['CMV Parts and Maintenance']

['Brakes']

10/30/2024

...

S1. Scope. This standard specifies requirements for service brake and associated parking brake systems.

S2. Purpose. The purpose of this standard is to ensure safe braking performance under normal and emergency driving conditions.

S3. Application. This standard applies to passenger cars manufactured on or after September 1, 2000 and to multi-purpose passenger vehicles, trucks and buses with a gross vehicle weight rating (GVWR) of 3,500 kilograms (7,716 pounds) or less, manufactured on or after September 1, 2002. In addition, at the option of the manufacturer, passenger cars manufactured before September 1, 2000, and multi-purpose passenger vehicles, trucks and buses with a GVWR of 3,500 kilograms (7,716 pounds) or less, manufactured before September 1, 2002, may meet the requirements of this standard instead of Federal Motor Vehicle No. 105, Hydraulic Brake Systems.

S4. Definitions.

Adhesion utilization curves

means curves showing, for specified load conditions, the adhesion utilized by each axle of a vehicle plotted against the braking ratio of the vehicle.

Antilock brake system or ABS

means a portion of a service brake system that automatically controls the degree of rotational wheel slip during braking by:

(1) Sensing the rate of angular rotation of the wheels;

(2) Transmitting signals regarding the rate of wheel angular rotation to one or more controlling devices which interpret those signals and generate responsive controlling output signals; and

(3) Transmitting those controlling signals to one or more modulator devices which adjust brake actuating forces in response to those signals.

Backup system

means a portion of a service brake system, such as a pump, that automatically supplies energy in the event of a primary brake power source failure.

Brake factor

means the slope of the linear least squares regression equation best representing the measured torque output of a brake as a function of the measured applied line pressure during a given brake application for which no wheel lockup occurs.

Brake hold-off pressure

means the maximum applied line pressure for which no brake torque is developed, as predicted by the pressure axis intercept of the linear least squares regression equation best representing the measured torque output of a brake as a function of the measured applied line pressure during a given brake application.

Brake power assist unit

means a device installed in a hydraulic brake system that reduces the amount of muscular force that a driver must apply to actuate the system, and that, if inoperative, does not prevent the driver from braking the vehicle by a continued application of muscular force on the service brake control.

Brake power unit

means a device installed in a brake system that provides the energy required to actuate the brakes, either directly or indirectly through an auxiliary device, with driver action consisting only of modulating the energy application level.

Braking ratio

means the deceleration of the vehicle divided by the gravitational acceleration constant.

Electric vehicle or EV

means a motor vehicle that is powered by an electric motor drawing current from rechargeable storage batteries, fuel cells, or other portable sources of electrical current, and which may include a non-electrical source of power designed to charge batteries and components thereof.

Electrically-actuated service brakes

means service brakes that utilize electrical energy to actuate the foundation brakes.

Functional failure

means a failure of a component (either electrical or mechanical in nature) which renders the system totally or partially inoperative yet the structural integrity of the system is maintained.

Hydraulic brake system

means a system that uses hydraulic fluid as a medium for transmitting force from a service brake control to the service brake and that may incorporate a brake power assist unit, or a brake power unit.

Initial brake temperature or IBT

means the average temperature of the service brakes on the hottest axle of the vehicle 0.32 km (0.2 miles) before any brake application.

Lightly loaded vehicle weight or LLVW

means unloaded vehicle weight plus the weight of a mass of 180 kg (396 pounds), including driver and instrumentation.

Maximum speed of a vehicle or VMax

means the highest speed attainable by accelerating at a maximum rate from a standing start for a distance of 3.2 km (2 miles) on a level surface, with the vehicle at its lightly loaded vehicle weight, and, if an EV, with the propulsion batteries at a state of charge of not less than 95 percent at the beginning of the run.

Objective brake factor

means the arithmetic average of all the brake factors measured over the twenty brake applications defined in S7.4, for all wheel positions having a given brake configuration.

Peak friction coefficient or PFC

means the ratio of the maximum value of braking test wheel longitudinal force to the simultaneous vertical force occurring prior to wheel lockup, as the braking torque is progressively increased.

Pressure component

means a brake system component that contains the brake system fluid and controls or senses the fluid pressure.

Regenerative braking system or RBS

means an electrical energy system that is installed in an EV for recovering or dissipating kinetic energy, and which uses the propulsion motor(s) as a retarder for partial braking of the EV while returning electrical energy to the propulsion battery(s) or dissipating electrical energy.

Snub

means the braking deceleration of a vehicle from a higher reference speed to a lower reference speed that is greater than zero.

Split service brake system

means a brake system consisting of two or more subsystems actuated by a single control, designed so that a single failure in any subsystem (such as a leakage-type failure of a pressure component of a hydraulic subsystem except structural failure of a housing that is common to two or more subsystems, or an electrical failure in an electric subsystem) does not impair the operation of any other subsystem.

Stopping distance

means the distance traveled by a vehicle from the point of application of force to the brake control to the point at which the vehicle reaches a full stop.

Variable brake proportioning system

means a system that has one or more proportioning devices which automatically change the brake pressure ratio between any two or more wheels to compensate for changes in wheel loading due to static load changes and/or dynamic weight transfer, or due to deceleration.

Wheel lockup

means 100 percent wheel slip.

S5. Equipment requirements.

S5.1. Service brake system. Each vehicle shall be equipped with a service brake system acting on all wheels.

S5.1.1. Wear adjustment. Wear of the service brakes shall be compensated for by means of a system of automatic adjustment.

S5.1.2. Wear status. The wear condition of all service brakes shall be indicated by either:

(a) Acoustic or optical devices warning the driver at his or her driving position when lining replacement is necessary, or

(b) A means of visually checking the degree of brake lining wear, from the outside or underside of the vehicle, utilizing only the tools or equipment normally supplied with the vehicle. The removal of wheels is permitted for this purpose.

S5.1.3 Regenerative braking system. (a) For an EV equipped with RBS, the RBS is considered to be part of the service brake system if it is automatically activated by an application of the service brake control, if there is no means provided for the driver to disconnect or otherwise deactivate it, and if it is activated in all transmission positions, including neutral.

(b) For an EV that is equipped with both ABS and RBS that is part of the service brake system, the ABS must control the RBS.

S5.2. Parking brake system. Each vehicle shall be equipped with a parking brake system of a friction type with solely mechanical means to retain engagement.

S5.3. Controls.

S5.3.1. The service brakes shall be activated by means of a foot control. The control of the parking brake shall be independent of the service brake control, and may be either a hand or foot control.

S5.3.2. For vehicles equipped with ABS, a control to manually disable the ABS, either fully or partially, is prohibited.

S5.4. Reservoirs.

S5.4.1. Master cylinder reservoirs. A master cylinder shall have a reservoir compartment for each service brake subsystem serviced by the master cylinder. Loss of fluid from one compartment shall not result in a complete loss of brake fluid from another compartment.

S5.4.2. Reservoir capacity. Reservoirs, whether for master cylinders or other type systems, shall have a total minimum capacity equivalent to the fluid displacement resulting when all the wheel cylinders or caliper pistons serviced by the reservoirs move from a new lining, fully retracted position (as adjusted initially to the manufacturer’s recommended setting) to a fully worn, fully applied position, as determined in accordance with S7.17(c) of this standard. Reservoirs shall have completely separate compartments for each subsystem except that in reservoir systems utilizing a portion of the reservoir for a common supply to two or more subsystems, individual partial compartments shall each have a minimum volume of fluid equal to at least the volume displaced by the master cylinder piston servicing the subsystem, during a full stroke of the piston. Each brake power unit reservoir servicing only the brake system shall have a minimum capacity equivalent to the fluid displacement required to charge the system piston(s) or accumulator(s) to normal operating pressure plus the displacement resulting when all the wheel cylinders or caliper pistons serviced by the reservoir or accumulator(s) move from a new lining, fully retracted position (as adjusted initially to the manufacturer’s recommended setting) to a fully worn, fully applied position.

