['Hazmat']

[]

10/14/2024

...

(a) The packing group of Division 6.1 materials shall be as assigned in Column 5 of the §172.101 Table. When the §172.101 Table provides more than one packing group or hazard zone for a hazardous material, the packing group and hazard zone shall be determined by applying the following criteria:

(1) The packing group assignment for routes of administration other than inhalation of vapors shall be in accordance with the following table:

| Packing Group | Oral toxicity LD50 (mg/kg) | Dermal toxicity LD50 (mg/kg) | Inhalation toxicity by dusts and mists LC50(mg/L) |

|---|---|---|---|

| I | ≤ 5.0 | ≤ 50 | ≤ 0.2 |

| II | > 5.0 and ≤ 50 | > 50 and ≤ 200 | > 0.2 and ≤ 2.0 |

| III | > 50 and ≤300 | > 200 and ≤1000 | > 2.0 and ≤4.0 |

(2)(i) The packing group and hazard zone assignments for liquids (see §173.115(c) of this subpart for gases) based on inhalation of vapors shall be in accordance with the following Table:

| Packing Group | Vapor concentration and toxicity |

|---|---|

| Note 1: V is the saturated vapor concentration in air of the material in mL/m3 at 20 °C and standard atmospheric pressure. | |

| Note 2: A liquid in Division 6.1 meeting criteria for Packing Group I, Hazard Zones A or B stated in paragraph (a)(2) of this section is a material poisonous by inhalation subject to the additional hazard communication requirements in §§172.203(m), §172.313 and table 1 of §172.504(e) of this subchapter. | |

| I (Hazard Zone A) | V ≥ 500 LC50 and LC50 ≤ 200 mL/M3. |

| I (Hazard Zone B) | V ≥ 10 LC50; LC50 ≤ 1000 mL/m3; and the criteria for Packing Group I, Hazard Zone A are not met. |

| II | V ≥ LC50; LC50 ≤ 3000 mL/m3; and the criteria for Packing Group I, are not met. |

| III | V ≥ .2 LC50; LC50 ≤ 5000 mL/m3; and the criteria for Packing Groups I and II, are not met. |

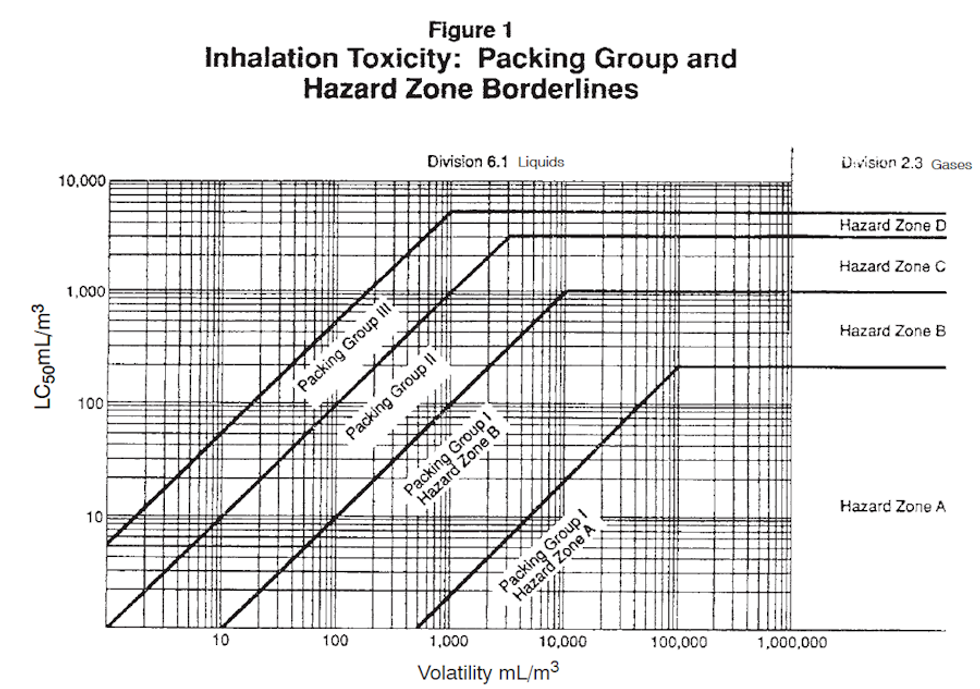

(ii) These criteria are represented graphically in Figure 1:

(3) When the packing group determined by applying these criteria is different for two or more (oral, dermal or inhalation) routes of administration, the packing group assigned to the material shall be that indicated for the highest degree of toxicity for any of the routes of administration.

(4) Notwithstanding the provisions of this paragraph, the packing group and hazard zone of a tear gas substance is as assigned in Column 5 of the §172.101 Table.

