['CMV Parts and Maintenance']

['Brakes']

01/07/2025

...

S1. Scope. This standard specifies requirements for fluids for use in hydraulic brake systems of motor vehicles, containers for these fluids, and labeling of the containers.

S2. Purpose. The purpose of this standard is to reduce failures in the hydraulic braking systems of motor vehicles which may occur because of the manufacture or use of improper or contaminated fluid.

S3. Application. This standard applies to all fluid for use in hydraulic brake systems of motor vehicles. In addition, S5.3 applies to passenger cars, multipurpose passenger vehicles, trucks, buses, trailers, and motorcycles.

S4. Definitions.

Blister means a cavity or sac on the surface of a brake cup.

Brake fluid means a liquid designed for use in a motor vehicle hydraulic brake system in which it will contact elastomeric components made of styrene and butadiene rubber (SBR), ethylene and propylene rubber (EPR), polychloroprene (CR) brake hose inner tube stock or natural rubber (NR).

Chipping means a condition in which small pieces are missing from the outer surface of a brake cup.

Duplicate samples means two samples of brake fluid taken from a single packaged lot and tested simultaneously.

Hydraulic system mineral oil means a mineral-oil-based fluid designed for use in motor vehicle hydraulic brake systems in which the fluid is not in contact with components made of SBR, EPR or NR.

Packager means any person who fills containers with brake fluid that are subsequently distributed for retail sale.

Packaged lot is that quantity of brake fluid shipped by the manufacturer to the packager in a single container, or that quantity of brake fluid manufactured by a single plant run of 24 hours or less, through the same processing equipment and with no change in ingredients.

Scuffing means a visible erosion of a portion of the outer surface of a brake cup.

A

silicone base brake fluid (SBBF) is a brake fluid which consists of not less than 70 percent by weight of a diorgano polysiloxane.

Sloughing means degradation of a brake cup as evidenced by the presence of carbon black loosely held on the brake cup surface, such that a visible black streak is produced when the cup, with a 500 ±10 gram deadweight on it, is drawn base down over a sheet of white bond paper placed on a firm flat surface.

Stickiness means a condition on the surface of a brake cup such that fibers will be pulled from a wad of U.S.P. absorbent cotton when it is drawn across the surface.

S5. Requirements. This section specifies performance requirements for DOT 3, DOT 4 and DOT 5 brake fluids; requirements for brake fluid certification; and requirements for container sealing, labeling and color coding for brake fluids and hydraulic system mineral oils. Where a range of tolerances is specified, the brake fluid shall meet the requirements at all points within the range.

S5.1 Brake fluid. When tested in accordance with S6, brake fluids shall meet the following requirements:

S5.1.1 Equilibrium reflux boiling point (ERBP). When brake fluid is tested according to S6.1, the ERBP shall not be less than the following value for the grade indicated:

(a) DOT 3: 205 °C. (401 °F.).

(b) DOT 4: 230 °C. (446 °F.).

(c) DOT 5: 260 °C. (500 °F.).

S5.1.2 Wet ERBP. When brake fluid is tested according to S6.2, the wet ERBP shall not be less than the following value for the grade indicated:

(a) DOT 3: 140 °C. (284 °F.).

(b) DOT 4: 155 °C. (311 °F.).

(c) DOT 5: 1 180 °C. (356 °F.).

S5.1.3. Kinematic viscosities. When brake fluid is tested according to S6.3, the kinematic viscosities in square millimeters per second at stated temperatures shall be neither less than 1.5 mm2/s at 100 °C. (212 °F.) nor more than the following maximum value for the grade indicated:

(a) DOT 3: 1,500 mm 2 /s at minus 40 °C. (minus 40 °F.).

(b) DOT 4: 1,800 mm 2 /s at minus 40 °C. (minus 40 °F.).

(c) DOT 5: 900 mm 2 /s at minus 40 °C. (minus 40 °F.).

S5.1.4 pH value. When brake fluid, except DOT 5 SBBF, is tested according to S6.4, the pH value shall not be less than 7.0 nor more than 11.5.

S5.1.5 Brake fluid stability.

S5.1.5.1 High-temperature stability. When brake fluid is tested according to S6.5.3 the ERBP shall not change by more than 3 °C. (5.4 °F.) plus 0.05° for each degree that the ERBP of the fluid exceeds 225 °C. (437 °F.).

S5.1.5.2 Chemical stability. When brake fluid, except DOT 5 SBBF, is tested according to S6.5.4, the change in temperature of the refluxing fluid mixture shall not exceed 3.0 °C (5.4 °F.) plus 0.05° for each degree that the ERBP of the fluid exceeds 225 °C (437 °F.).

S5.1.6 Corrosion. When brake fluid is tested according to S6.6—

(a) The metal test strips shall not show weight changes exceeding the limits stated in Table I.

| Test strip material | Maximum permissible weight change, mg./sq. cm. of surface |

|---|---|

| Steel, tinned iron, cast iron | 0.2 |

| Aluminum | .1 |

| Brass, copper | .4 |

(b) Excluding the area of contact (13 ±1 mm. ( 1/2 ± 1/32 inch) measured from the bolt hole end of the test strip), the metal test strips shall not show pitting or etching to an extent discernible without magnification;

(c) The water-wet brake fluid at the end of the test shall show no jelling at 23 ±5 °C (73.4 ±9 °F.);

(d) No crystalline deposit shall form and adhere to either the glass jar walls or the surface of the metal strips;

(e) At the end of the test, sedimentation of the water-wet brake fluid shall not exceed 0.10 percent by volume;

(f) The pH value of water-wet brake fluid, except DOT 5 SBBF, at the end of the test shall not be less than 7.0 nor more than 11.5;

(g) The cups at the end of the test shall show no disintegration, as evidenced by blisters or sloughing;

(h) The hardness of the cup shall not decrease by more than 15 International Rubber Hardness Degrees (IRHD); and

(i) The base diameter of the cups shall not increase by more than 1.4 mm. (0.055 inch).

S5.1.7 Fluidity and appearance at low temperature. When brake fluid is tested according to S6.7, at the storage temperature and for the storage times given in Table II—

(a) The fluid shall show no sludging, sedimentation, crystallization, or stratification;

(b) Upon inversion of the sample bottle, the time required for the air bubble to travel to the top of the fluid shall not exceed the bubble flow times shown in Table II; and

(c) On warming to room temperature, the fluid shall resume the appearance and fluidity that it had before chilling.

| Storage temperature | Storage time (hours) | Maximum bubble flow time (seconds) |

|---|---|---|

| Minus 40 ± 2° C. (minus 40 ± 3.6°F.) | 144 ± 4.0 | 10 |

| Minus 50 ± 2° C. (minus 58 ± 3.6°F.) | 6 ± 0.2 | 35 |

S5.1.9 Water tolerance. (a) At low temperature. When brake fluid is tested according to S6.9.3(a)—

(1) The fluid shall show no sludging, sedimentation, crystallization, or stratification;

(2) Upon inversion of the centrifuge tube, the air bubble shall travel to the top of the fluid in not more than 10 seconds;

(3) If cloudiness has developed, the wet fluid shall regain its original clarity and fluidity when warmed to room temperature; and

(b) At 60 °C. (140 °F.). When brake fluid is tested according to S6.9.3(b)—

(1) The fluid shall show no stratification; and

(2) Sedimentation shall not exceed 0.15 percent by volume after centrifuging.

S5.1.10 Compatibility.

(a) At low temperature. When brake fluid is tested according to S6.10.3(a), the test specimen shall show no sludging, sedimentation, or crystallization. In addition, fluids, except DOT 5 SBBF, shall show no stratification.

(b) At 60 °C. (140 °F.). When brake fluid is tested according to S6.10.3(b)—

(1) Sedimentation shall not exceed 0.05 percent by volume after centrifuging; and

(2) Fluids, except DOT 5 SBBF, shall show no stratification.

S5.1.11 Resistance to oxidation. When brake fluid is tested according to S6.11—

(a) The metal test strips outside the areas in contact with the tinfoil shall not show pitting or etching to an extent discernible without magnification;

(b) No more than a trace of gum shall be deposited on the test strips outside the areas in contact with the tinfoil;

(c) The aluminum strips shall not change in weight by more than 0.05 mg./sq. cm.; and

(d) The cast iron strips shall not change in weight by more than 0.3 mg./ sq. cm.

S5.1.12 Effects on cups. When brake cups are subjected to brake fluid in accordance with S6.12—

(a) The increase in the diameter of the base of the cups shall be not less than 0.15 mm. (0.006 inch) or more than 1.40 mm. (0.055 inch);

(b) The decrease in hardness of the cups shall be not more than 10 IRHD at 70 °C. (158 °F.) or more than 15 IRHD at 120 °C. (248 °F.), and there shall be no increase in hardness of the cups; and

(c) The cups shall show no disintegration as evidenced by stickiness, blisters, or sloughing.

S5.1.13 Stroking properties. When brake fluid is tested according to S6.13—

(a) Metal parts of the test system shall show no pitting or etching to an extent discernible without magnification;

(b) The change in diameter of any cylinder or piston shall not exceed 0.13 mm. (0.005 inch);

(c) The average decrease in hardness of seven of the eight cups tested (six wheel cylinder and one master cylinder primary) shall not exceed 15 IRHD. Not more than one of the seven cups shall have a decrease in hardness greater than 17 IRHD;

(d) None of the eight cups shall be in an unsatisfactory operating condition as evidenced by stickiness, scuffing, blisters, cracking, chipping, or other change in shape from its original appearance;

(e) None of the eight cups shall show an increase in base diameter greater than 0.90 mm (0.035 inch);

(f) The average lip diameter set of the eight cups shall not be greater than 65 percent.

(g) During any period of 24,000 strokes, the volume loss of fluid shall not exceed 36 milliliters;

(h) The cylinder pistons shall not freeze or function improperly throughout the test;

(i) The total loss of fluid during the 100 strokes at the end of the test shall not exceed 36 milliliters;

(j) The fluid at the end of the test shall show no formation of gels;

(k) At the end of the test the amount of sediment shall not exceed 1.5 percent by volume; and

(l) Brake cylinders shall be free of deposits that are abrasive or that cannot be removed when rubbed moderately with a nonabrasive cloth wetted with ethanol.

S5.1.14 Fluid color. Brake fluid and hydraulic system mineral oil shall be of the color indicated:

DOT 3, DOT 4, and DOT 5.1 non-SBBF—colorless to amber.

DOT 5 SBBF—purple.

Hydraulic system mineral oil—green.

S5.2 Packaging and labeling requirements for motor vehicle brake fluids.

S5.2.1 Container sealing. Each brake fluid or hydraulic system mineral oil container with a capacity of 177 mL or more shall be provided with a reseal-able closure that has an inner seal impervious to the packaged brake fluid. The container closure shall include a tamper-proof feature that will either be destroyed or substantially altered when the container closure is initially opened.

S5.2.2 Certification, marking, and labeling.

S5.2.2.1 Each manufacturer of a DOT grade brake fluid shall furnish to each packager, distributor, or dealer to whom he delivers brake fluid, the following information:

(a) A serial number identifying the production lot and the date of manufacture of the brake fluid.