S5.4.3. Reservoir labeling. Each vehicle equipped with hydraulic brakes shall have a brake fluid warning statement that reads as follows, in letters at least 3.2 mm ( 1/8 inch) high: “WARNING: Clean filler cap before removing. Use only ____ fluid from a sealed container.” (Inserting the recommended type of brake fluid as specified in 49 CFR 571.116, e.g., “DOT 3.”) The lettering shall be:

(a) Permanently affixed, engraved or embossed;

(b) Located so as to be visible by direct view, either on or within 100 mm (3.94 inches) of the brake fluid reservoir filler plug or cap; and

(c) Of a color that contrasts with its background, if it is not engraved or embossed.

S5.4.4. Fluid level indication. Brake fluid reservoirs shall be so constructed that the level of fluid can be checked without need for the reservoir to be opened. This requirement is deemed to have been met if the vehicle is equipped with a transparent brake fluid reservoir or a brake fluid level indicator meeting the requirements of S5.5.1(a)(1).

S5.5. Brake system warning indicator. Each vehicle shall have one or more visual brake system warning indicators, mounted in front of and in clear view of the driver, which meet the requirements of S5.5.1 through S5.5.5. In addition, a vehicle manufactured without a split service brake system shall be equipped with an audible warning signal that activates under the conditions specified in S5.5.1(a).

S5.5.1. Activation. An indicator shall be activated when the ignition (start) switch is in the “on” (”run”) position and whenever any of conditions (a) through (g) occur:

(a) A gross loss of fluid or fluid pressure (such as caused by rupture of a brake line but not by a structural failure of a housing that is common to two or more subsystems) as indicated by one of the following conditions (chosen at the option of the manufacturer):

(1) A drop in the level of the brake fluid in any master cylinder reservoir compartment to less than the recommended safe level specified by the manufacturer or to one-fourth of the fluid capacity of that reservoir compartment, whichever is greater.

(2) For vehicles equipped with a split service brake system, a differential pressure of 1.5 MPa (218 psi) between the intact and failed brake subsystems measured at a master cylinder outlet or a slave cylinder outlet.

(3) A drop in the supply pressure in a brake power unit to one-half of the normal system pressure.

(b) Any electrical functional failure in an antilock or variable brake proportioning system.

(c) Application of the parking brake.

(d) Brake lining wear-out, if the manufacturer has elected to use an electrical device to provide an optical warning to meet the requirements of S5.1.2(a).

(e) For a vehicle with electrically-actuated service brakes, failure of the source of electric power to those brakes, or diminution of state of charge of the batteries to less than a level specified by the manufacturer for the purpose of warning a driver of degraded brake performance.

(f) For a vehicle with electric transmission of the service brake control signal, failure of a brake control circuit.

(g) For an EV with a regenerative braking system that is part of the service brake system, failure of the RBS.

S5.5.2. Function check. (a) All indicators shall be activated as a check function by either:

(1) Automatic activation when the ignition (start) switch is turned to the “on” (”run”) position when the engine is not running, or when the ignition (”start”) switch is in a position between “on” (”run”) and “start” that is designated by the manufacturer as a check position, or

(2) A single manual action by the driver, such as momentary activation of a test button or switch mounted on the instrument panel in front of and in clear view of the driver, or, in the case of an indicator for application of the parking brake, by applying the parking brake when the ignition is in the “on” (”run”) position.

(b) In the case of a vehicle that has an interlock device that prevents the engine from being started under one or more conditions, check functions meeting the requirements of S5.5.2(a) need not be operational under any condition in which the engine cannot be started.

(c) The manufacturer shall explain the brake check function test procedure in the owner’s manual.

S5.5.3. Duration. Each indicator activated due to a condition specified in S5.5.1 shall remain activated as long as the condition exists, whenever the ignition (”start”) switch is in the “on” (”run”) position, whether or not the engine is running.

S5.5.4. Function. When a visual warning indicator is activated, it may be continuous or flashing, except that the visual warning indicator on a vehicle not equipped with a split service brake system shall be flashing. The audible warning required for a vehicle manufactured without a split service brake system may be continuous or intermittent.

S5.5.5. Labeling. (a) Each visual indicator shall display a word or words in accordance with the requirements of Standard No. 101 ( 49 CFR 571.101 ) and this section, which shall be legible to the driver under all daytime and nighttime conditions when activated. Unless otherwise specified, the words shall have letters not less than 3.2 mm ( 1/8 inch) high and the letters and background shall be of contrasting colors, one of which is red. Words or symbols in addition to those required by Standard No. 101 and this section may be provided for purposes of clarity.

(b) Vehicles manufactured with a split service brake system may use a common brake warning indicator to indicate two or more of the functions described in S5.5.1(a) through S5.5.1(g). If a common indicator is used, it shall display the word ”Brake.”

(c) A vehicle manufactured without a split service brake system shall use a separate indicator to indicate the failure condition in S5.5.1(a). This indicator shall display the words “STOP- BRAKE FAILURE” in block capital letters not less than 6.4 mm ( 1/4 inch) in height.

(d) If separate indicators are used for one or more of the conditions described in S5.5.1(a) through S5.5.1(g), the indicators shall display the following wording:

(1) If a separate indicator is provided for the low brake fluid condition in S5.5.1(a)(1), the words “Brake Fluid” shall be used except for vehicles using hydraulic system mineral oil.

(2) If a separate indicator is provided for the gross loss of pressure condition in S5.5.1(a)(2), the words “Brake Pressure” shall be used.

(3) If a separate indicator is provided for the condition specified in S5.5.1(b), the letters and background shall be of contrasting colors, one of which is yellow. The indicator shall be labeled with the words “Antilock” or “Anti-lock” or “ABS”; or “Brake Proportioning,” in accordance with Table 1 of Standard No. 101.

(4) If a separate indicator is provided for application of the parking brake as specified for S5.5.1(c), the single word “Park” or the words “Parking Brake” may be used.

(5) If a separate indicator is provided to indicate brake lining wear-out as specified in S5.5.1(d), the words ”Brake Wear” shall be used.

(6) If a separate indicator is provided for the condition specified in S5.5.1(g), the letters and background shall be of contrasting colors, one of which is yellow. The indicator shall be labeled with the symbol “RBS.” RBS failure in a system that is part of the service brake system may also be indicated by a yellow lamp that also indicates “ABS” failure and displays the symbol “ABS/ RBS.”

(7) If a separate indicator is provided for any other function, the display shall include the word “Brake” and the appropriate additional labeling.

S5.6. Brake system integrity. Each vehicle shall meet the complete performance requirements of this standard without:

(a) Detachment or fracture of any component of the braking system, such as brake springs and brake shoes or disc pad facings other than minor cracks that do not impair attachment of the friction facings. All mechanical components of the braking system shall be intact and functional. Friction facing tearout (complete detachment of lining) shall not exceed 10 percent of the lining on any single frictional element.

(b) Any visible brake fluid or lubricant on the friction surface of the brake, or leakage at the master cylinder or brake power unit reservoir cover, seal, and filler openings.

S6. General test conditions. Each vehicle must meet the performance requirements specified in S7 under the following test conditions and in accordance with the test procedures and test sequence specified. Where a range of conditions is specified, the vehicle must meet the requirements at all points within the range.

S6.1. Ambient conditions.

S6.1.1. Ambient temperature. The ambient temperature is any temperature between 0 ° C (32 ° F) and 40 ° C (104 ° F).

S6.1.2. Wind speed. The wind speed is not greater than 5 m/s (11.2 mph).

S6.2. Road test surface.