(b) The packing group and hazard zone for Division 6.1 mixtures that are poisonous (toxic) by inhalation may be determined by one of the following methods:

(1) Where LC50 data is available on each of the poisonous (toxic) substances comprising the mixture—

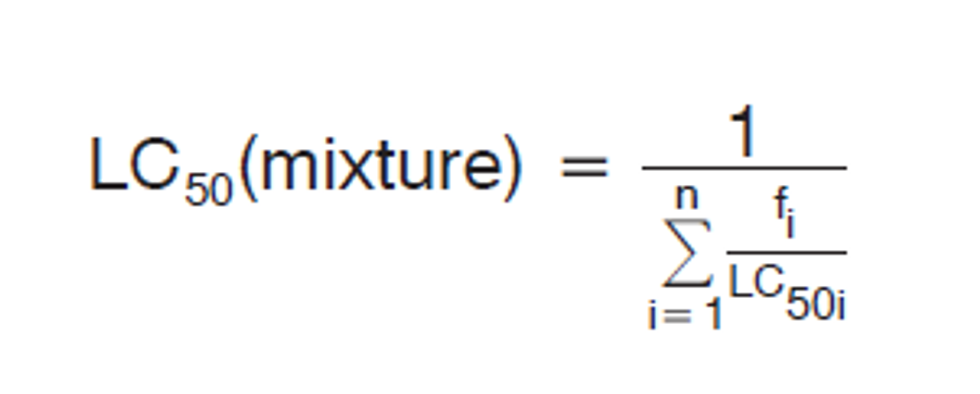

(i) The LC50 of the mixture is estimated using the formula:

|

| where fi=mole fraction of the ith component substance of the liquid.LC50i=mean lethal concentration of the ith component substance in mL/m3 |

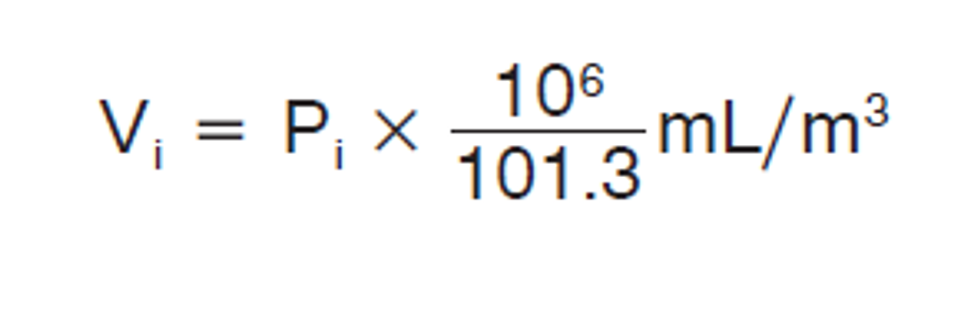

(ii) The volatility of each component substance is estimated using the formula:

|

| where:Pi=partial pressure of the ith component substance in kPa at 20 °C and one atmospheric pressure. Pi may be calculated according to Raoult’s Law using appropriate activity coefficients. Where activity coefficients are not available, the coefficient may be assumed to be 1.0. |

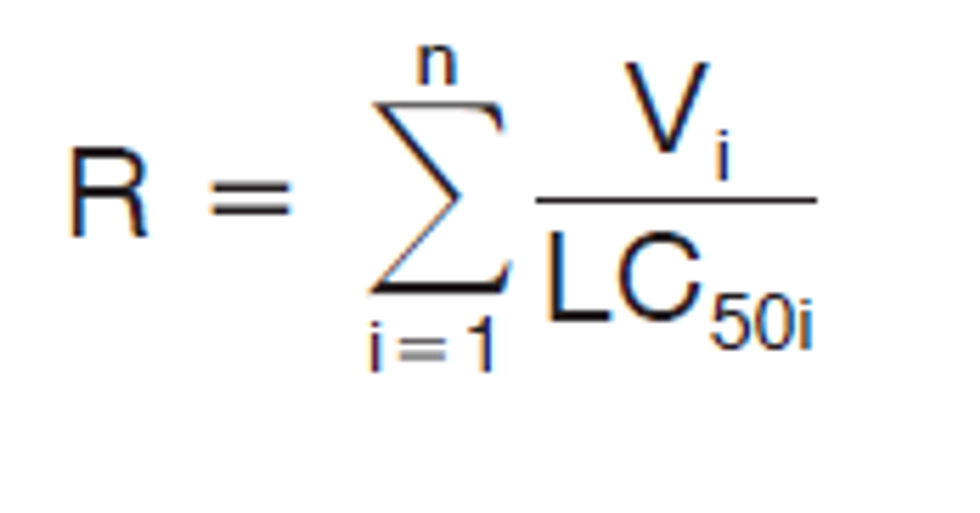

(iii) The ratio of the volatility to the LC50 is calculated using the formula:

|

(iv) Using the calculated values LC50 (mixture) and R, the packing group for the mixture is determined as follows:

| Packaging group (hazard zone) | Ratio of volatility and LC50 |

|---|---|

| I (Hazard Zone A) | R ≥500 and LC50 (mixture) ≤200 mL/m3. |

| I (Hazard Zone B) | R ≥ 10 and LC50 (mixture) ≤ 1000 mL/m3; and the criteria for Packing Group I, Hazard Zone A, are not met. |

| II | R ≥ 1 and LC50 (mixture) ≤ 3000 mL/m3; and the criteria for Packing Group I, Hazard Zones A and B are not met. |

| III | R ≥ 1/5 and LC50 (mixture) ≤ 5000 mL/m3; and the criteria for Packing Group I, Hazard Zones A and B and Packing Group II are not met. |

(2) In the absence of LC50 data on the poisonous (toxic) constituent substances, the mixture may be assigned a packing group and hazard zone based on the following simplified threshold toxicity tests. When these threshold tests are used, the most restrictive packing group and hazard zone must be determined and used for the transportation of the mixture.

