['Water Programs']

['Safe Drinking Water', 'Water Monitoring', 'Water Quality']

06/13/2024

...

(a) General applicability. This section specifies the monitoring and quality control requirements that must be followed if you own or operate a public water system (PWS) that is subject to the Unregulated Contaminant Monitoring Regulation (UCMR), as specified in paragraphs (a)(1) and (2) of this section. In addition, this section specifies the UCMR requirements for State and Tribal participation. For the purposes of this section, PWS “population served,” “State,” “PWS Official,” “PWS Technical Contact,” and “finished water” apply as defined in §141.35(a). The determination of whether a PWS is required to monitor under this rule is based on the type of system (e.g., community water system, non-transient non-community water system, etc.), and its retail population, as indicated by SDWIS/Fed on February 1, 2021 or subsequent corrections from the State.

(a)(1) Applicability to transient non-community systems. If you own or operate a transient non-community water system, you are not subject to monitoring requirements in this section.

(a)(2) Applicability to community water systems and non-transient non-community water systems. —(i) Large systems. If you own or operate a retail PWS (other than a transient non-community system) that serves more than 10,000 people, you must monitor according to the specifications in this paragraph (a)(2)(i). If you believe that your applicability status is different than EPA has specified in the notification letter that you received, or if you are subject to UCMR requirements and you have not been notified by either EPA or your State, you must report to EPA, as specified in §141.35(b)(2) or (c)(4).

(A) Assessment monitoring. You must monitor for the contaminants on List 1, per Table 1, UCMR Contaminant List, in paragraph (a)(3) of this section. If you serve a retail population of more than 10,000 people, you are required to perform this monitoring regardless of whether you have been notified by the State or EPA.

(B) Screening Survey. You must monitor for the unregulated contaminants on List 2 (Screening Survey) of Table 1, as specified in paragraph (a)(3) of this section, if your system serves 10,001 to 100,000 people and you are notified by EPA or your State that you are part of the State Monitoring Plan for Screening Survey testing. If your system serves more than 100,000 people, you are required to conduct this Screening Survey testing regardless of whether you have been notified by the State or EPA.

(C) Pre-Screen Testing. You must monitor for the unregulated contaminants on List 3 of Table 1, in paragraph (a)(3) of this section, if notified by your State or EPA that you are part of the Pre-Screen Testing.

(a)(2)(ii) Small systems. EPA will provide sample containers, provide pre-paid air bills for shipping the sampling materials, conduct the laboratory analysis, and report and review monitoring results for all small systems selected to conduct monitoring under paragraphs (a)(2)(ii)(A) through (C) of this section. If you own or operate a PWS (other than a transient non-community water system) that serves a retail population of 10,000 or fewer people and you are notified of monitoring requirements by the State or EPA, you must monitor as follows:

(A) Assessment Monitoring. You must monitor for the contaminants on List 1 per table 1 to paragraph (a)(3) if you are notified by your State or EPA that you are part of the State Monitoring Plan for Assessment Monitoring.

(B) Screening Survey. You must monitor for the unregulated contaminants on List 2 of Table 1, in paragraph (a)(3) of this section, if notified by your State or EPA that you are part of the State Monitoring Plan for the Screening Survey.

(C) Pre-screen testing. You must monitor for the contaminants on List 3 of Table 1, in paragraph (a)(3) of this section if you are notified by your State or EPA that you are part of the State Monitoring Plan for Pre-Screen Testing.

(a) (3) Analytes to be monitored. Lists 1, 2, and 3 contaminants are provided in table 1 to paragraph (a)(3):

| 1—Contaminant | 2—CASRN | 3—Analytical methods a | 4—Minimum reporting level b | 5—Sampling location c | 6—Period during which sample collection to be completed |

