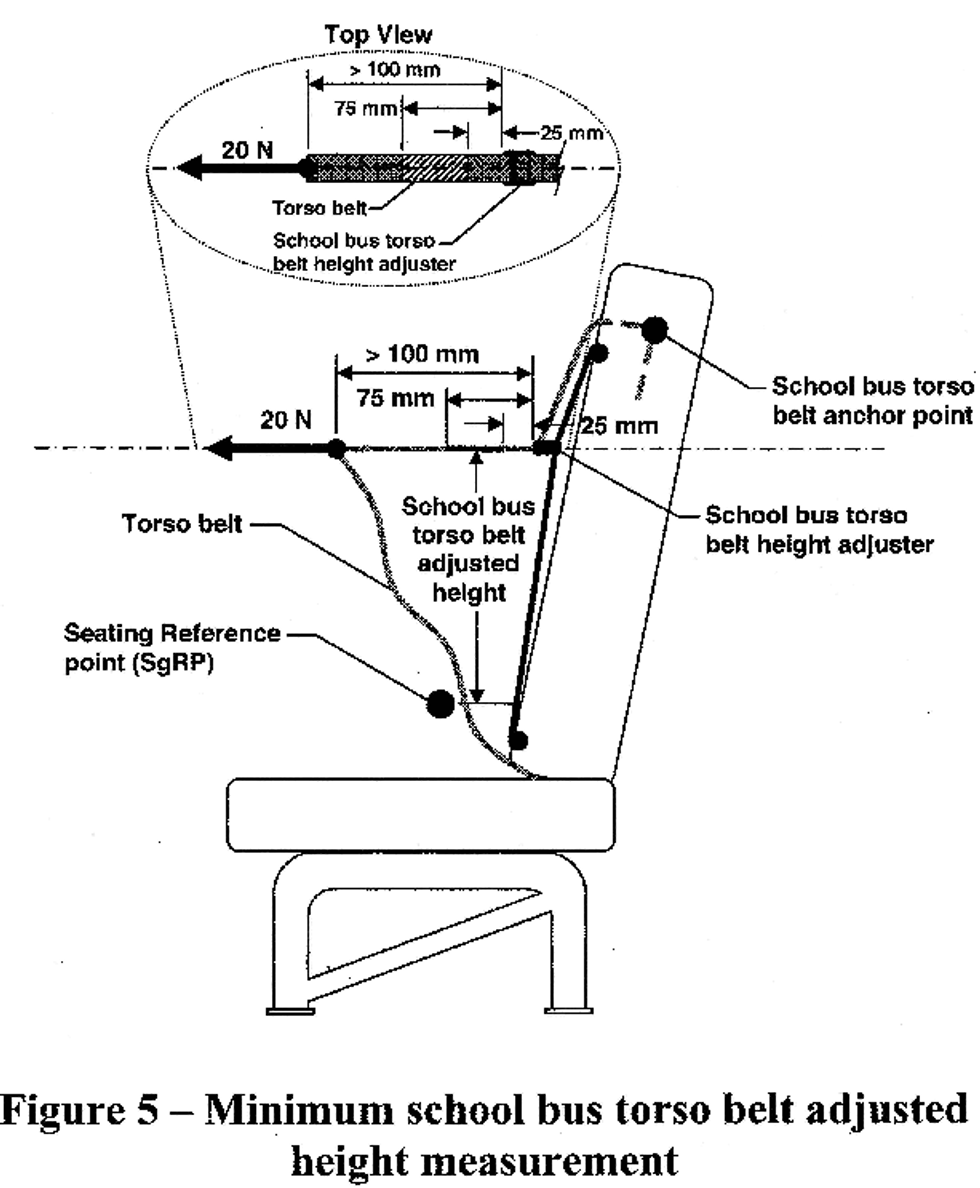

means the vertical height above the seating reference point (SgRP) of the horizontal plane containing a segment of the torso belt centerline located 25 mm to 75 mm forward of the torso belt height adjuster device, when the torso belt retractor is locked and the torso belt is pulled away from the seat back by applying a 20 N horizontal force in the forward direction through the webbing at a location 100 mm or more forward of the adjustment device as shown in Figure 5.

School bus torso belt anchor point

means the midpoint of the torso belt width where the torso belt first contacts the uppermost torso belt anchorage.

Seat belt anchorage

means any component, other than the webbing or straps, involved in transferring seat belt loads to the vehicle structure, including, but not limited to, the attachment hardware, seat frames, seat pedestals, the vehicle structure itself, and any part of the vehicle whose failure causes separation of the belt from the vehicle structure.

Seat reference plane

means the vertical plane that passes through the “seating reference point” (as defined at 49 CFR 571.3) and is parallel to the direction that the seat faces.

Small occupant

seating position is as defined in 49 CFR 571.222.

S4. Requirements.

S4.1 Type.

