...

(a) Scope. (1) Applicability. This section covers the requirements for electric equipment and wiring in locations that are classified depending on the properties of the flammable vapors, liquids or gases, or combustible dusts or fibers that may be present therein and the likelihood that a flammable or combustible concentration or quantity is present. Hazardous (classified) locations may be found in occupancies such as, but not limited to, the following: aircraft hangars, gasoline dispensing and service stations, bulk storage plants for gasoline or other volatile flammable liquids, paint-finishing process plants, health care facilities, agricultural or other facilities where excessive combustible dusts may be present, marinas, boat yards, and petroleum and chemical processing plants. Each room, section or area shall be considered individually in determining its classification.

(2) Classifications. (i) These hazardous (classified) locations are assigned the following designations:

(A) Class I, Division 1

(B) Class I, Division 2

(C) Class I, Zone 0

(D) Class I, Zone 1

(E) Class I, Zone 2

(F) Class II, Division 1

(G) Class II, Division 2

(H) Class III, Division 1

(I) Class III, Division 2

(ii) For definitions of these locations, see §1910.399.

(3) Other sections of this subpart. All applicable requirements in this subpart apply to hazardous (classified) locations unless modified by provisions of this section.

(4) Division and zone classification. In Class I locations, an installation must be classified as using the division classification system meeting paragraphs (c), (d), (e), and (f) of this section or using the zone classification system meeting paragraph (g) of this section. In Class II and Class III locations, an installation must be classified using the division classification system meeting paragraphs (c), (d), (e), and (f) of this section.

(b) Documentation. All areas designated as hazardous (classified) locations under the Class and Zone system and areas designated under the Class and Division system established after August 13, 2007 shall be properly documented. This documentation shall be available to those authorized to design, install, inspect, maintain, or operate electric equipment at the location.

(c) Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified) locations shall be intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location. Requirements for each of these options are as follows:

(1) Intrinsically safe. Equipment and associated wiring approved as intrinsically safe is permitted in any hazardous (classified) location for which it is approved;

(2) Approved for the hazardous (classified) location. (i) Equipment shall be approved not only for the class of location, but also for the ignitable or combustible properties of the specific gas, vapor, dust, or fiber that will be present.

Note to paragraph (c)(2)(i) of this section: NFPA 70, the National Electrical Code, lists or defines hazardous gases, vapors, and dusts by “Groups” characterized by their ignitable or combustible properties.

(ii) Equipment shall be marked to show the class, group, and operating temperature or temperature range, based on operation in a 40-degree C ambient, for which it is approved. The temperature marking may not exceed the ignition temperature of the specific gas or vapor to be encountered. However, the following provisions modify this marking requirement for specific equipment:

(A) Equipment of the nonheat-producing type, such as junction boxes, conduit, and fittings, and equipment of the heat-producing type having a maximum temperature not more than 100°C (212°F) need not have a marked operating temperature or temperature range;

(B) Fixed lighting fixtures marked for use in Class I, Division 2 or Class II, Division 2 locations only need not be marked to indicate the group;

(C) Fixed general-purpose equipment in Class I locations, other than lighting fixtures, that is acceptable for use in Class I, Division 2 locations need not be marked with the class, group, division, or operating temperature;

(D) Fixed dust-tight equipment, other than lighting fixtures, that is acceptable for use in Class II, Division 2 and Class III locations need not be marked with the class, group, division, or operating temperature; and

(E) Electric equipment suitable for ambient temperatures exceeding 40°C (104°F) shall be marked with both the maximum ambient temperature and the operating temperature or temperature range at that ambient temperature; and

(3) Safe for the hazardous (classified) location. Equipment that is safe for the location shall be of a type and design that the employer demonstrates will provide protection from the hazards arising from the combustibility and flammability of vapors, liquids, gases, dusts, or fibers involved.

Note to paragraph (c)(3) of this section: The National Electrical Code, NFPA 70, contains guidelines for determining the type and design of equipment and installations that will meet this requirement. Those guidelines address electric wiring, equipment, and systems installed in hazardous (classified) locations and contain specific provisions for the following: wiring methods, wiring connections; conductor insulation, flexible cords, sealing and drainage, transformers, capacitors, switches, circuit breakers, fuses, motor controllers, receptacles, attachment plugs, meters, relays, instruments, resistors, generators, motors, lighting fixtures, storage battery charging equipment, electric cranes, electric hoists and similar equipment, utilization equipment, signaling systems, alarm systems, remote control systems, local loud speaker and communication systems, ventilation piping, live parts, lightning surge protection, and grounding.