S6.2.1. Pavement friction. Unless otherwise specified, the road test surface produces a peak friction coefficient (PFC) of 1.02 when measured using an ASTM F2493 standard reference test tire, in accordance with ASTM E1337-19 (incorporated by reference, see §571.5), at a speed of 64.4 km/h (40 mph), without water delivery.

S6.2.2. Gradient. Except for the parking brake gradient holding test, the test surface has no more than a 1% gradient in the direction of testing and no more than a 2% gradient perpendicular to the direction of testing.

S6.2.3. Lane width. Road tests are conducted on a test lane 3.5 m (11.5 ft) wide.

S6.3. Vehicle conditions.

S6.3.1. Vehicle weight.

S6.3.1.1. For the tests at GVWR, the vehicle is loaded to its GVWR such that the weight on each axle as measured at the tire-ground interface is in proportion to its GAWR, with the fuel tank filled to 100% of capacity. However, if the weight on any axle of a vehicle at LLVW exceeds the axle’s proportional share of the GVWR, the load required to reach GVWR is placed so that the weight on that axle remains the same as at LLVW.

S6.3.1.2. For the test at LLVW, the vehicle is loaded to its LLVW such that the added weight is distributed in the front passenger seat area.

S6.3.2. Fuel tank loading. The fuel tank is filled to 100% of capacity at the beginning of testing and may not be less than 75% of capacity during any part of the testing.

S6.3.3. Lining preparation. At the beginning of preparation for the road tests, the brakes of the vehicle are in the same condition as when the vehicle was manufactured. No burnishing or other special preparation is allowed, unless all vehicles sold to the public are similarly prepared as a part of the manufacturing process.

S6.3.4. Adjustments and repairs. These requirements must be met without replacing any brake system parts or making any adjustments to the brake system except as specified in this standard. Where brake adjustments are specified (S7.1.3), adjust the brakes, including the parking brakes, in accordance with the manufacturer’s recommendation. No brake adjustments are allowed during or between subsequent tests in the test sequence.

S6.3.5. Automatic brake adjusters. Automatic adjusters are operational throughout the entire test sequence. They may be adjusted either manually or by other means, as recommended by the manufacturer, only prior to the beginning of the road test sequence.

S6.3.6. Antilock brake system (ABS). If a car is equipped with an ABS, the ABS is fully operational for all tests, except where specified in the following sections.

S6.3.7. Variable brake proportioning valve. If a car is equipped with a variable brake proportioning system, the proportioning valve is fully operational for all tests except the test for failed variable brake proportioning system.

S6.3.8. Tire inflation pressure. Tires are inflated to the pressure recommended by the vehicle manufacturer for the GVWR of the vehicle.

S6.3.9. Engine. Engine idle speed and ignition timing are set according to the manufacturer’s recommendations. If the vehicle is equipped with an adjustable engine speed governor, it is adjusted according to the manufacturer’s recommendations.

S6.3.10. Vehicle openings. All vehicle openings (doors, windows, hood, trunk, convertible top, cargo doors, etc.) are closed except as required for instrumentation purposes.

S6.3.11 State of charge of batteries for EVs.

S6.3.11.1 The state of charge of the propulsion batteries is determined in accordance with SAE Recommended Practice J227a (1976) (incorporated by reference, see §571.5 ). The applicable sections of J227a (1976) are 3.2.1 through 3.2.4, 3.3.1 through 3.3.2.2, 3.4.1 and 3.4.2, 4.2.1, 5.2, 5.2.1 and 5.3.

S6.3.11.2 At the beginning of the burnish procedure (S7.1 of this standard) in the test sequence, each propulsion battery is at the maximum state of charge recommended by the manufacturer, as stated in the vehicle operator’s manual or on a label that is permanently attached to the vehicle, of, if the manufacturer has made no recommendation, not less than 95 percent. During the 200-stop burnish procedure, the propulsion batteries are restored to the maximum state of charge determined as above, after each increment of 40 burnish stops until the burnish procedure is complete. The batteries may be charged at a more frequent interval during a particular 40-stop increment only if the EV is incapable of achieving the initial burnish test speed during that increment. During the burnish procedure, the propulsion batteries may be charged by external means or replaced by batteries that are at a state of charge of not less than 95 percent. For an EV having a manual control for setting the level of regenerative braking, the manual control, at the beginning of the burnish procedure, is set to provide maximum regenerative braking throughout the burnish.

S6.3.11.3 At the beginning of each performance test in the test sequence (S7.2 through S7.17 of this standard), unless otherwise specified, an EV’s propulsion batteries are at the state of charge recommended by the manufacturer, as stated in the vehicle operator’s manual or on a label that is permanently attached to the vehicle, or, if the manufacturer has made no recommendation, at a state of charge of not less than 95 percent. No further charging of any propulsion battery occurs during any of the performance tests in the test sequence of this standard. If the propulsion batteries are depleted during a test sequence such that the vehicle reaches automatic shut-down, will not accelerate, or the low state of charge brake warning lamp is illuminated, the vehicle is to be accelerated to brake test speed by auxiliary means. If a battery is replaced rather than recharged, the replacement battery shall be charged and measured for state of charge in accordance with these procedures.

S6.3.12 State of charge of batteries for electrically-actuated service brakes. A vehicle equipped with electrically-actuated service brakes also performs the following test series. Conduct 10 stopping tests from a speed of 100 kph or the maximum vehicle speed, whichever is less. At least two of the 10 stopping distances must be less than or equal to 70 meters. The vehicle is loaded to GVWR and the transmission is in the neutral position when the service brake control is actuated and throughout the remainder of the test. Each battery providing power to the electrically-actuated service brakes, shall be in a depleted state of charge for conditions (a), (b), or (c) of this paragraph as appropriate. An auxiliary means may be used to accelerate an EV to test speed.

(a) For an EV equipped with electrically-actuated service brakes deriving power from the propulsion batteries and with automatic shut-down capability of the propulsion motor(s), the propulsion batteries are at not more than five percent above the EV actual automatic shut-down critical value. The critical value is determined by measuring the state-of-charge of each propulsion battery at the instant that automatic shut-down occurs.

(b) For an EV equipped with electrically-actuated service brakes deriving power from the propulsion batteries and with no automatic shut-down capability of the propulsion motor(s), the propulsion batteries are at an average of not more than five percent above the actual state of charge at which the brake failure warning signal, required by S5.5.1(e) of this standard, is illuminated.

(c) For a vehicle which has one or more auxiliary batteries that provides electrical energy to operate the electrically-actuated service brakes, each auxiliary battery is at not more than five percent above the actual state of charge at which the brake failure warning signal, required by S5.5.1(e) of this standard, is illuminated.

S6.3.13 Electric vehicles.

S6.3.13.1 (a) For an EV equipped with an RBS that is part of the service brake system, the RBS is operational during the burnish and all tests, except for the test of a failed RBS.

(b) For an EV equipped with an RBS that is not part of the service brake system, the RBS is operational and set to produce the maximum regenerative braking effect during the burnish, and is disabled during the test procedures. If the vehicle is equipped with a neutral gear that automatically disables the RBS, the test procedures which are designated to be conducted in gear may be conducted in neutral.

S6.3.13.2 For tests conducted “in neutral”, the operator of an EV with no “neutral” position (or other means such as a clutch for disconnecting the drive train from the propulsion motor(s)) does not apply any electromotive force to the propulsion motor(s). Any electromotive force that is applied to the propulsion motor(s) automatically remains in effect unless otherwise specified by the test procedure.

S6.4. Instrumentation.