S4.1.1 Seat belt anchorages for a Type 1 or a Type 2 seat belt assembly shall be installed for each designated seating position for which a Type 1 or a Type 2 seat belt assembly is required by Standard No. 208 ( 49 CFR 571.208 ). Seat belt anchorages for a Type 2 seat belt assembly shall be installed for each designated seating position for which a Type 2 seat belt assembly is required by Standard No. 208 ( 49 CFR 571.208 ).

S4.1.2 (a) Notwithstanding the requirement of S4.1.1, each vehicle manufactured on or after September 1, 1987 that is equipped with an automatic restraint at the front right outboard designated seating position, which automatic restraint cannot be used for securing a child restraint system or cannot be adjusted by the vehicle owner to secure a child restraint system solely through the use of attachment hardware installed as an item of original equipment by the vehicle manufacturer, shall have, at the manufacturer’s option, either anchorages for a Type 1 seat belt assembly installed at that position or a Type 1 or Type 2 seat belt assembly installed at that position. If a manufacturer elects to install anchorages for a Type 1 seat belt assembly to comply with this requirement, those anchorages shall consist of, at a minimum, holes threaded to accept bolts that comply with S4.1(f) of Standard No. 209 ( 49 CFR 571.209 ).

(b) The requirement in S4.1.1 of this standard that seat belt anchorages for a Type 1 or a Type 2 seat belt assembly shall be installed for certain designated seating positions does not apply to any such seating positions that are equipped with a seat belt assembly that meets the frontal crash protection requirements of S5.1 of Standard No. 208 ( 49 CFR 571.208 ).

S4.1.3 School bus passenger seats.

S4.1.3.1 For school buses manufactured on or after October 21, 2011, seat belt anchorages for school bus passenger seats must be attached to the school bus seat structure, including seats with wheelchair positions or side emergency doors behind them. Seats with no other seats behind them, no wheelchair positions behind them and no side emergency door behind them are excluded from the requirement that the seat belt anchorages must be attached to the school bus seat structure. For school buses with a GVWR less than or equal to 4,536 kg (10,000 pounds), the seat belt shall be Type 2 as defined in S3. of FMVSS No. 209 (49 CFR 571.209 ). For school buses with a GVWR greater than 4,536 kg (10,000 pounds), the seat belt shall be Type 1 or Type 2 as defined in S3. of FMVSS No. 209 (49 CFR 571.209 ).

S4.1.3.2 Type 2 seat belt anchorages on school buses manufactured on or after October 21, 2011 must meet the following location requirements.

