...

(a) Definitions applicable to this section. (1) A

derrick

is an apparatus consisting of a mast or equivalent member held at the head by guys or braces, with or without a boom, for use with a hoisting mechanism and operating ropes.

(2)

A-frame derrick

means a derrick in which the boom is hinged from a cross member between the bottom ends of two upright members spread apart at the lower ends and joined at the top; the boom point secured to the junction of the side members, and the side members are braced or guyed from this junction point.

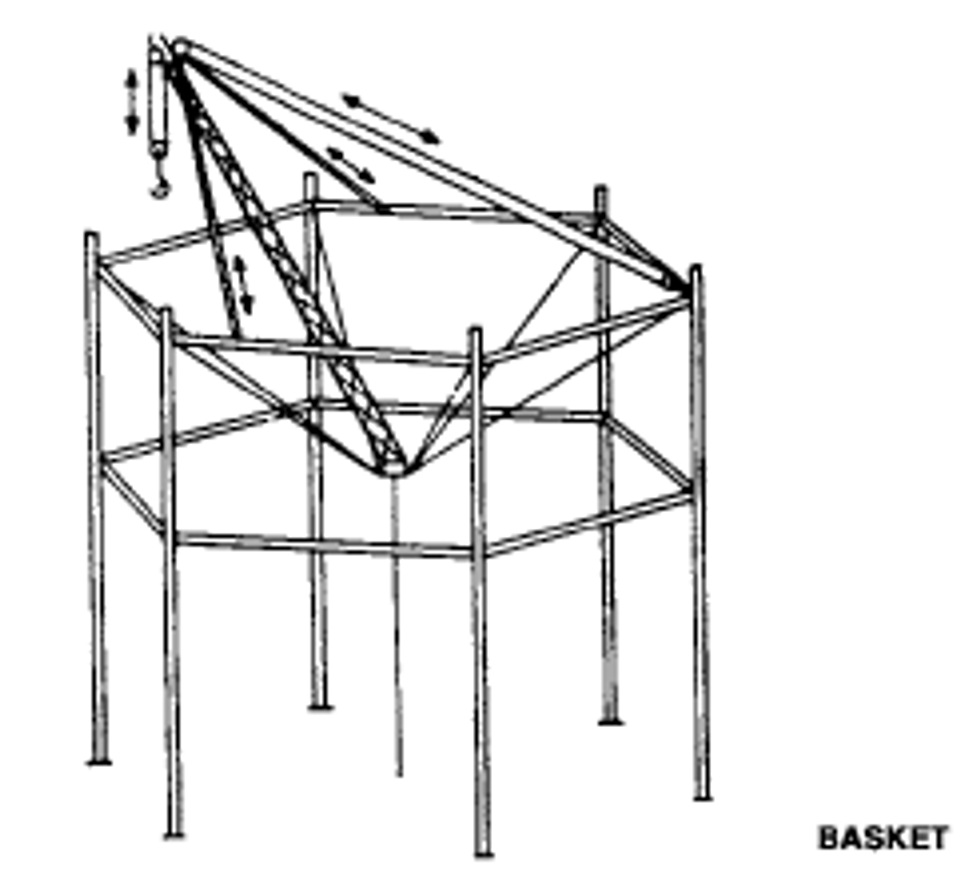

(3) A

basket derrick

is a derrick without a boom, similar to a gin pole, with its base supported by ropes attached to corner posts or other parts of the structure. The base is at a lower elevation than its supports. The location of the base of a basket derrick can be changed by varying the length of the rope supports. The top of the pole is secured with multiple reeved guys to position the top of the pole to the desired location by varying the length of the upper guy lines. The load is raised and lowered by ropes through a sheave or block secured to the top of the pole.

