['CMV Parts and Maintenance']

['Vehicle maintenance']

10/30/2024

...

S1. Scope. This standard establishes performance and equipment requirements for electronic stability control (ESC) systems.

S2. Purpose. The purpose of this standard is to reduce the number of deaths and injuries that result from crashes in which the driver loses directional control of the vehicle, including those resulting in vehicle rollover.

S3. Application. This standard applies to passenger cars, multipurpose passenger vehicles, trucks, and buses with a gross vehicle weight rating of 4,536 kilograms (10,000 pounds) or less, according to the phase-in schedule specified in S8 of this standard.

S4. Definitions.

Ackerman Steer Angle

means the angle whose tangent is the wheelbase divided by the radius of the turn at a very low speed.

Drive configuration

means the driver-selected, or default, condition for distributing power from the engine to the drive wheels (examples include, but are not limited to, 2-wheel drive, front-wheel drive, rear-wheel drive, all-wheel drive, 4-wheel drive high gear with locked differential, and 4-wheel drive low gear).

Electronic Stability Control System or ESC System

means a system that has all of the following attributes:

(1) That augments vehicle directional stability by applying and adjusting the vehicle brake torques individually to induce a correcting yaw moment to a vehicle;

(2) That is computer controlled with the computer using a closed-loop algorithm to limit vehicle oversteer and to limit vehicle understeer;

(3) That has a means to determine the vehicle’s yaw rate and to estimate its side slip or side slip derivative with respect to time;

(4) That has a means to monitor driver steering inputs;

(5) That has an algorithm to determine the need, and a means to modify engine torque, as necessary, to assist the driver in maintaining control of the vehicle, and

(6) That is operational over the full speed range of the vehicle (except at vehicle speeds less than 20 km/h (12.4 mph) when being driven in reverse, or during sytem initialization).

Lateral Acceleration

means the component of the vector acceleration of a point in the vehicle perpendicular to the vehicle's x-axis (longitudinal) and parallel to the road plane.

Low-range four-wheel drive configuration

means a drive configuration that has the effect of locking the drive gears at the front and rear axles together and providing an additional gear reduction between the engine speed and vehicle speed of at least 2.0.

Mode

means an ESC performance algorithm, whether driver-selected or not (examples include, but are not limited to, standard (default) mode, performance mode, snow or slippery road mode, or Off mode).

Oversteer

means a condition in which the vehicle’s yaw rate is greater than the yaw rate that would occur at the vehicle’s speed as a result of the Ackerman Steer Angle.

Sideslip or side slip angle

means the arctangent of the lateral velocity of the center of gravity of the vehicle divided by the longitudinal velocity of the center of gravity.

Understeer

means a condition in which the vehicle’s yaw rate is less than the yaw rate that would occur at the vehicle’s speed as result of the Ackerman Steer Angle.

Yaw rate

means the rate of change of the vehicle’s heading angle measured in degrees/second of rotation about a vertical axis through the vehicle’s center of gravity.

S5. Requirements. Subject to the phase-in set forth in S8, each vehicle must be equipped with an ESC system that meets the requirements specified in S5 under the test conditions specified in S6 and the test procedures specified in S7 of this standard.

S5.1 Required Equipment. Vehicles to which this standard applies must be equipped with an electronic stability control system that:

S5.1.1 Is capable of applying brake torques individually to all four wheels and has a control algorithm that utilizes this capability.

S5.1.2 Is operational during all phases of driving including acceleration, coasting, and deceleration (including braking), except when the driver has disabled ESC, the vehicle speed is below 20 km/h (12.4 mph), the vehicle is being driven in reverse, or during system initialization.

S5.1.3 Remains capable of activation even if the antilock brake system or traction control system is also activated.

S5.2 Performance Requirements. During each test performed under the test conditions of S6 and the test procedure of S7.9, the vehicle with the ESC system engaged must satisfy the stability criteria of S5.2.1 and S5.2.2, and it must satisfy the responsiveness criterion of S5.2.3 during each of those tests conducted with a commanded steering wheel angle of 5A or greater, where A is the steering wheel angle computed in S7.6.1.

