['Air Programs']

['Air Quality']

08/02/2023

...

(a) Definitions. All terms not defined in this paragraph (a) shall have the meaning given to them in the Act and in subpart A of 40 CFR part 60.

Affected unit means a cement kiln meeting the applicability criteria of this section.

Cement kiln means an installation, including any associated pre-heater or pre-calciner devices, that produces clinker by heating limestone and other materials to produce Portland cement.

Cement plant means any facility manufacturing cement by either the wet or dry process.

Clinker means the product of a cement kiln from which finished cement is manufactured by milling and grinding.

Operating day means a 24-hour period beginning at 12:00 midnight during which the kiln produces clinker at any time.

(b) Applicability. You are subject to the requirements of this section if you own or operate a new or existing cement kiln that emits or has the potential to emit 100 tons per year or more of NO X on or after August 4, 2023, and is located within any of the States listed in §52.40(c)(2), including Indian country located within the borders of any such State(s). Any existing cement kiln with a potential to emit of 100 tons per year or more of NO X on August 4, 2023, will continue to be subject to the requirements of this section even if that unit later becomes subject to a physical or operational limitation that lowers its potential to emit below 100 tons per year of NO X.

(c) Emissions limitations. If you are the owner or operator of an affected unit, you must meet the following emissions limitations on a 30-day rolling average basis during the 2026 ozone season and in each ozone season thereafter:

(1) Long wet kilns: 4.0 lb/ton of clinker;

(2) Long dry kilns: 3.0 lb/ton of clinker;

(3) Preheater kilns: 3.8 lb/ton of clinker;

(4) Precalciner kilns: 2.3 lb/ton of clinker; and

(5) Preheater/Precalciner kilns: 2.8 lb/ton of clinker.

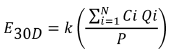

(d) Testing and monitoring requirements. (1) If you are the owner or operator of an affected unit you must conduct performance tests, on an annual basis, in accordance with the applicable reference test methods of 40 CFR part 60, appendix A–4, any alternative test method approved by the EPA as of June 5, 2023, under 40 CFR 59.104(f), 60.8(b)(3), 61.13(h)(1)(ii), 63.7(e)(2)(ii), or 65.158(a)(2) and available at the EPA's website (https://www.epa.gov/emc/broadly-applicable-approved-alternative-test-methods), or other methods and procedures approved by the EPA through notice-and-comment rulemaking. The annual performance test does not have to be performed during the ozone season. You must calculate and record the 30-operating day rolling average emissions rate of NO X as the total of all hourly emissions data for a cement kiln in the preceding 30 days, divided by the total tons of clinker produced in that kiln during the same 30-operating day period, using equation 1 to this paragraph (d)(1):

Equation 1 to Paragraph (d)(1)

Where:

E 30D = 30 kiln operating day average emissions rate of NO X, in lbs/ton of clinker.

Ci = Concentration of NO X for hour i, in ppm.

Qi = Volumetric flow rate of effluent gas for hour i, where Ci and Qi are on the same basis (either wet or dry), in scf/hr.

P = 30 days of clinker production during the same Time period as the NO X emissions measured, in tons.

k = Conversion factor, 1.194 × 10?7 for NO X, in lb/scf/ppm.

n = Number of kiln operating hours over 30 kiln operating days.

(2) If you are the owner or operator of an affected unit and are operating a NO X continuous emissions monitoring system (CEMS) that monitors NO X emissions from the affected unit, you may use the CEMS data in lieu of the annual performance tests and parametric monitoring required under this section. You must meet the following requirements for using CEMS to monitor NO X emissions:

(i) You shall install, calibrate, maintain, and operate a continuous emissions monitoring system (CEMS) for measuring NO X emissions and either oxygen (O 2) or carbon dioxide (CO 2).

(ii) The CEMS shall be operated and data recorded during all periods of operation during the ozone season of the affected unit except for CEMS breakdowns and repairs. Data shall be recorded during calibration checks and zero and span adjustments.

(iii) The 1-hour average NO X emissions rates measured by the CEMS shall be expressed in terms of lbs/ton of clinker and shall be used to calculate the average emissions rates to demonstrate compliance with the applicable emissions limits in this section.

(iv) The procedures under 40 CFR 60.13 shall be followed for installation, evaluation, and operation of the continuous monitoring systems.

(v) When NO X emissions data are not obtained because of CEMS breakdowns, repairs, calibration checks and zero and span adjustments, emissions data will be obtained by using standby monitoring systems, Method 7 of 40 CFR part 60, appendix A–4, Method 7A of 40 CFR part 60, appendix A–4, or other approved reference methods to provide emissions data for a minimum of 75 percent of the operating hours in each affected unit operating day, in at least 22 out of 30 successive operating days.

(3) If you are the owner or operator of an affected unit not operating NO X CEMS, you must conduct an initial performance test before the 2026 ozone season to establish appropriate indicator ranges for operating parameters and continuously monitor those operator parameters consistent with the requirements of paragraphs (d)(3)(i) through (v) of this section.

(i) You must monitor and record kiln stack exhaust gas flow rate, hourly clinker production rate or kiln feed rate, and kiln stack exhaust temperature during the initial performance test and subsequent annual performance tests to demonstrate continuous compliance with your NO X emissions limits.