|---|---|---|---|---|---|

| List 1: Assessment Monitoring | |||||

| Per- and Polyfluoroalkyl Substances (PFAS) | |||||

| 11-chloroeicosafluoro-3-oxaundecane-1-sulfonic acid (11Cl-PF3OUdS) | 763051-92-9 | EPA 533 | 0.005 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| 1H, 1H, 2H, 2H-perfluorodecane sulfonic acid (8:2 FTS) | 39108-34-4 | EPA 533 | 0.005 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| 1H, 1H, 2H, 2H-perfluorohexane sulfonic acid (4:2 FTS) | 757124-72-4 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| 1H, 1H, 2H, 2H-perfluorooctane sulfonic acid (6:2 FTS) | 27619-97-2 | EPA 533 | 0.005 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| 4,8-dioxa-3H-perfluorononanoic acid (ADONA) | 919005-14-4 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| 9-chlorohexadecafluoro-3-oxanone-1-sulfonic acid (9Cl-PF3ONS) | 756426-58-1 | EPA 533 | 0.002 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| hexafluoropropylene oxide dimer acid (HFPO-DA) (GenX) | 13252-13-6 | EPA 533 | 0.005 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| nonafluoro‐3,6‐dioxaheptanoic acid (NFDHA) | 151772-58-6 | EPA 533 | 0.02 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoro (2‐ethoxyethane) sulfonic acid (PFEESA) | 113507-82-7 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoro‐3‐methoxypropanoic acid (PFMPA) | 377-73-1 | EPA 533 | 0.004 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoro‐4‐methoxybutanoic acid (PFMBA) | 863090-89-5 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorobutanesulfonic acid (PFBS) | 375-73-5 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorobutanoic acid (PFBA) | 375-22-4 | EPA 533 | 0.005 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorodecanoic acid (PFDA) | 335-76-2 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorododecanoic acid (PFDoA) | 307-55-1 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoroheptanesulfonic acid (PFHpS) | 375-92-8 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoroheptanoic acid (PFHpA) | 375-85-9 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorohexanesulfonic acid (PFHxS) | 355-46-4 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorohexanoic acid (PFHxA) | 307-24-4 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorononanoic acid (PFNA) | 375-95-1 | EPA 533 | 0.004 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorooctanesulfonic acid (PFOS) | 1763-23-1 | EPA 533 | 0.004 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorooctanoic acid (PFOA) | 335-67-1 | EPA 533 | 0.004 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoropentanesulfonic acid (PFPeS) | 2706-91-4 | EPA 533 | 0.004 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoropentanoic acid (PFPeA) | 2706-90-3 | EPA 533 | 0.003 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluoroundecanoic acid (PFUnA) | 2058-94-8 | EPA 533 | 0.002 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| n-ethyl perfluorooctanesulfonamidoacetic acid (NEtFOSAA) | 2991-50-6 | EPA 537.1 | 0.005 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| n-methyl perfluorooctanesulfonamidoacetic acid (NMeFOSAA) | 2355-31-9 | EPA 537.1 | 0.006 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorotetradecanoic acid (PFTA) | 376-06-7 | EPA 537.1 | 0.008 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| perfluorotridecanoic acid (PFTrDA) | 72629-94-8 | EPA 537.1 | 0.007 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| Metal/Pharmaceutical | |||||

| Lithium | 7439-93-2 | EPA 200.7, SM 3120 B, ASTM D1976-20 | 9 µg/L | EPTDS | 1/1/2023-12/31/2025 |

| List 2: Screening Survey | |||||

| Reserved | Reserved | Reserved | Reserved | Reserved | Reserved |

| List 3: Pre-Screen Testing | |||||

| Reserved | Reserved | Reserved | Reserved | Reserved | Reserved |

| Column headings are: | |||||

| 1—Contaminant: The name of the contaminant to be analyzed. | |||||

| 2—CASRN (Chemical Abstracts Service Registry Number) or Identification Number: A unique number identifying the chemical contaminants. | |||||

| 3—Analytical Methods: Method numbers identifying the methods that must be used to test the contaminants. | |||||

| 4—Minimum Reporting Level (MRL): The value and unit of measure at or above which the concentration of the contaminant must be measured using the approved analytical methods. If EPA determines, after the first six months of monitoring that the specified MRLs result in excessive resampling, EPA will establish alternate MRLs and will notify affected PWSs and laboratories of the new MRLs. N/A is defined as non-applicable. | |||||

| 5—Sampling Location: The locations within a PWS at which samples must be collected. | |||||

| 6—Period During Which Sample Collection to be Completed: The time period during which the sampling and testing will occur for the indicated contaminant. | |||||

| a The analytical procedures shall be performed in accordance with the documents associated with each method, see paragraph (c) of this section. | |||||

| b The MRL is the minimum concentration of each analyte that must be reported to EPA. | |||||

| c Sampling must occur at your PWS's entry points to the distribution system (EPTDSs), after treatment is applied, that represent each non-emergency water source in routine use over the 12-month period of monitoring. Systems that purchase water with multiple connections from the same wholesaler may select one representative connection from that wholesaler. The representative EPTDS must be a location within the purchaser's water system. This EPTDS sampling location must be representative of the highest annual volume connections. If the connection selected as the representative EPTDS is not available for sampling, an alternate highest volume representative connection must be sampled. See 40 CFR 141.35(c)(3) for an explanation of the requirements related to the use of representative GW EPTDSs. | |||||