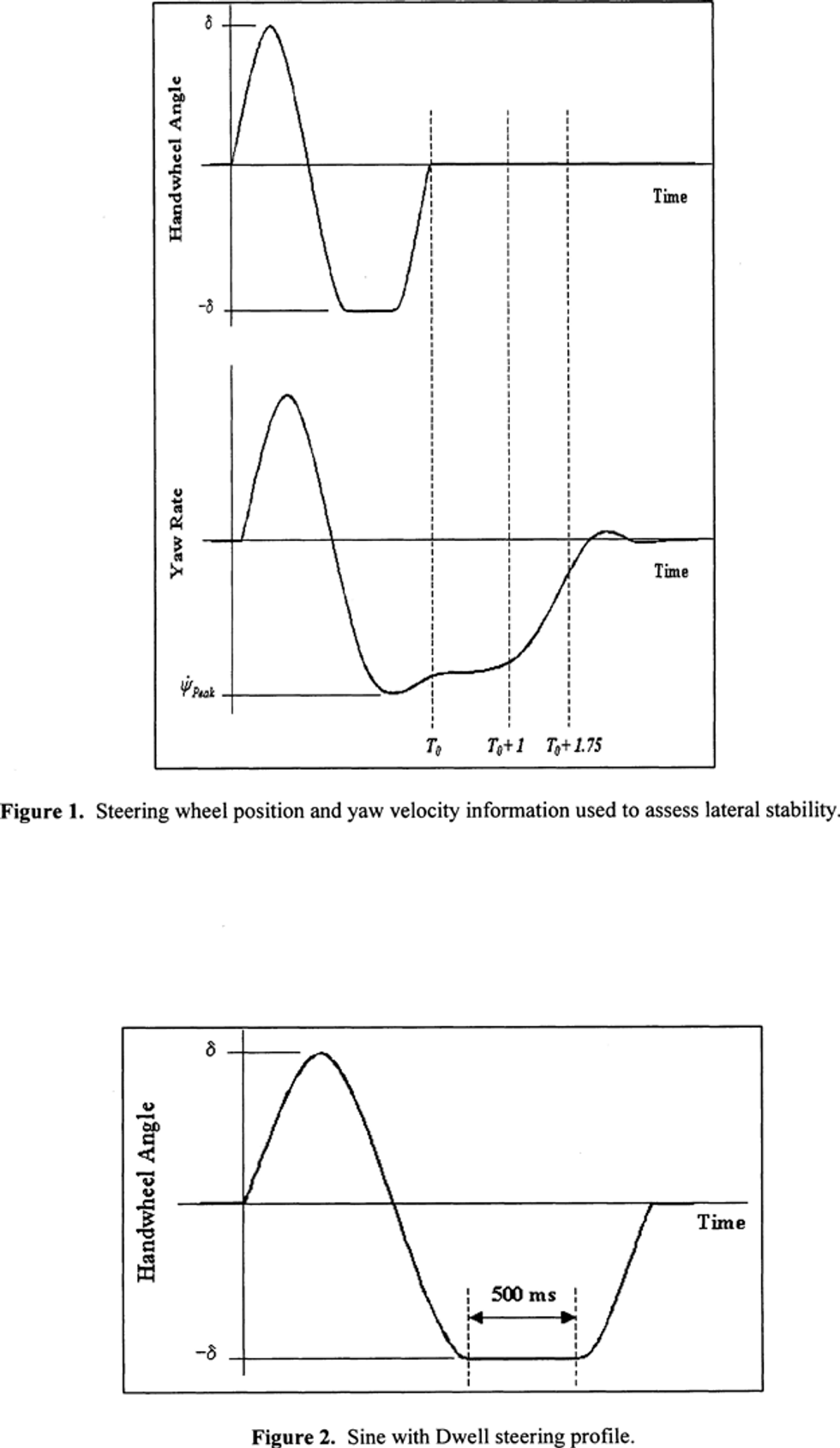

S5.2.1 The yaw rate measured one second after completion of the sine with dwell steering input (time T 0 + 1 in Figure 1) must not exceed 35 percent of the first peak value of yaw rate recorded after the steering wheel angle changes sign (between first and second peaks) (Peak in Figure 1) during the same test run, and

S5.2.2 The yaw rate measured 1.75 seconds after completion of the sine with dwell steering input must not exceed 20 percent of the first peak value of yaw rate recorded after the steering wheel angle changes sign (between first and second peaks) during the same test run.

S5.2.3 The lateral displacement of the vehicle center of gravity with respect to its initial straight path must be at least 1.83 m (6 feet) for vehicles with a GVWR of 3,500kg (7,716 lb) or less, and 1.52 m (5 feet) for vehicles with a GVWR greater than 3,500 kg (7,716 lb) when computed 1.07 seconds after the Beginning of Steer (BOS). BOS is defined in S7.11.6.

