['Air Programs']

['Air Quality']

06/06/2024

...

(a) Overview. This test is intended to determine the operational precision of the candidate sampler during a minimum of 10 days of field operation, using three collocated test samplers. Measurements of PM are made at a test site with all of the samplers and then compared to determine replicate precision. Candidate sequential samplers are also subject to a test for possible deposition of particulate matter on inactive filters during a period of storage in the sampler. This procedure is applicable to both reference and equivalent methods. In the case of equivalent methods, this test may be combined and conducted concurrently with the comparability test for equivalent methods (described in Subpart C of this part), using three reference method samplers collocated with three candidate equivalent method samplers and meeting the applicable site and other requirements of Subpart C of this part.

(b) Technical definition. (1) Field precision is defined as the standard deviation or relative standard deviation of a set of PM measurements obtained concurrently with three or more collocated samplers in actual ambient air field operation.

(2) Storage deposition is defined as the mass of material inadvertently deposited on a sample filter that is stored in a sequential sampler either prior to or subsequent to the active sample collection period.

(c) Test site. Any outdoor test site having PM 2.5 (or PM 10-2.5, as applicable) concentrations that are reasonably uniform over the test area and that meet the minimum level requirement of paragraph (g)(2) of this section is acceptable for this test.

(d) Required facilities and equipment. (1) An appropriate test site and suitable electrical power to accommodate three test samplers are required.

(2) Teflon sample filters, as specified in section 6 of 40 CFR part 50, appendix L, conditioned and preweighed as required by section 8 of 40 CFR part 50, appendix L, as needed for the test samples.

(e) Test setup. (1) Three identical test samplers shall be installed at the test site in their normal configuration for collecting PM samples in accordance with the instructions in the associated manual referred to in §53.4(b)(3) and also in accordance with applicable supplemental guidance provided in reference 3 in appendix A of this subpart. The test samplers' inlet openings shall be located at the same height above ground and between 2 (1 for samplers with flow rates less than 200 L/min.) and 4 meters apart horizontally. The samplers shall be arranged or oriented in a manner that will minimize the spatial and wind directional effects on sample collection of one sampler on any other sampler.

(2) Each test sampler shall be successfully leak checked, calibrated, and set up for normal operation in accordance with the instruction manual and with any applicable supplemental guidance provided in reference 3 in appendix A of this subpart.

(f) Test procedure. (1) Install a conditioned, preweighed filter in each test sampler and otherwise prepare each sampler for normal sample collection. Set identical sample collection start and stop times for each sampler. For sequential samplers, install a conditioned, preweighed specified filter in each available channel or station intended for automatic sequential sample filter collection (or at least five additional filters for magazine-type sequential samplers), as directed by the sampler's operation or instruction manual. Since the inactive sequential channels are used for the storage deposition part of the test, they may not be used to collect the active PM test samples.

(2) Collect either a nominal 24-hour or 48-hour atmospheric PM sample simultaneously with each of the three test samplers.

(3) Following sample collection, retrieve the collected sample from each sampler. For sequential samplers, retrieve the additional stored (blank, unsampled) filters after at least 5 days (120 hours) storage in the sampler if the active samples are 24-hour samples, or after at least 10 days (240 hours) if the active samples are 48-hour samples.

(4) Determine the measured PM mass concentration for each sample in accordance with the applicable procedures prescribed for the candidate method in appendix L or appendix O, as applicable, of part 50 of this chapter, and in accordance with the associated manual referred to in §53.4(b)(3) and supplemental guidance in reference 2 in appendix A of this subpart. For sequential samplers, also similarly determine the storage deposition as the net weight gain of each blank, unsampled filter after the 5-day (or 10-day) period of storage in the sampler.

(5) Repeat this procedure to obtain a total of 10 sets of any combination of (nominal) 24-hour or 48-hour PM measurements over 10 test periods. For sequential samplers, repeat the 5-day (or 10-day) storage test of additional blank filters once for a total of two sets of blank filters.

(g) Calculations. (1) Record the PM concentration for each test sampler for each test period as Ci,j, where i is the sampler number (i = 1,2,3) and j is the test period (j = 1,2, * * * 10).

(2)(i) For each test period, calculate and record the average of the three measured PM concentrations as Cave,j where j is the test period using equation 26 of this section:

(ii) If Cave,j <3 µg/m 3 for any test period, data from that test period are unacceptable, and an additional sample collection set must be obtained to replace the unacceptable data.

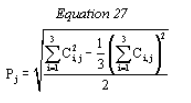

(3)(i) Calculate and record the precision for each of the 10 test periods, as the standard deviation, using equation 27 of this section:

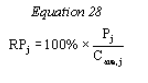

(ii) For each of the 10 test periods, also calculate and record the precision as the relative standard deviation, in percent, using equation 28 of this section:

(h) Test results. (1) The candidate method passes the precision test if either Pj or RPj is less than or equal to the corresponding specification in table E-1 of this subpart for all 10 test periods.

(2) The candidate sequential sampler passes the blank filter storage deposition test if the average net storage deposition weight gain of each set of blank filters (total of the net weight gain of each blank filter divided by the number of filters in the set) from each test sampler (six sets in all) is less than 50 µg.

[71 FR 61292, Oct. 17, 2006,as amended at 72 FR 32208, June 12, 2007]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.