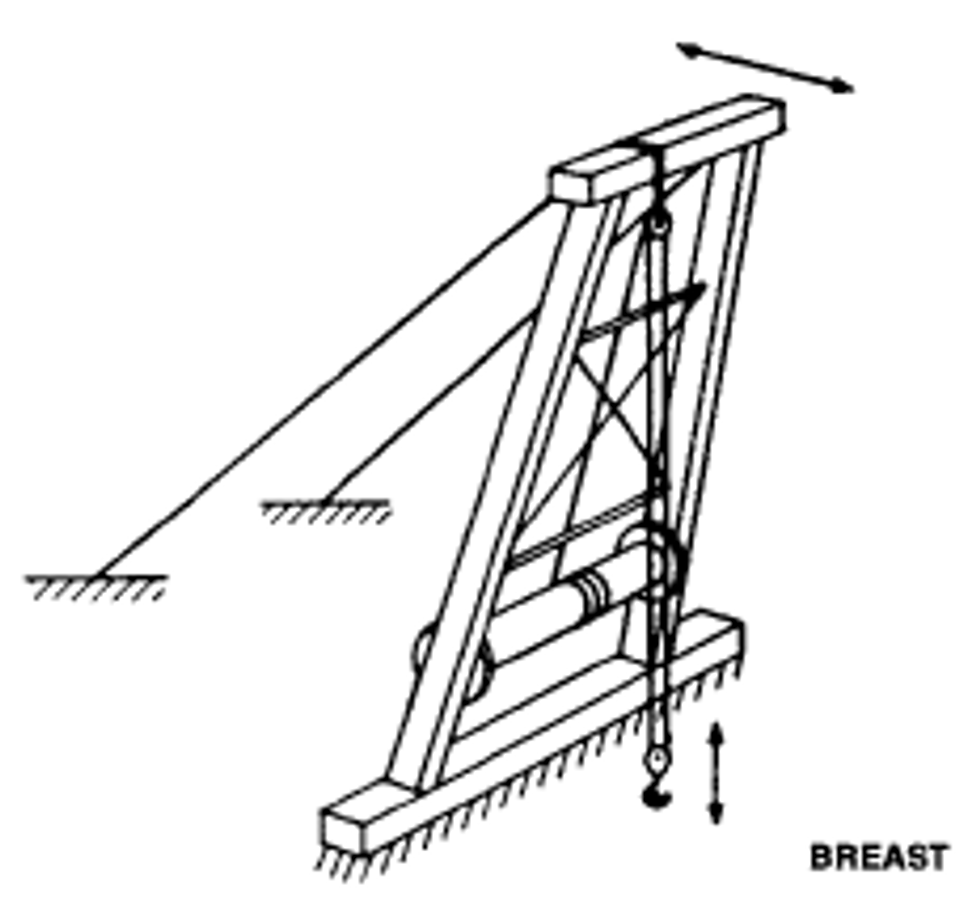

(4)

Breast derrick

means a derrick without boom. The mast consists of two side members spread farther apart at the base than at the top and tied together at top and bottom by rigid members. The mast is prevented from tipping forward by guys connected to its top. The load is raised and lowered by ropes through a sheave or block secured to the top crosspiece.

