['Hazmat']

['Hazmat Special Requirements']

10/14/2024

...

1. Test method D–1—leakage test

A wooden stick, 114 mm (4.5 inches) long and 4.8 mm (0.2 inch) inch in diameter, with a sharpened end is used to punch 5 holes in one end of the wrapper of a dynamite cartridge. A cork stopper is placed on the bottom of a glass volumetric cylinder. The dynamite cartridge is placed, perforated end down, resting on the cork stopper in the cylinder. The entire assembly is placed in an oven at 38°C (100°F) for 48 hours and then examined visually for evidence of leakage.

2. Test method D–2—centrifugal exudation test

The test apparatus consists of a glass tube, 135 mm (5.3 inches) long and one inch in diameter, with both ends open, and is assembled in the following manner:

(a) Close the bottom with a plastic plug of diameter equal to the inner diameter of the glass tube;

(b) Place a small amount of absorbent cotton on top of the plug;

(c) Place a plastic disk that matches the inner diameter to the glass tube and has seven small perforations on top of the cotton; and

(d) Place 10 g (0.35 ounce) of the dynamite sample on top of the disk.

The assembled glass tube is then placed in a hand-operated centrifuge and spun for one minute at 600 rpm (revolutions per minute). The dynamite sample is then removed from the glass tube and weighed to determine the percent of weight loss.

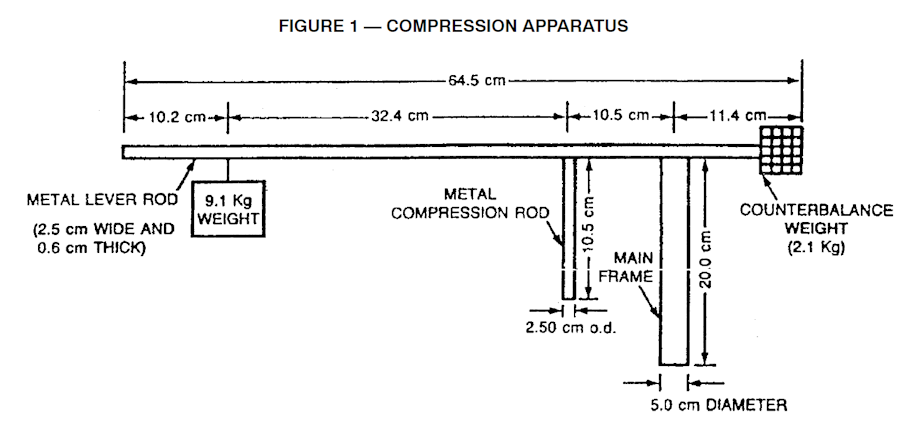

3. Test method D–3—compression exudation test.

The entire apparatus for this test is shown in Figure 1 of this appendix. The test is conducted using the following procedures:

(a) A glass tube, 135 mm (5.3 inches) long and one inch in diameter, is held on a wooden base;

(b) A small amount of absorbent cotton is placed into the bottom of the glass tube;

(c) Ten g (0.35 ounce) of dynamite sample are placed on top of the cotton in the glass tube;

(d) A small amount of absorbent cotton is placed on top of the dynamite sample;

(e) A plastic disk that matches the inner diameter of the glass tube and has seven small perforations is placed on top of the cotton;

(f) A plastic plug matching the inner diameter of the glass tube is then placed on top of the disk;

(g) The glass tube assembly is placed under the compression rod, and compression is applied by means of the weight on the metal lever rod. The sample is compressed for one minute; and

(h) The dynamite sample is then removed from the glass tube and weighed to determine the percent of weight loss.

[Amdt. 173-224, 55 FR 52671, Dec. 21, 1990, as amended by Amdt. 173-234, 58 FR 51533, Oct. 1, 1993]

['Hazmat']

['Hazmat Special Requirements']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.