['Air Programs']

['Air Quality']

06/06/2024

...

(a) Overview. This test is designed to ensure that the candidate method's losses due to volatility when sampling semi-volatile ambient aerosol will be comparable to that of a federal reference method sampler. This is accomplished by challenging the candidate sampler with a polydisperse, semi-volatile liquid aerosol in three distinct phases. During phase A of this test, the aerosol is elevated to a steady-state, test-specified mass concentration and the sample filters are conditioned and preweighed. In phase B, the challenge aerosol is simultaneously sampled by the candidate method sampler and a reference method sampler onto the preweighed filters for a specified time period. In phase C (the blow-off phase), aerosol and aerosol-vapor free air is sampled by the samplers for an additional time period to partially volatilize the aerosol on the filters. The candidate sampler passes the volatility test if the acceptance criteria presented in table F-1 of this subpart are met or exceeded.

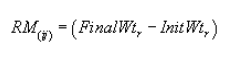

(b) Technical definitions. (1) Residual mass (RM) is defined as the weight of the filter after the blow-off phase subtracted from the initial weight of the filter.

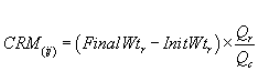

(2) Corrected residual mass (CRM) is defined as the residual mass of the filter from the candidate sampler multiplied by the ratio of the reference method flow rate to the candidate method flow rate.

(c) Facilities and equipment required - (1) Environmental chamber. Because the nature of a volatile aerosol is greatly dependent upon environmental conditions, all phases of this test shall be conducted at a temperature of 22.0 ±0.5°C and a relative humidity of 40 ±3 percent. For this reason, it is strongly advised that all weighing and experimental apparatus be housed in an environmental chamber capable of this level of control.

(2) Aerosol generator. The aerosol generator shall be a pressure nebulizer operated at 20 to 30 psig (140 to 207 kPa) to produce a polydisperse, semi-voltile aerosol with a mass median diameter larger than 1 µm and smaller than 2.5 µm. The nebulized liquid shall be A.C.S. reagent grade glycerol (C3H8O, FW = 92.09, CAS 56-81-5) of 99.5 percent minimum purity. For the purpose of this test the accepted mass median diameter is predicated on the stable aerosol inside the internal chamber and not on the aerosol emerging from the nebulizer nozzle. Aerosol monitoring and its stability are described in (c)(3) and (c)(4) of this section.

(3) Aerosol monitoring equipment. The evaporation and condensation dynamics of a volatile aerosol is greatly dependent upon the vapor pressure of the volatile component in the carrier gas. The size of an aerosol becomes fixed only when an equilibrium is established between the aerosol and the surrounding vapor; therefore, aerosol size measurement shall be used as a surrogate measure of this equilibrium. A suitable instrument with a range of 0.3 to 10 µm, an accuracy of 0.5 µm, and a resolution of 0.2 µm (e.g., an optical particle sizer, or a time-of-flight instrument) shall be used for this purpose. The parameter monitored for stability shall be the mass median instrument measured diameter (i.e. optical diameter if an optical particle counter is used). A stable aerosol shall be defined as an aerosol with a mass median diameter that has changed less than 0.25 µm over a 4 hour time period.

(4) Internal chamber. The time required to achieve a stable aerosol depends upon the time during which the aerosol is resident with the surrounding air. This is a function of the internal volume of the aerosol transport system and may be facilitated by recirculating the challenge aerosol. A chamber with a volume of 0.5 m 3 and a recirculating loop (airflow of approximately 500 cfm) is recommended for this purpose. In addition, a baffle is recommended to dissipate the jet of air that the recirculating loop can create. Furthermore, a HEPA filtered hole in the wall of the chamber is suggested to allow makeup air to enter the chamber or excess air to exit the chamber to maintain a system flow balance. The concentration inside the chamber shall be maintained at 1 mg/m 3 ±20 percent to obtain consistent and significant filter loading.

(5) Aerosol sampling manifold. A manifold shall be used to extract the aerosol from the area in which it is equilibrated and transport it to the candidate method sampler, the reference method sampler, and the aerosol monitor. The losses in each leg of the manifold shall be equivalent such that the three devices will be exposed to an identical aerosol.

(6) Chamber air temperature recorders. Minimum range 15-25°C, certified accuracy to within 0.2°C, resolution of 0.1°C. Measurement shall be made at the intake to the sampling manifold and adjacent to the weighing location.