S5.2.3.1 The computation of lateral displacement is performed using double integration with respect to time of the measurement of lateral acceleration at the vehicle center of gravity, as expressed by the formula:

Lateral Displacement = ∫∫ Ay C.G. dt

S5.2.3.2 Time t = 0 for the integration operation is the instant of steering initiation, known as the Beginning of Steer (BOS). BOS is defined in S7.11.6.

S5.3 ESC Malfunction. The vehicle must be equipped with a telltale that provides a warning to the driver of the occurrence of one or more malfunctions that affect the generation or transmission of control or response signals in the vehicle’s electronic stability control system. When tested according to S7.10, the ESC malfunction telltale:

S5.3.1 As of September 1, 2011, must be mounted inside the occupant compartment in front of and in clear view of the driver;

S5.3.2 As of September 1, 2011, must be identified by the symbol shown for “ESC Malfunction Telltale” or the specified words or abbreviations listed in Table 1 of Standard No. 101 (49 CFR 571.101);

S5.3.3 As of September 1, 2011, except as provided in paragraphs S5.3.4, S5.3.5, S5.3.8, and S5.3.10, the ESC malfunction telltale must illuminate only when a malfunction(s) of the ESC system exists and must remain continuously illuminated under the conditions specified in S5.3 for as long as the malfunction(s) exists (unless the “ESC malfunction” and “ESC Off” telltales are combined in a two-part telltale and the “ESC Off” telltale is illuminated), whenever the ignition locking system is in the “On” (“Run”) position; and

S5.3.4 As of September 1, 2011, except as provided in paragraph S5.3.5, each ESC malfunction telltale must be activated as a check of lamp function either when the ignition locking system is turned to the “On” (”Run”) position when the engine is not running, or when the ignition locking system is in a position between “On” (”Run”) and “Start” that is designated by the manufacturer as a check position.

S5.3.5 The ESC malfunction telltale need not be activated when a starter interlock is in operation.

S5.3.6 The requirement S5.3.4 does not apply to telltales shown in a common space.

S5.3.7 The ESC malfunction telltale must extinguish at the next ignition cycle after the malfunction has been corrected.

S5.3.8 The manufacturer may use the ESC malfunction telltale in a flashing mode to indicate ESC operation.

S5.3.9 Prior to September 1, 2011, a disconnection of the power to the ESC electronic control unit may be indicated by the ABS malfunction telltale instead of the ESC malfunction telltale.

S5.3.10 Manufacturers may use the ESC malfunction telltale in a steadyburning mode to indicate malfunctions of ESC-related systems and functions including traction control, trailer stability assist, corner brake control, and other similar functions that use throttle and/or individual wheel torque control to operate and share common components with the ESC system, and may use the ESC malfunction telltale in a flashing mode to indicate operation of these ESC-related systems.

S5.4. ESC Off and Other System Controls. The manufacturer may include an “ESC Off” control whose only purpose is to place the ESC system in a mode or modes in which it will no longer satisfy the performance requirements of S5.2.1, S5.2.2, and S5.2.3. An “ESC Off” control may be combined with other controls in a multi-function control. Manufacturers may also provide controls for other systems that have an ancillary effect upon ESC operation. Controls of either kind that place the ESC system in a mode in which it will no longer satisfy the performance requirements of S5.2.1, S5.2.2, and S5.2.3 are permitted, provided that:

S5.4.1 The vehicle’s ESC system must always return to the manufacturer’s original default ESC mode that satisfies the requirements of S5.1 and S5.2 at the initiation of each new ignition cycle, regardless of what ESC mode the driver had previously selected, unless (a) the vehicle is in a low-range four-wheel drive configuration selected by the driver on the previous ignition cycle that is designed for low-speed, off-road driving, or (b) the vehicle is in a four-wheel drive configuration selected by the driver on the previous ignition cycle that is designed for operation at higher speeds on snow-, sand-, or dirt-packed roads and that has the effect of locking the drive gears at the front and rear axles together, provided that the vehicle meets the stability performance requirements of S5.2.1 and S5.2.2 in this mode.

S5.4.2 In addition to the requirements of S5.4.1, if the vehicle’s ESC system has more than one ESC mode that satisfies the requirements of S5.1 and S5.2 within the drive configuration selected for the previous ignition cycle, the system must return to the manufacturer’s original default ESC mode.

