['CMV Parts and Maintenance', 'Passenger carriers']

['School buses']

10/30/2024

...

S1. Scope. This standard establishes requirements for devices that can be installed on school buses to improve the safety of pedestrians in the vicinity of stopped school buses.

S2. Purpose. The purpose of this standard is to reduce deaths and injuries by minimizing the likelihood of vehicles passing a stopped school bus and striking pedestrians in the vicinity of the bus.

S3. Application. This standard applies to school buses other than multifunction school activity buses.

S4. Definitions.

Stop signal arm means a device that can be extended outward from the side of a school bus to provide a signal to other motorists not to pass the bus because it has stopped to load or discharge passengers.

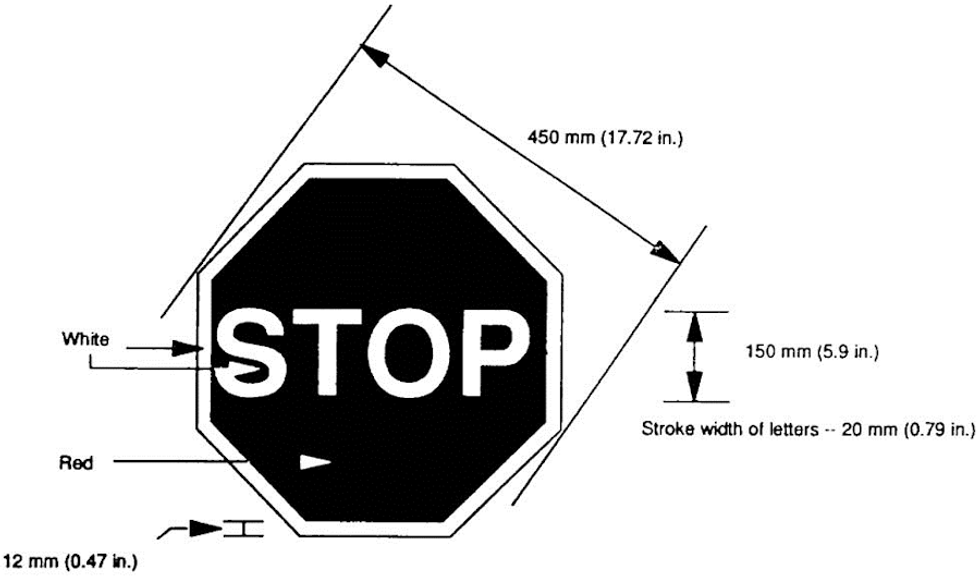

S5. Requirements. Each school bus shall be equipped with a stop signal arm meeting the requirements of S5.1 through S5.5 as depicted in Figure 1.

|

| Figure 1. Characteristics of Stop Signal Device |

S5.1 The stop signal arm shall be a regular octagon which is at least 450 mm ×450 mm (17.72 inches ×17.72 inches) in diameter.

S5.2 The stop signal arm shall be red on both sides, except as provided in S5.2.1 and S5.2.2, and S5.2.3.

S5.2.1 The stop signal arm shall have a white border at least 12 mm (0.47 inches) wide on both sides, except as provided in S5.2.3. Mounting brackets, clips, bolts, or other components necessary to the mechanical or electrical operation of the stop signal arm may not obscure more than 15 percent of the border on each side of the stop arm. The portion of the border that may be obscured is in addition to that portion which may be obscured by the two red lamps specified in S5.3.2.

S.5.2.2 The stop signal arm shall have the word “STOP” displayed in white upper-case letters on both sides, except as provided in S5.2.3. The letters shall be at least 150 mm (5.9 inches) in height. The letters shall have a stroke width of at least 20 mm (0.79 inches), except as provided in S.5.3.1.1.

S5.2.3 When two stop signal arms are installed on a school bus, the rearmost stop signal arm shall not contain any lettering, symbols, or markings on the forward side.

S5.3 Conspicuity. The stop signal arm shall comply with either S5.3.1 or S5.3.2, or both.

S5.3.1 Except as provided in S5.3.1.1, S5.3.1.2, or S5.3.1.3, the entire surface of both sides of each stop signal arm shall be reflectorized with Type III retroreflectorized material that meets the minimum specific intensity requirements of S6.1 and Table I.

S5.3.1.1 The legend of the retroreflective stop arm may be illuminated in a manner such that light is emitted from the surface of each letter or from the area immediately surrounding each letter. Only red lamps may be used. They shall form the complete shape of each letter of the legend, and shall be affixed to all letters (or to the areas immediately surrounding all letters) in the legend. The shape of each letter shall remain constant and, if the lamps are contained within each letter, the net stroke width (stroke width minus the width of the lamp(s)) of each letter of the legend, specified in S5.2.2, shall not be less than 15 mm (0.59 inch). When the stop arm is extended, the lamps shall flash at the rate specified in S6.2.2, with a current “on” time specified in S6.2.2.1. All lamps shall be positioned in one of the two following ways:

(1) centered within the stroke of each letter of the legend, or

(2) outlining each letter of the legend.