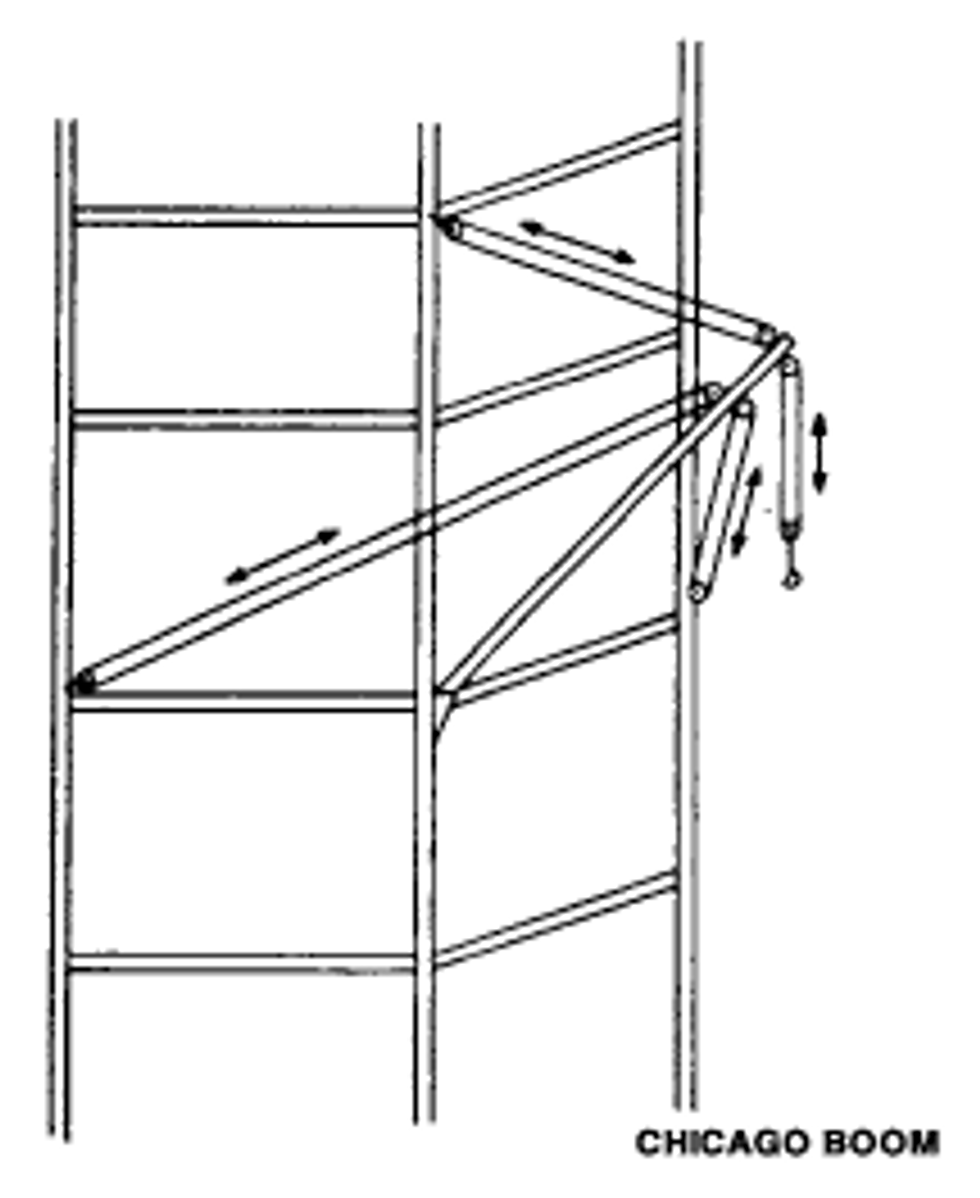

(5)

Chicago boom derrick

means a boom which is attached to a structure, an outside upright member of the structure serving as the mast, and the boom being stepped in a fixed socket clamped to the upright. The derrick is complete with load, boom, and boom point swing line falls.

(6) A

gin pole derrick

is a derrick without a boom. Its guys are so arranged from its top as to permit leaning the mast in any direction. The load is raised and lowered by ropes reeved through sheaves or blocks at the top of the mast.