S5.4.3 As of September 1, 2011, a control whose only purpose is to place the ESC system in a mode or modes in which it will no longer satisfy the performance requirements of S5.2.1, S5.2.2, and S5.2.3 must be identified by the symbol shown for “ESC Off” in Table 1 of Standard No. 101 (49 CFR 571.101), or the text, “ESC Off” as listed under “Word(s) or Abbreviations” in Table 1 of Standard No. 101 (49 CFR 571.101).

S5.4.4 A control for another system that has the ancillary effect of placing the ESC system in a mode in which it no longer satisfies the performance requirements of S5.2.1, S5.2.2, and S5.2.3 need not be identified by the “ESC Off” identifiers in Table 1 of Standard No. 101 (49 CFR 571.101), but the ESC status must be identified by the “ESC Off” telltale in accordance with S5.5, as of September 1, 2011, except if the vehicle is in a 4-wheel drive high gear configuration that has the effect of locking the drive gears at the front and rear axles together provided the vehicle meets the stability performance criteria of S5.2.1 and S5.2.2.

S5.5 ESC Off Telltale

S5.5.1 Except as provided in S5.5.10, the vehicle manufacturer must provide a telltale indicating that the vehicle has been put into a mode that renders it unable to satisfy the requirements of S5.2.1, S5.2.2 and S5.2.3, if such a mode is provided.

S5.5.2 As of September 1, 2011, the “ESC Off” telltale must be identified by the symbol shown for “ESC Off” in Table 1 of Standard No. 101 (49 CFR 571.101) or the text, “ESC Off” as listed under “Word(s) or Abbreviations” in Table 1 of Standard No. 101 (49 CFR 571.101).

S5.5.3 As of September 1, 2011, the “ESC Off” telltale must be mounted inside the occupant compartment in front of and in clear view of the driver.

S5.5.4 Except as provided in paragraph S5.4.4, the “ESC Off” telltale must remain continuously illuminated for as long as the ESC is in a mode that renders it unable to satisfy the requirements of S5.2.1, S5.2.2, and S5.2.3, and

S5.5.5 Notwithstanding S5.3.1(e) of 49 CFR 571.101, the vehicle manufacturer may use the “ESC Off” telltale to indicate an ESC level of function other than the fully functional default mode even if the vehicle would meet S5.2.1, S5.2.2 and S5.2.3 at that level of ESC function.

S5.5.6 As of September 1, 2011, except as provided in paragraph S5.5.7 and S5.5.8, each “ESC Off” telltale must be activated as a check of lamp function either when the ignition locking system is turned to the “On” (”Run”) position when the engine is not running, or when the ignition locking system is in a position between “On” (”Run”) and “Start” that is designated by the manufacturer as a check position.

S5.5.7 The “ESC Off” telltale need not be activated when a starter interlock is in operation.

S5.5.8 The requirement S5.5.6 does not apply to telltales shown in a common space.

S5.5.9 The “ESC Off” telltale must extinguish after the ESC system has been returned to its fully functional default mode.

S5.5.10 The “ESC Off” telltale need not illuminate when the vehicle is in a 4-wheel drive high gear locked differential configuration that has the effect of locking the drive gears at the front and rear axles together provided the vehicle meets the stability performance requirements of S5.2.1 and S5.2.2.

S5.6 ESC System Technical Documentation. To ensure a vehicle is equipped with an ESC system that meets the definition of ”ESC System” in S4, the vehicle manufacturer must make available to the agency, upon request, the following documentation:

S5.6.1 A system diagram that identifies all ESC system hardware. The diagram must identify what components are used to generate brake torques at each wheel, determine vehicle yaw rate, estimated side slip or the side slip derivative and driver steering inputs.

S5.6.2 A written explanation describing the ESC system basic operational characteristics. This explanation must include a discussion on the system’s capability to apply brake torques at each wheel and how the system modifies engine torque during ESC system activation. The explanation must also identify the vehicle speed range and the driving phases (acceleration, deceleration, coasting, during activation of the ABS or traction control) under which the ESC system can activate.

S5.6.3 A logic diagram that supports the explanation provided in S5.6.2.

S5.6.4 Specifically for mitigating vehicle understeer, a discussion of the pertinent inputs to the computer or calculations within the computer and how its algorithm uses that information and controls ESC system hardware to limit vehicle understeer.

S6. Test Conditions.

S6.1 Ambient conditions.

S6.1.1 The ambient temperature is between 7 °C (45 °F) and 40 °C (104 °F).

S6.1.2 The maximum wind speed is no greater than 10 m/s (22 mph) for passenger cars and 5 m/s (11 mph) for multipurpose passenger vehicles, trucks and buses.

S6.2 Road test surface.

