['General Packaging Requirements - Hazmat']

['General Packaging Requirements - Hazmat']

06/23/2022

...

(a) General. Each tank car owner must ensure that a tank car facility:

(1) Inspects and tests each item according to the requirements specified in this section;

(2) Evaluates each item according to the acceptable results of inspections and tests specified in §180.511;

(3) Marks each tank car as specified in §180.515 that is qualified to transport hazardous materials;

(4) Prepares the documentation as required by §180.517 for each item qualified under this section. A copy of the documentation required by §180.517 must be sent to the owner as appropriate and according to the owner's instructions.

(b) Conditions requiring qualification of tank cars. Without regard to the qualification compliance date requirements of any paragraph of this section, an owner of a tank car or an internal coating or lining must ensure an appropriate inspection and test according to the type of defect and the type of maintenance or repair performed if:

(1) The tank car shows evidence of abrasion, corrosion, cracks, dents, distortions, defects in welds, or any other condition that may make the tank car unsafe for transportation,

(2) The tank car was in an accident and shows evidence of damage to an extent that may adversely affect its capability to retain its contents or to otherwise remain railworthy.

(3) The tank bears evidence of damage caused by fire.

(4) The Associate Administrator for Railroad Safety, FRA, requires it based on the existence of an objectively reasonable and articulable belief that a tank car or a class or design of tank cars may be in an unsafe operating condition.

(c) Frequency of inspection and tests. Each tank car shall have an inspection and test according to the requirements of this paragraph.

(1) For Class 107 tank cars and tank cars of riveted construction, the tank car must have a hydrostatic pressure test and visual inspection conforming to the requirements in effect prior to July 1, 1996, for the tank specification.

(2) For Class DOT 113 tank cars, see §173.319(e) of this subchapter.

(3) Fusion welded tank cars must be inspected and tested to be qualified and maintained in accordance with the following table. All qualification requirements need not be done at the same time or at the same facility.

| Section 180.509(*) | Description | Maximum interval |

|---|---|---|

| D | Visual inspection | 10 years. |

| E | Structural integrity inspection | 10 years. |

| F | Thickness test | See §180.509(f). |

| H | Safety Systems | 10 years. |

| I | Internal coating or lining (for materials corrosive or reactive to the tank) (See definitions at §180.503) | See §180.509(i). |

| J | Leakage pressure test | After reassembly. |

| K | Service equipment (including pressure relief device) | See §180.509(k). |

(d) Visual inspection. At a minimum, each tank car facility must visually inspect the tank externally and internally as follows:

(1) An internal inspection of the tank shell and heads for abrasion, corrosion, cracks, dents, distortions, defects in welds, or any other condition that makes the tank car unsafe for transportation, and except in the areas where insulation or a thermal protection system precludes it, an external inspection of the tank shell and heads for abrasion, corrosion, cracks, dents, distortions, defects in welds, or any other condition that makes the tank car unsafe for transportation, and for DOT 115 class tank cars, an internal inspection of the inner container and external inspection of the outer shell and heads for defects in welds, or any other condition that may make the tank car unsafe for transportation;

(2) When an internal coating or lining, head protection, insulation, or thermal protection is removed in part or in whole, the internal and external exposed surface of the tank must be visually inspected for defects in welds or any other condition that may make the tank car unsafe for transportation, and this inspection must precede any application or reapplication of a coating or lining;

(3) An inspection of the service equipment, including gaskets, for indications of corrosion and other conditions that may make the tank car unsafe for transportation;

(4) An inspection for missing or loose bolts, nuts, or elements that may make the tank car unsafe for transportation;

(5) An inspection of all closures on the tank car for conditions that may make the tank car unsafe for transportation, including an inspection of the protective housings for proper condition;

(6) An inspection of excess flow valves with threaded seats for tightness; and

(7) An inspection of the required markings on the tank car for legibility.

(e) Structural integrity inspections and tests. (1) Each tank car owner must ensure the structural elements on the tank car qualify with the applicable requirements of this subchapter. At a minimum, the structural integrity inspection and test must include:

(i) All transverse fillet welds greater than 0.64 cm (0.25 inch) within 121.92 cm (4 feet) of the bottom longitudinal centerline except body bolster pad attachment welds;

(ii) The termination of longitudinal fillet welds greater than 0.64 cm (0.25 inch) within 121.92 cm (4 feet) of the bottom longitudinal centerline; and

(iii) The tank shell butt welds within 60.96 cm (2 feet) of the bottom longitudinal centerline, unless the tank car owner can determine by analysis (e.g., finite element analysis, damage-tolerance analysis, or service reliability assessment) that the structure will not develop defects that reduce the design level of safety and reliability or fail within its operational life or prior to the next required inspection. The owner must maintain all documentation used to make such determination at its principal place of business and make the data available to FRA or an authorized representative of the Department upon request.

(2) For DOT 115 class tanks, paragraphs (e)(1)(i) through (iii) of this section apply only to the outer shell fillet welds and to the non-reinforced exposed outer shell butt welds.