S5.3.1.2 Nonreflectorized mounting brackets, clips, bolts, or other components necessary to the mechanical or electrical operation of the stop signal arm shall not obscure more than 7.5 percent of the total surface area of either side of the stop signal arm.

S5.3.1.3 When two stop signal arms are installed on a school bus, the forward side of the rearmost stop signal arm shall not be reflectorized.

S5.3.2 Each side of the stop signal arm shall have at least two red lamps that meet the requirements of S6.2. The lamps shall be centered on the vertical centerline of the stop arm. One of the lamps shall be located at the extreme top of the stop arm and the other at its extreme bottom.

S5.4 The stop signal arm shall be installed on the left side of the bus.

S5.4.1 The stop signal arm shall be located such that, when in the extended position:

(a) The stop signal arm is perpendicular to the side of the bus, plus or minus five degrees;

(b) The top edge of the stop signal arm is parallel to and not more than 6 inches from a horizontal plane tangent to the lower edge of the frame of the passenger window immediately behind the driver’s window; and

(c) The vertical centerline of the stop signal arm is not less than 9 inches away from the side of the school bus.

S5.4.2 A second stop signal arm may be installed on a school bus. That stop signal arm shall comply with S5.4 and S5.4.1.

S5.5 The stop signal arm shall be automatically extended in such a manner that it complies with S5.4.1, at a minimum whenever the red signal lamps required by S5.1.4 of Standard No. 108 are activated; except that a device may be installed that prevents the automatic extension of a stop signal arm. The mechanism for activating the device shall be within the reach of the driver. While the device is activated, a continuous or intermittent signal audible to the driver shall sound. The audible signal may be equipped with a timing device requiring the signal to sound for at least 60 seconds. If a timing device is used, it shall automatically recycle every time the service entry door is opened while the engine is running and the manual override is engaged.

S6 Test Procedures.

S6.1 Reflectivity Test. When tested under the conditions specified in S6.2 (b), (c), and (d) of Federal motor vehicle safety standard 125, Warning Devices, ( 49 CFR 571.125 ), the retroreflective materials shall meet the criteria specified in table 1.

| Observation Angle (°) | Entrance Angle (°) | White | Red | |

|---|---|---|---|---|

| Type III Retroreflective Element Material | ||||

| A—Glass Bead Retroreflective Element Materials | ||||

| 0.2 | -4 | 250 | 45 | |

| 0.2 | +30 | 150 | 25 | |

| 0.5 | -4 | 95 | 15 | |

| 0.5 | +30 | 65 | 10 | |

| B—Prismatic Retroreflective Element Materials | ||||

| 0.2 | -4 | 250 | 45 | |

| 0.2 | +30 | 95 | 13.3 | |

| 0.5 | -4 | 200 | 28 | |

| 0.5 | +30 | 65 | 10 | |

S6.2 Lighting Tests.

S6.2.1 Color. The procedure shall be done in accordance with SAE Recommended Practice J578-1988 (incorporated by reference, see §571.5 ). When visually compared to the light emitted from a filter/source with a combination of chromaticity coordinates as explained in SAE Recommended Practice J578-1988 within specific boundaries [y=0.33 (yellow boundary) and y=0.98—×(purple boundary)] the color of light emitted from the test object shall not be less saturated (paler), yellower, or purpler. The test object shall be placed perpendicular to the light source to simulate lamps on stop signal arms. In making visual comparisons, the light from the test object shall light one portion of a comparison field and the light from the filter/source standard shall light an adjacent area. To make a valid visual comparison, the two fields to be viewed shall be of near equal luminance.

S6.2.2. Flash rate. The lamps on each side of the stop signal arm, when operated at the manufacturer’s design load, shall flash alternately at a rate of 60 to 120 flashes per minute.

S6.2.2.1 Lamps, except those subject to S6.2.2.2, shall have a current “on” time of 30 to 75 percent of the total flash cycle. The total current “on” time for the two terminals shall be between 90 and 110 percent of the total flash cycle.

S6.2.2.2 Xenon short-arc gaseous discharge lamps shall have an ”off” time before each flash of at least 50 percent of the total flash cycle.

S6.2.3 Vibration, Moisture, Dust, Corrosion, Photometry, and Warpage Tests. The procedure shall be done in accordance with SAE Recommended Practice J575-1983 (incorporated by reference, see §571.5 ) and SAE Recommended Practice J1133 (1984) (incorporated by reference, see §571.5 ). Lamps and lighting components shall meet the criteria for vibration, moisture, dust, corrosion, photometry, and warpage in SAE Recommended Practice J575-1983 and SAE Recommended Practice J1133 (1984) under the test conditions specified herein.

[56 FR 20370, May 3, 1991, as amended at 57 FR 40134, Sept. 2, 1992; 59 FR 26761, May 24, 1994; 63 FR 29143, May 28, 1998; 68 FR 44901, July 31, 2003; 77 FR 760, Jan. 6, 2012]

READ MORESHOW LESS

['CMV Parts and Maintenance', 'Passenger carriers']

['School buses']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.