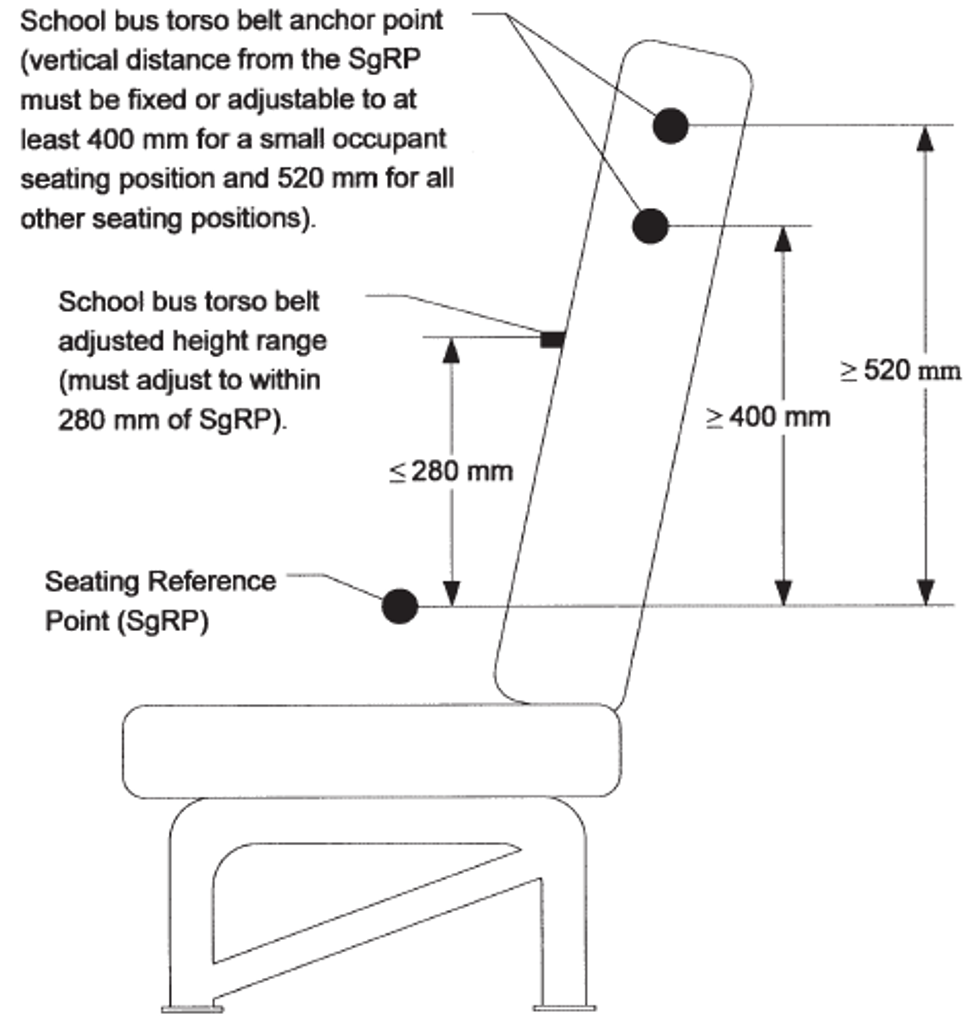

(a) For a small occupant seating position of a flexible occupancy seat, as defined in 49 CFR 571.222, the school bus torso belt anchor point must be 400 mm or more vertically above the seating reference point (SgRP) or adjustable to 400 mm or more vertically above the SgRP. For all other seating positions, the school bus torso belt anchor point must be 520 mm or more vertically above the SgRP or adjustable to 520 mm or more vertically above the SgRP. The school bus torso belt adjusted height at each seating position shall be adjustable to no more than 280 mm vertically above the SgRP in the lowest position and no less than the required vertical height of the school bus torso belt anchor point for that seating position in the highest position. ( See Figure 4.)

(b) The minimum lateral distance between the vertical centerline of the bolt holes or the centroid of any other means of attachment to the structure specified in 4.1.3.1, simultaneously achievable by all seating positions, must be:

(i) 280 mm for seating positions in a flexible occupancy seat in a maximum occupancy configuration, as defined in 49 CFR 571.222; and

(ii) 330 mm for all other seating positions.

S4.1.3.3 School buses with a GVWR less than or equal to 4,536 kg (10,000 pounds) must meet the requirements of S4.2.2 of this standard.

S4.1.3.4 School buses with a GVWR greater than 4,536 kg (10,000 pounds) manufactured on or after October 21, 2011, with Type 1 seat belt anchorages, must meet the strength requirements specified in S4.2.1 of this standard.

S4.1.3.5 School buses with a GVWR greater than 4,536 kg (10,000 pounds) manufactured on or after October 21, 2011, with Type 2 seat belt anchorages, must meet the strength requirements specified in S4.2.2 of this standard.

S4.2 Strength.

S4.2.1 Seats with Type 1 or certain Type 2 seat belt assemblies.

(a) For vehicles manufactured on or after September 17, 2024, and before September 1, 2027, except as provided in S4.2.5, the anchorages, attachment hardware, and attachment bolts for any of the following seat belt assemblies shall withstand a 22,241 N (5,000 pound) force when tested in accordance with, at the choice of the manufacturer, S5.1(a), (b), or (c):

(1) Type 1 seat belt assembly; and

(2) Lap belt portion of either a Type 2 or automatic seat belt assembly, if such seat belt assembly is equipped with a detachable upper torso belt.

(b) For vehicles manufactured on or after September 1, 2027, except as provided in S4.2.5, the anchorages, attachment hardware, and attachment bolts for any of the following seat belt assemblies shall withstand a 22,241 N (5,000 pound) force when tested in accordance with, at the choice of the manufacturer, S5.1(b) or (c):

(1) Type 1 seat belt assembly; and

(2) Lap belt portion of either a Type 2 or automatic seat belt assembly, if such seat belt assembly is equipped with a detachable upper torso belt.

S4.2.2 Seats with certain Type 2 or automatic seat belt assemblies.

(a) For vehicles manufactured on or after September 17, 2024, and before September 1, 2027, except as provided in S4.2.5, the anchorages, attachment hardware, and attachment bolts for any of the following seat belt assemblies shall withstand a 13,345 N (3,000 pound) force applied to the lap belt portion of the seat belt assembly simultaneously with a 13,345 N (3,000 pound) force applied to the shoulder belt portion of the seat belt assembly, when tested in accordance with, at the choice of the manufacturer, S5.2(a), (b), or (c):

(1) Type 2 and automatic seat belt assemblies that are installed to comply with Standard No. 208 (49 CFR 571.208); and

(2) Type 2 and automatic seat belt assemblies that are installed at a seating position required to have a Type 1 or Type 2 seat belt assembly by Standard No. 208 (49 CFR 571.208).

(b) For vehicles manufactured on or after September 1, 2027, except as provided in S4.2.5, the anchorages, attachment hardware, and attachment bolts for any of the following seat belt assemblies shall withstand a 13,345 N (3,000 pound) force applied to the lap belt portion of the seat belt assembly simultaneously with a 13,345 N (3,000 pound) force applied to the shoulder belt portion of the seat belt assembly, when tested in accordance with, at the choice of the manufacturer, S5.2(b) or (c):

(1) Type 2 and automatic seat belt assemblies that are installed to comply with Standard No. 208 (49 CFR 571.208); and

(2) Type 2 and automatic seat belt assemblies that are installed at a seating position required to have a Type 1 or Type 2 seat belt assembly by Standard No. 208 (49 CFR 571.208).