(a)(4) Sampling requirements (i) Large systems. If you serve more than 10,000 people and meet the UCMR applicability criteria specified in paragraph (a)(2)(i) of this section, you must comply with the requirements specified in paragraphs (a)(4)(i)(A) through (I) of this section. Your samples must be collected according to the schedule that you are assigned by EPA or your State, or the schedule that you revised using EPA’s electronic data reporting system on or before December 31, 2022. Your schedule must follow both the timing and frequency of monitoring specified in Tables 1 and 2 of this section.

(A) Sample collection period. You must collect the samples in one continuous 12-month period for List 1 Assessment Monitoring, and, if applicable, for List 2 Screening Survey, or List 3 Pre-Screen Testing, during the timeframe indicated in column 6 of table 1 to paragraph (a)(3) of this section. EPA or your State will specify the month(s) and year(s) in which your monitoring must occur. As specified in 40 CFR §141.35(c)(5), you must contact EPA if you believe you cannot collect samples according to your schedule.

(B) Frequency. You must collect the samples within the timeframe and according to the frequency specified by contaminant type and water source type for each sampling location, as specified in table 2 to this paragraph (a)(4)(i)(B). For the second or subsequent round of sampling, if a sample location is non-operational for more than one month before and one month after the scheduled sampling month ( i.e., it is not possible for you to sample within the window specified in table 2), you must notify EPA as specified in 40 CFR §141.35(c)(5) to reschedule your sampling.

| Contaminant type | Water source type | Timeframe | Frequency 1 |

|---|---|---|---|

| List 1 Cyanotoxins Chemicals | Surface water or Ground water under the direct influence of surface water (GWUDI) | March-November | You must monitor twice a month for four consecutive months (total of eight sampling events). Sample events must occur two weeks apart. |

| List 1 Contaminants—Additional Chemicals | Surface water or GWUDI | 12 months | You must monitor for four consecutive quarters. Sample events must occur three months apart. (Example: If first monitoring is in January, the second monitoring must occur any time in April, the third any time in July and the fourth any time in October). |

| Ground water | 12 months | You must monitor twice in a consecutive 12-month period. Sample events must occur 5-7 months apart. (Example: If the first monitoring event is in April, the second monitoring event must occur any time in September, October or November). | |

| 1 Systems must assign a sample event code for each contaminant listed in Table 1. Sample event codes must be assigned by the PWS for each sample event. For more information on sample event codes see §141.35(e) Table 1. | |||

(C) Location. You must collect samples for each List 1 Assessment Monitoring contaminant, and, if applicable, for each List 2 Screening Survey, or List 3 Pre-Screen Testing contaminant, as specified in table 1 to paragraph (a)(3) of this section. Samples must be collected at each sample point that is specified in column 5 and footnote c of table 1 to paragraph (a)(3) of this section. If you are a GW system with multiple EPTDSs, and you request and receive approval from EPA or the State for sampling at representative EPTDS(s), as specified in 40 CFR §141.35(c)(3), you must collect your samples from the approved representative sampling location(s).

(D) Sampling instructions. For each List 1 Assessment Monitoring contaminant, and, if applicable, for each List 2 Screening Survey, or List 3 Pre-Screen Testing contaminant, you must follow the sampling procedure for the method specified in column 3 of Table 1, in paragraph (a)(3) of this section. In addition, you must not composite (that is, combine, mix, or blend) the samples; you must collect and preserve each sample separately.

(E) Sample collection and shipping time. If you must ship the samples for analysis, you must collect the samples early enough in the day to allow adequate time to send the samples for overnight delivery to the laboratory. You should not collect samples on Friday, Saturday, or Sunday because sampling on these days may not allow samples to be shipped and received at the laboratory at the required temperature, unless you have made special arrangements with your laboratory to receive the samples.