S6.2.1 The tests are conducted on a dry, uniform, solid-paved surface. Surfaces with irregularities and undulations, such as dips and large cracks, are unsuitable.

S6.2.2 The road test surface must produce a peak friction coefficient (PFC) of 1.02 when measured using an ASTM F2493 standard reference test tire, in accordance with ASTM E1337-19 (incorporated by reference, see §571.5) at a speed of 64.4 km/h (40 mph), without water delivery.

S6.2.3 The test surface has a consistent slope between level and 1%.

S6.3 Vehicle conditions.

S6.3.1 The ESC system is enabled for all testing, except when it is turned off directly or by simulating a malfunction in accordance with S7.3 and S7.10, respectively. The ESC system shall be initialized as follows: Place the vehicle in a forward gear and obtain a vehicle speed of 48 ± 8 km/h (30 ± 5 mph). Drive the vehicle for at least two minutes including at least one left and one right turning maneuver and at least one application of the service brake.

S6.3.2 Test Weight. The vehicle is loaded with the fuel tank filled to at least 75 percent of capacity, and total interior load of 168 kg (370 lbs) comprised of the test driver, approximately 59 kg (130 lbs) of test equipment (automated steering machine, data acquisition system and the power supply for the steering machine), and ballast as required by differences in the weight of test drivers and test equipment. Where required, ballast shall be placed on the floor behind the passenger front seat or if necessary in the front passenger foot well area. All ballast shall be secured in a way that prevents it from becoming dislodged during test conduct.

S6.3.3 Tires. The vehicle is tested with the tires installed on the vehicle at time of initial vehicle sale. The tires are inflated to the vehicle manufacturer’s recommended cold tire inflation pressure(s) specified on the vehicle’s placard or the tire inflation pressure label. Tubes may be installed to prevent tire de-beading.

S6.3.4 Outriggers. Outriggers are used for testing trucks, multipurpose passenger vehicles, and buses. Vehicles with a baseline weight less than 1,588 kg (3,500 lbs) are equipped with “light” outriggers. Vehicles with a baseline weight equal to or greater than 1,588 kg (3,500 lbs) and less than 2,722 kg (6,000 lbs) are equipped with “standard” outriggers. Vehicles with a baseline weight equal to or greater than 2,722 kg (6,000 lbs) are equipped with “heavy” outriggers. A vehicle’s baseline weight is the weight of the vehicle delivered from the dealer, fully fueled, with a 73 kg (160 lb) driver. Light outriggers are designed with a maximum weight of 27 kg (59.5 lb) and a maximum roll moment of inertia of 27 kg-m 2 (19.9 ft-lb-sec 2 ). Standard outriggers are designed with a maximum weight of 32 kg (70 lb) and a maximum roll moment of inertia of 35.9 kg-m 2 (26.5 ft-lb-sec 2 ). Heavy outriggers are designed with a maximum weight of 39 kg (86 lb) and a maximum roll moment of inertia of 40.7 kg-m2 (30.0 ft-lb-sec 2 ).

S6.3.5 Automated steering machine. A steering machine programmed to execute the required steering pattern must be used in S7.5.2, S7.5.3, S7.6 and S7.9. The steering machine shall be capable of supplying steering torques between 40 to 60 Nm (29.5 to 44.3 lb-ft). The steering machine must be able to apply these torques when operating with steering wheel velocities up to 1200 degrees per second.

S7. Test Procedure.

S7.1 Inflate the vehicles’ tires to the cold tire inflation pressure(s) provided on the vehicle’s placard or the tire inflation pressure label.

S7.2 Telltale bulb check. With the vehicle stationary and the ignition locking system in the “Lock” or “Off” position, activate the ignition locking system to the “On” (”Run”) position or, where applicable, the appropriate position for the lamp check. The ESC malfunction telltale must be activated as a check of lamp function, as specified in S5.3.4, and if equipped, the “ESC Off” telltale must also be activated as a check of lamp function, as specified in S5.5.6. The telltale bulb check is not required for a telltale shown in a common space as specified in S5.3.6 and S5.5.8.

S7.3 ”ESC Off” control check. For vehicles equipped with an “ESC Off” control, with the vehicle stationary and the ignition locking system in the “Lock” or “Off” position, activate the ignition locking system to the “On” (”Run”) position. Activate the “ESC Off” control and verify that the ”ESC Off” telltale is illuminated, as specified in S5.5.4. Turn the ignition locking system to the “Lock” or “Off” position. Again, activate the ignition locking system to the “On” (”Run”) position and verify that the “ESC Off” telltale has extinguished indicating that the ESC system has been reactivated as specified in S5.4.1.