S4.2.3 Permanent deformation or rupture of a seat belt anchorage or its surrounding area is not considered to be a failure, if the required force is sustained for the specified time.

S4.2.4 Anchorages, attachment hardware, and attachment bolts shall be tested by simultaneously loading them in accordance with the applicable procedures set forth in S5 of this standard if the anchorages are either:

(a) For designated seating positions that are common to the same occupant seat and that face in the same direction, or

(b) For laterally adjacent designated seating positions that are not common to the same occupant seat, but that face in the same direction, if the vertical centerline of the bolt hole for at least one of the anchorages for one of those designated seating positions is within 305 mm of the vertical center line of the bolt hole for an anchorage for one of the adjacent seating positions.

S4.2.5 The attachment hardware of a seat belt assembly, which is subject to the requirements of S5.1 of Standard No. 208 ( 49 CFR 571.208 ) by virtue of any provision of Standard No. 208 other than S4.1.2.1(c)(2) of that standard, does not have to meet the requirements of S4.2.1 and S4.2.2 of this standard.

S4.2.6 Manufacturer's choice of compliance option. The manufacturer shall select the compliance option by the time it certifies the vehicle and may not thereafter select a different option for the vehicle. Each manufacturer shall, upon the request from the National Highway Traffic Safety Administration, provide information regarding which of the compliance options it selected for a particular vehicle or make/model.

S4.3 Location. As used in this section, ”forward” means the direction in which the seat faces, and other directional references are to be interpreted accordingly. Anchorages for seat belt assemblies that meet the frontal crash protection requirements of S5.1 of Standard No. 208 ( 49 CFR 571.208 ) are exempt from the location requirements of this section.

S4.3.1 Seat belt anchorages for Type 1 seat belt assemblies and the pelvic portion of Type 2 seat belt assemblies.

S4.3.1.1 In an installation in which the seat belt does not bear upon the seat frame:

(a) If the seat is a nonadjustable seat, then a line from the seating reference point to the nearest contact point of the belt with the anchorage shall extend forward from the anchorage at an angle with the horizontal of not less than 30 degrees and not more than 75 degrees.

(b) If the seat is an adjustable seat, then a line from a point 64 mm forward of and 10 mm above the seating reference point to the nearest contact point of the belt with the anchorage shall extend forward from the anchorage at an angle with the horizontal of not less than 30 degrees and not more than 75 degrees.

S4.3.1.2 In an installation in which the belt bears upon the seat frame, the seat belt anchorage, if not on the seat structure, shall be aft of the rearmost belt contact point on the seat frame with the seat in the rearmost position. The line from the seating reference point to the nearest belt contact point on the seat frame, with the seat positioned at the seating reference point, shall extend forward from that contact point at an angle with the horizontal of not less than 30 degrees and not more than 75 degrees.

S4.3.1.3 In an installation in which the seat belt attaches to the seat structure, the line from the seating reference point to the nearest contact point of the belt with the hardware attaching it to the seat structure shall extend forward from that contact point at an angle with the horizontal of not less than 30 degrees and not more than 75 degrees.

S4.3.1.4 Anchorages for an individual seat belt assembly shall be located at least 165 mm apart laterally, measured between the vertical center line of the bolt holes or, for designs using other means of attachment to the vehicle structure, between the centroid of such means.