(F) Analytical methods. For each contaminant, you must use the respective analytical methods for List 1, and, if applicable, for List 2, or List 3 that are specified in column 3 of Table 1, in paragraph (a)(3) of this section; report values at or above the minimum reporting levels for List 1, and, if applicable, for List 2 Screening Survey, or List 3 Pre-Screen Testing, that are specified in column 4 of Table 1, in paragraph (a)(3) of this section; and conduct the quality control procedures specified in paragraph (a)(5) of this section.

(G) Laboratory errors or sampling deviations. If the laboratory data do not meet the required QC criteria, as specified in paragraph (a)(5) of this section, or you do not follow the required sampling procedures, as specified in paragraphs (a)(4) of this section, you must resample within 30 days of being informed or becoming aware of these facts. This resampling is not for the purpose of confirming previous results, but to correct the sampling or laboratory error. All systems must report the results obtained from the first sampling for each sampling period, except for cases of sampling or laboratory errors. For the purposes of this rule, no samples are to be recollected for the purposes of confirming the results observed in a previous sampling.

(H) Analysis. For the List 1 contaminants, and, if applicable, List 2 Screening Survey, or List 3 Pre-Screen Testing contaminants, identified in Table 1, paragraph (a)(3) of this section, you must arrange for testing by a laboratory that has been approved by EPA according to requirements in paragraph (a)(5)(ii) of this section.

(I) Review and reporting of results. After you have received the laboratory results, you must review, approve, and submit the system information, and sample collection data and test results. You must report the results as provided in §141.35(c)(6).

(a)(4)(ii) Small systems. If you serve a population of 10,000 or fewer people and are notified that you are part of the State Monitoring Plan, you must comply with the requirements specified in paragraphs (a)(4)(ii)(A) through (H) of this section. If EPA or the State informs you that they will be collecting your UCMR samples, you must assist them in identifying the appropriate sampling locations and in collecting the samples.

(A) Sample collection and frequency. You must collect samples at the times specified for you by the State or EPA. Your schedule must follow both the timing of monitoring specified in table 1 to paragraph (a)(3) of this section, List 1, and, if applicable, List 2, or List 3, and the frequency of monitoring in table 2 to paragraph (a)(4)(i)(B) of this section.

(B) Location. You must collect samples at the locations specified for you by the State or EPA.

(C) Sample kits. You must store and maintain the sample collection kits sent to you by the UCMR Sampling Coordinator in accordance with the kit’s instructions. The sample kit will include all necessary containers, packing materials and cold packs, instructions for collecting the sample and sample treatment (such as dechlorination or preservation), report forms for each sample, contact name and telephone number for the laboratory, and a prepaid return shipping docket and return address label. If any of the materials listed in the kit’s instructions are not included in the kit or arrive damaged, you must notify the UCMR Sampling Coordinator who sent you the sample collection kits.

(D) Sampling instructions. You must comply with the instructions sent to you by the State or EPA concerning the use of containers, collection (how to fill the sample bottle), dechlorination and/or preservation, and sealing and preparation of sample and shipping containers for shipment. You must not composite (that is, combine, mix, or blend) the samples. You also must collect, preserve, and test each sample separately. You must also comply with the instructions sent to you by the UCMR Sampling Coordinator concerning the handling of sample containers for specific contaminants.

(E) Sampling deviations. If you do not collect a sample according to the instructions provided to you for a listed contaminant, you must report the deviation within 7 days of the scheduled monitoring on the sample reporting form, as specified in §141.35(d)(2). You must resample following instructions that you will be sent from the UCMR Sampling Coordinator or State. A copy of the form must be sent to the laboratory with the recollected samples, and to the UCMR Sampling Coordinator.

(F) [Reserved]

(G) Sampling forms. You must completely fill out each of the sampling forms and bottles sent to you by the UCMR Sampling Coordinator, including data elements listed in §141.35(e) for each sample, as specified in §141.35(d)(2). You must sign and date the sampling forms.

(H) Sample collection and shipping. You must collect the samples early enough in the day to allow adequate time to send the samples for overnight delivery to the laboratory. You should not collect samples on Friday, Saturday, or Sunday because sampling on these days may not allow samples to be shipped and received at the laboratory at the required temperature unless you have made special arrangements with EPA for the laboratory to receive the samples. Once you have collected the samples and completely filled in the sampling forms, you must send the samples and the sampling forms to the laboratory designated on the air bill.