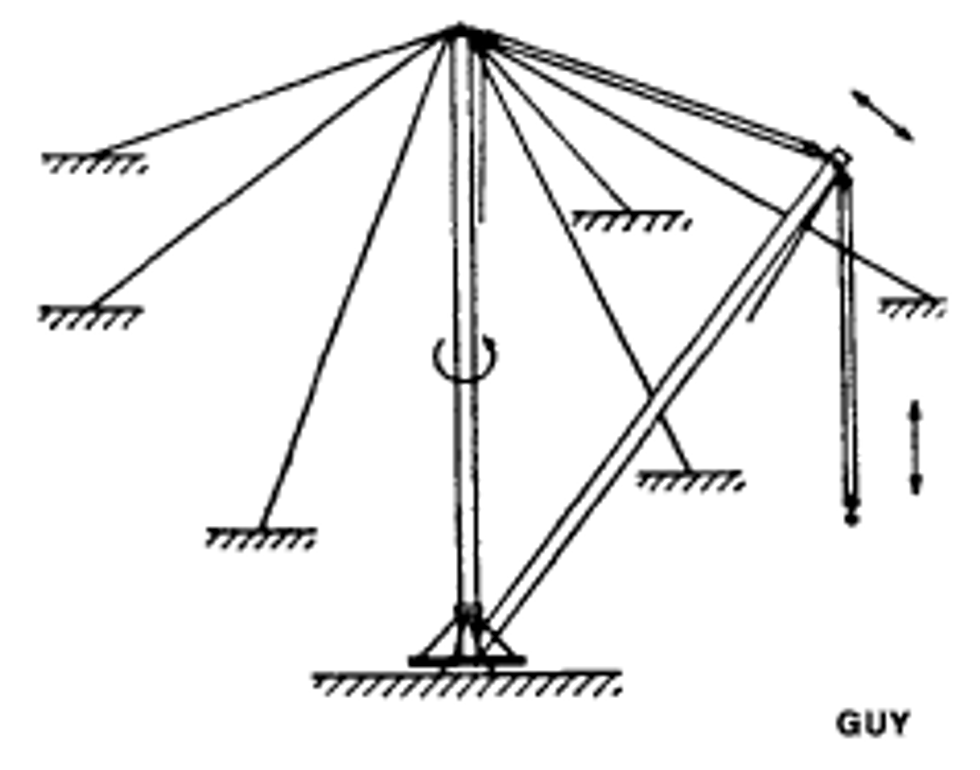

(7)

Guy derrick

means a fixed derrick consisting of a mast capable of being rotated, supported in a vertical position by guys, and a boom whose bottom end is hinged or pivoted to move in a vertical plane with a reeved rope between the head of the mast and the boom point for raising and lowering the boom, and a reeved rope from the boom

(8)

Shearleg derrick

means a derrick without a boom and similar to a breast derrick. The mast, wide at the bottom and narrow at the top, is hinged at the bottom and has its top secured by a multiple reeved guy to permit handling loads at various radii by means of load tackle suspended from the mast top.

(9) A

stiffleg derrick

is a derrick similar to a guy derrick except that the mast is supported or held in place by two or more stiff members, called stifflegs, which are capable of resisting either tensile or compressive forces. Sills are generally provided to connect the lower ends of the stif-flegs to the foot of the mast.

(10)

Appointed

means assigned specific responsibilities by the employer or the employer�s representative.

(11)

ANSI

means the American National Standards Institute.

(12) A

boom

is a timber or metal section or strut, pivoted or hinged at the heel (lower end) at a location fixed in height on a frame or mast or vertical member, and with its point (upper end) supported by chains, ropes, or rods to the upper end of the frame, mast, or vertical member. A rope for raising and lowering the load is reeved through sheaves or a block at the boom point. The length of the boom shall be taken as the straight line distance between the axis of the foot pin and the axis of the boom point sheave pin, or where used, the axis of the upper load block attachment pin.

(13)

Boom harness

means the block and sheave arrangement on the boom point to which the topping lift cable is reeved for lowering and raising the boom.

(14) The

boom point

is the outward end of the top section of the boom.

(15)

Derrick bullwheel

means a horizontal ring or wheel, fastened to the foot of a derrick, for the purpose of turning the derrick by means of ropes leading from this wheel to a powered drum.

(16)

Designated

means selected or assigned by the employer or employer�s representative as being qualified to perform specific duties.

(17)

Eye

means a loop formed at the end of a rope by securing the dead end to the live end at the base of the loop.

(18) A

fiddle block

is a block consisting of two sheaves in the same plane held in place by the same cheek plates.

(19) The

foot bearing or foot block (sill block)

is the lower support on which the mast rotates.

(20) A

gudgeon pin

is a pin connecting the mast cap to the mast allowing rotation of the mast.

(21) A

guy

is a rope used to steady or secure the mast or other member in the desired position.

(22)

Load, working

means the external load, in pounds, applied to the derrick, including the weight of load attaching equipment such as load blocks, shackles, and slings.

(23)

Load block, lower

means the assembly of sheaves, pins, and frame suspended by the hoisting rope.

(24)

Load block, upper

means the assembly of sheaves, pins, and frame suspended from the boom.

(25)

Mast

means the upright member of the derrick.

(26)

Mast cap (spider)

means the fitting at the top of the mast to which the guys are connected.

(27)

Reeving

means a rope system in which the rope travels around drums and sheaves.

(28)

Rope

refers to wire rope unless otherwise specified.

(29)

Safety Hook

means a hook with a latch to prevent slings or load from accidentally slipping off the hook.

(30)

Side loading

is a load applied at an angle to the vertical plane of the boom.

(31) The

sill

is a member connecting the foot block and stiffleg or a member connecting the lower ends of a double member mast.