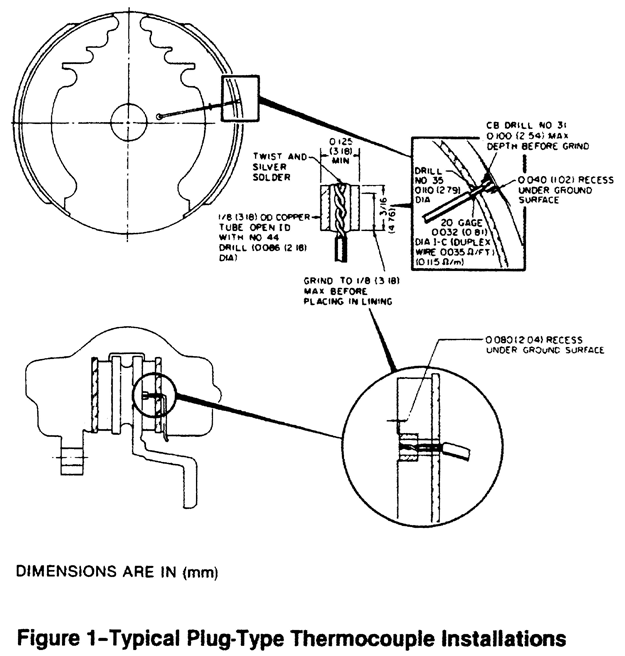

S6.4.1. Brake temperature measurement. The brake temperature is measured by plug-type thermocouples installed in the approximate center of the facing length and width of the most heavily loaded shoe or disc pad, one per brake, as shown in Figure 1. A second thermocouple may be installed at the beginning of the test sequence if the lining wear is expected to reach a point causing the first thermocouple to contact the metal rubbing surface of a drum or rotor. For center-grooved shoes or pads, thermocouples are installed within 3 mm (.12 in) to 6 mm (.24 in) of the groove and as close to the center as possible.

S6.4.2. Brake line pressure measurement for the torque wheel test. The vehicle shall be fitted with pressure transducers in each hydraulic circuit. On hydraulically proportioned circuits, the pressure transducer shall be downstream of the operative proportioning valve.

S6.4.3.

Brake torque measurement for the torque wheel test. The vehicle shall be fitted with torque wheels at each wheel position, including slip ring assemblies and wheel speed indicators to permit wheel lock to be detected.

S6.5. Procedural conditions.

S6.5.1. Brake control. All service brake system performance requirements, including the partial system requirements of S7.7, S7.10 and S7.11, must be met solely by use of the service brake control.

S6.5.2. Test speeds. If a vehicle is incapable of attaining the specified normal test speed, it is tested at a speed that is a multiple of 5 km/h (3.1 mph) that is 4 to 8 km/h (2.5 to 5.0 mph) less than its maximum speed and its performance must be within a stopping distance given by the formula provided for the specific requirement.

S6.5.3. Stopping distance.

S6.5.3.1. The braking performance of a vehicle is determined by measuring the stopping distance from a given initial speed.

S6.5.3.2. Unless otherwise specified, the vehicle is stopped in the shortest distance achievable (best effort) on all stops. Where more than one stop is required for a given set of test conditions, a vehicle is deemed to comply with the corresponding stopping distance requirements if at least one of the stops is made within the prescribed distance.

S6.5.3.3. In the stopping distance formulas given for each applicable test (such as S ≤ 0.10V+0.0060V 2 ), S is the maximum stopping distance in meters, and V is the test speed in km/h.

S6.5.4. Vehicle position and attitude.

S6.5.4.1. The vehicle is aligned in the center of the lane at the start of each brake application. Steering corrections are permitted during each stop.

S6.5.4.2. Stops are made without any part of the vehicle leaving the lane and without rotation of the vehicle about its vertical axis of more than ± 15 ° from the center line of the test lane at any time during any stop.

S6.5.5. Transmission selector control.

S6.5.5.1. For tests in neutral, a stop or snub is made in accordance with the following procedures:

(a) Exceed the test speed by 6 to 12 km/h (3.7 to 7.5 mph);

(b) Close the throttle and coast in gear to approximately 3 km/h (1.9 mph) above the test speed;

(c) Shift to neutral; and

(d) When the test speed is reached, apply the brakes.

S6.5.5.2. For tests in gear, a stop or snub is made in accordance with the following procedures:

(a) With the transmission selector in the control position recommended by the manufacturer for driving on a level surface at the applicable test speed, exceed the test speed by 6 to 12 km/h (3.7 to 7.5 mph);

(b) Close the throttle and coast in gear; and

(c) When the test speed is reached apply the brakes.

(d) To avoid engine stall, a manual transmission may be shifted to neutral (or the clutch disengaged) when the vehicle speed is below 30 km/h (18.6 mph).

S6.5.6. Initial brake temperature (IBT). If the lower limit of the specified IBT for the first stop in a test sequence (other than a parking brake grade holding test) has not been reached, the brakes are heated to the IBT by making one or more brake applications from a speed of 50 km/h (31.1 mph), at a deceleration rate not greater than 3 m/s 2 (9.8 fps 2 ).

S7. Road test procedures and performance requirements. Each vehicle shall meet all the applicable requirements of this section, when tested according to the conditions and procedures set forth below and in S6, in the sequence specified in Table 1:

| Testing order | Section No. |

|---|---|

| Vehicle loaded to GVWR: | |

| 1 Burnish | S7.1 |

| 2 Wheel lock sequence | S7.2 |

| Vehicle loaded to LLVW: | |

| 3 Wheel lock sequence | S7.2 |

| 4 ABS performance | S7.3 |

| 5 Torque wheel | S7.4 |

| Vehicle loaded to GVWR: | |

| 6 Torque wheel | S7.4 |

| 7 Cold effectiveness | S7.5 |

| 8 High speed effectiveness | S7.6 |

| 9 Stops with engine off | S7.7 |

| Vehicle loaded to LLVW: | |

| 10 Cold effectiveness | S7.5 |

| 11 High speed effectiveness | S7.6 |

| 12 Failed antilock | S7.8 |

| 13 Failed proportioning valve | S7.9 |

| 14 Hydraulic circuit failure | S7.10 |

| Vehicle loaded to GVWR: | |

| 15 Hydraulic circuit failure | S7.10 |

| 16 Failed antilock | S7.8 |

| 17 Failed proportioning valve | S7.9 |

| 18 Power brake unit failure | S7.11 |

| 19 Parking brake | S7.12 |

| 20 Heating snubs | S7.13 |

| 21 Hot performance | S7.14 |

| 22 Brake cooling | S7.15 |

| 23 Recovery performance | S7.16 |

| 24 Final inspection | S7.17 |

S7.1. Burnish.

S7.1.1. General information. Any pretest instrumentation checks are conducted as part of the burnish procedure, including any necessary rechecks after instrumentation repair, replacement or adjustment. Instrumentation check test conditions must be in accordance with the burnish test procedure specified in S7.1.2 and S7.1.3.

S7.1.2. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In gear.

S7.1.3. Test conditions and procedures. The road test surface conditions specified in S6.2 do not apply to the burnish procedure.

(a) IBT: ≤ 100 ° C (212 ° F).

(b) Test speed: 80 km/h (49.7 mph).

(c) Pedal force: Adjust as necessary to maintain specified constant deceleration rate.

(d) Deceleration rate: Maintain a constant deceleration rate of 3.0 m/s 2 (9.8 fps 2 ).

(e) Wheel lockup: No lockup of any wheel allowed for longer than 0.1 seconds at speeds greater than 15 km/h (9.3 mph).

(f) Number of runs: 200 stops.

(g) Interval between runs: The interval from the start of one service brake application to the start of the next is either the time necessary to reduce the IBT to 100 ° C (212 ° F) or less, or the distance of 2 km (1.24 miles), whichever occurs first.

(h) Accelerate to 80 km/h (49.7 mph) after each stop and maintain that speed until making the next stop.

(i) After burnishing, adjust the brakes as specified in S6.3.4.

S7.2 Wheel lockup sequence.