(a)(5) Quality control requirements. If your system serves more than 10,000 people, you must ensure that the quality control requirements listed below are met during your sampling procedures and by the laboratory conducting your analyses. You must also ensure that all method quality control procedures and all UCMR quality control procedures are followed.

(a)(5)(i) Sample collection/preservation. You must follow the sample collection and preservation requirements for the specified method for each of the contaminants in Table 1, in paragraph (a)(3) of this section. These requirements specify sample containers, collection, dechlorination, preservation, storage, sample holding time, and extract storage and/or holding time that you must assure that the laboratory follow.

(a)(5)(ii) Laboratory approval for Lists 1, List 2 and List 3. To be approved to conduct UCMR testing, the laboratory must be certified under §141.28 for one or more compliance analyses; demonstrate for each analytical method it plans to use for UCMR testing that it can meet the Initial Demonstration of Capability (IDC) requirements detailed in the analytical methods specified in column 3 of Table 1, in paragraph (a)(3) of this section; and successfully participate in the UCMR Proficiency Testing (PT) Program administered by EPA for each analytical method it plans to use for UCMR testing. UCMR laboratory approval decisions will be granted on an individual method basis for the methods listed in column 3 of Table 1 in paragraph (a)(3) of this section for List 1, List 2, and List 3 contaminants. Laboratory approval is contingent upon the capability of the laboratory to post monitoring data to the EPA electronic data reporting system. To participate in the UCMR Laboratory Approval Program, the laboratory must register and complete the necessary application materials by August 1, 2022. Correspondence must be addressed to: UCMR Laboratory Approval Coordinator, USEPA, Technical Support Center, 26 West Martin Luther King Drive, (MS 140), Cincinnati, Ohio 45268; or emailed to EPA at: UCMR_Lab_Approval@epa.gov.

(a)(5)(iii) Minimum Reporting Level. The MRL is defined by EPA as the quantitation limit achievable, with 95 percent confidence, by 75 percent of laboratories nationwide, assuming the use of good instrumentation and experienced analysts.

(A) Validation of laboratory performance. Your laboratory must be capable of quantifying each contaminant listed in Table 1, at or below the MRL specified in column 4 of Table 1, in paragraph (a)(3) of this section. You must ensure that the laboratory completes and has on file and available for your inspection, records of two distinct procedures. First, your laboratory must have conducted an IDC involving replicate analyses at or below the MRL as described in this paragraph. Second, for each day that UCMR analyses are conducted by your laboratory, a validation of its ability to quantify each contaminant, at or below the MRL specified in column 4 of Table 1, in paragraph (a)(3) of this section, following the procedure listed in paragraph (a)(5)(iii)(B) of this section, must be performed. The procedure for initial validation of laboratory performance at or below the MRL is as follows:

(1) All laboratories performing analysis under UCMR must demonstrate that they are capable of meeting data quality objectives at or below the MRL listed in Table 1, column 4, in paragraph (a)(3) of this section.

(2) The MRL, or any concentration below the MRL, at which performance is being evaluated, must be contained within the range of calibration. The calibration curve regression model and the range of calibration levels that are used in these performance validation steps must be used in all routine sample analyses used to comply with this regulation. Only straight line or quadratic regression models are allowed. The use of either weighted or unweighted models is permitted. The use of cubic regression models is not permitted.

(3) Replicate analyses of at least seven (7) fortified samples in reagent water must be performed at or below the MRL for each analyte, and must be processed through the entire method procedure ( i.e. , including extraction, where applicable, and with all preservatives).

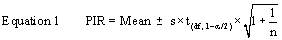

(4) A prediction interval of results (PIR), which is based on the estimated arithmetic mean of analytical results and the estimated sample standard deviation of measurement results, must be determined by Equation 1:

Where:

t is the Student’s t value with df degrees of freedom and confidence level (1–α),

s is the sample standard deviation of n replicate samples fortified at the MRL,

n is the number of replicates.

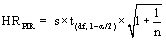

(5) The values needed to calculate the PIR using Equation 1 are: Number of replicates (n); Student’s t value with a two-sided 99% confidence level for n number of replicates; the average (mean) of at least seven replicates; and the sample standard deviation. Factor 1 is referred to as the Half Range PIR (HRPIR).