(b) The grade (DOT 3, DOT 4, DOT 5) of the brake fluid. If DOT 5 grade brake fluid, it shall be further distinguished as “DOT 5 SILICONE BASE” or “DOT 5.1 NON-SILICONE BASE.”

(c) The minimum wet boiling point in Fahrenheit of the brake fluid.

(d) Certification that the brake fluid conforms to §571.116.

S5.2.2.2 Each packager of brake fluid shall furnish the information specified in paragraphs (a) through (g) of this S5.2.2.2 by clearly marking it on each brake fluid container or on a label (labels) permanently affixed to the container, in any location except a removable part such as a lid. After being subjected to the operations and conditions specified in S6.14, the information required by this section shall be legible to an observer having corrected visual acuity of 20/40 (Snellen ratio) at a distance of 305 mm, and any label affixed to the container in compliance with this section shall not be removable without its being destroyed or defaced.

(a) Certification that the brake fluid conforms to §571.116.

(b) The name of the packager of the brake fluid, which may be in code form.

(c) The name and complete mailing address of the distributor.

(d) A serial number identifying the packaged lot and date of packaging.

(e) Designation of the contents as “DOT—MOTOR VEHICLE BRAKE FLUID” (Fill in DOT 3, DOT 4, DOT 5 SILICONE BASE, or DOT 5.1 NON-SILICONE BASE as applicable).

(f) The minimum wet boiling point in Fahrenheit of the DOT brake fluid in the container.

(g) The following safety warnings in capital and lower case letters as indicated:

(1) FOLLOW VEHICLE MANUFACTURER’S RECOMMENDATIONS WHEN ADDING BRAKE FLUID.

(2) KEEP BRAKE FLUID CLEAN AND DRY. Contamination with dirt, water, petroleum products or other materials may result in brake failure or costly repairs.

(3) STORE BRAKE FLUID ONLY IN ITS ORIGINAL CONTAINER. KEEP CONTAINER CLEAN AND TIGHTLY CLOSED TO PREVENT ABSORPTION OF MOISTURE.

(4) CAUTION: DO NOT REFILL CONTAINER, AND DO NOT USE FOR OTHER LIQUIDS. (Not required for containers with a capacity in excess of 19 L.)

S5.2.2.3 Each packager of hydraulic system mineral oil shall furnish the information specified in paragraphs (a) through (e) of this S5.2.2.3 by clearly marking it on each brake fluid container or on a label (labels) permanently affixed to the container, in any location except a removable part such as a lid. After being subjected to the operations and conditions specified in S6.14, the information required by this section shall be legible to an observer having corrected visual acuity of 20/40 (Snellen ratio) at a distance of 305 mm and any label affixed to the container in compliance with this section shall not be removable without its being destroyed or defaced.

(a) The name of the packager of the hydraulic system mineral oil, which may be in code form.

(b) The name and complete mailing address of the distributor.

(c) A serial number identifying the packaged lot and date of packaging.

(d) Designation of the contents as “HYDRAULIC SYSTEM MINERAL OIL” in capital letters at least 3 mm high.

(e) The following safety warnings in capital and lower case letters as indicated:

(1) FOLLOW VEHICLE MANUFACTURER’S RECOMMENDATIONS WHEN ADDING HYDRAULIC SYSTEM MINERAL OIL.

(2) Hydraulic System Mineral Oil is NOT COMPATIBLE with the rubber components of brake systems designed for use with DOT brake fluids.

(3) KEEP HYDRAULIC SYSTEM MINERAL OIL CLEAN. Contamination with dust or other materials may result in brake failure or costly repair.

(4) CAUTION: STORE HYDRAULIC SYSTEM MINERAL OIL ONLY IN ITS ORIGINAL CONTAINER. KEEP CONTAINER CLEAN AND TIGHTLY CLOSED. DO NOT REFILL CONTAINER OR USE OTHER LIQUIDS. (The last sentence is not required for containers with a capacity in excess of 19 L.) S5.2.2.4 If a container for brake fluid or hydraulic system mineral oil is not normally visible but designed to be protected by an outer container or carton during use, the outer container or carton rather than the inner container shall meet the labeling requirements of S5.2.2.2 or S5.2.2.3, as appropriate.

S5.3 Motor vehicle requirement. Each passenger car, multipurpose passenger vehicle, truck, bus, trailer, and motorcycle that has a hydraulic brake system shall be equipped with fluid that has been manufactured and packaged in conformity with the requirements of this standard.

S6. Test procedures.

S6.1 Equilibrium reflux boiling point. Determine the ERBP of a brake fluid by running duplicate samples according to the following procedure and averaging the results.

S6.1.1 Summary of procedure. Sixty milliliters (ml.) of brake fluid are boiled under specified equilibrium conditions (reflux) at atmospheric pressure in a 100-ml. flask. The average temperature of the boiling fluid at the end of the reflux period, corrected for variations in barometric pressure if necessary, is the ERBP.

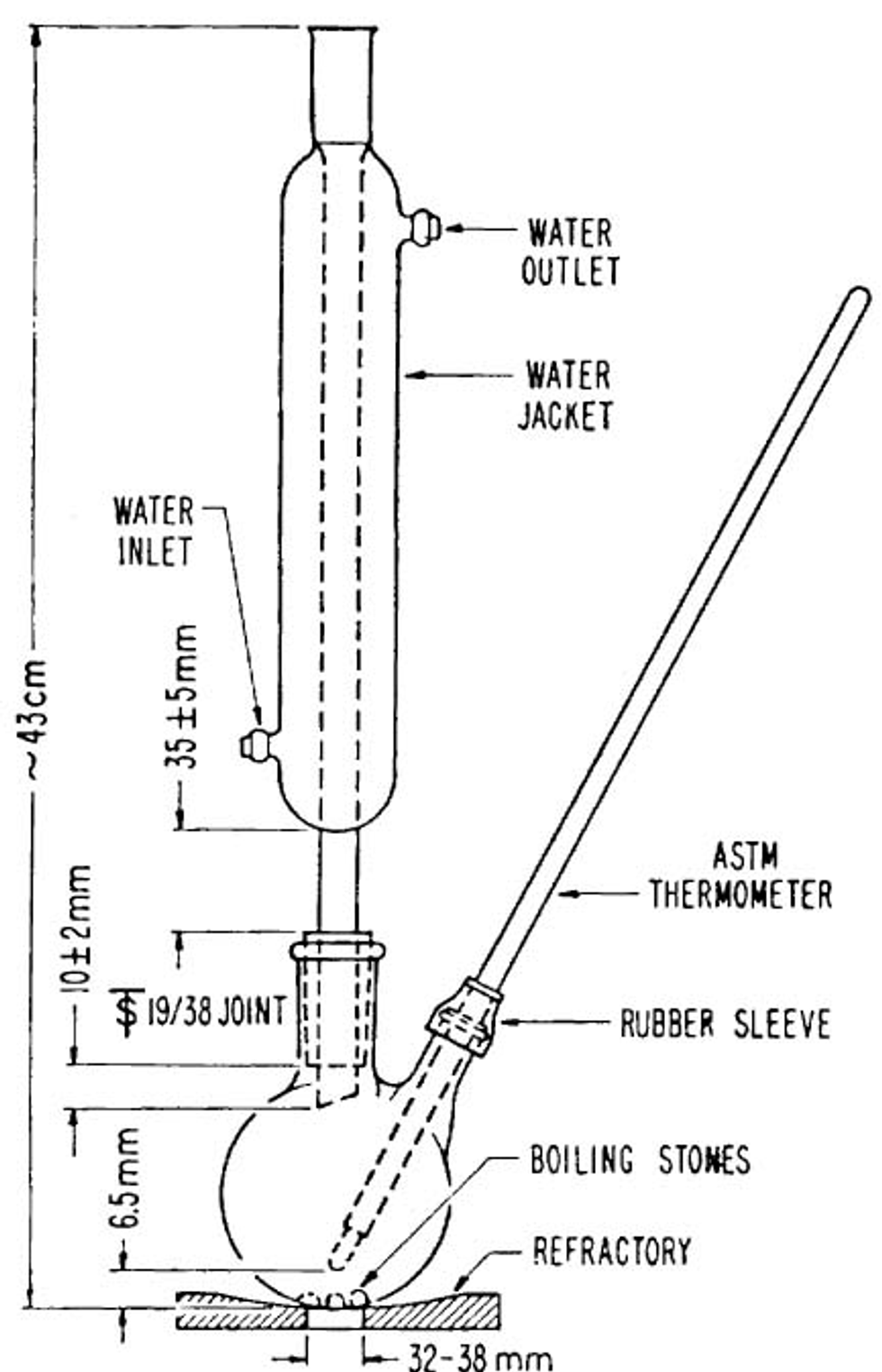

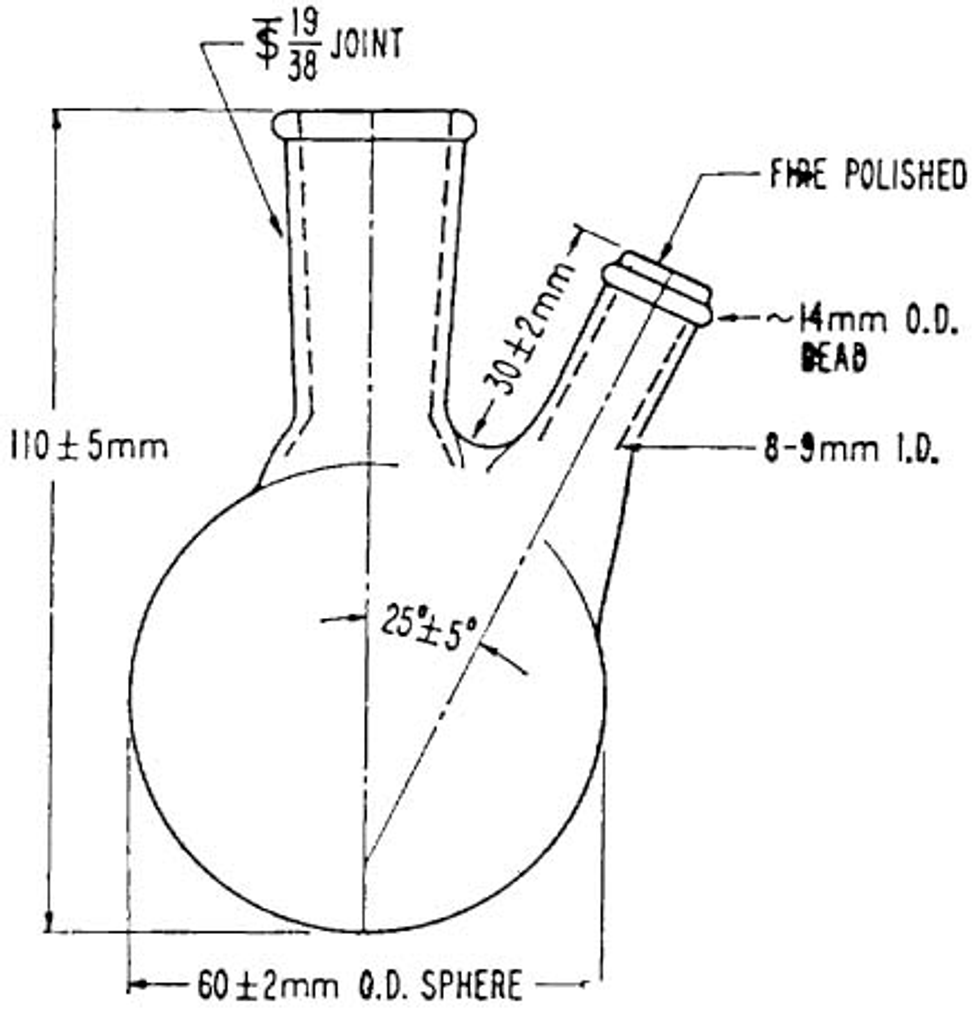

S6.1.2 Apparatus. (See Figure 1) The test apparatus shall consist of—

(a) Flask. (See Figure 2) A 100-ml. round-bottom, short-neck heat-resistant glass flask having a neck with a 19⁄38 standard taper, female ground-glass joint and a side-entering tube, with an outside diameter of 10 millimeters (mm.), which centers the thermometer bulb in the flask 6.5 mm. from the bottom;