S7.4 Brake Conditioning. Condition the vehicle brakes as follows:

S7.4.1 Ten stops are performed from a speed of 56 km/h (35 mph), with an average deceleration of approximately 0.5 g.

S7.4.2 Immediately following the series of 56 km/h (35 mph) stops, three additional stops are performed from 72 km/h (45 mph).

S7.4.3 When executing the stops in S7.4.2, sufficient force is applied to the brake pedal to activate the vehicle’s antilock brake system (ABS) for a majority of each braking event.

S7.4.4 Following completion of the final stop in S7.4.2, the vehicle is driven at a speed of 72 km/h (45 mph) for five minutes to cool the brakes.

S7.5 Tire Conditioning. Condition the tires using the following procedure to wear away mold sheen and achieve operating temperature immediately before beginning the test runs of S7.6 and S7.9.

S7.5.1 The test vehicle is driven around a circle 30 meters (100 feet) in diameter at a speed that produces a lateral acceleration of approximately 5 to 0.6 g for three clockwise laps followed by three counterclockwise laps.

S7.5.2 Using a sinusoidal steering pattern at a frequency of 1 Hz, a peak steering wheel angle amplitude corresponding to a peak lateral acceleration of 0.5-0.6 g, and a vehicle speed of 56 km/h (35 mph), the vehicle is driven through four passes performing 10 cycles of sinusoidal steering during each pass.

S7.5.3 The steering wheel angle amplitude of the final cycle of the final pass is twice that of the other cycles. The maximum time permitted between all laps and passes is five minutes.

S7.6 Slowly Increasing Steer Test. The vehicle is subjected to two series of runs of the Slowly Increasing Steer Test using a constant vehicle speed of 80 ± 2 km/h (50 ± 1 mph) and a steering pattern that increases by 13.5 degrees per second until a lateral acceleration of approximately 0.5 g is obtained. Three repetitions are performed for each test series. One series uses counterclockwise steering, and the other series uses clockwise steering. The maximum time permitted between each test run is five minutes.

S7.6.1 From the Slowly Increasing Steer tests, the quantity ”A” is determined. “A” is the steering wheel angle in degrees that produces a steady state lateral acceleration (corrected using the methods specified in S7.11.3) of 0.3 g for the test vehicle. Utilizing linear regression, A is calculated, to the nearest 1 degrees, from each of the six Slowly Increasing Steer tests. The absolute value of the six A’s calculated is averaged and rounded to the nearest 0.1 degrees to produce the final quantity, A, used below.

S7.7 After the quantity A has been determined, without replacing the tires, the tire conditioning procedure described in S7.5 is performed immediately prior to conducting the Sine with Dwell Test of S7.9. Initiation of the first Sine with Dwell test series shall begin within two hours after completion of the Slowly Increasing Steer tests of S7.6.

S7.8 Check that the ESC system is enabled by ensuring that the ESC malfunction and “ESC Off” (if provided) telltales are not illuminated.

S7.9 Sine with Dwell Test of Oversteer Intervention and Responsiveness. The vehicle is subjected to two series of test runs using a steering pattern of a sine wave at 0.7 Hz frequency with a 500 ms delay beginning at the second peak amplitude as shown in Figure 2 (the Sine with Dwell tests). One series uses counterclockwise steering for the first half cycle, and the other series uses clockwise steering for the first half cycle. The vehicle is provided a cool-down period between each test run of 90 seconds to five minutes, with the vehicle stationary.

S7.9.1 The steering motion is initiated with the vehicle coasting in high gear at 80 ±2 km/h (50 ±1 mph).

S7.9.2 In each series of test runs, the steering amplitude is increased from run to run, by 0.5A, provided that no such run will result in a steering amplitude greater than that of the final run specified in S7.9.4.

S7.9.3 The steering amplitude for the initial run of each series is 1.5A where A is the steering wheel angle determined in S7.6.1.

S7.9.4 The steering amplitude of the final run in each series is the greater of 6.5A or 270 degrees, provided the calculated magnitude of 6.5A is less than or equal to 300 degrees. If any 0.5A increment, up to 6.5A, is greater than 300 degrees, the steering amplitude of the final run shall be 300 degrees.

S7.9.5 Upon completion of the two series of test runs, post processing of yaw rate and lateral acceleration data is done as specified in S7.11.

S7.10 ESC Malfunction Detection.