(d) Conduits. All conduits shall be threaded and shall be made wrench-tight. Where it is impractical to make a threaded joint tight, a bonding jumper shall be utilized.

(e) Equipment in Division 2 locations. Equipment that has been approved for a Division 1 location may be installed in a Division 2 location of the same class and group. General-purpose equipment or equipment in general-purpose enclosures may be installed in Division 2 locations if the employer can demonstrate that the equipment does not constitute a source of ignition under normal operating conditions.

(f) Protection techniques. The following are acceptable protection techniques for electric and electronic equipment in hazardous (classified) locations.

(1) Explosion-proof apparatus. This protection technique is permitted for equipment in the Class I, Division 1 and 2 locations for which it is approved.

(2) Dust ignition-proof. This protection technique is permitted for equipment in the Class II, Division 1 and 2 locations for which it is approved.

(3) Dust-tight. This protection technique is permitted for equipment in the Class II, Division 2 and Class III locations for which it is approved.

(4) Purged and pressurized. This protection technique is permitted for equipment in any hazardous (classified) location for which it is approved.

(5) Nonincendive circuit. This protection technique is permitted for equipment in Class I, Division 2; Class II, Division 2; or Class III, Division 1or 2 locations.

(6) Nonincendive equipment. This protection technique is permitted for equipment in Class I, Division 2; Class II, Division 2; or Class III, Division 1 or 2 locations.

(7) Nonincendive component. This protection technique is permitted for equipment in Class I, Division 2; Class II, Division 2; or Class III, Division 1 or 2 locations.

(8) Oil immersion. This protection technique is permitted for current-interrupting contacts in Class I, Division 2 locations as described in the Subpart.

(9) Hermetically sealed. This protection technique is permitted for equipment in Class I, Division 2; Class II, Division 2; and Class III, Division 1 or 2 locations.

(10) Other protection techniques. Any other protection technique that meets paragraph (c) of this section is acceptable in any hazardous (classified) location.

(g) Class I, Zone 0, 1, and 2 locations. (1) Scope. Employers may use the zone classification system as an alternative to the division classification system for electric and electronic equipment and wiring for all voltage in Class I, Zone 0, Zone 1, and Zone 2 hazardous (classified) locations where fire or explosion hazards may exist due to flammable gases, vapors, or liquids.

(2) Location and general requirements. (i) Locations shall be classified depending on the properties of the flammable vapors, liquids, or gases that may be present and the likelihood that a flammable or combustible concentration or quantity is present. Where pyrophoric materials are the only materials used or handled, these locations need not be classified.

(ii) Each room, section, or area shall be considered individually in determining its classification.

(iii) All threaded conduit shall be threaded with an NPT (National (American) Standard Pipe Taper) standard conduit cutting die that provides 3/4 -in. taper per foot. The conduit shall be made wrench tight to prevent sparking when fault current flows through the conduit system and to ensure the explosion proof or flameproof integrity of the conduit system where applicable.

(iv) Equipment provided with threaded entries for field wiring connection shall be installed in accordance with paragraph (g)(2)(iv)(A) or (g)(2)(iv)(B) of this section.

(A) For equipment provided with threaded entries for NPT threaded conduit or fittings, listed conduit, conduit fittings, or cable fittings shall be used.

(B) For equipment with metric threaded entries, such entries shall be identified as being metric, or listed adaptors to permit connection to conduit of NPT-threaded fittings shall be provided with the equipment. Adapters shall be used for connection to conduit or NPT-threaded fittings.

(3) Protection techniques. One or more of the following protection techniques shall be used for electric and electronic equipment in hazardous (classified) locations classified under the zone classification system.

(i) Flameproof “d”—This protection technique is permitted for equipment in the Class I, Zone 1 locations for which it is approved.

(ii) Purged and pressurized—This protection technique is permitted for equipment in the Class I, Zone 1 or Zone 2 locations for which it is approved.