(ii) You must determine hourly clinker production by one of two methods:

(A) Install, calibrate, maintain, and operate a permanent weigh scale system to record weight rates of the amount of clinker produced in tons of mass per hour. The system of measuring hourly clinker production must be maintained within ±5 percent accuracy; or

(B) Install, calibrate, maintain, and operate a permanent weigh scale system to measure and record weight rates of the amount of feed to the kiln in tons of mass per hour. The system of measuring feed must be maintained within ±5 percent accuracy. Calculate your hourly clinker production rate using a kiln specific feed-to-clinker ratio based on reconciled clinker production rates determined for accounting purposes and recorded feed rates. This ratio should be updated monthly. Note that if this ratio changes at clinker reconciliation, you must use the new ratio going forward, but you do not have to retroactively change clinker production rates previously estimated.

(C) For each kiln operating hour for which you do not have data on clinker production or the amount of feed to the kiln, use the value from the most recent previous hour for which valid data are available.

(D) If you measure clinker production directly, record the daily clinker production rates; if you measure the kiln feed rates and calculate clinker production, record the daily kiln feed and clinker production rates.

(iii) You must use the kiln stack exhaust gas flow rate, hourly kiln production rate or kiln feed rate, and kiln stack exhaust temperature during the initial performance test and subsequent annual performance tests as indicators of NO X operating parameters to demonstrate continuous compliance and establish site-specific indicator ranges for these operating parameters.

(iv) You must repeat the performance test annually to reassess and adjust the site-specific operating parameter indicator ranges in accordance with the results of the performance test.

(v) You must report and include your ongoing site-specific operating parameter data in the annual reports required under paragraph (e) of this section and semi-annual title V monitoring reports to the relevant permitting authority.

(e) Recordkeeping requirements. If you are the owner or operator of an affected unit, you shall maintain records of the following information for each day the affected unit operates:

(1) Calendar date;

(2) The average hourly NO X emissions rates measured or predicted;

(3) The 30-day average NO X emissions rates calculated at the end of each affected unit operating day from the measured or predicted hourly NO X emissions rates for the preceding 30 operating days;

(4) Identification of the affected unit operating days when the calculated 30-day average NO X emissions rates are in excess of the applicable site-specific NO X emissions limit with the reasons for such excess emissions as well as a description of corrective actions taken;

(5) Identification of the affected unit operating days for which pollutant data have not been obtained, including reasons for not obtaining sufficient data and a description of corrective actions taken;

(6) Identification of the times when emissions data have been excluded from the calculation of average emissions rates and the reasons for excluding data;

(7) If a CEMS is used to verify compliance:

(i) Identification of the times when the pollutant concentration exceeded full span of the CEMS;

(ii) Description of any modifications to the CEMS that could affect the ability of the CEMS to comply with Performance Specification 2 or 3 in appendix B to 40 CFR part 60; and

(iii) Results of daily CEMS drift tests and quarterly accuracy assessments as required under Procedure 1 of 40 CFR part 60, appendix F;

(8) Operating parameters required under paragraph (d) of this section to demonstrate compliance during the ozone season;

(9) Each fuel type, usage, and heat content; and

(10) Clinker production rates.

(f) Reporting requirements. (1) If you are the owner or operator of an affected unit, you shall submit the results of the performance test or performance evaluation of the CEMS following the procedures specified in §52.40(g) within 60 days after the date of completing each performance test required by this section.

(2) If you are the owner or operator of an affected unit, you are required to submit excess emissions reports for any excess emissions that occurred during the reporting period. Excess emissions are defined as any calculated 30-day rolling average NO X emissions rate that exceeds the applicable emissions limit established under paragraph (c) of this section. Excess emissions reports must be submitted in PDF format to the EPA via CEDRI or analogous electronic reporting approach provided by the EPA to report data required by this section following the procedures specified in §52.40(g).

(3) If you are the owner or operator of an affected unit, you shall submit an annual report in PDF format to the EPA by January 30th of each year via CEDRI or analogous electronic reporting approach provided by the EPA to report data required by this section. Annual reports shall be submitted following the procedures in §52.40(g). The report shall include records all records required by paragraph (d) of this section, including record of CEMS data or operating parameters required by paragraph (d) to demonstrate continuous compliance the applicable emissions limits under paragraph (c) of this section.

(g) Initial notification requirements for existing affected units. (1) The requirements of this paragraph (g) apply to the owner or operator of an existing affected unit.

(2) The owner or operator of an existing affected unit that emits or has a potential to emit 100 tons per year or greater as of August 4, 2023, shall notify the Administrator via the CEDRI or analogous electronic submission system provided by the EPA that the unit is subject to this section. The notification, which shall be submitted not later than December 4, 2023, shall be submitted in PDF format to the EPA via CEDRI, which can be accessed through the EPA's CDX (https://cdx.epa.gov/). The notification shall provide the following information:

(i) The name and address of the owner or operator;

(ii) The address (i.e., physical location) of the affected unit;

(iii) An identification of the relevant standard, or other requirement, that is the basis for the notification and the unit's compliance date; and

(iv) A brief description of the nature, size, design, and method of operation of the facility and an identification of the types of emissions points (units) within the facility subject to the relevant standard.

[88 FR 36869, June 5, 2023]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.