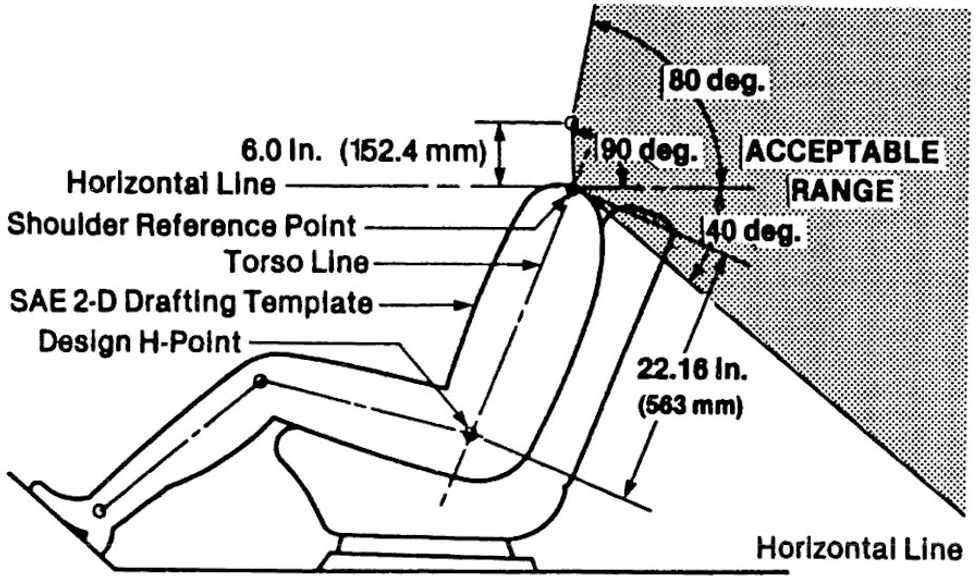

S4.3.2 Seat belt anchorages for the upper torso portion of Type 2 seat belt assemblies. Adjust the seat to its full rearward and downward position and adjust the seat back to its most upright position. Except a small occupant seating position as defined in 49 CFR 571.222, with the seat and seat back so positioned, as specified by subsection (a) or (b) of this section, the upper end of the upper torso restraint shall be located within the acceptable range shown in Figure 1, with reference to a two-dimensional drafting template described in SAE Standard J826 MAY87 (incorporated by reference, see §571.5 ). The template's “H” point shall be at the design “H” point of the seat for its full rearward and full downward position, as defined in SAE Recommended Practice J1100 JUN84 (incorporated by reference, see §571.5 ), and the template's torso line shall be at the same angle from the vertical as the seat back.

(a) For fixed anchorages, compliance with this section shall be determined at the vertical centerline of the bolt holes or, for designs using another means of attachment to the vehicle structure, at the centroid of such means.

(b) For adjustable anchorages, compliance with this section shall be determined at the midpoint of the range of all adjustment positions.

S5. Test procedures.

(a) General provisions. Where a range of values is specified, the vehicle shall be able to meet the requirements at all points within the range. The anchorage shall be connected to material whose breaking strength is equal to or greater than the breaking strength of the webbing for the seat belt assembly installed as original equipment at that seating position. The geometry of the attachment duplicates the geometry, at the initiation of the test, of the attachment of the originally installed seat belt assembly.

(b) Seat adjustment. If adjustable, the seat shall be adjusted in the following way. Using any seat adjustment controls, place the seat and its components into the configurations and positions of the rearmost normal design driving or riding position consistent with the seating reference point (SgRP), where rearmost is in reference to the direction the seat is facing. The seat may face any direction in which it can be occupied while the vehicle is in motion.

(c) Shoulder belt anchorage height adjustment. The shoulder belt anchorage height adjustment (D-ring) may be set to any height.

S5.1 Seats with Type 1 or certain Type 2 seat belt assemblies.

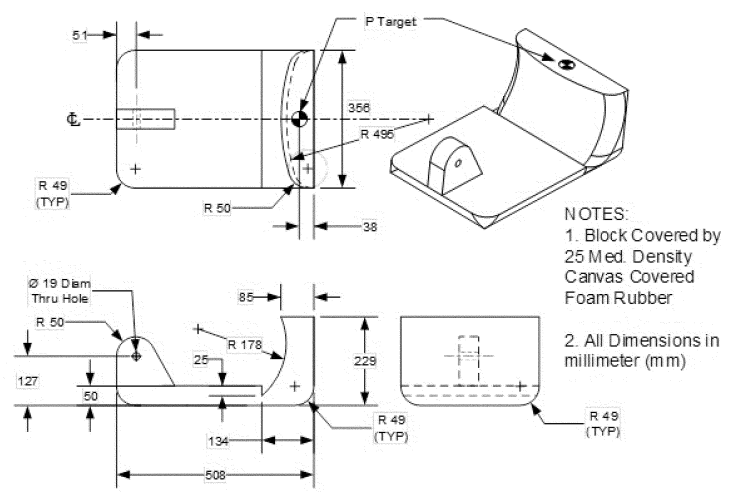

(a) Apply a force of 22,241 N (5,000 pounds) in the direction in which the seat faces to a pelvic body block as described in figure 2A to this standard, in a plane parallel to the seat reference plane with an initial force application angle of not less than 5 degrees or more than 15 degrees above the horizontal. Apply the force at the onset rate of not more than 222,411 N (50,000 pounds) per second. Attain the 22,241 N (5,000 pound) force in not more than 30 seconds and maintain it for 10 seconds. At the manufacturer's option, the pelvic body block described in figure 2B to this standard may be substituted for the pelvic body block described in figure 2A to apply the specified force to the center set(s) of anchorages for any group of three or more sets of anchorages that are simultaneously loaded in accordance with S4.2.4.

(b) Choose the FAD(s) in accordance with S5.4 and position the FAD(s) in accordance with S5.5. Apply a force of 22,241 N (5,000 pounds) to the actuator attachment point of the bridged pull yoke attached to the FAD1 or FAD2 in the direction in which the seat faces, in a plane parallel to the seat reference plane with an initial force application angle of not less than 5 degrees or more than 15 degrees above the horizontal. Apply the force at the onset rate of not more than 222,411 N (50,000 pounds) per second. Attain the 22,241 N (5,000 pound) force in not more than 30 seconds and maintain it for 10 seconds.

