['Air Programs']

['Air Emissions']

06/26/2024

...

This section describes procedures for measuring emissions of nonmethane organic gas (NMOG), oxides of nitrogen (NO X), particulate matter (PM), and carbon monoxide (CO) and determining fuel economy on a cold day using the FTP test cycle (see §1066.801). For Tier 3 and earlier motor vehicles, measurement procedures are based on nonmethane hydrocarbon (NMHC) emissions instead of NMOG emissions; NO X and PM measurement requirements do not apply.

(a) Follow the exhaust emission measurement procedures specified in §§1066.410 through 1066.425 and §1066.815(d), subject to the following exceptions and additional provisions:

(1) Measure and control ambient conditions as specified in paragraph (b) of this section.

(2) Use the vehicle's heater and defroster as specified in paragraph (c) of this section.

(3) Precondition and stabilize the vehicle as specified in paragraphs (d) and (e) of this section. Ensure that there is no precipitation or dew on the vehicle before the emission test.

(4) For dynamometers that have independently heated bearings, start the emission test within 20 minutes after warming up the dynamometer; for other types of dynamometers, start the emission test within 10 minutes after warming up the dynamometer.

(5) Adjust the dynamometer to simulate vehicle operation on the road at −7°C as described in §1066.305(b).

(6) Analyze samples for NMOG, NO X , PM, CO, and CO 2 .

(b) Maintain ambient conditions as follows instead of following the specifications in subpart E of this part:

(1) Ambient temperature for emission tests. Measure and record ambient temperature in the test cell at least once every 60 seconds during the sampling period. The temperature must be (−7.0 ±1.7)°C at the start of the test and average temperature must be (−7.0 ±2.8)°C during the test. Instantaneous temperature values may be above −4.0°C or below −9.0°C, but not for more than 3 minutes at a time during the test. At no time may the ambient temperatures be below −12.0°C or above −1.0°C.

(2) Ambient temperature for preconditioning. Instantaneous ambient temperature values may be above −4.0 °C or below −9.0 °C but not for more than 3 minutes at a time during the preconditioning period. At no time may ambient temperatures be below −12.0 °C or above −1.0 °C. The average ambient temperature during preconditioning must be (−7.0 ±2.8) °C. You may precondition vehicles at temperatures above −7.0 °C or with a temperature tolerance greater than that described in this section (or both) if you determine that this will not cause NMOG, NO X , PM, CO, or CO 2 emissions to decrease; if you modify the temperature specifications for vehicle preconditioning, adjust the procedures described in this section appropriately for your testing.

(3) Ambient humidity. Maintain humidity low enough to prevent condensation on the dynamometer rolls during testing.

(c) During the test, operate the vehicle's interior climate control system with the heat on and air conditioning off. You may not use any supplemental auxiliary heat during this testing. You may set the heater to any temperature and fan setting during vehicle preconditioning.

(1) Manual and automatic temperature control. Unless you rely on full automatic control as specified in paragraph (c)(2) of this section, take the following steps to control heater settings:

(i) Set the climate control system as follows before the first acceleration (t = 20 s), or before starting the vehicle if the climate control system allows it:

(A) Temperature. Set controls to maximum heat. For automatic temperature control systems that allow the operator to select a specific temperature, set the heater control to 72°F or higher.

(B) Fan speed. Set the fan speed to full off or the lowest available speed if a full off position is not available.

(C) Airflow direction. Direct airflow to the front window (window defrost mode).

(D) Air source. If independently controllable, set the system to draw in outside air.

(ii) At the second idle of the test cycle, which occurs 125 seconds after the start of the test, set the fan speed to maximum. Complete by 130 seconds after the start of the test. Leave temperature and air source settings unchanged.

(iii) At the sixth idle of the test interval, which occurs at the deceleration to zero miles per hour 505 seconds after the start of the test, set the fan speed to the lowest setting that maintains air flow. Complete these changes by 510 seconds after the start of the test. You may use different vent and fan speed settings for the remainder of the test. Leave the temperature and air source settings unchanged.

(2) Full automatic control. Vehicles with full automatic control systems may instead operate as described in this paragraph (c)(2). Set the temperature to 72°F in full automatic control for the whole test, allowing the vehicle to adjust the air temperature and direction of the airflow.

(3) Multiple-zone systems. For vehicles that have separate driver and passenger controls or separate front and rear controls, you must set all temperature and fan controls as described in paragraphs (c)(1) and (2) of this section, except that rear controls need not be set to defrost the front window.

(4) Alternative test procedures. We may approve the use of other settings under 40 CFR 86.1840 if a vehicle's climate control system is not compatible with the provisions of this section.

(d) Take the following steps to prepare and precondition vehicles for testing under this section:

(1) Prepare the vehicle as described in §1066.810(a).

(2) Fdill the fuel tank to approximately 40% of the manufacturer's nominal fuel tank capacity. Use the appropriate gasoline test fuel for low-temperature testing as specified 40 CFR 1065.710 or use ultra low-sulfur diesel fuel as specified in 40 CFR 1065.703. However, you may ask us to approve an alternative formulation of diesel fuel under 40 CFR 1065.10(c)(1) if that better represents in-use diesel fuel in winter conditions. The temperature of the dispensed test fuel must be at or below 15.5 °C. If the leftover fuel in the fuel tank before the refueling event does not meet these specifications, drain the fuel tank before refueling. You may operate the vehicle prior to the preconditioning drive to eliminate fuel effects on adaptive memory systems.