(b) Condenser. A water-cooled, reflux, glass-tube type, condenser having a jacket 200 mm. in length, the bottom end of which has a 19⁄38 standard-taper, drip-tip, male ground-glass joint;

(c) Boiling stones. Three clean, unused silicon carbide grains (approximately 2 mm. (0.08 inch) in diameter, grit No. 8);

(d) Thermometer. Standardized calibrated partial immersion (76 mm.), solid stem, thermometers conforming to the requirements for an ASTM 2C or 2F, and an ASTM 3C or 3F thermometer; and

(e) Heat source. Variable autotransformer-controlled heating mantle designed to fit the flask, or an electric heater with rheostat heat control.

|

| Figure 1 Boiling Point Test Apparatus |

|

| Figure 2 Detail of 100 ml Short-Neck Flask |

S6.1.3 Preparation of apparatus. (a) Thoroughly clean and dry all glassware.

(b) Insert thermometer through the side tube until the tip of the bulb is 6.5 mm. ( 1/4 inch) from the bottom center of the flask. Seal with a short piece of natural rubber, EPDM, SBR, or butyl tubing.

(c) Place 60 ±1 ml. of brake fluid and the silicon carbide grains into the flask.

(d) Attach the flask to the condenser. When using a heating mantle, place the mantle under the flask and support it with a ring-clamp and laboratory-type stand, holding the entire assembly in place by a clamp. When using a rheostat-controlled heater, center a standard porcelain or hard asbestos refractory, having a diameter opening 32 to 38 mm., over the heating element and mount the flask so that direct heat is applied only through the opening in the refractory. Place the assembly in an area free from drafts or other types of sudden temperature changes. Connect the cooling water inlet and outlet tubes to the condenser. Turn on the cooling water. The water supply temperature shall not exceed 28 °C. (82.4 °F.) and the temperature rise through the condenser shall not exceed 2 °C. (3.6 °F.).

S6.1.4 Procedure. Apply heat to the flask so that within 10 ±2 minutes the fluid is refluxing in excess of 1 drop per second. The reflux rate shall not exceed 5 drops per second at any time. Immediately adjust the heating rate to obtain an equilibrium reflux rate of 1 to 2 drops per second over the next 5 ±2 minutes. Maintain this rate for an additional 2 minutes, taking four temperature readings at 30–second intervals. Record the average of these as the observed ERBP. If no reflux is evident when the fluid temperature reaches 260 °C (500 °F), discontinue heating and report ERBP as in excess of 260 °C (500 °F).

S6.1.5 Calculation. (a) Thermometer inaccuracy. Correct the observed ERBP by applying any correction factor obtained in standardizing the thermometer.

(b) Variation from standard barometric pressure. Apply the factor shown in Table III to calculate the barometric pressure correction to the ERBP.

| Observed ERBP corrected for thermometer inaccuracy | Correction per 1 mm difference in pressure a | |

|---|---|---|

| °C. | (°F.) | |

| 100° C. (212° F.) to 190° C. (374° F.) | 0.039 | (0.07) |

| Over 190° C. (374° F.) | 0.04 | (0.08) |

| a To be added in case barometric pressure is below 760 mm.; to be subtracted in case barometric pressure is above 670 mm. | ||

(c) If the two corrected observed ERBP’s agree within 2 °C. (4 °C. for brake fluids having an ERBP over 230 °C./446 °F.) average the duplicate runs as the ERBP; otherwise, repeat the entire test, averaging the four corrected observed values to determine the original ERBP.

S6.2 Wet ERBP. Determine the wet ERBP of a brake fluid by running duplicate samples according to the following procedure.

S6.2.1. Summary of procedure. A 350 ml. sample of the brake fluid is humidified under controlled conditions; 350 ml. of SAE triethylene glycol monomethyl ether, brake fluid grade, referee material (TEGME) as described in appendix E of SAE Standard J1703 NOV83 (incorporated by reference, see §571.5 ), is used to establish the end point for humidification. After humidification, the water content and ERBP of the brake fluid are determined.

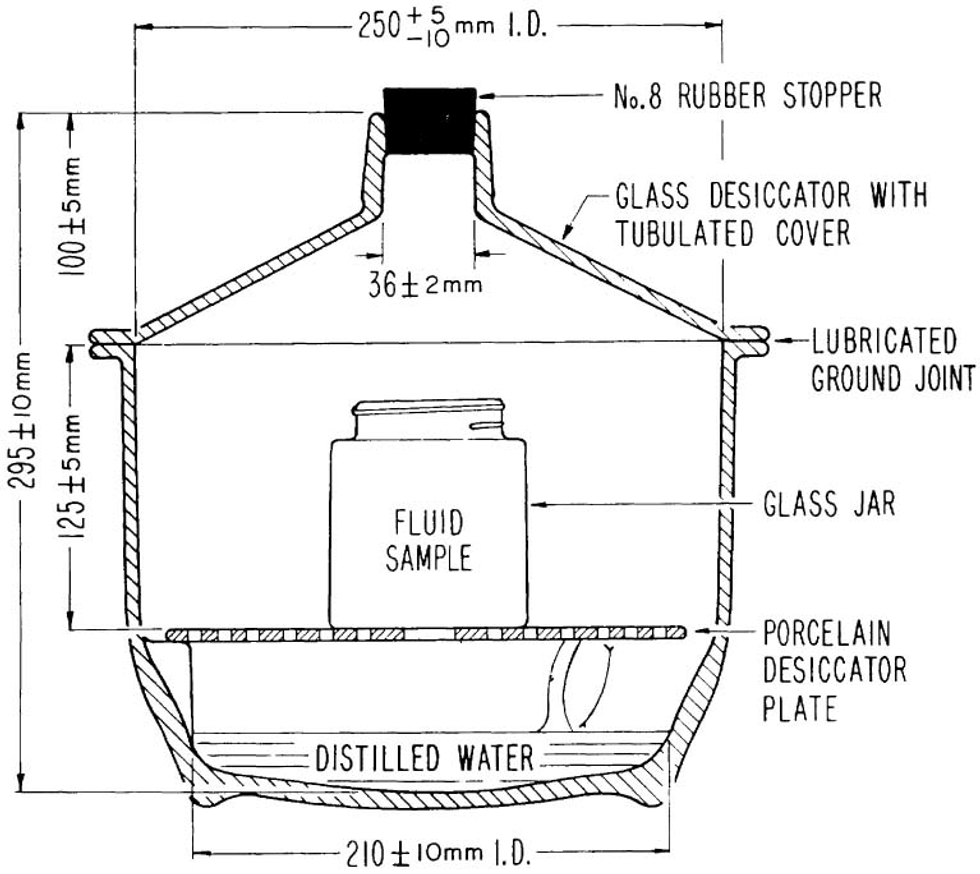

S6.2.2 Apparatus for humidification. (See Figure 3).

Test apparatus shall consist of—

(a) Glass jars. Four SAE RM–49 corrosion test jars or equivalent screwtop, straight-sided, round glass jars each having a capacity of about 475 ml. and approximate inner dimensions of 100 mm. in height by 75 mm. in diameter, with matching lids having new, clean inserts providing water-vapor-proof seals;

(b) Desiccator and cover. Two bowl-form glass desiccators, 250-mm. inside diameter, having matching tubulated covers fitted with No. 8 rubber stoppers; and

(c) Desiccator plate. Two 230-mm. diameter, perforated porcelain desiccator plates, without feet, glazed on one side.

S6.2.3 Reagents and materials. (a) Distilled water, see S7.1.

(b) SAE TEGME referee material (see Appendix E of SAE Standard J1703 NOV83 (incorporated by reference, see §571.5 )).

S6.2.4 Preparation of apparatus. Lubricate the ground-glass joint of the desiccator. Pour 450 ±10 ml. of distilled water into each desiccator and insert perforated porcelain desiccator plates. Place the desiccators in an oven with temperature controlled at 50 ±1 °C. (122 ±1.8 °F.) throughout the humidification procedure.

S6.2.5 Procedure. Pour 350 ±5 ml. of brake fluid into an open corrosion test jar. Prepare in the same manner a duplicate test fluid sample and two duplicate specimens of the SAE TEGME referee material (350 ±5 ml. of TEGME in each jar). The water content of the SAE TEGME fluid is adjusted to 0.50 ±0.05 percent by weight at the start of the test in accordance with S7.2. Place one sample each of the test brake fluid and the prepared TEGME sample into the same desiccator. Repeat for the second sample of test brake fluid and TEGME in a second desiccator. Place the desiccators in the 50 °C. (122 °F.) controlled oven and replace desiccator covers. At intervals, during oven humidification, remove the rubber stoppers in the tops of desiccators. Using a long needled hypodermic syringe, take a sample of not more than 2 ml. from each TEGME sample and determine its water content. Remove no more than 10 ml. of fluid from each SAE TEGME sample during the humidification procedure. When the water content of the SAE fluid reaches 3.70 ±0.05 percent by weight (average of the duplicates). remove the two test fluid specimens from their desiccators and promptly cap each jar tightly. Allow the sealed jars to cool for 60 to 90 minutes at 23° ±5 °C. (73.4° ±9 °F.). Measure the water contents of the test fluid specimens in accordance with S7.2 and determine their ERBP’s in accordance with S6.1. If the two ERBPs agree within 4 °C. (8 °F.), average them to determine the wet ERBP; otherwise repeat and average the four individual ERBPs as the wet ERBP of the brake fluid.

|

| Fig-3 HUMIDIFICATION APPARATUS |

S6.3 Kinematic viscosities. Determine the kinematic viscosity of a brake fluid in mm2/s by the following procedure. Run duplicate samples at each of the specified temperatures, making two times runs on each sample.

S6.3.1 Summary of the procedure. The time is measured for a fixed volume of the brake fluid to flow through a calibrated glass capillary viscometer under an accurately reproducible head and at a closely controlled temperature. The kinematic viscosity is then calculated from the measured flow time and the calibration constant of the viscometer.

