['CMV Parts and Maintenance']

['Vehicle maintenance']

10/30/2024

...

S1. Scope. This standard establishes strength requirements for the passenger compartment roof.

S2. Purpose. The purpose of this standard is to reduce deaths and injuries due to the crushing of the roof into the occupant compartment in rollover crashes.

S3. Application.

(a) This standard applies to passenger cars, and to multipurpose passenger vehicles, trucks and buses with a GVWR of 2,722 kilograms (6,000 pounds) or less. However, it does not apply to—

(b) Vehicles that conform to the rollover test requirements (S5.3) of Standard No. 208 ( §571.208 ) by means that require no action by vehicle occupants;

(c) Convertibles, except for optional compliance with the standard as an alternative to the rollover test requirements in S5.3 of Standard No. 208; or

(d) Vehicles certified to comply with §571.216a.

S4. Definitions.

Altered roof

means the replacement roof on a motor vehicle whose original roof has been removed, in part or in total, and replaced by a roof that is higher than the original roof. The replacement roof on a motor vehicle whose original roof has been replaced, in whole or in part, by a roof that consists of glazing materials, such as those in T-tops and sunroofs, and is located at the level of the original roof, is not considered to be an altered roof.

Raised roof

means, with respect to a roof which includes an area that protrudes above the surrounding exterior roof structure, that protruding area of the roof.

Roof over the front seat area

means the portion of the roof, including windshield trim, forward of a transverse vertical plane passing through a point 162 mm rearward of the SgRP of the rearmost front outboard seating position.

Windshield trim

means molding of any material between the windshield glazing and the exterior roof surface, including material that covers a part of either the windshield glazing or exterior roof surface.

S5. Requirements. Subject to S5.1, when the test device described in S6 is used to apply a force to either side of the forward edge of a vehicle’s roof in accordance with the procedures of S7, the lower surface of the test device must not move more than 127 millimeters. The applied force in Newtons is equal to 1.5 times the unloaded vehicle weight of the vehicle, measured in kilograms and multiplied by 9.8, but does not exceed 22,240 Newtons for passenger cars. Both the left and right front portions of the vehicle’s roof structure must be capable of meeting the requirements. A particular vehicle need not meet further requirements after being tested at one location.

S5.1 For multipurpose passenger vehicles, trucks and buses that have a raised roof or altered roof, manufacturers have the option of using the test procedures of S8 instead of the procedures of S7 until October 25, 2000. The option of using the test procedures of S8 ceases to be available on that date.

S6. Test device. The test device is a rigid unyielding block whose lower surface is a flat rectangle measuring 762 millimeters by 1,829 millimeters.

S7. Test procedure. Each vehicle must be capable of meeting the requirements of S5 when tested in accordance with the procedure in S7.1 through 7.6.

S7.1 Place the sills or the chassis frame of the vehicle on a rigid horizontal surface, fix the vehicle rigidly in position, close all windows, close and lock all doors, and secure any convertible top or removable roof structure in place over the occupant compartment. Remove roof racks or other non-structural components.

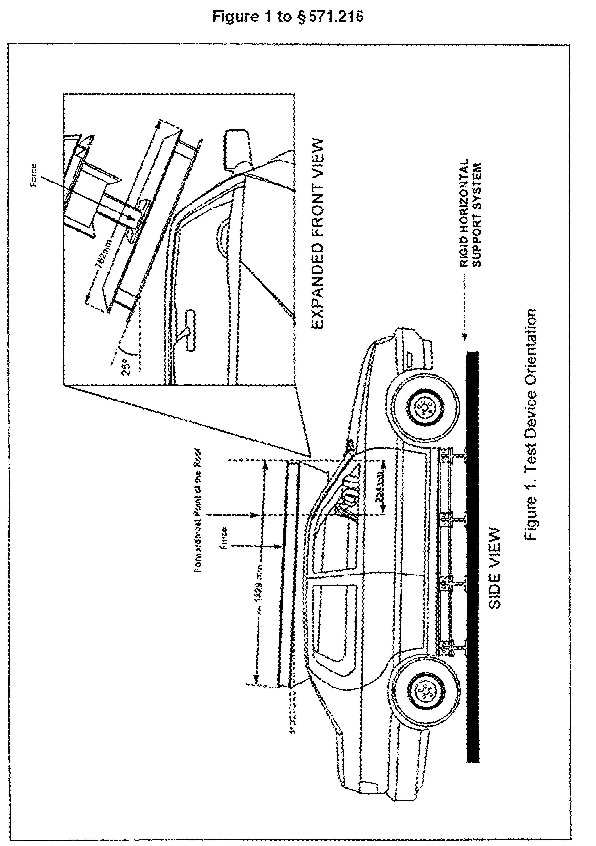

S7.2 Orient the test device as shown in Figure 1 of this section, so that-

(a) Its longitudinal axis is at a forward angle (in side view) of 5 degrees below the horizontal, and is parallel to the vertical plane through the vehicle’s longitudinal centerline;