(c) Apply a force of 22,241 N (5,000 pounds) in the direction in which the seat faces to a pelvic body block as described in figure 2A to this standard and positioned in accordance with S5.3.1, in a plane parallel to the seat reference plane with an initial force application angle of not less than 5 degrees or more than 15 degrees above the horizontal. Apply the force at the onset rate of not more than 222,411 N (50,000 pounds) per second. Attain the 22,241 N (5,000 pound) force in not more than 30 seconds and maintain it for 10 seconds. At the manufacturer's option, the pelvic body block described in figure 2B to this standard may be substituted for the pelvic body block described in figure 2A to apply the specified force to the center set(s) of anchorages for any group of three or more sets of anchorages that are simultaneously loaded in accordance with S4.2.4.

S5.2 Seats with certain Type 2 or automatic seat belt assemblies.

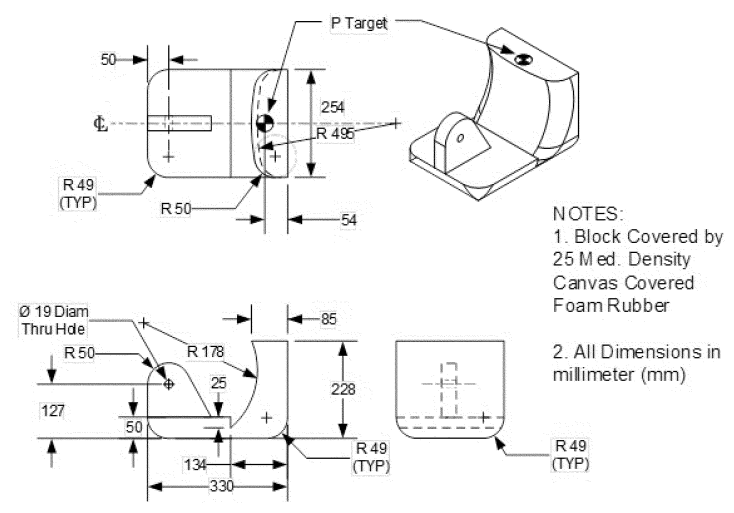

(a) Apply forces of 13,345 N (3,000 pounds) in the direction in which the seat faces simultaneously to a pelvic body block (as described in figure 2A to this standard) and an upper torso body block (as described in figure 3 to this standard) in a plane parallel to the seat reference plane with an initial force application angle of not less than 5 degrees or more than 15 degrees above the horizontal. Apply the forces at the onset rate of not more than 133,447 N (30,000 pounds) per second. Attain the 13,345 N (3,000 pound) force in not more than 30 seconds and maintain it for 10 seconds. At the manufacturer's option, the pelvic body block described in figure 2B to this standard may be substituted for the pelvic body block described in figure 2A to apply the specified force to the center set(s) of anchorages for any group of three or more sets of anchorages that are simultaneously loaded in accordance with S4.2.4.

(b) Choose the FAD(s) in accordance with S5.4 and position the FAD(s) in accordance with S5.5. Apply forces of 13,345 N (3,000 pounds) in the direction in which the seat faces simultaneously, to the eye bolt attached to the pull bracket of the torso pull yoke on the FAD and the thru hole on the pelvis of the FAD in a plane parallel to the seat reference plane with an initial force application angle of not less than 5 degrees or more than 15 degrees above the horizontal. Apply the forces at the onset rate of not more than 133,447 N (30,000 pounds) per second. Attain the 13,345 N (3,000 pound) force in not more than 30 seconds and maintain it for 10 seconds.

(c) Position a pelvic body block (as described in figure 2A to this standard) and an upper torso body block (as described in figure 3 to this standard) as described in S5.3. There shall be no contact between the pelvic and torso body blocks at the end of the preload force application (i.e., before the test force is applied). Apply forces of 13,345 N (3,000 pounds) in the direction in which the seat faces simultaneously to the pelvic body block and the upper torso body block in a plane parallel to the seat reference plane with an initial force application angle of not less than 5 degrees or more than 15 degrees above the horizontal. Apply the forces at the onset rate of not more than 133,447 N (30,000 pounds) per second. Attain the 13,345 N (3,000 pound) force in not more than 30 seconds and maintain it for 10 seconds. At the manufacturer's option, the pelvic body block described in figure 2B to this standard may be substituted for the pelvic body block described in figure 2A to apply the specified force to the center set(s) of anchorages for any group of three or more sets of anchorages that are simultaneously loaded in accordance with S4.2.4.

S5.3 Body Block Zones.

S5.3.1 Pelvic Body Block Zone.