(32) A

standby derrick

is a derrick not in regular service which is used occasionally or intermittently as required.

(33)

Stiffleg

means a rigid member supporting the mast at the head.

(34)

Swing

means rotation of the mast and/or boom for movements of loads in a horizontal direction about the axis of rotation.

(b) General requirements. (1) Application. This section applies to guy, stiffleg, basket, breast, gin pole, Chicago boom and A-frame derricks of the stationary type, capable of handling loads at variable reaches and powered by hoists through systems of rope reeving, used to perform lifting hook work, single or multiple line bucket work, grab, grapple, and magnet work. Derricks may be permanently installed for temporary use as in construction work. The requirements of this section also apply to any modification of these types which retain their fundamental features, except for floating derricks.

(2) New and existing equipment. All new derricks constructed and installed on or after August 31, 1971, shall meet the design specifications of the American National Standard Safety Code for Derricks, ANSI B30.6-1969, which is incorporated by reference as specified in �1910.6.

(3) Designated personnel. Only designated personnel shall be permitted to operate a derrick covered by this section.

(c) Load ratings. (1) Rated load marking. For permanently installed derricks with fixed lengths of boom, guy, and mast, a substantial, durable, and clearly legible rating chart shall be provided with each derrick and securely affixed where it is visible to personnel responsible for the safe operation of the equipment. The chart shall include the following data:

(i) Manufacturer�s approved load ratings at corresponding ranges of boom angle or operating radii.

(ii) Specific lengths of components on which the load ratings are based.

(iii) Required parts for hoist reeving. Size and construction of rope may be shown either on the rating chart or in the operating manual.

(2) Nonpermanent installations. For nonpermanent installations, the manufacturer shall provide sufficient information from which capacity charts can be prepared for the particular installation. The capacity charts shall be located at the derricks or the jobsite office.

(d) Inspection. (1) Inspection classification. (i) Prior to initial use all new and altered derricks shall be inspected to insure compliance with the provisions of this section.

(ii) Inspection procedure for derricks in regular service is divided into two general classifications based upon the intervals at which inspection should be performed. The intervals in turn are dependent upon the nature of the critical components of the derrick and the degree of their exposure to wear, deterioration, or malfunction. The two general classifications are herein designated as frequent and periodic with respective intervals between inspections as defined below:

(a) Frequent inspection: Daily to monthly intervals.

(b) Periodic inspection: 1- to 12-month intervals, or as specified by the manufacturer.

(2) Frequent inspection. Items such as the following shall be inspected for defects at intervals as defined in paragraph (d)(1)(ii) (a) of this section or as specifically indicated, including observation during operation for any defects which might appear between regular inspections. Deficiencies shall be carefully examined for any safety hazard:

(i) All control mechanisms: Inspect daily for adjustment, wear, and lubrication.

(ii) All chords and lacing: Inspect daily, visually.

(iii) Tension in guys: Daily.

(iv) Plumb of the mast.

(v) Deterioration or leakage in air or hydraulic systems: Daily.

(vi) Derrick hooks for deformations or cracks; for hooks with cracks or having more than 15 percent in excess of normal throat opening or more than 10� twist from the plane of the unbent hook, refer to paragraph (e)(3)(iii) of this section.

(vii) Rope reeving; visual inspection for noncompliance with derrick manufacturer�s recommendations.

(viii) Hoist brakes, clutches, and operating levers: check daily for proper functioning before beginning operations.

(ix) Electrical apparatus for malfunctioning, signs of excessive deterioration, dirt, and moisture accumulation.

(3) Periodic inspection. (i) Complete inspections of the derrick shall be performed at intervals as generally defined in paragraph (d)(1)(ii) (b) of this section depending upon its activity, severity of service, and environment, or as specifically indicated below. These inspections shall include the requirements of paragraph (d)(2) of this section and in addition, items such as the following. Deficiencies shall be carefully examined and a determination made as to whether they constitute a safety hazard:

(a) Structural members for deformations, cracks, and corrosion.

(b) Bolts or rivets for tightness.

(c) Parts such as pins, bearings, shafts, gears, sheaves, drums, rollers, locking and clamping devices, for wear, cracks, and distortion.

(d) Gudgeon pin for cracks, wear, and distortion each time the derrick is to be erected.

