['Air Programs']

['Air Emissions']

03/16/2023

...

This section describes how to determine deterioration factors, either with pre-existing test data or with new emission measurements.

(a) You may ask us to approve deterioration factors for an emission family based on emission measurements from similar engines if you have already given us these data for certifying other engines in the same or earlier model years. Use good engineering judgment to decide whether the two engines are similar. We will approve your request if you show us that the emission measurements from other engines reasonably represent in-use deterioration for the engine family for which you have not yet determined deterioration factors.

(b) If you are unable to determine deterioration factors for an emission family under paragraph (a) of this section, select engines, subsystems, or components for testing. Determine deterioration factors based on service accumulation and related testing. Include consideration of wear and other causes of deterioration expected under typical consumer use. Determine deterioration factors as follows:

(1) Measure emissions from the emission-data engine at a low-hour test point, at the midpoint of the useful life, and at the end of the useful life, except as specifically allowed by this paragraph (b). You may test at additional evenly spaced intermediate points. Collect emission data using measurements to at least one more decimal place than the emission standard in subpart B of this part.

(2) Operate the engine over a duty cycle that is representative of in-use operation for a period at least as long as the useful life (in hours). You may operate the engine continuously. You may also use an engine installed in nonroad equipment to accumulate service hours instead of running the engine only in the laboratory.

(3)In the case of dual-fuel or flexible-fuel engines, you may accumulate service hours on a single emission-data engine using the type or mixture of fuel expected to have the highest combustion and exhaust temperatures; you may ask us to approve a different fuel mixture for flexible-fuel engines if you demonstrate that a different criterion is more appropriate. For dual-fuel engines, you must measure emissions on each fuel type at each test point, either with separate engines dedicated to a given fuel, or with different configurations of a single engine.

(4) You may perform maintenance on emission-data engines as described in �1054.125 and 40 CFR part 1065, subpart E. If you change one or more spark plugs on an emission-data engine as allowed under �1054.125, you must measure emissions before and after this maintenance. If you clean or change an air filter on an emission-data engine as allowed under �1054.125, you must measure emissions before and after every second time you perform this maintenance. Use the average values from these two measurements to calculate deterioration factors. The emission-data engine must meet applicable emission standards before and after maintenance to be considered in compliance, as described in �1054.240(a) and (b).

(5) Calculate your deterioration factor using a linear least-squares fit of your test data but treat the low-hour test point as occurring at hour zero. Your deterioration factor is the ratio of the calculated emission level at the point representing the full useful life to the calculated emission level at zero hours, expressed to one more significant figure than the emission standard in subpart B of this part.

(6) If you test more than one engine to establish deterioration factors, average the deterioration factors from all the engines before rounding.

(7) If your durability engine fails between 80 percent and 100 percent of useful life, you may use the last emission measurement as the test point representing the full useful life, provided it occurred after at least 80 percent of the useful life.

(8) If your useful life is 1,000 hours or longer, and your durability engine fails between 50 percent and 100 percent of useful life, you may extrapolate your emission results to determine the emission level representing the full useful life, provided emissions were measured at least once after 50 percent of the useful life.

(9) Use good engineering judgment for all aspects of the effort to establish deterioration factors under this paragraph (b).

(10) You may use other testing methods to determine deterioration factors, consistent with good engineering judgment, as long as we approve those methods in advance.

(c) If you qualify for using assigned deterioration factors under �1054.240, determine the deterioration factors as follows:

(1) For two-stroke engines without aftertreatment, use a deterioration factor of 1.1 for HC, NOX, and CO. For four-stroke engines without aftertreatment, use deterioration factors of 1.4 for HC, 1.0 for NOX, and 1.1 for CO for Class 2 engines, and use 1.5 for HC and NOX, and 1.1 for CO for all other engines.

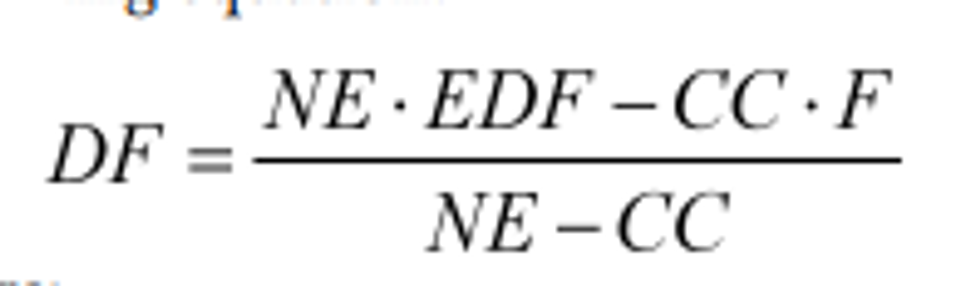

(2) For Class 2 engines with aftertreatment, use a deterioration factor of 1.0 for NOX. For all other cases involving engines with aftertreatment, calculate separate deterioration factors for HC, NOX, and CO using the following equation:

Where:

NE = engine-out emission levels (pre-catalyst) from the low-hour test result for a given pollutant, in g/kW-hr.

EDF = the deterioration factor specified in paragraph (c)(1) of this section for the type of engine for a given pollutant.

CC = the catalyst conversion from the low-hour test, in g/kW-hr. This is the difference between the official emission result and NE.

F = 1.0 for NOX and 0.8 for HC and CO.

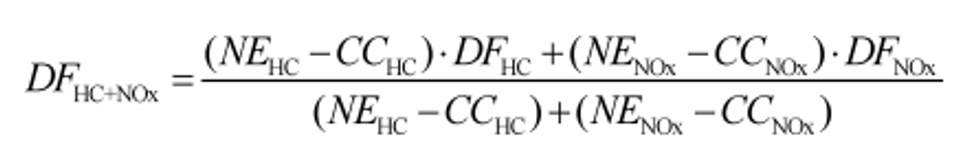

(3) Combine separate deterioration factors for HC and NOX from paragraph (c)(2) of this section into a combined deterioration factor for HC+NOX using the following equation:

(d) Include the following information in your application for certification:

(1) If you determine your deterioration factors based on test data from a different emission family, explain why this is appropriate and include all the emission measurements on which you base the deterioration factor.

(2) If you do testing to determine deterioration factors, describe the form and extent of service accumulation, including the method you use to accumulate hours.

(3) If you calculate deterioration factors under paragraph (c) of this section, identify the parameters and variables you used for the calculation.

[86 FR 34520, Jun. 29, 2021]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.