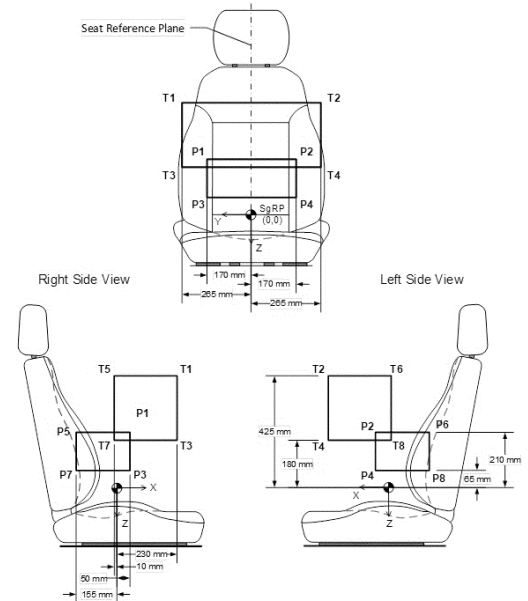

(a) With a 1,335 N (300 pound) force being applied to the pelvic body block in the direction in which the seat faces, the target depicted in figure 2A or figure 2B to this standard shall lie within the zone described in S5.3.1(a)(1) through (3) and in table 1 to this standard (and depicted in figure 6 to this standard):

(1) At or rearward of the transverse vertical plane of the vehicle located 50 mm longitudinally forward of the SgRP and at or forward of the transverse vertical plane located 155 mm rearward of the SgRP.

(2) At or below the horizontal plane located 210 mm above the SgRP and at or above the horizontal plane 65 mm above the SgRP.

(3) At or rightward of the plane parallel to the seat reference plane and located 170 mm to the left of the SgRP and at or leftward of the plane parallel to the seat reference plane and located 170 mm to the right of the SgRP.

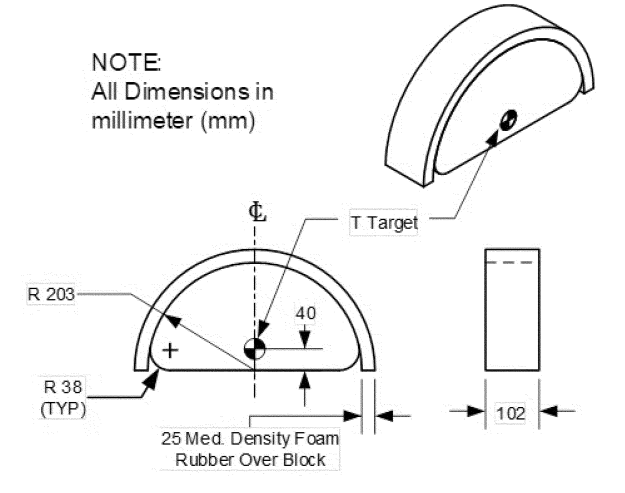

S5.3.2 Torso Body Block Zone.

(a) With a 1,335 N (300 pound) force being applied to the torso body block in the direction in which the seat faces, the target depicted in figure 3 to this standard shall lie within the zones described in S5.3.2(a)(1) through (3) and in table 1 to this standard (and depicted in figure 6 to this standard):

(1) At or rearward of the transverse vertical plane of the vehicle located 230 mm longitudinally forward of the SgRP and at or forward of the transverse vertical plane located 10 mm rearward of the SgRP.

(2) At or below the horizontal plane located 425 mm above the SgRP and at or above the horizontal plane 180 mm above the SgRP.

(3) At or rightward of the plane parallel to the seat reference plane and located 265 mm to the left of the SgRP and at or leftward of the plane parallel to the seat reference plane and located 265 mm to the right of the SgRP.

S5.4 Choice of FAD.

(a) If testing in accordance with S4.2.4, position a FAD1 in accordance with S5.5 at each DSP being simultaneously tested. If there is contact between adjacent FAD1s when positioned as required by S5.5, or if adjacent FAD1s cannot be positioned as required by S5.5 due to contact with each other, then replace the FAD1(s) according to the following hierarchy.

(1) For forward or rearward facing designated seating positions:

(i) If contact occurs between a FAD1 in an inboard seat and a FAD1 in an outboard seat, replace the FAD1 in the inboard seat with a FAD2.

(ii) If contact occurs between adjacent FAD1s in inboard seats, replace the FAD1 on the right-hand side (as viewed in the direction the seat is facing) with a FAD2. For multiple instances of contact between FAD1s, begin replacing FAD1s at the rightmost seating position.

(iii) If contact occurs between an inboard FAD1 and an inboard FAD2, replace the FAD1 with a FAD2.

(iv) If contact occurs between a FAD1 in an outboard seat and a FAD2 in an inboard seat, replace the FAD1 in the outboard seat with a FAD2.

(2) For non-forward and non-rearward facing designated seating positions:

(i) If contact occurs between adjacent FAD1s, replace the FAD1 on the right-hand side (as viewed in the direction the seat is facing) with a FAD2. If contact remains, replace the FAD1 on the left-hand side with a FAD2. For multiple instances of contact between FAD1s, begin replacing FAD1s at the rightmost seating position.

S5.5 FAD Positioning Procedure.