(3)The inspection requirements of paragraph (e)(1)(iii) of this section do not apply to reinforced tank shell butt welds until the time of lining removal or application for tank cars with an internal lead, glass, or rubber lining.

(4) Each tank car facility must inspect and test the elements identified in paragraph (e)(1) of this section by one or more of the following methods:

(i) Dye penetrant testing (PT);

(ii) Radiographic examination (RT);

(iii) Magnetic particle testing (MT);

(iv) Ultrasonic testing (UT); and

(v) Direct, remote, or enhanced visual inspection, using, for example, magnifiers, fiberscopes, borescopes, and/or machine vision technology (VT).

(f) Thickness tests. (1) The tank car owner must ensure that each tank car facility measures the thickness of the tank car shell, heads, sumps, protective housing (i.e., domes), and nozzles on each tank car by using a device capable of accurately measuring the thickness to within ±0.05 mm (±0.002 inch).

(2) The tank car owner must ensure that each tank car has a thickness test measurement:

(i) At the time of an internal coating or lining application or replacement, or

(ii) At least once every ten (10) years for a tank that does not have an internal coating or lining, or

(iii) At least once every five (5) years for a tank that does not have an internal coating or lining when:

(A) The tank is used to transport a material that is corrosive or reactive to the tank (see Appendix D of this part) or service equipment as defined §180.503, and

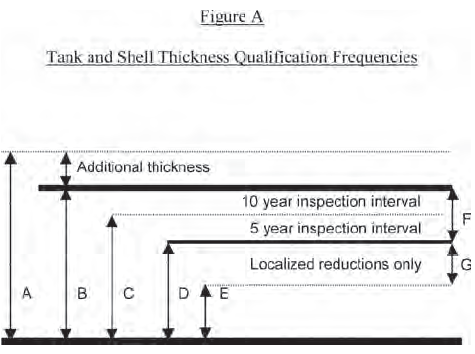

(B) The remaining shell and head thickness is tested and determined to be at or below line C in Figure A of this paragraph.

|

| Where: A. As-built tank shell or head thickness with additional thickness. B. Required minimum tank shell or head thickness after forming per part 179. C. Inspection frequency adjustment point (design minimum shell or head thickness, minus 1/2 of the table value in paragraph (g) of this section). D. Condemning limit for general corrosion (required minimum shell or head thickness, minus the value in paragraph (g) of this section). E. Condemning limit for localized corrosion (required minimum shell or head thickness, minus the table value in paragraph (g) of this section, minus 1.58 mm (1/16 inch)). See Note 1 in paragraph (g) of this section for diameter limitations and minimum separation distances. F. Allowable shell or head thickness reduction (table value in paragraph (g) of this section). G. Additional thickness reduction for localized areas in paragraph (g) of this section. |

(3) For a localized repair of an internal coating or lining where a material corrosive to the tank or service equipment as defined §180.503 has contacted the tank, a qualified individual must verify the coating or lining's conformance with paragraph (g) of this section by measuring the shell or head in the area of the repair. The thickness test applies only to the non-lined or coated repaired area, and is not a qualification event. Modification of the tank stencil is not required.

(4) Operation of a tank car below the condemning limit for general corrosion or the condemning limit for localized corrosion (as shown in Figure A of this section) is prohibited.

(5) For sumps, protective housing (i.e., domes), nozzles, and nozzle reinforcing pads, the tank car owner must determine if any reduction in wall thickness affects the design levels of reliability and safety built into sump, protective housing, nozzle, or nozzle reinforcement. Each tank car owner must maintain at its principal place of business documentation describing the allowable thickness reductions for sumps, protective housings, and nozzles, and nozzle reinforcements. This documentation must be made available to FRA or an authorized representative of the Department upon request.

(6) After repairs, alterations, conversions, modifications, or blasting of tank car that results in a reduction of the tank's thickness, and anytime a tank car coating or lining is removed, a qualified individual must measure the thickness of the tank in the area of reduced thickness to ensure that the thickness of the tank conforms to paragraph (g) of this section.

(g) Service life thickness allowance. (1) A tank car found with a thickness below the required minimum thickness after forming for its specification, as stated in part 179 of this subchapter, may continue in service if any reduction in the required minimum thickness is not more than that provided in the following table:

| Marked tank test pressure | Top shell and tank head | Bottom shell |

|---|---|---|

| Note 1. A tank car owner may add an extra 1.58 mm (1/16 inch) to the values in the table for local reductions. Local reductions are those that do not exceed 20.32 linear centimeters (8 linear inches) measured at the longest diameter, and are separated from the other local reductions by at least 40.64 cm (16 inches). Note 2. Any reduction in the tank car shell thickness may not affect the structural strength of the tank car to the extent that the tank car no longer conforms to the applicable provisions of Section 6.2 of the AAR Specifications for Tank Cars (IBR, see §171.7 of this subchapter). Note 3. For DOT 115 class tank cars, shell thickness reductions apply only to the outer shell of the tank car. There is no shell or head thickness reduction authorized for the inner tank. | ||

| 60 psig < 200 psig | 3.17 mm 1/8 inch | 1.58 mm. 1/16 inch. |

| ?200 psig | 0.79 mm 1/32 inch | 0.79 mm. 1/32 inch. |

(2) [Reserved]

(h) Safety system inspections. Each tank car owner must ensure qualification of the tank car safety systems. However, inspections of foam or cork insulation systems are not required.