(e) Powerplants for proper performance and compliance with applicable safety requirements.

(f) Hooks.

(ii) Foundation or supports shall be inspected for continued ability to sustain the imposed loads.

(4) Derricks not in regular use. (i) A derrick which has been idle for a period of 1 month or more, but less than 6 months, shall be given an inspection conforming with requirements of paragraph (d)(2) of this section and paragraph (g)(3) of this section before placing in service.

(ii) A derrick which has been idle for a period of over 6 months shall be given a complete inspection conforming with requirements of paragraphs (d) (2) and (3) of this section and paragraph (g)(3) of this section before placing in service.

(iii) Standby derricks shall be inspected at least semi-annually in accordance with requirements of paragraph (d)(2) of this section and paragraph (g)(3) of this section.

(e) Testing. (1) Operational tests. Prior to initial use all new and altered derricks shall be tested to insure compliance with this section including the following functions:

(i) Load hoisting and lowering.

(ii) Boom up and down.

(iii) Swing.

(iv) Operation of clutches and brakes of hoist.

(2) Anchorages. All anchorages shall be approved by the appointed person. Rock and hairpin anchorages may require special testing.

(f) Maintenance. (1) Preventive maintenance. A preventive maintenance program based on the derrick manufacturer�s recommendations shall be established.

(2) Maintenance procedure. (i) Before adjustments and repairs are started on a derrick the following precautions shall be taken:

(a) The derrick to be repaired shall be arranged so it will cause the least interference with other equipment and operations in the area.

(b) All hoist drum dogs shall be engaged.

(c) The main or emergency switch shall be locked in the open position, if an electric hoist is used.

(d) Warning or out of order signs shall be placed on the derrick and hoist.

(e) The repairs of booms of derricks shall either be made when the booms are lowered and adequately supported or safely tied off.

(f) A good communication system shall be set up between the hoist operator and the appointed individual in charge of derrick operations before any work on the equipment is started.

(ii) After adjustments and repairs have been made the derrick shall not be operated until all guards have been reinstalled, safety devices reactivated, and maintenance equipment removed.

(3) Adjustments and repairs. (i) Any unsafe conditions disclosed by inspection shall be corrected before operation of the derrick is resumed.

(ii) Adjustments shall be maintained to assure correct functioning of components.

(iii) Repairs or replacements shall be provided promptly as needed for safe operation. The following are examples of conditions requiring prompt repair or replacement:

(a) Hooks showing defects described in paragraph (d)(2)(vi) of this section shall be discarded.

(b) All critical parts which are cracked, broken, bent, or excessively worn.

(c) [Reserved]

(d) All replacement and repaired parts shall have at least the original safety factor.

(g) Rope inspection. (1) Running ropes. A thorough inspection of all ropes in use shall be made at least once a month and a certification record which includes the date of inspection, the signature of the person who performed the inspection, and an identifier for the ropes which were inspected shall be prepared and kept on file where readily available. Any deterioration, resulting in appreciable loss of original strength shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

(i) Reduction of rope diameter below nominal diameter due to loss of core support, internal or external corrosion, or wear of outside wires.

(ii) A number of broken outside wires and the degree of distribution or concentration of such broken wires.

(iii) Worn outside wires.

(iv) Corroded or broken wires at end connections.

(v) Corroded, cracked, bent, worn, or improperly applied end connections.

(vi) Severe kinking, crushing, cutting, or unstranding.

(2) Limited travel ropes. Heavy wear and/or broken wires may occur in sections in contact with equalizer sheaves or other sheaves where rope travel is limited, or with saddles. Particular care shall be taken to inspect ropes at these locations.

(3) Idle ropes. All rope which has been idle for a period of a month or more due to shutdown or storage of a derrick on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration. A certification record shall be prepared and kept readily available which includes the date of inspection, the signature of the person who performed the inspection, and an identifier for the ropes which were inspected.

(4) Nonrotating ropes. Particular care shall be taken in the inspection of nonrotating rope.

(h) Operations of derricks. Derrick operations shall be directed only by the individual specifically designated for that purpose.

(i) Handling the load. (1) Size of load. (i) No derrick shall be loaded beyond the rated load.