S7.2.1 General information. (a) The purpose of this test is to ensure that lockup of both front wheels occurs either simultaneously with, or at a lower deceleration rate than, the lockup of both rear wheels, when tested on road surfaces affording adhesion such that wheel lockup of the first axle occurs at a braking ratio of between 0.15 and 0.80, inclusive.

(b) This test is for vehicles without antilock brake systems.

(c) This wheel lock sequence test is to be used as a screening test to evaluate a vehicle’s axle lockup sequence and to determine whether the torque wheel test in S7.4 must be conducted.

(d) For this test, a simultaneous lockup of the front and rear wheels refers to the conditions when the time interval between the first occurrence of lockup of the last (second) wheel on the rear axle and the first occurrence of lockup of the last (second) wheel on the front axle is ≤ 0.1 second for vehicle speeds > 15 km/h (9.3 mph).

(e) A front or rear axle lockup is defined as the point in time when the last (second) wheel on an axle locks up.

(f) Vehicles that lock their front axle simultaneously or at lower deceleration rates than their rear axle need not be tested to the torque wheel procedure.

(g) Vehicles which lock their rear axle at deceleration rates lower than the front axle shall also be tested in accordance with the torque wheel procedure in S7.4.

(h) Any determination of noncompliance for failing adhesion utilization requirements shall be based on torque wheel test results.

S7.2.2 Vehicle conditions. (a) Vehicle load: GVWR and LLVW.

(b) Transmission position: In neutral.

S7.2.3. Test Conditions and Procedures. (a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 65 km/h (40.4 mph) for a braking ratio ≤ 0.50; 100 km/h (62.1 mph) for a braking ratio > 0.50.

(c) Pedal force:

(1) Pedal force is applied and controlled by the vehicle driver or by a mechanical brake pedal actuator.

(2) Pedal force is increased at a linear rate such that the first axle lockup occurs no less than one-half (0.5) second and no more than one and one-half (1.5) seconds after the initial application of the pedal.

(3) The pedal is released when the second axle locks, or when the pedal force reaches 1kN (225 lbs), or 0.1 seconds after first axle lockup, whichever occurs first.

(d) Wheel lockup: Only wheel lockups above a vehicle speed of 15 km/h (9.3 mph) are considered in determining the results of this test.

(e) Test surfaces: This test is conducted, for each loading condition, on two different test surfaces that will result in a braking ratio of between 0.15 and 0.80, inclusive. NHTSA reserves the right to choose the test surfaces to be used based on adhesion utilization curves or any other method of determining “worst case” conditions.

(f) The data recording equipment shall have a minimum sampling rate of 40 Hz.

(g) Data to be recorded. The following information must be automatically recorded in phase continuously throughout each test run such that values of the variables can be cross referenced in real time.

(1) Vehicle speed.

(2) Brake pedal force.

(3) Angular velocity at each wheel.

(4) Actual instantaneous vehicle deceleration or the deceleration calculated by differentiation of the vehicle speed.

(h) Speed channel filtration. For analog instrumentation, the speed channel shall be filtered by using a low-pass filter having a cut-off frequency of less than one fourth the sampling rate.

(i) Test procedure. For each test surface, three runs meeting the pedal force application and time for wheel lockup requirements shall be made. Up to a total of six runs will be allowed to obtain three valid runs. Only the first three valid runs obtained shall be used for data analysis purposes.

S7.2.4. Performance requirements. (a) In order to pass this test a vehicle shall be capable of meeting the test requirements on all test surfaces that will result in a braking ratio of between 0.15 and 0.80, inclusive.

(b) If all three valid runs on each surface result in the front axle locking before or simultaneously with the rear axle, or the front axle locks up with only one or no wheels locking on the rear axle, the torque wheel procedure need not be run, and the vehicle is considered to meet the adhesion utilization requirements of this Standard. This performance requirement shall be met for all vehicle braking ratios between 0.15 and 0.80.

(c) If any one of the three valid runs on any surface results in the rear axle locking before the front axle or the rear axle locks up with only one or no wheels locking on the front axle the torque wheel procedure shall be performed. This performance requirement shall be met for all vehicle braking ratios between 0.15 and 0.80.

(d) If any one of the three valid runs on any surface results in neither axle locking (i.e., only one or no wheels locked on each axle) before a pedal force of 1kN (225 lbs) is reached, the vehicle shall be tested to the torque wheel procedure.

(e) If the conditions listed in paragraph (c) or (d) of this section occur, vehicle compliance shall be determined from the results of a torquesults of a torque wheel test performed in accordance with S7.4.

(f) An EV with RBS that is part of the service brake system shall meet the performance requirements over the entire normal operating range of the RBS.

S7.3. ABS performance. [Reserved]

S7.4. Adhesion utilization (Torque Wheel Method).

S7.4.1. General information. This test is for vehicles without any ABS. The purpose of the test is to determine the adhesion utilization of a vehicle.

S7.4.2. Vehicle conditions. (a) Vehicle load: GVWR and LLVW.

(b) Transmission position: In neutral.

(c) Tires: For this test, a separate set of tires, identical to those used for all other tests under Section 7.0, may be used.

S7.4.3. Test conditions and procedures.

(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speeds: 100 km/h (62.1 mph), and 50 km/h (31.1 mph).

(c) Pedal force: Pedal force is increased at a linear rate between 100 and 150 N/sec (22.5 and 33.7 lbs/sec) for the 100 km/h test speed, or between 100 and 200 N/sec (22.5 and 45.0 lbs/sec) for the 50 km/h test speed, until the first axle locks or until a pedal force of 1 kN (225 lbs) is reached, whichever occurs first.

(d) Cooling: Between brake applications, the vehicle is driven at speeds up to 100 km/h (62.1 mph) until the IBT specified in S7.4.3(a) is reached.

(e) Number of runs: With the vehicle at LLVW, run five stops from a speed of 100 km/h (62.1 mph) and five stops from a speed of 50 km/h (31.1 mph), while alternating between the two test speeds after each stop. With the vehicle at GVWR, repeat the five stops at each test speed while alternating between the two test speeds.

(f) Test surface: PFC of at least 1.02.

(g) Data to be recorded. The following information must be automatically recorded in phase continuously throughout each test run such that values of the variables can be cross referenced in real time:

(1) Vehicle speed.

(2) Brake pedal force.

(3) Angular velocity at each wheel.

(4) Brake torque at each wheel.

(5) Hydraulic brake line pressure in each brake circuit. Hydraulically proportioned circuits shall be fitted with transducers on at least one front wheel and one rear wheel downstream of the operative proportioning or pressure limiting valve(s).

(6) Vehicle deceleration.

(h) Sample rate: All data acquisition and recording equipment shall support a minimum sample rate of 40 Hz on all channels.

(i) Determination of front versus rear brake pressure. Determine the front versus rear brake pressure relationship over the entire range of line pressures. Unless the vehicle has a variable brake proportioning system, this determination is made by static test. If the vehicle has a variable brake proportioning system, dynamic tests are run with the vehicle both empty and loaded. 15 snubs from 50 km/h (31.1 mph) are made for each of the two load conditions, using the same initial conditions specified in this section.

S7.4.4. Data reduction. (a) The data from each brake application under S7.4.3 is filtered using a five-point, on-center moving average for each data channel.

(b) For each brake application under S7.4.3 determine the slope (brake factor) and pressure axis intercept (brake hold-off pressure) of the linear least squares equation best describing the measured torque output at each braked wheel as a function of measured line pressure applied at the same wheel. Only torque output values obtained from data collected when the vehicle deceleration is within the range of 0.15g to 0.80g are used in the regression analysis.

(c) Average the results of paragraph

(b) of this section to calculate the average brake factor and brake hold-off pressure for all brake applications for the front axle.

(d) Average the results of paragraph

(b) of this section to calculate the average brake factor and brake hold-off pressure for all brake applications for the rear axle.