(b) Its transverse axis is at an outboard angle, in the front view projection, of 25 degrees below the horizontal.

S7.3 Maintaining the orientation specified in S7.2-

(a) Lower the test device until it initially makes contact with the roof of the vehicle.

(b) Position the test device so that-

(1) The longitudinal centerline on its lower surface is on the initial point of contact, or on the center of the initial contact area, with the roof; and

(2) Except as specified in S7.4, the midpoint of the forward edge of the lower surface of the test device is within 10 mm of the transverse vertical plane 254 mm forward of the forwardmost point on the exterior surface of the roof, including windshield trim, that lies in the longitudinal vertical plane passing through the vehicle’s longitudinal centerline.

S7.4 If the vehicle being tested is a multipurpose passenger vehicle, truck, or bus that has a raised roof or altered roof, and the initial contact point of the test device is on the raised roof or altered roof to the rear of the roof over the front seat area, the plate is positioned so that the midpoint of the rearward edge of the lower surface of the test device is within 10 mm of the transverse vertical plane located at the rear of the roof over the front seat area.

S7.5 Apply force so that the test device moves in a downward direction perpendicular to the lower surface of the test device at a rate of not more than 13 millimeters per second until reaching the force level specified in S5. Guide the test device so that throughout the test it moves, without rotation, in a straight line with its lower surface oriented as specified in S7.2(a) and S7.2(b). Complete the test within 120 seconds.

S7.6 Measure the distance that the test device moved, i.e., the distance between the original location of the lower surface of the test device and its location as the force level specified in S5 is reached.

S8 Alternate test procedure for multipurpose passenger vehicles, trucks and buses that have a raised roof or altered roof manufactured until October 25, 2000 (see S5.1). Each vehicle shall be capable of meeting the requirements of S5 when tested in accordance with the following procedure.

S8.1 Place the sills or the chassis frame of the vehicle on a rigid horizontal surface, fix the vehicle rigidly in position, close all windows, close and lock all doors, and secure any convertible top or removable roof structure in place over the passenger compartment.

S8.2 Orient the test device as shown in Figure 2, so that-

(a) Its longitudinal axis is at a forward angle (side view) of 5° below the horizontal, and is parallel to the vertical plane through the vehicle’s longitudinal centerline;

(b) Its lateral axis is at a lateral outboard angle, in the front view projection, of 25° below the horizontal;

(c) Its lower surface is tangent to the surface of the vehicle; and

(d) The initial contact point, or center of the initial contact area, is on the longitudinal centerline of the lower surface of the test device and 254 millimeters from the forwardmost point of that centerline.

S8.3 Apply force in a downward direction perpendicular to the lower surface of the test device at a rate of not more than 13 millimeters per second until reaching a force in Newtons of 1 1⁄ 2 times the unloaded vehicle weight of the tested vehicle, measured in kilograms and multiplied by 9.8. Complete the test within 120 seconds. Guide the test device so that throughout the test it moves, without rotation, in a straight line with its lower surface oriented as specified in S8.2(a) through S8.2(d).

S8.4 Measure the distance that the test device moves, i.e., the distance between the original location of the lower surface of the test device and its location as the force level specified in S8.3 is reached.

|

|

[36 FR 23300, Dec. 8, 1971, as amended at 38 FR 21930, Aug. 14, 1973; 56 FR 15517, Apr. 17, 1991; 58 FR 5633, Jan. 22, 1993; 60 FR 13647, Mar. 14, 1995; 64 FR 22578, Apr. 27, 1999; 65 FR 4581, Jan. 31, 2000; 74 FR 22384 May 12, 2009]

READ MORESHOW LESS

['CMV Parts and Maintenance']

['Vehicle maintenance']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.