(ii) When loads approach the maximum rating of the derrick, it shall be ascertained that the weight of the load has been determined within plus or minus 10 percent before it is lifted.

(2) Attaching the load. (i) The hoist rope shall not be wrapped around the load.

(ii) The load shall be attached to the hook by means of slings or other suitable devices.

(3) Moving the load. (i) The load shall be well secured and properly balanced in the sling or lifting device before it is lifted more than a few inches.

(ii) Before starting to hoist, the following conditions shall be noted:

(a) Hoist rope shall not be kinked.

(b) Multiple part lines shall not be twisted around each other.

(c) The hook shall be brought over the load in such a manner as to prevent swinging.

(iii) During hoisting, care shall be taken that:

(a) There is no sudden acceleration or deceleration of the moving load.

(b) Load does not contact any obstructions.

(iv) A derrick shall not be used for side loading except when specifically authorized by a responsible person who has determined that the various structural components will not be overstressed.

(v) No hoisting, lowering, or swinging shall be done while anyone is on the load or hook.

(vi) The operator should avoid carrying loads over people.

(vii) The operator shall test the brakes each time a load approaching the rated load is handled by raising it a few inches and applying the brakes.

(viii) Neither the load nor boom shall be lowered below the point where less than two full wraps of rope remain on their respective drums.

(ix) When rotating a derrick, sudden starts and stops shall be avoided. Rotational speed shall be such that the load does not swing out beyond the radius at which it can be controlled.

(x) Boom and hoisting rope systems shall not be twisted.

(4) Holding the load. (i) The operator shall not be allowed to leave his position at the controls while the load is suspended.

(ii) People should not be permitted to stand or pass under a load on the hook.

(iii) If the load must remain suspended for any considerable length of time, a dog, or pawl and ratchet, or other equivalent means, rather than the brake alone, shall be used to hold the load.

(5) Use of winch heads. (i) Ropes shall not be handled on a winch head without the knowledge of the operator.

(ii) While a winch head is being used, the operator shall be within convenient reach of the power unit control lever.

(6) Securing boom. Dogs, pawls, or other positive holding mechanism on the hoist shall be engaged. When not in use, the derrick boom shall:

(i) Be laid down;

(ii) Be secured to a stationary member, as nearly under the head as possible, by attachment of a sling to the load block; or

(iii) Be hoisted to a vertical position and secured to the mast.

(j) Other requirements. (1) Guards. (i) Exposed moving parts, such as gears, ropes, setscrews, projecting keys, chains, chain sprockets, and reciprocating components, which constitute a hazard under normal operating conditions shall be guarded.

(ii) Guards shall be securely fastened.

(iii) Each guard shall be capable of supporting without permanent distortion, the weight of a 200-pound person unless the guard is located where it is impossible for a person to step on it.

(2) Hooks. (i) Hooks shall meet the manufacturer�s recommendations and shall not be overloaded.

(ii) Safety latch type hooks shall be used wherever possible.

(3) Fire extinguishers. (i) A carbon dioxide, dry chemical, or equivalent fire extinguisher shall be kept in the immediate vicinity of the derrick.

(ii) Operating and maintenance personnel shall be familiar with the use and care of the fire extinguishers provided.

(4) Refueling. (i) Refueling with portable containers shall be done with approved safety type containers equipped with automatic closing cap and flame arrester. Refer to �1910.155(c)(3) for definition of Approved.

(ii) Machines shall not be refueled with the engine running.

(5) Operations near overhead lines. For operations near overhead electric lines, see �1910.333(c)(3).

(6) Cab or operating enclosure. (i) Necessary clothing and personal belongings shall be stored in such a manner as to not interfere with access or operation.

(ii) Tools, oilcans, waste, extra fuses, and other necessary articles shall be stored in the toolbox, and shall not be permitted to lie loose in or about the cab or operating enclosure.

[37 FR 22102, Oct. 18, 1972, as amended at 38 FR 14373, June 1, 1973; 43 FR 49750, Oct. 24, 1978; 49 FR 5323, Feb. 10, 1984; 51 FR 34561, Sept. 29, 1986; 53 FR 12122, Apr. 12, 1988; 55 FR 32015, Aug. 6, 1990; 61 FR 9240, Mar. 7, 1996]