(e) Using the relationship between front and rear brake line pressure determined in S7.4.3(i) and the tire rolling radius, calculate the braking force at each axle as a function of front brake line pressure.

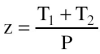

(f) Calculate the braking ratio of the vehicle as a function of the front brake line pressure using the following equation:

where

- z = braking ratio at a given front line pressure;

- T 1, T 2 = Braking forces at the front and rear axles, respectively, corresponding to the same front brake line pressure, and

- P = total vehicle weight.

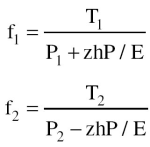

(g) Calculate the adhesion utilized at each axle as a function of braking ratio using the following equations:

where

- f i = adhesion utilized by axle i

- T i = braking force at axle i (from (e))

- P i = static weight on axle i i = 1 for the front axle, or 2 for the rear axle

- z = braking ratio (from (f))

- h = height of center of gravity of the vehicle

- P = total vehicle weight

- E = wheelbase

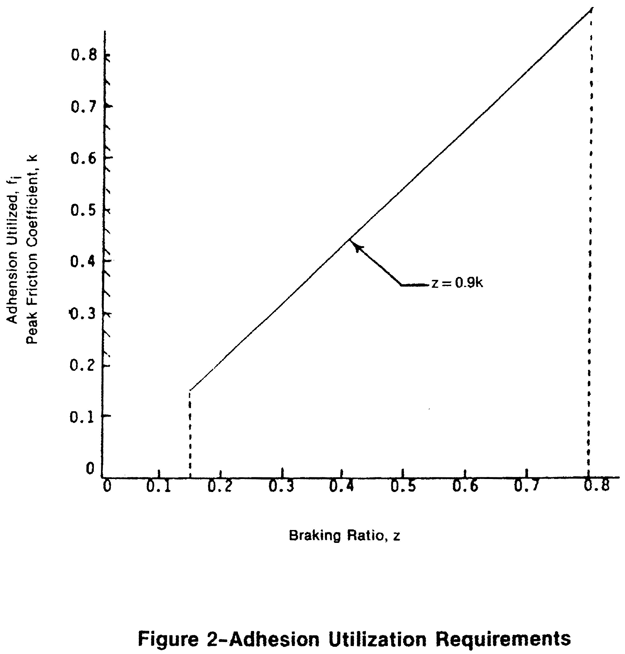

(h) Plot f

1 and f

2 obtained in (g) as a function of z, for both GVWR and LLVW load conditions. These are the adhesion utilization curves for the vehicle, which are compared to the performance requirements in S7.4.5. shown graphically in Figure 2:

S7.4.5. Performance requirements. For all braking ratios between 0.15 and 0.80, each adhesion utilization curve for a rear axle shall be situated below a line defined by z=0.9k where z is the braking ratio and k is the PFC.

S7.4.5.1 An EV with RBS that is part of the service brake system shall meet the performance requirement over the entire normal operating range of the RBS.

S7.5. Cold effectiveness.

S7.5.1. Vehicle conditions. (a) Vehicle load: GVWR and LLVW.

(b) Transmission position: In neutral.

S7.5.2. Test conditions and procedures.

(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force: ≤ 65N (14.6 lbs), ≤ 500N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(e) Number of runs: 6 stops.

(f) Test surface: PFC of 1.02.

(g) For each stop, bring the vehicle to test speed and then stop the vehicle in the shortest possible distance under the specified conditions.

S7.5.3. Performance requirements. (a) Stopping distance for 100 km/h test speed: ≤ 70m (230 ft).

(b) Stopping distance for reduced test speed: S ≤ 0.10V+0.0060V 2.

S7.6. High speed effectiveness. This test is not run if vehicle maximum speed is less than or equal to 125 km/h (77.7 mph).

S7.6.1. Vehicle conditions.(a) Vehicle load: GVWR and LLVW.

(b) Transmission position: In gear.

S7.6.2. Test conditions and procedures.(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 80% of vehicle maximum speed if 125 km/h (77.7 mph) < vehicle maximum speed < 200 km/h (124.3 mph), or 160 km/h (99.4 mph) if vehicle maximum speed ≤ 200 km/h (124.3 mph).

(c) Pedal force: ≤ 65N (14.6 lbs), ≤ 500N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(e) Number of runs: 6 stops.

(f) Test surface: PFC of 1.02.

S7.6.3. Performance requirements. Stopping distance: S ≤ 0.10V+0.0067V 2.

S7.7. Stops with Engine Off.

S7.7.1. General information. This test is for vehicles equipped with one or more brake power units or brake power assist units. This test is also for EVs.

S7.7.2. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In neutral.

(c) Vehicle engine: Off (not running).

(d) Ignition key position: May be returned to ”on” position after turning engine off, or a device may be used to “kill” the engine while leaving the ignition key in the “on” position.

S7.7.3. Test conditions and procedures.

(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force: ≤ 65N (14.6 lbs), ≤ 500N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel allowed for longer than 0.1 seconds at speeds greater than 15 km/h (9.3 mph).

(e) Number of runs: 6 stops.

(f) Test surface: PFC of 1.02.

(g) All system reservoirs (brake power and/or assist units) are fully charged and the vehicle’s engine is off (not running) at the beginning of each stop.

(h) For an EV, this test is conducted with no electrical power supplied to the vehicle’s propulsion motor(s), but with the RBS and brake power or power assist still operating, unless cutting off the supply of electrical power to the propulsion motor(s) also disables those systems.

S7.7.4. Performance requirements. (a) Stopping distance for 100 km/h test speed: ≤ 70m (230 ft.)

(b) Stopping distance for reduced test speed: S ≤ 0.10V + 0.0060V 2.

S7.8. Antilock functional failure.

S7.8.1. Vehicle conditions. (a) Vehicle loading: LLVW and GVWR.

(b) Transmission position: In neutral.

S7.8.2. Test conditions and procedures.

(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force: ≤ 65 N (14.6 lbs), ≤ 500 N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel for more than 0.1 seconds allowed at speeds greater than 15 km/h

(9.3 mph).

(e) Number of runs: 6 stops.

(f) Test surface: PFC of 1.02.

(g) Functional failure simulation:

(1) Disconnect the functional power source, or any other electrical connector that creates a functional failure.

(2) Determine whether the brake system indicator is activated when any electrical functional failure of the antilock system is created.

(3) Restore the system to normal at the completion of this test.

(h) If more than one antilock brake subsystem is provided, repeat test for each subsystem.

S7.8.3. Performance requirements. For service brakes on a vehicle equipped with one or more antilock systems, in the event of any single functional failure in any such system, the service brake system shall continue to operate and shall stop the vehicle as specified in S7.8.3(a) or S7.8.3(b).

(a) Stopping distance for 100 km/h test speed: ≤ 85 m (279 ft).

(b) Stopping distance for reduced test speed: S ≤ 0.10V + 0.0075V 2.

S7.9. Variable brake proportioning system functional failure.

S7.9.1. Vehicle conditions. (a) Vehicle load: LLVW and GVWR.

(b) Transmission position: In neutral.

S7.9.2. Test conditions and procedures.

(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force: ≤ 65 N (14.6 lbs), ≤ 500 N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(e) Number of runs: 6 stops.

(f) Test surface: PFC of 1.02.

(g) Functional failure simulation:

(1) Disconnect the functional power source or mechanical linkage to render the variable brake proportioning system inoperative.

(2) If the system utilizes electrical components, determine whether the brake system indicator is activated when any electrical functional failure of the variable proportioning system is created.

(3) Restore the system to normal at the completion of this test.

(h) If more than one variable brake proportioning subsystem is provided, repeat the test for each subsystem.

S7.9.3. Performance requirements. The service brakes on a vehicle equipped with one or more variable brake proportioning systems, in the event of any single functional failure in any such system, shall continue to operate and shall stop the vehicle as specified in S7.9.3(a) or S7.9.3(b).