(7) Chamber air relative humidity recorders. Minimum range 30 - 50 percent, certified accuracy to within 1 percent, resolution of 0.5 percent. Measurement shall be made at the intake to the sampling manifold and adjacent to the weighing location.

(8) Clean air generation system. A source of aerosol and aerosol-vapor free air is required for phase C of this test. This clean air shall be produced by filtering air through an absolute (HEPA) filter.

(9) Balance. Minimum range 0 - 200 mg, certified accuracy to within 10 µg, resolution of 1 µg.

(d) Additional filter handling conditions - (1) Filter handling. Careful handling of the filter during sampling, conditioning, and weighing is necessary to avoid errors due to damaged filters or loss of collected particles from the filters. All filters must be weighed immediately after phase A dynamic conditioning and phase C.

(2) Dynamic conditioning of filters. Total dynamic conditioning is required prior to the initial weight determined in phase A. Dynamic conditioning refers to pulling clean air from the clean air generation system through the filters. Total dynamic conditioning can be established by sequential filter weighing every 30 minutes following repetitive dynamic conditioning. The filters are considered sufficiently conditioned if the sequential weights are repeatable to ±3 µg.

(3) Static charge. The following procedure is suggested for minimizing charge effects. Place six or more Polonium static control devices (PSCD) inside the microbalance weighing chamber, (MWC). Two of them must be placed horizontally on the floor of the MWC and the remainder placed vertically on the back wall of the MWC. Taping two PSCD's together or using double-sided tape will help to keep them from falling. Place the filter that is to be weighed on the horizontal PSCDs facing aerosol coated surface up. Close the MWC and wait 1 minute. Open the MWC and place the filter on the balance dish. Wait 1 minute. If the charges have been neutralized the weight will stabilize within 30-60 seconds. Repeat the procedure of neutralizing charges and weighing as prescribed above several times (typically 2-4 times) until consecutive weights will differ by no more than 3 micrograms. Record the last measured weight and use this value for all subsequent calculations.

(e) Test procedure - (1) Phase A - Preliminary steps. (i) Generate a polydisperse glycerol test aerosol.

(ii) Introduce the aerosol into the transport system.

(iii) Monitor the aerosol size and concentration until stability and level have been achieved.

(iv) Condition the candidate method sampler and reference method sampler filters until total dynamic conditioning is achieved as specified in paragraph (d)(2) of this section.

(v) Record the dynamically conditioned weight as InitWtc and InitWtr where c is the candidate method sampler and r is the reference method sampler.

(2) Phase B - Aerosol loading. (i) Install the dynamically conditioned filters into the appropriate samplers.

(ii) Attach the samplers to the manifold.

(iii) Operate the candidate and the reference samplers such that they simultaneously sample the test aerosol for 2 hours for a candidate sampler operating at 16.7 L/min or higher, or proportionately longer for a candidate sampler operating at a lower flow rate.

(3) Phase C - Blow-off. (i) Alter the intake of the samplers to sample air from the clean air generation system.

(ii) Sample clean air for one of the required blow-off time durations (1, 2, 3, and 4 hours).

(iii) Remove the filters from the samplers.

(iv) Weigh the filters immediately and record this weight, FinalWtc and FinalWtr, where c is the candidate method sampler and r is the reference method sampler.

(v) Calculate the residual mass for the reference method sampler:

Equation 41a

where:

i = repetition number; and

j = blow-off time period.

(vi) Calculate the corrected residual mass for the candidate method sampler as:

Equation 41b

where:

i = repetition number;

j = blow-off time period;

Qc = candidate method sampler flow rate, and

Qr = reference method sampler flow rate.

(4) Repeat steps in paragraph (e)(1) through (e)(3) of this section until three repetitions have been completed for each of the required blow-off time durations (1, 2, 3, and 4 hours).

(f) Calculations and analysis. (1) Perform a linear regression with the candidate method CRM as the dependent variable and the reference method RM as the independent variable.

(2) Determine the following regression parameters: slope, intercept, and correlation coefficient (r).

(g) Test results. The candidate method passes the volatility test if the regression parameters meet the acceptance criteria specified in table F-1 of this subpart.

[62 FR 38814, July 18, 1997, as amended at 71 FR 61295, Oct. 17, 2006]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.