(3) You may start the preconditioning drive once the fuel in the fuel tank reaches (−12.6 to −1.4)°C. Precondition the vehicle as follows:

(i) Push or drive the vehicle onto the dynamometer.

(ii) Operate the vehicle over one UDDS. You may perform additional vehicle preconditioning with repeated driving over the UDDS, subject to our advance approval.

(iii) Turn off the test vehicle and any cooling fans within 5 minutes after completing the preconditioning drive. Ambient temperature must be between (−12.0 and −1.0)°C in the 5 minutes following the preconditioning drive.

(iv) Do not manually purge or load the evaporative canister.

(e) Soak the vehicle for (12 to 36) hours to stabilize it at test temperatures before starting the emission test as described in this paragraph (e). If you move a stabilized vehicle through a warm area when transporting it to the dynamometer for testing, you must restabilize the vehicle by holding it at an ambient temperature within the range specified in paragraph (b)(1) of this section for at least six times as long as the vehicle was exposed to warmer temperatures. Use one of the following methods to reach a stabilized condition:

(1) Cold storage. Measure and record ambient temperature in the test cell at least once every 60 seconds during the ambient cold soak period. These ambient temperatures may be above −4.0°C or below −9.0°C, but not for more than 3 minutes at a time. Use measured values to calculate an hourly average temperature. Each hourly average temperature must be (−7.0°C ±2.8)°C.

(2) Forced-cooling or warming. Position fans to blow temperature-controlled air onto the vehicle to stabilize the vehicle at the specified temperatures for emission testing. Position fans to target the vehicle's drive train, engine block, and radiator rather than the oil pan. You may not place fans under the vehicle. You may consider the vehicle to be stabilized at the test temperature when the bulk oil temperature reaches (−8.7 to −5.3)°C; measure oil temperature at one or more points away from the side or bottom surfaces of the oil pan. Each oil temperature measurement must be within the specified range before stabilization is complete. Once the vehicle reaches this stabilized condition, cold soak the vehicle within the stabilized temperature range for at least one hour before starting the emission test. During this time, keep the ambient temperature within the range specified in paragraph (b)(1) of this section.

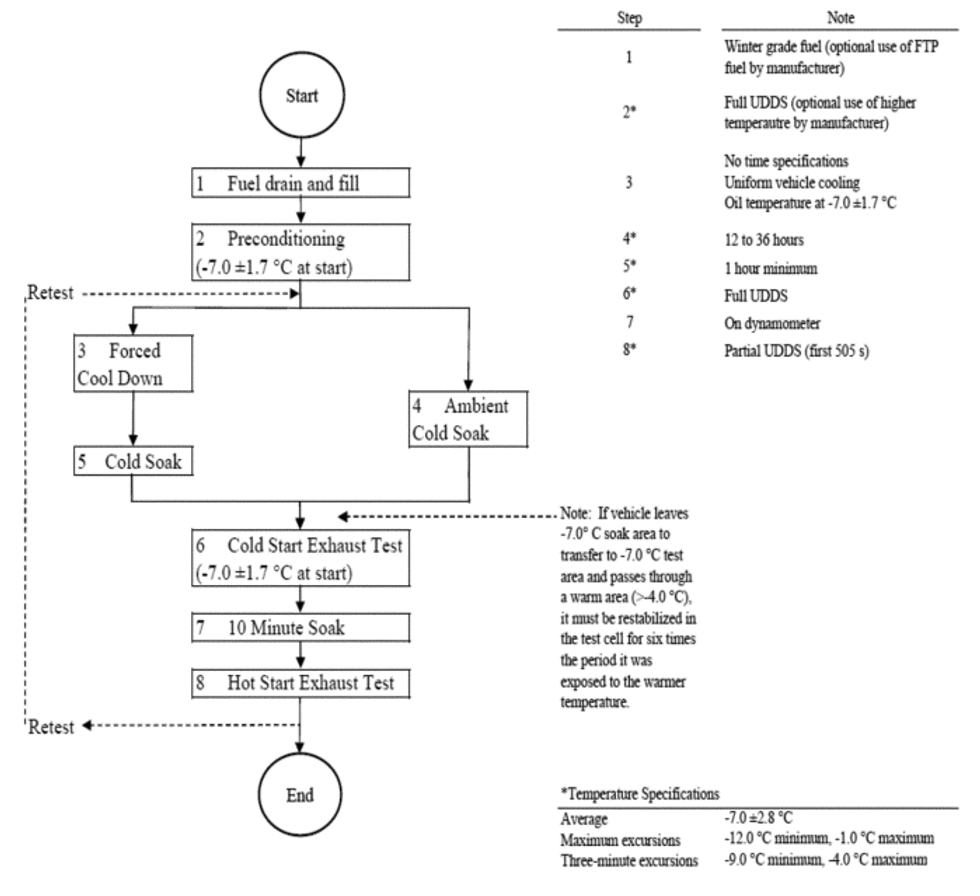

(f) The following figure illustrates the cold temperature testing sequence for measuring CO and NMHC emissions and determining fuel economy:

Figure 1 to paragraph (f) §1066.710—Cold Temperature Testing Sequence for Measuring CO and NMHC Emissions and Determining Fuel Economy

[79 FR 23823, Apr. 28, 2014, as amended at 80 FR 9122, Feb. 19, 2015; 81 FR 74213, Oct. 25, 2016; 86 FR 34583, Jun. 29, 2021; 88 FR 4708, Jan. 24, 2023; 89 FR 28212, Apr. 18, 2024]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.