(a) Stopping distance for 100 km/h test speed: ≤ 110 m (361 ft).

(b) Stopping distance for reduced test speed: S ≤ 0.10V + 0.0100V 2.

S7.10. Hydraulic circuit failure.

S7.10.1. General information. This test is for vehicles manufactured with or without a split service brake system.

S7.10.2. Vehicle conditions. (a) Vehicle load: LLVW and GVWR.

(b) Transmission position: In neutral.

S7.10.3. Test conditions and procedures.

(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force: ≤ 65N (14.6 lbs), ≤ 500 N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(e) Test surface: PFC of 1.02.

(f) Alter the service brake system to produce any single failure. For a hydraulic circuit, this may be any single rupture or leakage type failure, other than a structural failure of a housing that is common to two or more subsystems. For a vehicle in which the brake signal is transmitted electrically between the brake pedal and some or all of the foundation brakes, regardless of the means of actuation of the foundation brakes, this may be any single failure in any circuit that electrically transmits the brake signal. For an EV with RBS that is part of the service brake system, this may be any single failure in the RBS.

(g) Determine the control force pressure level or fluid level (as appropriate for the indicator being tested) necessary to activate the brake warning indicator.

(h) Number of runs: After the brake warning indicator has been activated, make the following stops depending on the type of brake system:

(1) 4 stops for a split service brake system.

(2) 10 consecutive stops for a non-split service brake system.

(i) Each stop is made by a continuous application of the service brake control.

(j) Restore the service brake system to normal at the completion of this test.

(k) Repeat the entire sequence for each of the other subsystems.

S7.10.4 Performance requirements. For vehicles manufactured with a split service brake system, in the event of any failure in a single subsystem, as specified in S7.10.3(f) of this standard, and after activation of the brake system indicator as specified in S5.5.1, the remaining portions of the service brake system shall continue to operate and shall stop the vehicle as specified in S7.10.4(a) or S7.10.4(b). For vehicles not manufactured with a split service brake system, in the event of any failure in any component of the service brake system, as specified in S7.10.3(f), and after activation of the brake system indicator as specified in S5.5.1 of this standard, the vehicle shall, by operation of the service brake control, stop 10 times consecutively as specified in S7.10.4(a) or S7.10.4(b).

(a) Stopping distance from 100 km/h test speed: ≤ 168 m (551 ft).

(b) Stopping distance for reduced test speed: S ≤ 0.10V + 0.0158V 2.

S7.11. Brake power unit or brake power assist unit inoperative (System depleted).

S7.11.1. General information. This test is for vehicles equipped with one or more brake power units or brake power assist units.

S7.11.2. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In neutral.

S7.11.3. Test conditions and procedures.

(a) IBT: ≤ 65 ° C (149 ° F), ≤ 100 ° C (212 ° F).

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force: ≤ 65 N (14.6 lbs), ≤ 500 N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(e) Number of runs: 6 stops.

(f) Test surface: PFC of 1.02.

(g) Disconnect the primary source of power for one brake power assist unit or brake power unit, or one of the brake power unit or brake power assist unit subsystems if two or more subsystems are provided.

(h) If the brake power unit or power assist unit operates in conjunction with a backup system and the backup system is automatically activated in the event of a primary power service failure, the backup system is operative during this test.

(i) Exhaust any residual brake power reserve capability of the disconnected system.

(j) Make each of the 6 stops by a continuous application of the service brake control.

(k) Restore the system to normal at completion of this test.

(l) For vehicles equipped with more than one brake power unit or brake power assist unit, conduct tests for each in turn.

(m) For vehicles with electrically-actuated service brakes (brake power unit), this test is conducted with any single electrical failure in the electrically-actuated service brakes instead of a failure of any other brake power or brake power assist unit, and all other systems intact.

S7.11.4. Performance requirements. The service brakes on a vehicle equipped with one or more brake power assist units or brake power units, with one such unit inoperative and depleted of all reserve capability, shall stop the vehicle as specified in S7.11.4(a) or S7.11.4(b).

(a) Stopping distance from 100 km/h test speed: ≤ 168 m (551 ft).

(b) Stopping distance for reduced test speed: S ≤ 0.10V + 0.0158V 2.

S7.12. Parking brake.

S7.12.1. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In neutral.

(c) Parking brake burnish:

(1) For vehicles with parking brake systems not utilizing the service friction elements, the friction elements of such a system are burnished prior to the parking brake test according to the published recommendations furnished to the purchaser by the manufacturer.

(2) If no recommendations are furnished, the vehicle’s parking brake system is tested in an unburnished condition.

(d) Parking brake applications: 1 application and up to 2 reapplications, if necessary.

S7.12.2. Test conditions and procedures.

(a) IBT:

(1) Parking brake systems utilizing service brake friction materials shall be tested with the IBT ≤ 100 ° C (212 ° F) and shall have no additional burnishing or artificial heating prior to the start of the parking brake test.

(2) Parking brake systems utilizing non-service brake friction materials shall be tested with the friction materials at ambient temperature at the start of the test. The friction materials shall have no additional burnishing or artificial heating prior to or during the parking brake test.

(b) Parking brake control force: Hand control ≤ 400 N (89.9 lbs); foot control ≤ 500 N (112.4 lbs).

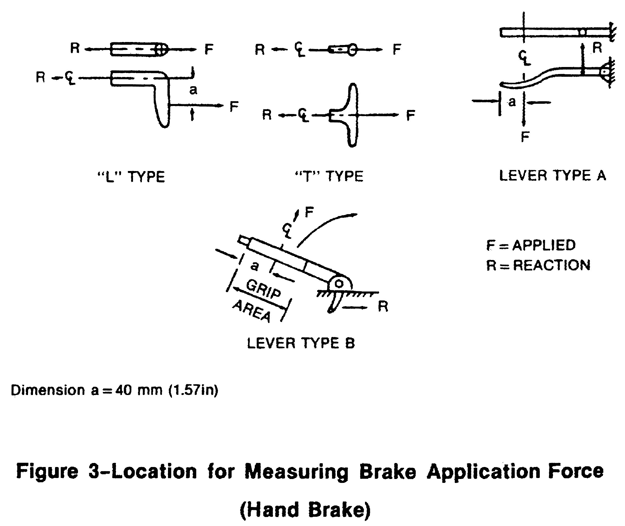

(c) Hand force measurement locations: The force required for actuation of a hand-operated brake system is measured at the center of the hand grip area or at a distance of 40 mm (1.57 in) from the end of the actuation lever as illustrated in Figure 3.

(d) Parking brake applications: 1 application and up to 2 reapplications, if necessary.

(e) Test surface gradient: 20% grade.

(f) Drive the vehicle onto the grade with the longitudinal axis of the vehicle in the direction of the slope of the grade.

(g) Stop the vehicle and hold it stationary by applying the service brake control and place the transmission in neutral.

(h) With the service brake applied sufficiently to just keep the vehicle from rolling, apply the parking brake as specified in S7.12.2(i) or S7.12.2(j).

(i) For a vehicle equipped with mechanically-applied parking brakes, make a single application of the parking brake control with a force not exceeding the limits specified in S7.12.2(b). For a vehicle using an electrically-activated parking brake, apply the parking brake by activating the parking brake control.

(j) In the case of a parking brake system that does not allow application of the specified force in a single application, a series of applications may be made to achieve the specified force.

(k) Following the application of the parking brakes, release all force on the service brake control and, if the vehicle remains stationary, start the measurement of time.

(l) If the vehicle does not remain stationary, reapplication of a force to the parking brake control at the level specified in S7.12.2(b) as appropriate for the vehicle being tested (without release of the ratcheting or other holding mechanism of the parking brake) is used up to two times to attain a stationary position.