(iii) Intrinsic safety—This protection technique is permitted for equipment in the Class I, Zone 0 or Zone 1 locations for which it is approved.

(iv) Type of protection “n”—This protection technique is permitted for equipment in the Class I, Zone 2 locations for which it is approved. Type of protection “n” is further subdivided into nA, nC, and nR.

(v) Oil Immersion “o”—This protection technique is permitted for equipment in the Class I, Zone 1 locations for which it is approved.

(vi) Increased safety “e”—This protection technique is permitted for equipment in the Class I, Zone 1 locations for which it is approved.

(vii) Encapsulation “m”—This protection technique is permitted for equipment in the Class I, Zone 1 locations for which it is approved.

(viii) Powder Filling “q”—This protection technique is permitted for equipment in the Class I, Zone 1 locations for which it is approved.

(4) Special precaution. Paragraph (g) of this section requires equipment construction and installation that will ensure safe performance under conditions of proper use and maintenance.

(i) Classification of areas and selection of equipment and wiring methods shall be under the supervision of a qualified registered professional engineer.

(ii) In instances of areas within the same facility classified separately, Class I, Zone 2 locations may abut, but not overlap, Class I, Division 2 locations. Class I, Zone 0 or Zone 1 locations may not abut Class I, Division 1 or Division 2 locations.

(iii) A Class I, Division 1 or Division 2 location may be reclassified as a Class I, Zone 0, Zone 1, or Zone 2 location only if all of the space that is classified because of a single flammable gas or vapor source is reclassified.

Note to paragraph (g)(4) of this section: Low ambient conditions require special consideration. Electric equipment depending on the protection techniques described by paragraph (g)(3)(i) of this section may not be suitable for use at temperatures lower than ?20°C (?4°F) unless they are approved for use at lower temperatures. However, at low ambient temperatures, flammable concentrations of vapors may not exist in a location classified Class I, Zone 0, 1, or 2 at normal ambient temperature.

(5) Listing and marking. (i) Equipment that is listed for a Zone 0 location may be installed in a Zone 1 or Zone 2 location of the same gas or vapor. Equipment that is listed for a Zone 1 location may be installed in a Zone 2 location of the same gas or vapor.

(ii) Equipment shall be marked in accordance with paragraph (g)(5)(ii)(A) and (g)(5)(ii)(B) of this section, except as provided in (g)(5)(ii)(C).

(A) Equipment approved for Class I, Division 1 or Class 1, Division 2 shall, in addition to being marked in accordance with (c)(2)(ii), be marked with the following:

(1) Class I, Zone 1 or Class I, Zone 2 (as applicable);

(2) Applicable gas classification groups; and

(3) Temperature classification; or

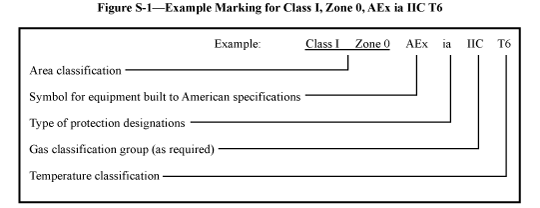

(B) Equipment meeting one or more of the protection techniques described in paragraph (g)(3) of this section shall be marked with the following in the order shown:

(1) Class, except for intrinsically safe apparatus;

(2) Zone, except for intrinsically safe apparatus;

(3) Symbol “AEx;”

(4) Protection techniques;

(5) Applicable gas classification groups; and

(6) Temperature classification, except for intrinsically safe apparatus.

Note to paragraph (g)(5)(ii)(B) of this section: An example of such a required marking is “Class I, Zone 0, AEx ia IIC T6.” See Figure S–1 for an explanation of this marking.

(C) Equipment that the employer demonstrates will provide protection from the hazards arising from the flammability of the gas or vapor and the zone of location involved and will be recognized as providing such protection by employees need not be marked.

Note to paragraph (g)(5)(ii)(C) of this section: The National Electrical Code, NFPA 70, contains guidelines for determining the type and design of equipment and installations that will meet this provision.

[46 FR 4056, Jan. 16, 1981; 46 FR 40185, Aug. 7, 1981; 72 FR 7210, Feb. 14, 2007]