S6.3.2 Apparatus.

(a) Viscometers. Calibrated glass capillary-type viscometers, ASTM D2515-66 (incorporated by reference, see §571.5 ), measuring viscosity within the precision limits of S6.4.7. Use suspended level viscometers for viscosity measurements at low temperatures. Use Cannon–Fenske Routine or other modified Ostwald viscometers at ambient temperatures and above.

(b) Viscometer holders and frames. Mount a viscometer in the constant-temperature bath so that the mounting tube is held within 1° of the vertical.

(c) Viscometer bath. A transparent liquid bath of sufficient depth such that at no time during the measurement will any portion of the sample in the viscometer be less than 2 cm. below the surface or less than 2 cm. above the bottom. The bath shall be cylindrical in shape, with turbulent agitation sufficient to meet the temperature control requirements. For measurements within 15° to 100 °C. (60° to 212 °F.) the temperature of the bath medium shall not vary by more than 0.01 °C. (0.02 °F.) over the length of the viscometers, or between the positions of the viscometers, or at the locations of the thermometers. Outside this range, the variation shall not exceed 0.03 °C. (0.05 °F.).

(d) Thermometers. Liquid–in–Glass Kinematic Viscosity Test Thermometers, covering the range of test temperatures indicated in Table IV and conforming to ASTM E1–68 (incorporated by reference, see §571.5 ), and in the IP requirements for IP Standard Thermometers. Use two standardized thermometers in the bath.

| Temperature range | For tests at | Subdivisions | Thermometer number | ||||

|---|---|---|---|---|---|---|---|

| °C. | °F. | °C. | °F. | °C. | °F. | ASTM | IP |

| Minus 55.3 to minus 52.5 | Minus 67.5 to minus 62.5 | Minus 55 | Minus 67 | 0.05 | 0.1 | 74 F | 69 F. or C. |

| Minus 41.4 to minus 38.6 | Minus 42.5 to minus 37.5 | Minus 40 | Minus 40 | 0.05 | 0.1 | 73 F | 68 F. or C. |

| 98.6 to 101.4 | 207.5 to 212.5 | 100 | 212 | 0.05 | 0.1 | 30 F | 32 F. or C. |

(e) Timing device. Stop watch or other timing device graduated in divisions representing not more than 0.2 second, with an accuracy of at least ±0.05 percent when tested over intervals of 15 minutes. Electrical timing devices may be used when the current frequency is controlled to an accuracy of 0.01 percent or better.

S6.3.3 Standardization.

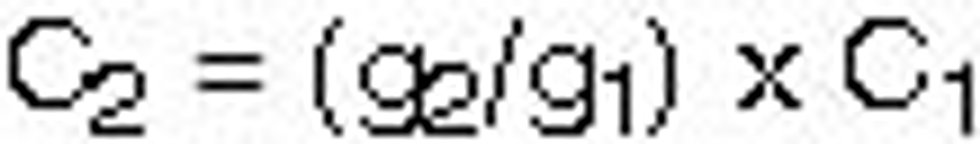

(a) Viscometers. Use viscometers calibrated in accordance with appendix 1 of ASTM D445-65 (incorporated by reference, see §571.5 ). The calibration constant, C, is dependent upon the gravitational acceleration at the place of calibration. This must, therefore, be supplied by the standardization laboratory together with the instrument constant. Where the acceleration of gravity, g, in the two locations differs by more than 0.1%, correct the calibration constant as follows:

C 2 =(g 2 /g 1 )×C 1

where the subscripts 1 and 2 indicate respectively the standardization laboratory and the testing laboratory.

(b) Thermometers. Check liquid–in–glass thermometers to the nearest 0.01 °C (0.02 °F) by direct comparison with a standardized thermometer. Kinematic Viscosity Test Thermometers shall be standardized at “total immersion.” The ice point of standardized thermometers shall be determined before use and the official corrections shall be adjusted to conform to the changes in ice points. (See ASTM E77-66 (incorporated by reference, see §571.5 )).

(c) Timers. Time signals are broadcast by the National Bureau of Standards, Station WWV, Washington, DC at 2.5, 5, 10, 15, 20, 25, 30, and 35 Mc/sec (MHz). Time signals are also broadcast by Station CHU from Ottawa, Canada, at 3.330, 7.335, and 14.670 Mc/sec, and Station MSF at Rugby, United Kingdom, at 2.5, 5, and 10 Mc/sec.

S6.3.4 Procedure. (a) Set and maintain the bath at the appropriate test temperature (see S5.1.3) within the limits specified in S6.3.2(c). Apply the necessary corrections, if any, to all thermometer readings.

(b) Select a clean, dry, calibrated viscometer giving a flow time not less than its specified minimum, or 200 seconds, whichever is the greater.

(c) Charge the viscometer in the manner used when the instrument was calibrated. Do not filter or dry the brake fluid, but protect it from contamination by dirt and moisture during filling and measurements.

(1) Charge the suspended level viscometers by tilting about 30° from the vertical and pouring sufficient brake fluid through the fill tube into the lower reservoir so that when the viscometer is returned to vertical position the meniscus is between the fill marks. For measurements below 0 °C. (32 °F.), before placing the filled viscometer into the constant temperature bath, draw the sample into the working capillary and timing bulb and insert small rubber stoppers to suspend the fluid in this position, to prevent accumulation of water condensate on the walls of the critical portions of the viscometer. Alternatively, fit loosely packed drying tubes into the open ends of the viscometer to prevent water condensation, but do not restrict the flow of the sample under test by the pressures created in the instrument.

(2) If a Cannon-Fenske Routine viscometer is used, charge by inverting and immersing the smaller arm into the brake fluid and applying vacuum to the larger arm. Fill the tube to the upper timing mark, and return the viscometer to an upright position.

(d) Mount the viscometer in the bath in a true vertical position (see S6.3.2(b)).

(e) The viscometer shall remain in the bath until it reaches the test temperature.

(f) At temperatures below 0 °C. (32 °F.) conduct an untimed preliminary run by allowing the brake fluid to drain through the capillary into the lower reservoir after the test temperature has been established.

(g) Adjust the head level of the brake fluid to a position in the capillary arm about 5 mm. above the first timing mark.

(h) With brake fluid flowing freely measure to within 0.2 second the time required for the meniscus to pass from the first timing mark to the second. If this flow time is less than the minimum specified for the viscometer, or 200 seconds, whichever is greater, repeat using a viscometer with a capillary of smaller diameter.

(i) Repeat S6.3.4 (g) and (h). If the two timed runs do not agree within 0.2 percent, reject and repeat using a fresh sample of brake fluid.

S6.3.5 Cleaning the viscometers. (a) Periodically clean the instrument with chromic acid to remove organic deposits. Rinse thoroughly with distilled water and acetone, and dry with clean dry air.

(b) Between successive samples rinse the viscometer with ethanol (isopropanol when testing DOT 5 fluids) followed by an acetone or ether rinse. Pass a slow stream of filtered dry air through the viscometer until the last trace of solvent is removed.

S6.3.6 Calculation. (a) The following viscometers have a fixed volume charged at ambient temperature, and as a consequence C varies with test temperature: Cannon-Fenske Routine, Pinkevitch, Cannon–Manning Semi–Micro, and Cannon Fenske Opaque. To calculate C at test temperatures other than the calibration temperature for these viscometers, see ASTM D2515-66 (incorporated by reference, see §571.5 ) or follow instructions given on the manufacturer's certificate of calibration.

(b) Average the four timed runs on the duplicate samples to determine the kinematic viscosities.

S6.3.7 Precision (at 95 percent confidence level).

(a) Repeatability. If results on duplicate samples by the same operator differ by more than 1 percent of their mean, repeat the tests.

S6.4 pH value. Determine the pH value of a brake fluid by running one sample according to the following procedure.

S6.4.1 Summary of the procedure. Brake fluid is diluted with an equal volume of an ethanol-water solution. The pH of the resultant mixture is measured with a prescribed pH meter assembly at 23 °C. (73.4 °F.).

S6.4.2 Apparatus. The pH assembly consists of the pH meter, glass electrode, and calomel electrode, as specified in Appendices A1.1, A1.2, and A1.3 of ASTM D1121-67 (incorporated by reference, see §571.5 ) The glass electrode is a full range type (pH 0–14), with low sodium error.

S6.4.3 Reagents. Reagent grade chemicals conforming to the specifications of the Committee on Analytical Reagents of the American Chemical Society.

(a) Distilled water. Distilled water (S7.1) shall be boiled for about 15 minutes to remove carbon dioxide, and protected with a soda-lime tube or its equivalent while cooling and in storage. (Take precautions to prevent contamination by the materials used for protection against carbon dioxide.) The pH of the boiled distilled water shall be between 6.2 and 7.2 at 25 °C. (77 °F.).

(b) Standard buffer solutions. Prepare buffer solutions for calibrating the pH meter and electrode pair from salts sold specifically for use, either singly or in combination, as pH standards. Dry salts for 1 hour at 110 °C. (230 °F.) before use except for borax which shall be used as the decahydrate. Store solutions with pH less than 9.5 in bottles of chemically resistant glass or polyethylene. Store the alkaline phosphate solution in a glass bottle coated inside with paraffin. Do not use a standard with an age exceeding three months.

(1) Potassium hydrogen phthalate buffer solution (0.05 M, pH=4.01 at 25 °C. (77 °F.)). Dissolve 10.21 g. of potassium hydrogen phthalate (KHC 8 H 4 O 4 ) in distilled water. Dilute to 1 liter.

(2) Neutral phosphate buffer solution (0.025 M with respect to each phosphate salt, pH=6.86 at 25 °C. (77 °F.)). Dissolve 3.40 g. of potassium dihydrogen phosphate (KH 2 PO 4 ) and 3.55 g. of anhydrous disodium hydrogen phosphate (Na 2 HPO 4 ) in distilled water.

(3) Borax buffer solution (0.01 M, pH=9.18 at 25 °C. (77 °F.)). Dissolve 3.81 g.of disodium tetraborate decahydrate (Na 2 B 4 O 7 °10H 2 O) in distilled water, and dilute to 1 liter. Stopper the bottle except when actually in use.

(4) Alkaline phosphate buffer solution (0.01 M trisodium phosphate, pH=11.72 at 25 °C. (77 °F.)). Dissolve 1.42 g. of anhydrous disodium hydrogen phosphate (Na 2 HPO 4 ) in 100 ml. of a 0.1 M carbonate-free solution of sodium hydroxide. Dilute to 1 liter with distilled water.

(5) Potassium chloride electrolyte. Prepare a saturated solution of potassium chloride (KCl) in distilled water.

(c) Ethanol-water mixture. To 80 parts by volume of ethanol (S7.3) add 20 parts by volume of distilled water. Adjust the pH of the mixture to 7 ±0.1 using 0.1 N sodium hydroxide (NaOH) solution. If more than 4 ml. of NaOH solution per liter of mixture is required for neutralization, discard the mixture.