(m) Verify the operation of the parking brake application indicator.

(n) Following observation of the vehicle in a stationary condition for the specified time in one direction, repeat the same test procedure with the vehicle orientation in the opposite direction on the same grade.

S7.12.3. Performance requirement. The parking brake system shall hold the vehicle stationary for 5 minutes in both a forward and reverse direction on the grade.

S7.13. Heating Snubs.

S7.13.1. General information. The purpose of the snubs is to heat up the brakes in preparation for the hot performance test which follows immediately.

S7.13.2. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In gear.

S7.13.3. Test conditions and procedures.

(a) IBT:

(1) Establish an IBT before the first brake application (snub) of ≤ 55 ° C (131 ° F), ≤ 65 ° C (149 ° F).

(2) IBT before subsequent snubs are those occurring at the distance intervals.

(b) Number of snubs: 15.

(c) Test speeds: The initial speed for each snub is 120 km/h (74.6 mph) or 80% of Vmax, whichever is slower. Each snub is terminated at one-half the initial speed.

(d) Deceleration rate:

(1) Maintain a constant deceleration rate of 3.0 m/s 2 (9.8 fps 2 ).

(2) Attain the specified deceleration within one second and maintain it for the remainder of the snub.

(e) Pedal force: Adjust as necessary to maintain the specified constant deceleration rate.

(f) Time interval: Maintain an interval of 45 seconds between the start of brake applications (snubs).

(g) Accelerate as rapidly as possible to the initial test speed immediately after each snub.

(h) Immediately after the 15th snub, accelerate to 100 km/h (62.1 mph) and commence the hot performance test.

S7.14. Hot performance.

S7.14.1. General information. The hot performance test is conducted immediately after completion of the 15th heating snub.

S7.14.2. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In neutral.

S7.14.3. Test conditions and procedures.

(a) IBT: Temperature achieved at completion of heating snubs.

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force:

(1) The first stop is done with an average pedal force not greater than the average pedal force recorded during the shortest GVWR cold effectiveness stop.

(2) The second stop is done with a pedal force not greater than 500 N (112.4 lbs).

(d) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(e) Number of runs: 2 stops.

(f) Immediately after the 15th heating snub, accelerate to 100 km/h (62.1 mph) and commence the first stop of the hot performance test.

(g) If the vehicle is incapable of attaining 100 km/h, it is tested at the same speed used for the GVWR cold effectiveness test.

(h) Immediately after completion of the first hot performance stop, accelerate as rapidly as possible to the specified test speed and conduct the second hot performance stop.

(i) Immediately after completion of the second hot performance stop, drive 1.5 km (0.93 mi) at 50 km/h (31.1 mph) before the first cooling stop.

S7.14.4.

Performance requirements.

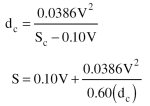

(a) For the first hot stop, the stopping distance must be less than or equal to a calculated distance which is based on 60 percent of the deceleration actually achieved on the shortest GVWR cold effectiveness stop. The following equations shall be used in calculating the performance requirement:

where

- d c = the average deceleration actually achieved during the shortest cold effectiveness stop at GVWR (m/s 2 ),

- S c = actual stopping distance measured on the shortest cold effectiveness stop at GVWR (m), and

- V = cold effectiveness test speed (km/h).

(b) In addition to the requirement in S7.14.4(a), the stopping distance for at least one of the two hot stops must be S ≤ 89 m (292 ft) from a test speed of 100 km/h (62.1 mph) or, for reduced test speed, S ≤ 0.10V + 0.0079V 2. The results of the second stop may not be used to meet the requirements of S7.14.4(a).

S7.15. Brake cooling stops.

S7.15.1. General information. The cooling stops are conducted immediately after completion of the hot performance test.

S7.15.2. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In gear.

S7.15.3. Test conditions and procedures.

(a) IBT: Temperature achieved at completion of hot performance.

(b) Test speed: 50 km/h (31.1 mph).

(c) Pedal force: Adjust as necessary to maintain specified constant deceleration rate.

(d) Deceleration rate: Maintain a constant deceleration rate of 3.0 m/s 2 (9.8 fps 2 ).

(e) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(f) Number of runs: 4 stops.

(g) Immediately after the hot performance stops drive 1.5 km (0.93 mi) at 50 km/h (31.1 mph) before the first cooling stop.

(h) For the first through the third cooling stops:

(1) After each stop, immediately accelerate at the maximum rate to 50 km/h (31.1 mph).

(2) Maintain that speed until beginning the next stop at a distance of 1.5 km (0.93 mi) from the beginning of the previous stop.

(i) For the fourth cooling stop:

(1) Immediately after the fourth stop, accelerate at the maximum rate to 100 km/h (62.1 mph).

(2) Maintain that speed until beginning the recovery performance stops at a distance of 1.5 km (0.93 mi) after the beginning of the fourth cooling stop.

S7.16. Recovery performance.

S7.16.1. General information. The recovery performance test is conducted immediately after completion of the brake cooling stops.

S7.16.2. Vehicle conditions. (a) Vehicle load: GVWR only.

(b) Transmission position: In neutral.

S7.16.3. Test conditions and procedures.

(a) IBT: Temperature achieved at completion of cooling stops.

(b) Test speed: 100 km/h (62.1 mph).

(c) Pedal force: The average pedal force shall not be greater than the average pedal force recorded during the shortest GVWR cold effectiveness stop.

(d) Wheel lockup: No lockup of any wheel for longer than 0.1 seconds allowed at speeds greater than 15 km/h (9.3 mph).

(e) Number of runs: 2 stops.

(f) Immediately after the fourth cooling stop, accelerate at the maximum rate to 100 km/h (62.1 mph).

(g) Maintain that speed until beginning the first recovery performance stop at a distance of 1.5 km (0.93 mi) after the beginning of the fourth cooling stop.

(h) If the vehicle is incapable of attaining 100 km/h, it is tested at the same speed used for the GVWR cold effectiveness test.

(i) Immediately after completion of the first recovery performance stop accelerate as rapidly as possible to the specified test speed and conduct the second recovery performance stop.

S7.16.4. Performance requirements.

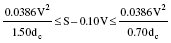

The stopping distance, S, for at least one of the two stops must be within the following limits:

where

- d c and V are defined in S7.14.4(a).

S7.17. Final Inspection. Inspect:

(a) The service brake system for detachment or fracture of any components, such as brake springs and brake shoes or disc pad facings.

(b) The friction surface of the brake, the master cylinder or brake power unit reservoir cover, and seal and filler openings, for leakage of brake fluid or lubricant.

(c) The master cylinder or brake power unit reservoir for compliance with the volume and labeling requirements of S5.4.2 and S5.4.3. In determining the fully applied worn condition, assume that the lining is worn to (1) rivet or bolt heads on riveted or bolted linings or (2) within 0.8 mm ( 1/32 inch) of shoe or pad mounting surface on bonded linings or (3) the limit recommended by the manufacturer, whichever is larger relative to the total possible shoe or pad movement. Drums or rotors are assumed to be at nominal design drum diameter or rotor thickness. Linings are assumed adjusted for normal operating clearance in the released position.

(d) The brake system indicators, for compliance with operation in various key positions, lens color, labeling, and location, in accordance with S5.5.

[60 FR 6434, Feb. 2, 1995; as amended at 60 FR 37847, July 24, 1995; 60 FR 44548, Aug. 28, 1995; 62 FR 46917, Sept. 5, 1997; 62 FR 51070, Sept. 30, 1997; 65 FR 6332, Feb. 9, 2000; 70 FR 37713, June 30, 2005; 77 FR 760, Jan. 6, 2012; 86 FR 1298, Jan. 8, 2021; 87 FR 34810, June 8, 2022]

READ MORESHOW LESS

['CMV Parts and Maintenance']

['Brakes']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.