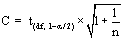

For a certain number of replicates and for a certain confidence level in Student’s t, this factor

is constant, and can be tabulated according to replicate number and confidence level for the Student’s t. Table 3 in this paragraph lists the constant factor (C) for replicate sample numbers 7 through 10 with a confidence level of 99% for Student’s t.

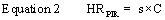

(6) The HRPIR is calculated by Equation 2:

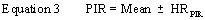

(7) The PIR is calculated by Equation 3:

| Replicates | Degrees of freedom | Constant factor (C) to be multiplied by the standard deviation |

| 7 | 6 | 3.963 |

| 8 | 7 | 3.711 |

| 9 | 8 | 3.536 |

| 10 | 9 | 3.409 |

aThe critical t -value for a two-sided 99% confidence interval is equivalent to the critical t-value for a one-sided 99.5% confidence interval, due to the symmetry of the t-distribution. PIR = Prediction Interval of Results.

(8) The lower and upper result limits of the PIR must be converted to percent recovery of the concentration being tested. To pass criteria at a certain level, the PIR lower recovery limits cannot be lower than the lower recovery limits of the QC interval (50%), and the PIR upper recovery limits cannot be greater than the upper recovery limits of the QC interval (150%). When either of the PIR recovery limits falls outside of either bound of the QC interval of recovery (higher than 150% or less than 50%), laboratory performance is not validated at the concentration evaluated. If the PIR limits are contained within both bounds of the QC interval, laboratory performance is validated for that analyte.

(B) Quality control requirements for validation of laboratory performance at or below the MRL.

(1) You must ensure that the calibration curve regression model and that the range of calibration levels that are used in these performance validation steps are used in future routine sample analysis. Only straight line or quadratic regression models are allowed. The use of either weighted or unweighted models is permitted. The use of cubic regression models is not permitted.

(2) You must ensure, once your laboratory has performed an IDC as specified in each analytical method (demonstrating that DQOs are met at or below an MRL), that a daily performance check is performed for each analyte and method. A single laboratory blank, fortified at or below the MRL for each analyte, must be processed through the entire method procedure. The measured concentration for each analyte must be converted to a percent recovery, and if the recovery is within 50%-150% (inclusive), the daily performance of the laboratory has been validated. The results for any analyte for which 50%-150% recovery cannot be demonstrated during the daily check are not valid. Laboratories may elect to re-run the daily performance check sample if the performance for any analyte or analytes cannot be validated. If performance is validated for these analytes, the laboratory performance is considered validated. Alternatively, the laboratory may re-calibrate and repeat the performance validation process for all analytes.

(a)(5)(iv) [Reserved]

(a)(5)(v) Method defined quality control. You must ensure that your laboratory analyzes Laboratory Fortified Blanks and conducts Laboratory Performance Checks, as appropriate to the method's requirements, for those methods listed in column 3 in table 1 to paragraph (a)(3) of this section. Each method specifies acceptance criteria for these QC checks.

(a)(5)(vi) Reporting. You must require your laboratory, on your behalf, to post and approve these data in EPA's electronic data reporting system, accessible at https://www.epa.gov/dwucmr, for your review within 90 days from the sample collection date. You then have 30 days from when the laboratory posts and approves your data to review, approve, and submit the data to the State and EPA, via the agency's electronic data reporting system. If you do not electronically approve and submit the laboratory data to EPA within 30 days of the laboratory posting approved data, the data will be considered approved by you and available for State and EPA review.

(a)(6) Violation of this rule —(i) Monitoring violations. Any failure to monitor in accordance with §141.40(a)(3)-(5) is a monitoring violation.

(a)(6)(ii) Reporting violations. Any failure to report in accordance with §141.35 is a reporting violation.

(b) Petitions and Waivers by States— (1) Governors’ petition for additional contaminants. The Safe Drinking Water Act allows Governors of seven (7) or more States to petition the EPA Administrator to add one or more contaminants to the UCMR Contaminant List in paragraph (a)(3) of this section. The petition must clearly identify the reason(s) for adding the contaminant(s) to the monitoring list, including the potential risk to public health, particularly any information that might be available regarding disproportional risks to the health and safety of children, the expected occurrence documented by any available data, any analytical methods known or proposed to be used to test for the contaminant(s), and any other information that could assist the Administrator in determining which contaminants present the greatest public health concern and should, therefore, be included on the UCMR Contaminant List in paragraph (a)(3) of this section.