S6.4.4 Preparation of electrode system.

(a) Maintenance of electrodes. Clean the glass electrode before using by immersing in cold chromic-acid cleaning solution. Drain the calomel electrode and fill with KCl electrolyte, keeping level above that of the mixture at all times. When not in use, immerse the lower halves of the electrodes in distilled water, and do not immerse in the mixture for any appreciable period of time between determinations.

(b) Preparation of electrodes. Condition new glass electrodes and those that have been stored dry as recommended by the manufacturer. Before and after using, wipe the glass electrode thoroughly with a clean cloth, or a soft absorbent tissue, and rinse with distilled water. Before each pH determination, soak the prepared electrode in distilled water for at least 2 minutes. Immediately before use, remove any excess water from the tips of the electrode.

S6.4.5 Standardization of the pH assembly and testing of the electrodes. (a) Immediately before use, standardize the pH assembly with a standard buffer solution. Then use a second standard buffer solution to check the linearity of the response of the electrodes at different pH values, and to detect a faulty glass electrode or incorrect temperature compensation. The two buffer solutions bracket the anticipated pH value of the test brake fluid.

(b) Allow instrument to warm up, and adjust according to the manufacturer’s instructions. Immerse the tips of the electrodes in a standard buffer solution and allow the temperature of the buffer solution and the electrodes to equalize. Set the temperature knob at the temperature of the buffer solution. Adjust the standardization or asymmetry potential control until the meter registers a scale reading, in pH units, equal to the known pH of the standardizing buffer solution.

(c) Rinse the electrodes with distilled water and remove excess water from the tips. Immerse the electrodes in a second standard buffer solution. The reading of the meter shall agree with the known pH of the second standard buffer solution within ±0.05 unit without changing the setting of the standardization of asymmetry potential control.

(d) A faulty electrode is indicated by failure to obtain a correct value for the pH of the second standard buffer solution after the meter has been standardized with the first.

S6.4.6 Procedure. To 50 ±1 ml. of the test brake fluid add 50 ±1 ml. of the ethanol-water (S6.4.3(c)) and mix thoroughly. Immerse the electrodes in the mixture. Allow the system to come to equilibrium, readjust the temperature compensation if necessary, and take the pH reading.

S6.5 Fluid stability. Evaluate the heat and chemical stability of a brake fluid by the following procedure, running duplicate samples for each test and averaging the results.

S6.5.1 Summary of the procedure. The degradation of the brake fluid at elevated temperature, alone or in a mixture with a reference fluid, is evaluated by determining the change in boiling point after a period of heating under reflux conditions.

S6.5.2 Apparatus. Use the apparatus and preparation specified in S6.1.2 and S6.1.3.

S6.5.3 High temperature stability.

S6.5.3.1 Procedure. (a) Heat a new 60 ±1 ml. sample of the brake fluid to 185° ±2 °C. (365° ±3.6 °F.). Hold at this temperature for 120 ±5 minutes. Bring to a reflux rate in excess of 1 drop per second within 5 minutes. The reflux rate should not exceed 5 drops per second at any time. Over the next 5 ±2 minutes adjust the heating rate to obtain an equilibrium reflux rate of 1 to 2 drops per second. Maintain this rate for an additional 2 minutes, taking four temperature readings at 30–second intervals. Average these as the observed ERBP. If no reflux is evident when the fluid temperature reaches 260 °C. (500 °F), discontinue heating and report ERBP as in excess of 260 °C. (500 °F.).

S6.5.3.2 Calculation. Correct the observed ERBP for thermometer and barometric pressure factors according to S6.1.5 (a) and (b). Average the corrected ERBP’s of the duplicate samples. The difference between this average and the original ERBP obtained in S6.1 is the change in ERBP of the fluid.

S6.5.4 Chemical stability.

S6.5.4.1 Materials. SAE RM-66-04 Compatibility Fluid as described in appendix B of SAE Standard J1703 JAN95 (incorporated by reference, see §571.5 ).

(a) Mix 30 ±1 ml. of the brake fluid with 30 ±1 ml. of SAE RM–66–04 Compatibility Fluid in a boiling point flask (S6.1.2(a)). Determine the initial ERBP of the mixture by applying heat to the flask so that the fluid is refluxing in 10 ±2 minutes at a rate in excess of 1 drop per second, but not more than 5 drops per second. Note the maximum fluid temperature observed during the first minute after the fluid begins refluxing at a rate in excess of 1 drop per second. Over the next 15 ±1 minutes, adjust and maintain the reflux rate at 1 to 2 drops per second. Maintain this rate for an additional 2 minutes, recording the average value of four temperature readings taken at 30 second intervals as the final ERBP.

(b) Thermometer and barometric corrections are not required.

S6.5.4.3 Calculation. The difference between the initial ERBP and the final average temperature is the change in temperature of the refluxing mixture. Average the results of the duplicates to the nearest 0.5 °C (1.0 °F).

S6.6 Corrosion. Evaluate the corrosiveness of a brake fluid by running duplicate samples according to the following procedure.

S6.6.1 Summary of the procedure. Six specified metal corrosion test strips are polished, cleaned, and weighed, then assembled as described. Assembly is placed on a standard wheel cylinder cup in a corrosion test jar, immersed in the water-wet brake fluid, capped and placed in an oven at 100 °C. (212 °F.) for 120 hours. Upon removal and cooling, the strips, fluid, and cups are examined and tested.

S6.6.2 Equipment. (a) Balance. An analytical balance having a minimum capacity of 50 grams and capable of weighing to the nearest 0.1 mg.

(b) Desiccators. Desiccators containing silica gel or other suitable desiccant.

(c) Oven. Gravity convection oven capable of maintaining the desired set point within 2 °C. (3.6 °F.).

(d) Micrometer. A machinist’s micrometer 25 to 50 mm. (1 to 2 inches) capacity, or an optical comparator, capable of measuring the diameter of the SBR wheel cylinder (WC) cups to the nearest 0.02 mm. (0.001 inch).

S6.6.3 Materials. (a) Corrosion test strips.Two sets of strips from each of the metals listed in Appendix C of SAE Standard J1703b (1970) (incorporated by reference, see §571.5 ). Each strip shall be approximately 8 cm long, 1.3 cm wide, not more than 0.6 cm thick, and have a surface area of 25±5 cm2 and a hole 4 to 5 mm (0.16 to 0.20 inch) in diameter on the centerline about 6 mm from one end. The hole shall be clean and free from burrs. Tinned iron strips shall be unused. Other strips, if used, shall not be employed if they cannot be polished to a high finish.

(b) SBR cups. Two unused standard SAE SBR wheel cylinder (WC) cups, as specified in S7.6.

(c) Corrosion test jars and lids. Two screw-top straight-sided round glass jars, each having a capacity of approximately 475 ml. and inner dimensions of approximately 100 mm. in height and 75 mm. in diameter, and a tinned steel lid (no insert or organic coating) vented with a hole 0.8 ±0.1 mm. (0.031 ±0.004 inch) in diameter (No. 68 drill).

(d) Machine screws and nuts. Clean, rust and oil-free, uncoated mild steel round or fillister head machine screws, size 6 or 8–32 UNC-Class 2A, five-eighths or three-fourths inch long (or equivalent metric sizes), and matching uncoated nuts.

(e) Supplies for polishing strips. Waterproof silicon carbide paper, grit No. 320A and grit 1200; lint-free polishing cloth.

(f) Distilled water as specified in S7.1.

(g) Ethanol as specified in S7.3.

(h) Isopropanol as specified in S7.7.

S6.6.4 Preparation.

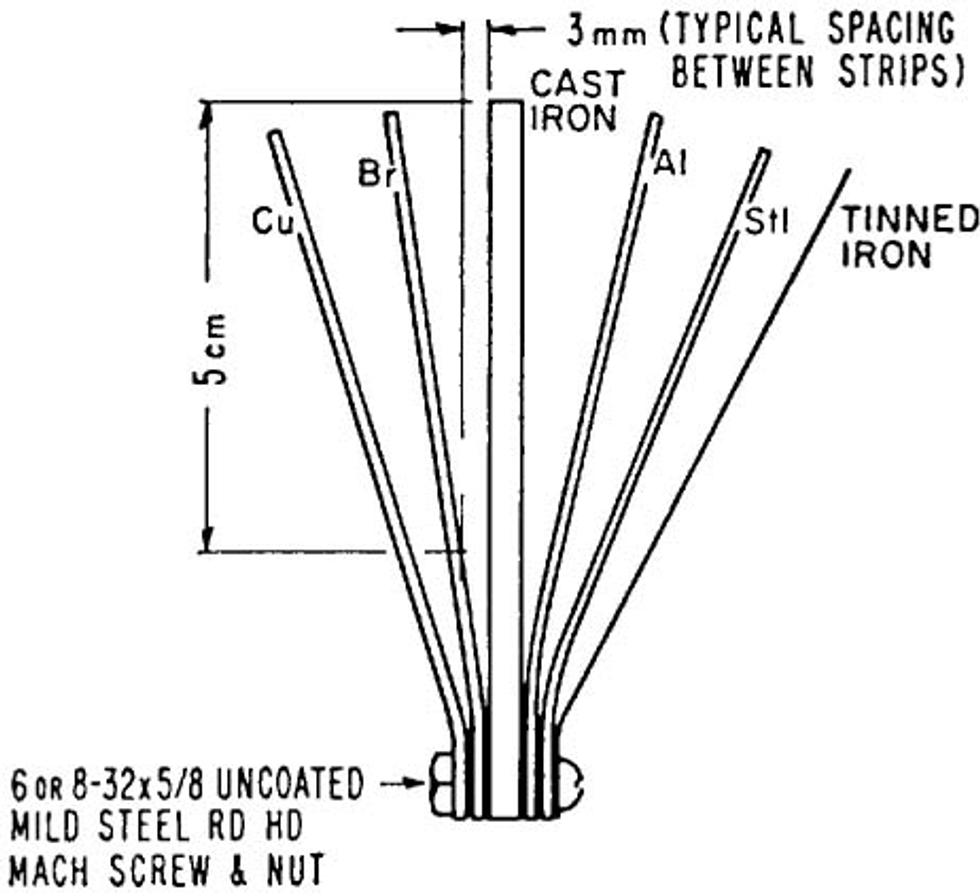

(a) Corrosion test strips. Except for the tinned iron strips, abrade corrosion test strips on all surface areas with 320A silicon carbide paper wet with ethanol (isopropanol when testing DOT 5 SBBF fluids) until all surface scratches, cuts and pits visible to an observer having corrected visual acuity of 20/40 (Snellen ratio) at a distance of 300 mm (11.8 inches) are removed. Use a new piece of paper for each different type of metal. Except for the tinned iron strips, further abrade the test strips on all surface areas with 1200 silicon carbide paper wet with ethanol (isopropanol when testing DOT 5 SBBF fluids), again using a new piece of paper for each different type of metal. Handle the strips with forceps after polishing. Weigh and record the weight of each strip to the nearest 0.1 mg. Assemble the strips on a clean dry machine screw, with matching plain nut, in the order of tinned iron, steel, aluminum, cast iron, brass, and copper. Bend the strips, other than the cast iron, so that there is a separation of 3 ± 1/2 mm. ( 1/8 ± 1/64 inch) between adjacent strips for a distance of about 5 cm. (2 inches) from the free end of the strips. (See Figure 4.) Tighten the screw on each test strip assembly so that the strips are in electrolytic contact, and can be lifted by either of the outer strips (tinned iron or copper) without any of the strips moving relative to the others when held horizontally. Immerse the strip assemblies in 90 percent ethyl alcohol. Dry with dried filtered compressed air, then desiccate at least 1 hour before use.

|

| Fig 4. Corrosion Strip Assembly |

(b) SBR WC cups. Measure the base diameters of the two standard SBR cups, using an optical comparator or micrometer, to the nearest 0.02 mm. (0.001 inch) along the centerline of the SAE and rubber-type identifications and at right angles to this centerline. Take the measurements at least 0.4 mm. (0.015 inch) above the bottom edge and parallel to the base of the cup. Discard any cup if the two measured diameters differ by more than 0.08 mm. (0.003 inch). Average the two readings on each cup. Determine the hardness of the cups according to S7.4.