(i) Internal coating and lining inspection and test. (1) At a minimum, the owner of an internal coating or lining applied to protect a tank used to transport a material that is corrosive or reactive to the tank must ensure an inspection adequate enough to detect defects or other conditions that could reduce the design level of reliability and safety of the tank is performed. In addition, the owner of a coating or lining of tank cars used to transport hazardous materials must ensure the lining complies with §173.24(b)(2) and (b)(3) of this subchapter.

(2) The owner of the internal coating or lining must establish and maintain a record of the service life of the coating or lining and commodity combination, that is, the specific hazardous materials that were loaded into a tank and the coating or lining in place at the time of loading. The owner of the internal coating or lining must use its knowledge of the service life of each coating or lining and commodity combination to establish an appropriate inspection interval for that coating or lining and commodity combination. This interval must not exceed eight (8) years, unless the coating or lining owner can establish, document, and show that the service history or scientific analysis of the coating or lining and commodity pairing supports a longer inspection interval. The owner must maintain at its principal place of business a written procedure for collecting and documenting the performance of the coating or lining applied within the tank car for its service life. The internal coating or lining owner must provide this documentation, including inspection and test, repair, removal, and application procedures, to the FRA or car owner upon request. Further, the offeror must provide commodity information to the car owner and the owner of the internal coating or lining upon request.

(3) The owner of the internal coating or lining must provide the test method and acceptance criteria to the tank car owner and to the person responsible for qualifying the coating or lining. The tank car facility inspecting and testing the internal coating or lining must follow the inspection and test procedure, including the acceptance requirements, established by the internal coating or lining owner.

(j) Leakage pressure test. Unless the design of the service equipment arrangement precludes it (e.g., there is no fitting to pressurize the tank), each owner of a tank car must ensure that the tank, service equipment, and closures installed, replaced, or reinstalled on the tank car are leak tested. The test may be conducted with the lading in the tank. When the test pressure exceeds the start-to-discharge or burst pressure of a pressure relief device, the device must be rendered inoperative. The written procedures and test method for leak testing must ensure the sensitivity and reliability of the test method to prevent premature failure. This section does not apply to facilities that remove closures for the sole purpose of loading or unloading the lading (e.g., blind flanges, pipe plugs, etc.).

(k) Service equipment inspection and test. (1) Each tank car owner must ensure the qualification of tank car service equipment at least once every ten (10) years. The tank car owner must analyze the service equipment inspection and test results for any given lading and, based on the analysis, adjust the inspection and test frequency to ensure that the design level of reliability and safety of the equipment is met. The owner must maintain at its principal place of business all supporting documentation used to make such analyses and inspection and test frequency adjustments. The supporting documentation must be made available to FRA or an authorized representative of the Department upon request.

(2) Each tank car facility must qualify service equipment, including reclosing pressure relief devices and interior heater systems in accordance with the applicable provisions of Appendix D of the AAR Specifications for Tank Cars (IBR, see §171.7 of this subchapter).

(l) Alternative inspection and test procedures. When approved by the Associate Administrator for Railroad Safety, FRA, a tank car owner, or a coating or lining owner may use an alternative inspection and test procedure or interval based on a damage-tolerance analysis (that must include a determination of the probable locations and modes of damage due to fatigue, corrosion, and accidental damage), or based on a service reliability assessment (that must be supported by analysis of systematically collected data) in lieu of the other requirements of this section.

(m) Inspection and test compliance date for tank cars. (1) After July 1, 2000, each tank car with a metal jacket or with a thermal protection system shall have an inspection and test conforming to this section no later than the date the tank car requires a periodic hydrostatic pressure test (i.e., the marked due date on the tank car for the hydrostatic test).

(2) After July 1, 1998, each tank car without a metal jacket shall have an inspection and test conforming to this section no later than the date the tank car requires a periodic hydrostatic pressure test (i.e., the marked due date on the tank car for the hydrostatic test).

(3) For tank cars on a 20-year periodic hydrostatic pressure test interval (i.e., Class DOT 103W, 104W, 111A60W1, 111A100W1, and 111A100W3 tank cars), the next inspection and test date is the midpoint between the compliance date in paragraph (l)(1) or (2) of this section and the remaining years until the tank would have had a hydrostatic pressure test.

[Amdt. 180–8, 60 FR 49079, Sept. 21, 1995, as amended by Amdt. 179–50, 61 FR 33256, June 26, 1996; 62 FR 51561, Oct. 1, 1997; 63 FR 52851, Oct. 1, 1998; 66 FR 45391, Aug. 28, 2001; 68 FR 75765, Dec. 31, 2003; 71 FR 54398, Sept. 14, 2006; 77 FR 37987, June 25, 2012]

['General Packaging Requirements - Hazmat']

['General Packaging Requirements - Hazmat']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.