...

(a) The provisions in this section apply to metal IBCs intended to contain liquids and solids. Metal IBC types are designated:

(1) 11A, 11B, 11N for solids that are loaded or discharged by gravity.

(2) 21A, 21B, 21N for solids that are loaded or discharged at a gauge pressure greater than 10 kPa (1.45 psig).

(3) 31A, 31B, 31N for liquids.

(b) Definitions for metal IBCs:

(1) Metal IBC means an IBC with a metal body, together with appropriate service and structural equipment.

(2) Protected means providing the IBC body with additional external protection against impact and abrasion. For example, a multi-layer (sandwich) or double wall construction or a frame with a metal lattice-work casing.

(c) Construction requirements for metal IBCs are as follows:

(1) Body. The body must be made of ductile metal materials. Welds must be made so as to maintain design type integrity of the receptacle under conditions normally incident to transportation.

(i) The use of dissimilar metals must not result in deterioration that could affect the integrity of the body.

(ii) Aluminum IBCs intended to containflammable liquids must have no movable parts, such as covers and closures, made of unprotected steel liable to rust, which might cause a dangerous reaction from friction or percussive contact with the aluminum.

(iii) Metals used in fabricating the body of a metal IBC must meet the following requirements:

(A) For steel, the percentage elongation at fracture must not be less than 10,000/Rm with a minimum of 20 percent; where Rm = minimum tensile strength of the steel to be used, in N/mm2; if U.S. Standard units of psi are used for tensile strength then the ratio becomes 10,000 x (145/Rm).

(B) For aluminum, the percentage elongation at fracture must not be less than 10,000/(6Rm) with an absolute minimum of eight percent; if U.S. Standard units of psi are used for tensile strength then the ratio becomes 10,000 x 145/(6Rm).

(C) Specimens used to determine the elongation at fracture must be taken transversely to the direction of rolling and be so secured that:

| where: Lo = gauge length of the specimen before the testd = diameterA = cross-sectional area of test specimen. |

(iv) Minimum wall thickness. For metal IBCs with a capacity of more than 1500 liters, the minimum wall thickness must be determined as follows:

(A) For a reference steel having a product of Rm × Ao = 10,000, where Ao is the minimum elongation (as a percentage) of the reference steel to be used on fracture under tensile stress (Rm × Ao = 10,000 × 145; if tensile strength is in U.S. Standard units of pounds per square inch), the wall thickness must not be less than:

| Types 11A, 11B, 11N | Types 21A, 21B, 21N, 31A, 31B, 31N | ||

|---|---|---|---|

| Unprotected | Protected | Unprotected | Protected |

| T = C/2000 + 1.5 | T = C/2000 + 1.0 | T = C/1000 + 1.0 | T = C/2000 + 1.5 |

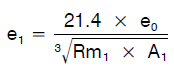

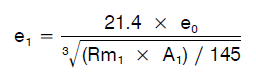

(B) For metals other than the reference steel described in paragraph (c)(1)(iii)(A) of this section, the minimum wall thickness is the greater of 1.5 mm (0.059 inches) or as determined by use of the following equivalence formula:

|

|

| where:e1 = required equivalent wall thickness of the metal to be used (in mm or if eo is in inches, use formula for U.S. Standard units).eo = required minimum wall thickness for the reference steel (in mm or if eo is in inches, use formula for U.S. Standard units).Rm1 = guaranteed minimum tensile strength of the metal to be used (in N/mm2 or for U.S. Standard units, use psi).A1 = minimum elongation (as a percentage) of the metal to be used on fracture under tensile stress (see paragraph (c)(1) of this section). |

(C) For purposes of the calculation described in paragraph (c)(1)(iv)(B) of this section, the guaranteed minimum tensile strength of the metal to be used (Rm1) must be the minimum value according to material standards. However, for austenitic (stainless) steels, the specified minimum value for Rm, according to the material standards, may be increased by up to 15% when a greater value is provided in the material inspection certificate. When no material standard exists for the material in question, the value of Rm must be the minimum value indicated in the material inspection certificate.

(2) Pressure relief. The following pressure relief requirements apply to IBCs intended for liquids:

(i) IBCs must be capable of releasing a sufficient amount of vapor in the event of fire engulfment to ensure that no rupture of the body will occur due to pressure build-up. This can be achieved by spring-loaded or non-reclosing pressure relief devices or by other means of construction.

(ii) The start-to-discharge pressure may not be higher than 65 kPa (9 psig) and no lower than the vapor pressure of the hazardous material plus the partial pressure of the air or other inert gases, measured in the IBC at 55°C (131°F), determined on the basis of a maximum degree of filling as specified in §173.35(d) of this subchapter. This does not apply to fusible devices unless such devices are the only source of pressure relief for the IBC. Pressure relief devices must be fitted in the vapor space.

(d) Metal IBCs may not have a volumetric capacity greater than 3,000 L (793 gallons) or less than 450 L (119 gallons).

[Amdt. 178–103, 59 FR 38068, July 26, 1994, as amended by Amdt. 178–108, 60 FR 40038, Aug. 4, 1995; Amdt. 178–117, 61 FR 50629, Sept. 26, 1996; 66 FR 33452, June 21, 2001; 66 FR 45386, 45387, Aug. 28, 2001; 68 FR 45041, July 31, 2003; 75 FR 5396, Feb. 2, 2010; 78 FR 1097, Jan. 7, 2013; 87 FR 45000, July 26, 2022]