S6.6.5 Procedure. Rinse the cups in ethanol (isopropanol when testing DOT 5 SBBF fluids) for not more than 30 seconds and wipe dry with a clean lint-free cloth. Place one cup with lip edge facing up, in each jar. Insert a metal strip assembly inside each cup with the fastened end down and the free end extending upward. (See Figure 5.) When testing brake fluids, except DOT 5 SBBF, mix 760 ml. of brake fluid with 40 ml. of distilled water. When testing DOT 5 SBBF’s, humidify 800 ml. of brake fluid in accordance with S6.2, eliminating determination of the ERBP. Using this water-wet mixture, cover each strip assembly to a minimum depth of 10 mm. above the tops of the strips. Tighten the lids and place the jars for 120 ±2 hours in an oven maintained at 100° ±2 °C. (212° ±3.6 °F.). Allow the jars to cool at 23° ±5 °C. (73.4° ±9 °F.) for 60 to 90 minutes. Immediately remove the strips from the jars using forceps, agitating the strip assembly in the fluid to remove loose adhering sediment. Examine the test strips and jars for adhering crystalline deposits. Disassemble the metal strips, and remove adhering fluid by flushing with water; clean each strip by wiping with a clean cloth wetted with ethanol (isopropanol when testing DOT 5 fluids). Examine the strips for evidence of corrosion and pitting. Disregard staining or discoloration. Place the strips in a desiccator containing silica gel or other suitable desiccant, maintained at 23° ±5 °C. (73.4° ±9 °F.), for at least 1 hour. Weigh each strip to the nearest 0.1 mg. Determine the change in weight of each metal strip. Average the results for the two strips of each type of metal. Immediately following the cooling period, remove the cups from the jars with forceps. Remove loose adhering sediment by agitation of the cups in the mixture. Rinse the cups in ethanol (isopropanol when testing DOT 5 fluids) and air-dry. Examine the cups for evidence of sloughing, blisters, and other forms of disintegration. Measure the base diameter and hardness of each cup within 15 minutes after removal from the mixture. Examine the mixture for gelling. Agitate the mixture to suspend and uniformly disperse sediment. From each jar, transfer a 100 ml. portion of the mixture to an ASTM cone-shaped centrifuge tube. Determine the percent sediment after centrifuging as described in S7.5. Measure the pH value of the corrosion text fluid according to S6.4.6. Measure the pH value of the test mixture according to S6.4.6.

|

| Fig 5. Corrosion Test Apparatus |

S6.6.6 Calculation. (a) Measure the area of each type of test strip to the nearest square centimeter. Divide the average change in mass for each type by the area of that type.

(b) Note other data and evaluations indicating compliance with S5.1.6. In theevent of a marginal pass on inspection by attributes, or of a failure in one of the duplicates, run another set of duplicate samples. Both repeat samples shall meet all requirements of S5.1.6.

S6.7 Fluidity and appearance at low temperatures. Determine the fluidity and appearance of a sample of brake fluid at each of two selected temperatures by the following procedure.

S6.7.1 Summary of procedure. Brake fluid is chilled to expected minimum exposure temperatures and observed for clarity, gellation, sediment, separation of components, excessive viscosity or thixotropy.

S6.7.2 Apparatus. (a) Oil sample bottle. Two clear flint glass 4–ounce bottles made especially for sampling oil and other liquids, with a capacity of approximately 125 ml., an outside diameter of 37 ±0.05 mm. and an overall height of 165 ±2.5 mm.

(b) Cold chamber. An air bath cold chamber capable of maintaining storage temperatures down to minus 55 °C. (minus 67 °F.) with an accuracy of ±2 °C. (3.6 °F.).

(c) Timing device. A timing device in accordance with S6.3.2(e).

S6.7.3 Procedure. (a) Place 100 ±1 ml. of brake fluid at room temperature in an oil sample bottle. Stopper the bottle with an unused cork and place in the cold chamber at the higher storage temperature specified in Table II (S5.1.7(c)). After 144 ±4 hours remove the bottle from the chamber, quickly wipe it with a clean, lint-free cloth, saturated with ethanol (isopropanol when testing DOT 5 fluids) or acetone. Examine the fluid for evidence of sludging, sedimentation, crystallization, or stratification. Invert the bottle and determine the number of seconds required for the air bubble to travel to the top of the fluid. Let sample warm to room temperature and examine.

(b) Repeat S6.7.3(a), substituting the lower cold chamber temperature specified in Table II, and a storage period of 6 hours ±12 minutes.

NOTE: Test specimens from either storage temperature may be used for the other only after warming up to room temperature.

S6.8 [Reserved]

S6.9 Water tolerance. Evaluate the water tolerance characteristics of a brake fluid by running one test specimen according to the following procedure.

S6.9.1 Summary of the procedure.

Brake fluid, except DOT 5 SBBF, is diluted with 3.5 percent water (DOT 5 SBBF is humidified), then stored at minus 40 °C. (minus 40 °F.) for 120 hours. The cold, water-wet fluid is first examined for clarity, stratification, and sedimentation, then placed in an oven at 60 °C. (140 °F.) for 24 hours. On removal, it is again examined for stratification, and the volume percent of sediment determined by centrifuging.

S6.9.2 Apparatus.

(a) Centrifuge tube. See S7.5.1(a).

(b) Centrifuge. See S7.5.1(b).

(c) Cold chamber. See S6.7.2(b).

(d) Oven. Gravity or forced convection oven.

(e) Timing device. See S6.3.2(e).

S6.9.3 Procedure.

(a) At low temperature. Humidify 100 ±1 ml. of DOT 5 SBBF brake fluid in accordance with S6.2 eliminating determination of the ERBP. When testing brake fluids except DOT 5 SBBF, mix 3.5 ±0.1 ml. of distilled water with 100 ±1 ml. of the brake fluid; pour into a centrifuge tube. Stopper the tube with a clean cork and place in the cold chamber maintained at minus 40 ±2 °C. (minus 40 ±3.6 °F.). After 120 hours ±2 hours remove the tube, quickly wipe with clean lint-free cloth saturated with ethanol or acetone and examine the fluid for evidence of sludging, sedimentation, crystallization, or stratification. Invert the tube and determine the number of seconds required for the air bubble to travel to the top of the fluid. (The air bubble is considered to have reached the top of the fluid when the top of the bubble reaches the 2 ml. graduation of the centrifuge tube.) If the wet fluid has become cloudy, warm to 23 ±5 °C. (73.4 ±9 °F.) and note appearance and fluidity.

(b) At 60 °C. (140 °F.). Place tube and brake fluid from S6.9.3(a) in an oven maintained at 60° ±2 °C. (140° ±3.6 °F.) for 24 ±2 hours. Remove the tube and immediately examine the contents for evidence of stratification. Determine the percent sediment by centrifuging as described in S7.5.

S6.10 Compatibility. The compatibility of a brake fluid with other brake fluids shall be evaluated by running one test sample according to the following procedure.

S6.10.1 Summary of the procedure.

Brake fluid is mixed with an equal volume of SAE RM–66–04 Compatibility Fluid, then tested in the same way as for water tolerance (S6.9) except that the bubble flow time is not measured. This test is an indication of the compatibility of the test fluid with other motor vehicle brake fluids at both high and low temperatures.

S6.10.2 Apparatus and materials.

(a) Centrifuge tube. See S7.5.1(a).

(b) Centrifuge. See S7.5.1(b).

(c) Cold Chamber. See S6.7.2(b)

(d) Oven. See S6.9.2(d)

(e) SAE RM–66–04 Compatibility Fluid. As described in appendix B of SAE Standard J1703 JAN95 (incorporated by reference, see §571.5 ).

S6.10.3 Procedure.

(a) At low temperature.

Mix 50 ±0.5 mL of brake fluid with 50 ±0.5 mL of SAE RM–66–04 Compatibility Fluid. Pour this mixture into a centrifuge tube and stopper with a clean dry cork. Place tube in the cold chamber maintained at minus 40° ±2 °C. (minus 40° ±4 °F). After 24 ±2 hours, remove tube, quickly wipe with a clean lint-free cloth saturated with ethanol (isopropanol when testing DOT 5 fluids) or acetone. Examine the test specimen for evidence of slugging, sedimentation, or crystallization. Test fluids, except DOT 5 SBBF, shall be examined for stratification.

S6.11 Resistance to oxidation. The stability of a brake fluid under oxidative conditions shall be evaluated by running duplicate samples according to the following procedure.

S6.11.1 Summary of procedure.

Brake fluids, except DOT 5 SBBF, are activated with a mixture of approximately 0.2 percent benzoyl peroxide and 5 percent water. DOT 5 SBBF is humidified in accordance with S6.2 eliminating determination of the ERBP, and then approximately 0.2 percent benzoyl peroxide is added. A corrosion test strip assembly consisting of cast iron and an aluminum strip separated by tinfoil squares at each end is then rested on a piece of SBR WC cup positioned so that the test strip is half immersed in the fluid and oven aged at 70 °C. (158 °F.) for 168 hours. At the end of this period, the metal strips are examined for pitting, etching, and loss of mass.

S6.11.2 Equipment.

(a) Balance. See S6.6.2(a).

(b) Desiccators. See S6.6.2(b).

(c) Oven. See S6.6.2(c).

(d) Three glass test tubes approximately 22 mm. outside diameter by 175 mm. in length.

S6.11.3 Reagents and materials.

(a) Benzoyl peroxide, reagent grade, 96 percent. (Benzoyl peroxide that is brownish, or dusty, or has less than 90% purity, must be discarded.) Reagent strength may be evaluated by ASTM E298-68 (incorporated by reference, see §571.5 ).

(b) Corrosion test strips. Two sets of cast iron and aluminum metal test strips as described in appendix C of SAE Standard J1703b (1970) (incorporated by reference, see §571.5 ).

(c) Tinfoil. Four unused pieces of tinfoil approximately 12 mm. ( 1/2 inch) square and between 0.02 and 0.06 mm. (0.0008 and 0.0024 inch) in thickness. The foil shall be at least 99.9 percent tin and contain not more than 0.025 percent lead.

