...

(a) General. Each cylinder or UN pressure receptacle requalified in accordance with this subpart with acceptable results must be marked as specified in this section. Required specification markings may not be altered or removed.

(b) Placement of markings. Each cylinder must be plainly and permanently marked on the metal of the cylinder as permitted by the applicable specification. Unless authorized by the cylinder specification, marking on the cylinder sidewall is prohibited.

(1) Requalification and required specification markings must be legible so as to be readily visible at all times. Illegible specification markings may be remarked on the cylinder as provided by the original specification. Requalification markings may be placed on any portion of the upper end of the cylinder excluding the sidewall, as provided in this section. Requalification and required specification markings that are illegible may be reproduced on a metal plate and attached as provided by the original specification.

(2) Previous requalification markings may not be obliterated, except that, when the space originally provided for requalification dates becomes filled, additional dates may be added as follows:

(i) All preceding requalification dates may be removed by peening provided that—

(A) Permission is obtained from the cylinder owner;

(B) The minimum wall thickness is maintained in accordance with manufacturing specifications for the cylinder; and

(C) The original manufacturing test date is not removed.

(ii) When the cylinder is fitted with a footring, additional dates may be marked on the external surface of the footring.

(c) Requalification marking method. The depth of requalification markings may not be greater than specified in the applicable specification. The markings must be made by stamping, engraving, scribing or applying a label embedded in epoxy that will remain legible and durable throughout the life of the cylinder, or by other methods that produce a legible, durable mark.

(1) A cylinder used as a fire extinguisher (see §180.209(j)) may be marked by using a pressure sensitive label.

(2) For a DOT 3HT cylinder, when stamped, the test date and RIN must be applied by low-stress steel stamps to a depth no greater than that prescribed at the time of manufacture. Stamping on the sidewall is not authorized.

(3) For a composite cylinder, the requalification markings must be applied on a pressure sensitive label, securely affixed and overcoated with epoxy in a manner prescribed by the cylinder manufacturer, near the original manufacturer's label. Stamping of the composite surface is not authorized.

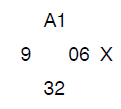

(d) Requalification markings. Each cylinder successfully passing requalification must be marked with the RIN set in a square pattern, between the month and year of the requalification date. The first character of the RIN must appear in the upper left corner of the square pattern; the second in the upper right; the third in the lower right; and the fourth in the lower left. Example: A cylinder requalified in September 2006, and approved by a person who has been issued RIN ‘‘A123’’, would be marked plainly and permanently into the metal of the cylinder in accordance with location requirements of the cylinder specification or on a metal plate permanently secured to the cylinder in accordance with paragraph (b) of this section. An example of the markings prescribed in this paragraph (d) is as follows:

|

| Where:‘‘9’’ is the month of requalification,‘‘A123’’ is the RIN,‘‘06’’ is the year of requalification, and‘‘X’’ represents the symbols described in paragraphs (f)(2) through (f)(9) of this section. |

(1) Upon written request, variation from the marking requirement may be approved by the Associate Administrator.

(2) A cylinder subject to the requirements of §171.23(a)(5) of this subchapter must be marked with the date and RIN in accordance with this paragraph (d) and paragraph (f)(11) of this section, or marked in accordance with the requalification authorized by the Associate Administrator in accordance with §171.23(a)(5)(i) of this subchapter.

(e) Size of markings. The size of the markings must be at least 6.35 mm (1/4 in.) high, except RIN characters must be at least 3.18 mm (1/8 in.) high.

(f) Marking illustrations. Examples of required requalification markings for DOT specification and special permit cylinders are illustrated as follows:

(1) For designation of the 5-year volumetric expansion test, 10-year volumetric expansion test for UN cylinders and cylinders conforming to §180.209(f) and (h), or 12-year volumetric expansion test for fire extinguishers conforming to §173.309(a) of this subchapter and cylinders conforming to §180.209(e) and (g), the marking is as illustrated in paragraph (d) of this section.

(2) For designation of the 10-year volumetric expansion test for cylinders conforming to §180.209(b), the marking is as illustrated in paragraph (d) of this section, except that the ‘‘X’’ is replaced with a five-point star.

(3) For designation of special filling limits up to 10% in excess of the marked service pressure for cylinders conforming to §173.302a(b) of this subchapter, the marking is as illustrated in paragraph (d) of this section, except that the ‘‘X’’ is replaced with a plus sign ‘‘+’’.

(4) For designation of the proof pressure test, the marking is as illustrated in paragraph (d) of this section, except that the ‘‘X’’ is replaced with the letter ‘‘S’’.

(5) For designation of the 5-year external visual inspection for cylinders conforming to §180.209(g), the marking is as illustrated in paragraph (d) of this section, except that the ‘‘X’’ is replaced with the letter ‘‘E’’.

(6) For designation of DOT 8 series cylinder shell re-qualification only, the marking is as illustrated in paragraph (d) of this section, except that the ‘‘X’’ is replaced with the letter ‘‘S’’.

(7) For designation of DOT 8 series and UN cylinder shell and porous filler requalification, the marking is as illustrated in paragraph (d) of this section, except that the ‘‘X’’ is replaced with the letters ‘‘FS.’’

(8) For designation of a nondestructive examination combined with a visual inspection, the marking is as illustrated in paragraph (d) of this section, except that the “X” is replaced with the type of test performed, for example the letters “AE” for acoustic emission or “UE” for ultrasonic examination.

(9) For designation of the eddy current examination combined with a visual inspection, the marking is as illustrated in paragraph (d) of this section, except the “X” is replaced with the letters “VE.”

(10) For designation of grinding with ultrasonic wall thickness examination, the marking is as illustrated in paragraph (d) of this section, except the “X” is replaced with the letter “R”.

(11) For designation of requalification of a foreign cylinder requalified in conformance with §§171.23(a)(5) of this subchapter and 180.209(l), the marking is as illustrated in paragraph (d) of this section, except that the “X” is replaced with the letters “EX” to indicate that the cylinder is for export only.

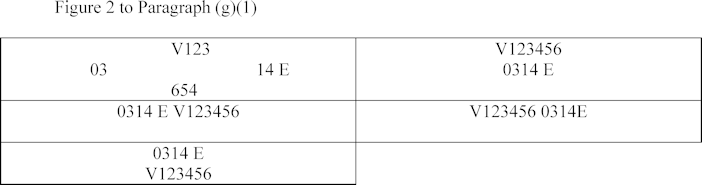

(g) Visual inspection requalification markings.(1) Alternative to the marking requirements of paragraphs (d) and (f)(5) of this section, each cylinder successfully passing a visual inspection only, in accordance with §180.209(g), may be marked with the visual inspection number (e.g., V123456) issued to a person performing visual inspections. Examples of the way the markings may be applied are as follows:

(2) Where:

(i) “03” is the month of requalification (the additional numeral “0” is optional”);

(ii) “V123456” is the RIN;

(iii) “14” is the year of requalification; and

(iv) “E” to indicate visual inspection.

[67 FR 51660, Aug. 8, 2002, as amended at 70 FR 73166, Dec. 9, 2005; 71 FR 33896, June 12, 2006; 71 FR 51128, Aug. 29, 2006; 71 FR 78635, Dec. 29, 2006; 75 FR 53597, Sept. 1, 2010; 80 FR 72929, Nov. 23, 2015; 81 FR 3686, Jan. 21, 2016; 85 FR 75717, Nov. 25, 2020; 85 FR 85434, Dec. 28, 2020]