S7.10.1 Simulate one or more ESC malfunction(s) by disconnecting the power source to any ESC component, or disconnecting any electrical connection between ESC components (with the vehicle power off). When simulating an ESC malfunction, the electrical connections for the telltale lamp(s) are not to be disconnected.

S7.10.2 With the vehicle initially stationary and the ignition locking system in the “Lock” or “Off” position, activate the ignition locking system to the “Start” position and start the engine. Place the vehicle in a forward gear and obtain a vehicle speed of 48 ± 8 km/h (30 ± 5 mph). Drive the vehicle for at least two minutes including at least one left and one right turning maneuver and at least one application of the service brake. Verify that within two minutes after obtaining this vehicle speed the ESC malfunction indicator illuminates in accordance with S5.3.

S7.10.3 As of September 1, 2011, stop the vehicle, deactivate the ignition locking system to the “Off” or “Lock” position. After a five-minute period, activate the vehicle’s ignition locking system to the “Start” position and start the engine. Verify that the ESC malfunction indicator again illuminates to signal a malfunction and remains illuminated as long as the engine is running or until the fault is corrected.

S7.10.4 Deactivate the ignition locking system to the “Off” or “Lock” position. Restore the ESC system to normal operation, activate the ignition system to the “Start” position and start the engine. Place the vehicle in a forward gear and obtain a vehicle speed of 48 ± 8 km/h (30 ± 5 mph). Drive the vehicle for at least two minutes including at least one left and one right turning maneuver and at least one application of the service brake. Verify that within two minutes after obtaining this vehicle speed that the ESC malfunction indicator has extinguished.

S7.11 Post Data Processing-Calculations for Performance Metrics. Yaw rate and lateral displacement measurements and calculations must be processed utilizing the following techniques:

S7.11.1 Raw steering wheel angle data is filtered with a 12-pole phaseless Butterworth filter and a cutoff frequency of 10Hz. The filtered data is then zeroed to remove sensor offset utilizing static pretest data.

S7.11.2 Raw yaw rate data is filtered with a 12-pole phaseless Butterworth filter and a cutoff frequency of 6Hz. The filtered data is then zeroed to remove sensor offset utilizing static pretest data.

S7.11.3 Raw lateral acceleration data is filtered with a 12-pole phaseless Butterworth filter and a cutoff frequency of 6Hz. The filtered data is then zeroed to remove sensor offset utilizing static pretest data. The lateral acceleration data at the vehicle center of gravity is determined by removing the effects caused by vehicle body roll and by correcting for sensor placement via use of coordinate transformation. For data collection, the lateral accelerometer shall be located as close as possible to the position of the vehicle’s longitudinal and lateral centers of gravity.

S7.11.4 Steering wheel velocity is determined by differentiating the filtered steering wheel angle data. The steering wheel velocity data is then filtered with a moving 0.1 second running average filter.

S7.11.5 Lateral acceleration, yaw rate and steering wheel angle data channels are zeroed utilizing a defined “zeroing range.” The methods used to establish the zeroing range are defined in S7.11.5.1 and S7.11.5.2.

S7.11.5.1 Using the steering wheel rate data calculated using the methods described in S7.11.4, the first instant steering wheel rate exceeds 75 deg/sec is identified. From this point, steering wheel rate must remain greater than 75 deg/sec for at least 200 ms. If the second condition is not met, the next instant steering wheel rate exceeds 75 deg/sec is identified and the 200 ms validity check applied. This iterative process continues until both conditions are ultimately satisfied.

S7.11.5.2 The “zeroing range” is defined as the 1.0 second time period prior to the instant the steering wheel rate exceeds 75 deg/sec ( i.e., the instant the steering wheel velocity exceeds 75 deg/sec defines the end of the “zeroing range”).

S7.11.6 The Beginning of Steer (BOS) is defined as the first instance filtered and zeroed steering wheel angle data reaches -5 degrees (when the initial steering input is counterclockwise) or +5 degrees (when the initial steering input is clockwise) after time defining the end of the “zeroing range.” The value for time at the BOS is interpolated.

S7.11.7 The Completion of Steer (COS) is defined as the time the steering wheel angle returns to zero at the completion of the Sine with Dwell steering maneuver. The value for time at the zero degree steering wheel angle is interpolated.

S7.11.8 The second peak yaw rate is defined as the first local yaw rate peak produced by the reversal of the steering wheel. The yaw rates at 1.000 and 750 seconds after COS are determined by interpolation.