(d) SBR cups. Two unused, approximately one-eighth sections of a standard SAE SBR WC cup (as described in S7.6).

(e) Machine screw and nut. Two clean oil-free, No. 6 or 8–32× 3/8 - or 1/2 –inch long (or equivalent metric size), round or fillister head, uncoated mild steel machine screws, with matching plain nuts.

S6.11.4 Preparation.

(a) Corrosion test strips. Prepare two sets of aluminum and cast iron test strips according to S6.6.4(a) except for assembly. Weigh each strip to the nearest 0.1 mg. and assemble a strip of each metal on a machine screw, separating the strips at each end with a piece of tinfoil. Tighten the nut enough to hold both pieces of foil firmly in place.

(b) Test mixture. Place 30 ±1 ml. of the brake fluid under test in a 22 by 175 mm. test tube. For all fluids except DOT 5 SBBF, add 0.060 ±.002 grams of benzoyl peroxide, and 1.50 ±0.05 ml. of distilled water. For DOT 5 SBBF, use test fluid humidified in accordance with S6.2, and add only the benzoyl peroxide. Stopper the tube loosely with a clean dry cork, shake, and place in an oven for 2 hours at 70° ±2 °C. (158° ±3.6 °F.). Shake every 15 minutes to effect solution of the peroxide, but do not wet cork. Remove the tube from the oven and allow to cool to 23° ±5 °C. (73.4° ±9 °F.) Begin testing according to paragraph S6.11.5 not later than 24 hours after removal of tube from oven.

S6.11.5 Procedure. Place a one-eighth SBR cup section in the bottom of each tube. Add 10 ml. of prepared test mixture to each test tube. Place a metal-strip assembly in each, the end of the strip without the screw resting on the rubber, and the solution covering about one-half the length of the strips. Stopper the tubes with clean dry corks and store upright for 70 ±2 hours at 23° ±5 °C. (73.4° ±9 °F.). Loosen the corks and place the tubes for 168 ±2 hours in an oven maintained at 70° ±2 °C. (158° ±3.6 °F.). Afterwards remove and disassemble strips. Examine the strips and note any gum deposits. Wipe the strips with a clean cloth wet with ethanol (isopropanol when testing DOT 5 fluids) and note any pitting, etching or roughening of surface disregarding stain or discoloration. Place the strips in a desiccator over silica gel or other suitable desiccant, at 23° ±5 °C. (73.4° ±9 °F.) for at least 1 hour. Again weigh each strip to the nearest 0.1 mg.

S6.11.6 Calculation. Determine corrosion loss by dividing the change in mass of each metal strip by the total surface area of each strip measured in square millimeters (mm2), to the nearest square millimeter (mm2). Average the results for the two strips of each type of metal, rounding to the nearest 0.05 mg. per 100 square millimeter (mm2). If only one of the duplicates fails for any reason, run a second set of duplicate samples. Both repeat samples shall meet all requirements of S5.1.11.

S6.12 Effect on SBR cups. The effects of a brake fluid in swelling, softening, and otherwise affecting standard SBR WC cups shall be evaluated by the following procedure.

S6.12.1 Summary of the procedure. Four standard SAE SBR WC cups are measured and their hardnesses determined. The cups, two to a jar, are immersed in the test brake fluid. One jar is heated for 70 hours at 70 °C. (158 °F), and the other for 70 hours at 120 °C (248 °F). Afterwards, the cups are washed, examined for disintegration, remeasured and their hardnesses redetermined.

S6.12.2 Equipment and supplies.

(a) Oven. See S6.6.2(c).

(b) Glass jars and lids. Two screw-top, straight-sided round glass jars, each having a capacity of approximately 250 ml. and inner dimensions of approximately 125 mm. in height and 50 mm. in diameter, and a tinned steel lid (no insert or organic coating).

(c) SBR cups. See S7.6.

S6.12.3 Preparation. Measure the base diameters of the SBR cups as described in S6.6.4(b), and the hardness of each as described in S7.4.

S6.12.4 Procedure. Wash the cups in 90 percent ethanol (isopropanol when testing DOT 5 fluids) (see S7.3), for not longer than 30 seconds and quickly dry with a clean, lint-free cloth. Using forceps, place two cups into each of the two jars; add 75 ml. of brake fluid to each jar and cap tightly. Place one jar in an oven held at 70° ±2 °C. (158 ±3.6°F.) for 70 ±2 hours. Place the other jar in an oven held at 120° ±2 °C. (248° ±3.6 °F.) for 70 ±2 hours. Allow each jar to cool for 60 to 90 minutes at 23° ±5 °C. (73.4° ±9 °F.). Remove cups, wash with ethanol (isopropanol when testing DOT 5 fluids) for not longer than 30 seconds, and quickly dry. Examine the cups for disintegration as evidenced by stickiness, blisters, or sloughing. Measure the base diameter and hardness of each cup within 15 minutes after removal from the fluid.

S6.12.5 Calculation. (a) Calculate the change in base diameter for each cup. If the two values, at each temperature, do not differ by more than 0.10 mm. (0.004 inch) average them to the nearest 0.02 mm. (0.001 inch). If the two values differ by more than 0.10 mm., repeat the test at the appropriate temperature and average the four values as the change in base diameter.

(b) Calculate the change in hardness for each cup. The average of the two values for each pair is the change in hardness.

(c) Note disintegration as evidenced by stickiness, blisters, or sloughing.

S6.13 Stroking properties. Evaluate the lubricating properties, component compatibility, resistance to leakage, and related qualities of a brake fluid by running one sample according to the following procedures.

S6.13.1 Summary of the procedure. Brake fluid is stroked under controlled conditions at an elevated temperature in a simulated motor vehicle hydraulic braking system consisting of three slave wheel cylinders and an actuating master cylinder connected by steel tubing. Referee standard parts are used. All parts are carefully cleaned, examined, and certain measurements made immediately prior to assembly for test. During the test, temperature, rate of pressure rise, maximum pressure, and rate of stroking are specified and controlled. The system is examined periodically during stroking to assure that excessive leakage of fluid is not occurring. Afterwards, the system is torn down. Metal parts and SBR cups are examined and remeasured. The brake fluid and any resultant sludge and debris are collected, examined, and tested.

S6.13.2 Apparatus and equipment. Either the drum and shoe type of stroking apparatus (see Figure 1 of SAE Standard J1703b (1970) (incorporated by reference, see §571.5 )), except using only three sets of drum and shoe assemblies, or the stroking fixture type of apparatus as shown in Figure 2 of SAE Standard J1703 NOV83 (incorporated by reference, see §571.5 ) with the components arranged as shown in Figure 1 of SAE Standard J1703 NOV83. The following components are required.

(a) Brake assemblies. With the drum and shoe apparatus: three drum and shoe assembly units (SAE RM–29a) consisting of three forward brake shoes and three reverse brake shoes with linings and three front wheel brake drum assemblies with assembly component parts. With stroking fixture type apparatus: three fixture units including appropriate adapter mounting plates to hold brake wheel cylinder assemblies.

(b) Braking pressure actuation mechanism. An actuating mechanism for applying a force to the master cylinder pushrod without side thrust. The amount of force applied by the actuating mechanism shall be adjustable and capable of applying sufficient thrust to the master cylinder to create a pressure of at least 6895 kPa (1,000 p.s.i.) in the simulated brake system. A hydraulic gage or pressure recorder, having a range of at least 0 to 6895 kPa (0 to 1,000 p.s.i), shall be installed between the master cylinder and the brake assemblies and shall be provided with a shutoff valve and with a bleeding valve for removing air from the connecting tubing. The actuating mechanism shall be designed to permit adjustable stroking rates of approximately 1,000 strokes per hour. Use a mechanical or electrical counter to record the total number of strokes.

(c) Heated air bath cabinet. An insulated cabinet or oven having sufficient capacity to house the three mounted brake assemblies or stroking fixture assemblies, master cylinder, and necessary connections. A thermostatically controlled heating system is required to maintain a temperature of 70° ±5 °C (158° ±9 °F) or 120° ±5 °C (248° ±9 °F). Heaters shall be shielded to prevent direct radiation to wheel or master cylinder.

(d) Master cylinder (MC) assembly (SAE RM–15a). One cast iron housing hydraulic brake system cylinder having a diameter of approximately 28 mm. ( 11/8 inch) and fitted for a filler cap and standpipe (see S6.13.2(e)). The MC piston shall be made from SAE CA360 copperbase alloy (half hard). A new MC assembly is required for each test.

(e) Filler cap and standpipe. MC filler cap provided with a glass or uncoated steel standpipe. Standpipe must provide adequate volume for thermal expansion, yet permit measurement and adjustment of the fluid level in the system to ±3 ml. Cap and standpipe may be cleaned and reused.

(f) Wheel cylinder (WC) assemblies (SAE RM–14a). Three unused cast iron housing straight bore hydraulic brake WC assemblies having diameters of approximately 28 mm ( 11/8 inch) for each test. Pistons shall be made from unanodized SAE AA 2024 aluminum alloy.

(g) Micrometer. Same as S6.6.2(d).

S6.13.3 Materials.

(a) Standard SBR brake cups. Six standard SAE SBR wheel cylinder test cups, one primary MC test cup, and one secondary MC test cup, all as described in S7.6, for each test.

(b) Steel tubing. Double wall steel tubing meeting SAE Standard J527a (1967) (incorporated by reference, see §571.5 ). A complete replacement of tubing is essential when visual inspection indicates any corrosion or deposits on inner surface of tubing. Tubing from master cylinder to one wheel cylinder shall be replaced for each test (minimum length.9 m). Uniformity in tubing size is required between master cylinder and wheel cylinder. The standard master cylinder has two outlets for tubing, both of which must be used.

S6.13.4 Preparation of test apparatus.

(a) Wheel cylinder assemblies. Use unused wheel cylinder assemblies. Disassemble cylinders and discard cups. Clean all metal parts with ethanol (isopropanol when testing DOT 5 fluids). Inspect the working surfaces of all metal parts for scoring, galling, or pitting and cylinder bore roughness, and discard all defective parts. Remove any stains on cylinder walls with crocus cloth and ethanol (isopropanol when testing DOT 5 fluids). If stains cannot be removed, discard the cylinder. Measure the internal diameter of each cylinder at a location approximately 19 mm. (0.75 inch) from each end of the cylinder bore, taking measurements in line with the hydraulic inlet opening and at right angles to this centerline. Discard the cylinder if any of these four readings exceeds the maximum or minimum limits of 28.66 to 28.60 mm. (1.128 to 1.126 inch). Measure the outside diameter of each piston at two points approximately 90° apart. Discard any piston if either reading exceeds the maximum or minimum limits of 28.55 to 28.52 mm. (1.124 to 1.123 inch). Select parts to insure that the clearance between each piston and mating cylinder is within 0.08 to 0.13 mm. (0.003 to 0.005 inch). Use unused SBR cups. To remove dirt and debris, rinse the cups in 90 percent ethyl alcohol for not more than 30 seconds and wipe dry with a clean lint-free cloth. Discard any cups showing defects such as cuts, molding flaws, or blisters. Measure the lip and base diameters of all cups with an optical comparator or micrometer to the nearest 0.02 mm. (0.001 inch) along the centerline of the SAE and rubber-type identifications and at right angles to this centerline. Determine base diameter measurements at least 0.4 mm. (0.015 inch) above the bottom edge and parallel to the base of the cup. Discard any cup if the two measured lip or base diameters differ by more than 0.08 mm.(0.003 inch). Average the lip and base diameters of each cup. Determine the hardness of all cups according to S7.4. Dip the rubber and metal parts of wheel cylinders, except housing and rubber boots, in the fluid to be tested and install them in accordance with the manufacturer’s instructions. Manually stroke the cylinders to insure that they operate easily. Install cylinders in the simulated brake system.