(i) A mixture is assigned to Packing Group I, Hazard Zone A only if both the following criteria are met:

(A) A sample of the liquid mixture is vaporized and diluted with air to create a test atmosphere of 200 mL/m3 vaporized mixture in air. Ten albino rats (five male and five female) are exposed to the test atmosphere as determined by an analytical method appropriate for the material being classified for one hour and observed for fourteen days. If five or more of the animals die within the fourteen-day observation period, the mixture is presumed to have an LC50 equal to or less than 200 mL/m3.

(B) A sample of the vapor in equilibrium with the liquid mixture is diluted with 499 equal volumes of air to form a test atmosphere. Ten albino rats (five male and five female) are exposed to the test atmosphere for one hour and observed for fourteen days. If five or more of the animals die within the fourteen-day observation period, the mixture is presumed to have a volatility equal to or greater than 500 times the mixture LC50.

(ii) A mixture is assigned to Packing Group I, Hazard Zone B only if both the following criteria are met, and the mixture does not meet the criteria for Packing Group I, Hazard Zone A:

(A) A sample of the liquid mixture is vaporized and diluted with air to create a test atmosphere of 1000 mL/m3 vaporized mixture in air. Ten albino rats (five male and five female) are exposed to the test atmosphere for one hour and observed for fourteen days. If five or more of the animals die within the fourteen-day observation period, the mixture is presumed to have an LC50 equal to or less than 1000 mL/m3.

(B) A sample of the vapor in equilibrium with the liquid mixture is diluted with 9 equal volumes of air to form a test atmosphere. Ten albino rats (five male and five female) are exposed to the test atmosphere for one hour and observed for fourteen days. If five or more of the animals die within the fourteen-day observation period, the mixture is presumed to have a volatility equal to or greater than 10 times the mixture LC50.

(iii) A mixture is assigned to Packing Group II only if both the following criteria are met, and the mixture does not meet the criteria for Packing Group I (Hazard Zones A or B):

(A) A sample of the liquid mixture is vaporized and diluted with air to create a test atmosphere of 3000 mL/m3 vaporized mixture in air. Ten albino rats (five male and five female) are exposed to the test atmosphere for one hour and observed for fourteen days. If five or more of the animals die within the fourteen-day observation period, the mixture is presumed to have an LC50 equal to or less than 3000 mL/m3.

(B) A sample of the vapor in equilibrium with the liquid mixture is used to form a test atmosphere. Ten albino rats (five male and five female) are exposed to the test atmosphere for one hour and observed for fourteen days. If five or more of the animals die within the fourteen-day observation period, the mixture is presumed to have a volatility equal to or greater than the mixture LC50.

(iv) A mixture is assigned to Packing Group III only if both the following criteria are met, and the mixture does not meet the criteria for Packing Groups I (Hazard Zones A or B) or Packing Group II (Hazard Zone C):

(A) A sample of the liquid mixture is vaporized and diluted with air to create a test atmosphere of 5000 mL/m3 vaporized mixture in air. Ten albino rats (five male and five female) are exposed to the test atmosphere for one hour and observed for fourteen days. If five or more of the animals die within the fourteen-day observation period, the mixture is presumed to have an LC50 equal to or less than 5000 mL/m3.

(B) The vapor pressure of the liquid mixture is measured and if the vapor concentration is equal to or greater than 1000 mL/m3, the mixture is presumed to have a volatility equal to or greater than 1/5 the mixture LC50.

(c) Transitional provisions. The criteria for packing group assignments in effect on December 31, 2006, may continue to be used until January 1, 2012.

[Amdt. 173–224, 55 FR 52634, Dec. 21, 1990, as amended at 56 FR 66268–66270, Dec. 20, 1991; 57 FR 45461–45463, Oct. 1, 1992; Amdt. 173–234, 58 FR 51532, Oct. 1, 1993; Amdt. 173–138, 59 FR 49133, Sept. 26, 1994; Amdt. 173–255, 61 FR 50626, Sept. 26, 1996; 66 FR 45183, 45380, Aug. 28, 2001; 66 FR 49556, Sept. 28, 2001; 69 FR 54046, Sept. 7, 2004; 71 FR 54395, Sept. 14, 2006; 71 FR 78631, Dec. 29, 2006; 74 FR 53188, Oct. 16, 2009; 76 FR 43530 July 20, 2011]

['Hazmat']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.