S7.11.9 Determine lateral velocity by integrating corrected, filtered and zeroed lateral acceleration data. Zero lateral velocity at BOS event. Determine lateral displacement by integrating zeroed lateral velocity. Zero lateral displacement at BOS event. Lateral displacement at 1.07 seconds from BOS event is determined by interpolation.

S8. Phase-in schedule.

S8.1 Vehicles manufactured on or after September 1, 2008, and before September 1, 2009. For vehicles manufactured on or after September 1, 2008, and before September 1, 2009, the number of vehicles complying with this standard must not be less than 55 percent of:

(a) The manufacturer’s average annual production of vehicles manufactured on or after September 1, 2005, and before September 1, 2008; or

(b) The manufacturer’s production on or after September 1, 2008, and before September 1, 2009.

S8.2 Vehicles manufactured on or after September 1, 2009, and before September 1, 2010. For vehicles manufactured on or after September 1, 2009, and before September 1, 2010, the number of vehicles complying with this standard must not be less than 75 percent of:

(a) The manufacturer’s average annual production of vehicles manufactured on or after September 1, 2006, and before September 1, 2009; or

(b) The manufacturer’s production on or after September 1, 2009, and before September 1, 2010.

S8.3 Vehicles manufactured on or after September 1, 2010, and before September 1, 2011. For vehicles manufactured on or after September 1, 2010, and before September 1, 2011, the number of vehicles complying with this standard must not be less than 95 percent of:

(a) The manufacturer’s average annual production of vehicles manufactured on or after September 1, 2007, and before September 1, 2010; or

(b) The manufacturer’s production on or after September 1, 2010, and before September 1, 2011.

S8.4 Vehicles manufactured on or after September 1, 2011. All vehicles manufactured on or after September 1, 2011 must comply with this standard.

S8.5 Calculation of complying vehicles.

(a) For purposes of complying with S8.1, a manufacturer may count a vehicle if it is certified as complying with this standard and is manufactured on or after June 5, 2007, but before September 1, 2009.

(b) For purpose of complying with S8.2, a manufacturer may count a vehicle if it:

(1)(i) Is certified as complying with this standard and is manufactured on or after June 5, 2007, but before September 1, 2010; and

(ii) Is not counted toward compliance with S8.1; or

(2) Is manufactured on or after September 1, 2009, but before September 1, 2010.

(c) For purposes of complying with S8.3, a manufacturer may count a vehicle if it:

(1)(i) Is certified as complying with this standard and is manufactured on or after June 5, 2007, but before September 1, 2011; and

(ii) Is not counted toward compliance with S8.1 or S8.2; or

(2) Is manufactured on or after September 1, 2010, but before September 1, 2011.

S8.6 Vehicles produced by more than one manufacturer.

S8.6.1 For the purpose of calculating average annual production of vehicles for each manufacturer and the number of vehicles manufactured by each manufacturer under S8.1 through S8.4, a vehicle produced by more than one manufacturer must be attributed to a single manufacturer as follows, subject to S8.6.2:

(a) A vehicle that is imported must be attributed to the importer.

(b) A vehicle manufactured in the United States by more than one manufacturer, one of which also markets the vehicle, must be attributed to the manufacturer that markets the vehicle.

S8.6.2 A vehicle produced by more than one manufacturer must be attributed to any one of the vehicle’s manufacturers specified by an express written contract, reported to the National Highway Traffic Safety Administration under 49 CFR Part 585, between the manufacturer so specified and the manufacturer to which the vehicle would otherwise be attributed under S8.6.1.

S8.7 Small volume manufacturers.

Vehicles manufactured during any of the three years of the September 1, 2008 through August 31, 2011 phase-in by a manufacturer that produces fewer than 5,000 vehicles for sale in the United States during that year are not subject to the requirements of S8.1, S8.2, S8.3, and S8.5.

S8.8 Final-stage manufacturers and alterers.

Vehicles that are manufactured in two or more stages or that are altered (within the meaning of 49 CFR 567.7) after having previously been certified in accordance with Part 567 of this chapter are not subject to the requirements of S8.1 through S8.5. Instead, all vehicles produced by these manufacturers on or after September 1, 2012 must comply with this standard.

[72 FR 17310, Apr. 6, 2007, as amended at 72 FR 34410, June 22, 2007; 76 FR 55833, Sept. 9, 2011; 77 FR 760, Jan. 6, 2012; 80 FR 36105, June 23, 2015; 87 FR 34810, June 8, 2022]

READ MORESHOW LESS

['CMV Parts and Maintenance']

['Vehicle maintenance']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.