(b) Master cylinder assembly. Use an unused master cylinder and unused standard SBR primary and secondary MC cups which have been inspected, measured and cleaned in the manner specified in S6.13.4(a), omitting hardness of the secondary MC cup. However, prior to determining the lip and base diameters of the secondary cup, dip the cup in test brake fluid, assemble on the MC piston, and maintain the assembly in a vertical position at 23° ±5 °C. (73.4° ±9 °F.) for at least 12 hours. Inspect the relief and supply ports of the master cylinder; discard the cylinder if ports have burrs or wire edges. Measure the internal diameter of the cylinder at two locations (approximately midway between the relief and supply ports and approximately 19 mm. (0.75 inch) beyond the relief port toward the bottom or discharge end of the bore), taking measurements at each location on the vertical and horizontal centerline of the bore. Discard the cylinder if any reading exceeds the maximum or minimum limits of 28.65 to 28.57 mm. (1.128 to 1.125 inch). Measure the outside diameter of each end of the master cylinder piston at two points approximately 90° apart. Discard the piston if any of these four readings exceed the maximum or minimum limits of 28.55 to 28.52 mm. (1.124 to 1.123 inch). Dip the rubber and metal parts of the master cylinder, except the housing and push rod-boot assembly, in the brake fluid and install in accordance with manufacturer’s instructions. Manually stroke the master cylinder to insure that it operates easily. Install the master cylinder in the simulated brake system.

(c) Assembly and adjustment of test apparatus.

(1) When using a shoe and drum type apparatus, adjust the brake shoe toe clearances to 1.0 ±0.1 mm (0.040 ±0.004 inch). Fill the system with brake fluid, bleeding all wheel cylinders and the pressure gage to remove entrapped air. Operate the actuator manually to apply a pressure greater than the required operating pressure and inspect the system for leaks. Adjust the actuator and/or pressure relief valve to obtain a pressure of 6895 kPa ±345 kPa (1,000 ±50 p.s.i.). A smooth pressure stroke pattern is required when using a shoe and drum type apparatus. The pressure is relatively low during the first part of the stroke and then builds up smoothly to the maximum stroking pressure at the end of the stroke, to permit the primary cup to pass the compensating hole at a relatively low pressure. Using stroking fixtures, adjust the actuator and/or pressure relief valve to obtain a pressure of 6895 kPa ±345 kPa (1,000 ±50 p.s.i.).

(2) Adjust the stroking rate to 1,000 ±100 strokes per hour. Record the fluid level in the master cylinder standpipe.

S6.13.5 Procedure. Operate the system for 16,000 ±1,000 cycles at 23° ±5 °C. (73.4° ±9 °F.). Repair any leakage, readjust the brake shoe clearances, and add fluid to the master cylinder standpipe to bring to the level originally recorded, if necessary. Start the test again and raise the temperature of the cabinet within 6 ±2 hours to 120° ±5 °C. (248° ±9 °F.). During the test observe operation of wheel cylinders for improper functioning and record the amount of fluid required to replenish any loss, at intervals of 24,000 strokes. Stop the test at the end of 85,000 total recorded strokes. These totals shall include the number of strokes during operation at 23° ±5 °C. (73.4° ±9 °F.) and the number of strokes required to bring the system to the operating temperature. Allow equipment to cool to room temperature. Examine the wheel cylinders for leakage. Stroke the assembly an additional 100 strokes, examine wheel cylinders for leakage and record volume loss of fluid. Within 16 hours after stopping the test, remove the master and wheel cylinders from the system, retaining the fluid in the cylinders by immediately capping or plugging the ports. Disassemble the cylinders, collecting the fluid from the master cylinder and wheel cylinders in a glass jar. When collecting the stroked fluid, remove all residue which has deposited on rubber and metal internal parts by rinsing and agitating such parts in the stroked fluid and using a soft brush to assure that all loose adhering sediment is collected. Clean SBR cups in ethanol (isopropanol when testing DOT 5 fluids) and dry. Inspect the cups for stickiness, scuffing, blistering, cracking, chipping, and change in shape from original appearance. Within 1 hour after disassembly, measure the lip and base diameters of each cylinder cup by the procedures specified in S6.13.4 (a) and (b) with the exception that lip or base diameters of cups may now differ by more than 0.08 mm. (0.003 inch). Determine the hardness of each cup according to S7.4. Note any sludge or gel present in the test fluid. Within 1 hour after draining the cylinders, agitate the fluid in a glass jar to suspend and uniformly disperse sediment and transfer a 100 ml. portion of this fluid to a centrifuge tube and determine percent sediment as described in S7.5. Allow the tube and fluid to stand for 24 hours, recentrifuge and record any additional sediment recovered. Inspect cylinder parts, note any gumming or any pitting on pistons and cylinder walls. Disregard staining or discoloration. Rub any deposits adhering to cylinder walls with a clean soft cloth wetted with ethanol (isopropanol when testing DOT 5 fluids) to determine abrasiveness and removability. Clean cylinder parts in ethanol (isopropanol when testing DOT 5 fluids) and dry. Measure and record diameters of pistons and cylinders according to S6.13.4(a) and (b). Repeat the test if mechanical failure occurs that may affect the evaluation of the brake fluid.

S6.13.6 Calculation. (a) Calculate the changes in diameters of cylinders and pistons (see S5.1.13(b)).

(b) Calculate the average decrease in hardness of the seven cups tested, as well as the individual values (see S5.1.13(c)).

(c) Calculate the increases in base diameters of the eight cups (see S5.1.13(e)).

(d) Calculate the lip diameter interference set for each of the eight cups by the following formula and average the eight values (see S5.1.13(f)).

|

| where:D 1 = Original lip diameter.D 2 = Final lip diameter.D 3 = Original cylinder bore diameter. |

| where: D 1 =Original lip diameter. D 2 =Final lip diameter. D 3 =Original cylinder bore diameter. |

S6.14 Container information. Each container with information marked directly on the container surface or on a label (labels) affixed to the container pursuant to S5.2.2.2 or S5.2.2.3 is subjected to the following procedure:

(a) If the container has a label affixed to it, make a single vertical cut all the way through the label with the container in the vertical position.

(b) Immerse the container in the same brake fluid or hydraulic system mineral oil contained therein for 15 minutes at room temperature (23 ±5 °C; 73.4 ±9 °F).

(c) Within 5 minutes after removing the container from the fluid or oil, remove excess liquid from the surface of the container by wiping with a clean dry cloth.

S7. Auxiliary test methods and reagent standards.

S7.1 Distilled water. Nonreferee reagent water as specified in ASTM D1193-70 (incorporated by reference, see §571.5 ) or water of equal purity.

S7.2 Water content of motor vehicle brake fluids. Use analytical methods based on ASTM D1123-59 (incorporated by reference, see §571.5 ) for determining the water content of brake fluids, or other methods of analysis yielding comparable results. To be acc3eptable for use, such other method must measure the weight of water added to samples of the SAE RM-66-04 (see Appendix A of SAE Standard J1703 NOV83 (incorporated by reference in §571.5 )) and TEGME Compatibility Fluids (see Appendix B of SAE Standard J1703 JAN95 (incorporated by reference in §571.5 )) within ± 15 percent of the water added for additions up to 0.8 percent by weight, and within ± 5 percent of the water added for additions greater than 0.8 percent by weight. The SAE RM-66-04 Compatibility Fluid used to prepare the samples must have an original ERBP of not less than 205 °C (401 °F) when tested in accordance with S6.1. The SAE TEGME fluid used to prepare the samples must have an original ERBP of not less than 240°C (464°F) when tested in accordance with S6.1.

S7.3 Ethanol. 95 percent (190 proof) ethyl alcohol, USP or ACS, or Formula 3–A Specially Denatured Alcohol of the same concentration (as specified at 27 CFR 21.35). For pretest washings of equipment, use approximately 90 percent ethyl alcohol, obtained by adding 5 parts of distilled water to 95 parts of ethanol.

S7.4 Measuring the hardness of SBR brake cups. Hardness measurements on SBR wheel cylinder cups and master cylinder primary cups shall be made by using the following apparatus and the following procedure.

S7.4.1 Apparatus.

(a) Anvil. A rubber anvil having a flat circular top 20 ±1 mm. ( 13/16 ± 1/16 inch) in diameter, a thickness of at least 9 mm. ( 3/8 inch) and a hardness within 5 IRHDs of the SBR test cup.

(b) Hardness tester. A hardness tester meeting the requirements for the standard instrument as described in ASTM D1415-68 (incorporated by reference, see §571.5 ) and graduated directly in IRHD units.

S7.4.2 Procedure. Make hardness measurements at 23° ±2 °C. (73.4° ±4 °F.). Equilibrate the tester and anvils at this temperature prior to use. Center brake cups lip side down on an anvil of appropriate hardness. Following the manufacturer’s operating instructions for the hardness tester, make one measurement at each of four points 6 mm from the center of the cup and spaced 90° apart. Average the four values, and round off to the nearest IRHD.

S7.5 Sediment by centrifuging. The amount of sediment in the test fluid shall be determined by the following procedure.

S7.5.1 Apparatus.

(a) Centrifuge tube. Cone-shaped centrifuge tubes conforming to the dimensions given in Figure 6, and made of thoroughly annealed glass. The graduations shall be numbered as shown in Figure 6, and shall be clear and distinct. Scale-error tolerances and smallest graduations between various calibration marks are given in Table V and apply to calibrations made with air-free water at 20 °C. (68 °F.).

|

| Fig 6 ASTM 8-in Centrifuge Tube |

| RANGE, ML | SUBDIVISION, ML | VOLUME TOLERANCE, ML |

|---|---|---|

| 0 to 0.1 | 0.05 | ±0.02 |

| Above 0.1 to 0.3 | 0.05 | ±0.03 |

| Above 0.3 to 0.5 | 0.05 | ±0.05 |

| Above 0.5 to 1 | 0.10 | ±0.05 |

| Above 1 to 2 | 0.10 | ±0.10 |

| Above 2 to 3 | 0.20 | ±0.10 |

| Above 3 to 5 | 0.5 | ±0.20 |

| Above 5 to 10 | 1. | ±0.50 |

| Above 10 to 25 | 5. | ±1.00 |

| Above 25 to 100 | 25. | ±1.00 |