(b)(2) State-wide waivers. A State can waive monitoring requirements only with EPA approval and under very limited conditions. Conditions and procedures for obtaining a waiver are as follows:

(b)(2)(i) Application. A State may apply to EPA for a State-wide waiver from the unregulated contaminant monitoring requirements for PWSs serving more than 10,000 people. To apply for such a waiver, the State must submit an application to EPA that includes the following information: The list of contaminants on the UCMR Contaminant List for which a waiver is requested, along with documentation for each contaminant in the request demonstrating that the contaminants or their parent compounds do not occur naturally in the State, and certifying that during the past 15 years they have not been used, applied, stored, disposed of, released, or detected in the source waters or distribution systems in the State.

(b)(2)(ii) Approval. EPA will review State applications and notify the State whether it accepts or rejects the request. The State must receive written approval from EPA before issuing a State-wide waiver.

(c) Incorporation by reference. The standards required in this section are incorporated by reference into this section with the approval of the Director of the Federal Register under 5 U.S.C. 552(a) and 1 CFR part 51. All approved material is available for inspection at U.S. Environmental Protection Agency, Water Docket, EPA/DC, EPA West, Room 3334, 1301 Constitution Ave. NW, Washington, DC 20004, (202) 566-1744, email Docket-customerservice@epa.gov, or go to https://www.epa.gov/dockets/epa-docket-center-reading-room, and is available from the sources indicated elsewhere in this paragraph. The material is also available for inspection at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, email fr.inspection@nara.gov, or go to www.archives.gov/federal-register/cfr/ibr-locations.html.

(1) U.S. Environmental Protection Agency, EPA West, Room 3334, 1301 Constitution Ave. NW, Washington, DC 20004; telephone: (202) 566-1744.

(i) Method 200.7, “Determination of Metals and Trace Elements in Water and Wastes by Inductively Coupled Plasma-Atomic Emission Spectrometry,” Revision 4.4, EMMC Version, 1994. Available at https://www.epa.gov/esam/method-2007-determination-metals-and-trace-elements-water-and-wastes-inductively-coupled-plasma.

(ii) Method 537.1, “Determination of Selected Per- and Polyfluorinated Alkyl Substances in Drinking Water by Solid Phase Extraction and Liquid Chromatography/Tandem Mass Spectrometry,” Version 2.0, 2020. Available at https://www.epa.gov/water-research/epa-drinking-water-research-methods.

(iii) Method 533, “Determination of Per- and Polyfluoroalkyl Substances in Drinking Water by Isotope Dilution Anion Exchange Solid Phase Extraction and Liquid Chromatography/Tandem Mass Spectrometry,” November 2019, EPA 815-B-19-020. Available at https://www.epa.gov/dwanalyticalmethods.

(2) American Public Health Association, 800 I Street NW, Washington, DC 20001-3710; telephone: (202) 777-2742; email: comments@apha.org; www.apha.org.

(i) “Standard Methods for the Examination of Water & Wastewater,” 23rd edition (2017).

(A) SM 3120 B, “Metals by Plasma Emission Spectroscopy (2017): Inductively Coupled Plasma (ICP) Method.”

(B) [Reserved]

(ii) “Standard Methods Online,” approved 1999; https://www.standardmethods.org.

(A) SM 3120 B, “Metals by Plasma Emission Spectroscopy: Inductively Coupled Plasma (ICP) Method,” revised December 14, 2020.

(B) [Reserved]

(3) ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959; telephone: (610) 832-9500; email: service@astm.org; www.astm.org.

(i) ASTM D1976-20, “Standard Test Method for Elements in Water by Inductively-Coupled Plasma Atomic Emission Spectroscopy,” approved May 1, 2020.

(ii) [Reserved]

[72 FR 393, Jan. 4, 2007; 72 FR 3916, Jan. 26, 2007; 77 FR 26098, May 2, 2012; 81 FR 92688, Dec. 20, 2016; 86 FR 73155, Dec. 27. 2021]

['Water Programs']

['Safe Drinking Water', 'Water Monitoring', 'Water Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.