(a) Place the FAD1 or FAD2 on the seat such that the midsagittal plane is parallel to and within 10 mm of the seat reference plane, with the torso portion of the FAD contacting the seat back.

(b) While keeping the midsagittal plane within 10 mm of the seat reference plane, move the pelvis portion of the FAD toward the seat back until it contacts the seat back.

(c) If the torso is not in contact with the seat back, rotate the torso portion of the FAD while holding the pelvis in place until the back of the torso contacts the seat back.

(d) Buckle and position the seat belt so that the lap belt secures the pelvis portion of the FAD and the shoulder belt secures the torso portion of the FAD.

(e) Remove all slack from the seat belt.

(f) If testing a Type 2 or Type 2A seat belt assembly, attach one actuator to the eye bolt attached to the pull bracket of the torso pull yoke on the FAD and one to the thru hole on the pelvis of the FAD. If testing a Type 1 seat belt assembly, attach the actuator to the actuator attachment point on the bridged pull yoke attached to the FAD.

|

| FIGURE 1 - LOCATION OF ANCHORAGE FOR UPPER TORSO RESTRAINT |

Figure 2A to §571.210—Body Block for Lap Belt Anchorage and Target Location

Figure 2B to §571.210—Optional Body Block for Center Seating Positions Lap Belt Anchorage and Target Location

Figure 3 to §571.210—Body Block for Combination Shoulder and Lap Belt Anchorage and Target Location

|

| FIGURE 4 - SEAT BELT ANCHORAGE DIAGRAM |

|

Figure 6 to §571.210—Body Block Zones (provided for illustration purposes)

Figure 7 to §571.210—FAD1 (provided for illustration purposes)

Figure 8 to §571.210—FAD2 (provided for illustration purposes)

S6. Owner’s Manual Information. The owner’s manual in each vehicle with a gross vehicle weight rating of 4,536 kg or less manufactured after September 1, 1987 shall include:

(a) A section explaining that all child restraint systems are designed to be secured in vehicle seats by lap belts or the lap belt portion of a lap-shoulder belt. The section shall also explain that children could be endangered in a crash if their child restraints are not properly secured in the vehicle.

(b) In a vehicle with rear designated seating positions, a statement alerting vehicle owners that, according to accident statistics, children are safer when properly restrained in the rear seating positions than in the front seating positions.

| Coordinates of Zone Vertices from SgRP; [(X,Y,Z) in (mm) and (in) ] | |||||

| Vertices of Torso Body Block Zone | T1 | (230, 265, −425) (9.1, 10.4, −16.7) | Vertices of Pelvic Body Block Zone | P1 | (50, 170, −210) (2, 6.7, −8.3) |

| T2 | (230, −265, −425) (9.1, −10.4, −16.7) | P2 | (50, −170, −210) (2, −6.7, −8.3) | ||

| T3 | (230, 265, −180) (9.1, 10.4, −7.1) | P3 | (50, 170, −65) (2, 6.7, −2.6) | ||

| T4 | (230, −265, −180) (9.1, −10.4, −7.1) | P4 | (50, −170, −65) (2, −6.7, −2.6) | ||

| T5 | (−10, 265, −425) (−.4, 10.4, −16.7) | P5 | (−155, 170, −210) (−6.1, 6.7, −8.3) | ||

| T6 | (−10, −265, −425) (−.4, −10.4, −16.7) | P6 | (−155, −170, −210) (−6.1, −6.7, −8.3) | ||

| T7 | (−10, 265, −180) (−.4, 10.4, −7.1) | P7 | (−155, 170, −65) (−6.1, 6.7, −2.6) | ||

| T8 | (−10, −265, −180) (−.4, −10.4, −7.1) | P8 | (−155, −170, −65) (−6.1, −6.7, −2.6) | ||

[36 FR 22902, Dec. 2, 1971, as amended at 37 FR 9323, May 9, 1972; 43 FR 21892, May 22, 1978; 43 FR 53442, Nov. 16, 1978; 50 FR 41359, Oct. 10, 1985; 51 FR 9813, Mar. 21, 1986; 51 FR 29555, Aug. 19, 1986; 54 FR 25278, June 14, 1989; 54 FR 46268, Nov. 2, 1989; 55 FR 17983, Apr. 30, 1990; 55 FR 24241, June 15, 1990; 56 FR 63681, 63685, Dec. 5, 1991; 57 FR 32904, July 24, 1992; 60 FR 3775, Jan. 19, 1995; 61 FR 19561, May 2, 1996; 63 FR 28941, 28942, May 27, 1998; 63 FR 32143, June 12, 1998; 73 FR 62779, Oct. 21, 2008; 75 FR 66697, Oct. 29, 2010; 77 FR 767, Jan. 6, 2012; 78 FR 68757, Nov. 15, 2013; 89 FR 76271, Sep. 10, 2024]

['CMV Parts and Maintenance']

['Vehicle maintenance']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.