['Air Programs']

['Greenhouse Gases']

05/22/2023

...

In addition to the information required by §98.3(c), you must include in each annual report the following information for each electronics manufacturing facility:

(a) Annual manufacturing capacity of each fab at your facility used to determine the annual manufacturing capacity of your facility in Equation I-5 of this subpart.

(b) For facilities that manufacture semiconductors, the diameter of wafers manufactured at each fab at your facility (mm).

(c) Annual emissions, on a fab basis as described in paragraph (c)(1) through (5) of this section.

(1) When you use the procedures specified in §98.93(a) of this subpart, each fluorinated GHG emitted from each process type for which your fab is required to calculate emissions as calculated in Equations I-6 and I-7 of this subpart.

(2) When you use the procedures specified in §98.93(a), each fluorinated GHG emitted from each process type or process sub-type as calculated in Equations I-8 and I-9 of this subpart, as applicable.

(3) N2O emitted from all chemical vapor deposition processes and N2O emitted from the aggregate of other N2O-using manufacturing processes as calculated in Equation I-10 of this subpart.

(4) Each fluorinated heat transfer fluid emitted as calculated in Equation 1–16 of this subpart.

(5) When you use the procedures specified in §98.93(i) of this subpart, annual emissions of each fluorinated GHG, on a fab basis.

(d) The method of emissions calculation used in §98.93 for each fab.

(e) Annual production in terms of substrate surface area (e.g., silicon, PV-cell, glass) for each fab, including specification of the substrate.

(f) [Reserved]

(g) [Reserved]

(h) [Reserved]

(i) [Reserved]

(j) [Reserved]

(k) [Reserved]

(l) [Reserved]

(m) For the fab-specific apportioning model used to apportion fluorinated GHG and N2O consumption under §98.94(c), the following information to determine it is verified in accordance with procedures in §98.94(c)(1) and (2):

(1) Identification of the quantifiable metric used in your fab-specific engineering model to apportion gas consumption for each fab, and/or an indication if direct measurements were used in addition to, or instead of, a quantifiable metric.

(2) The start and end dates selected under §98.94(c)(2)(i).

(3) Certification that the gas(es) you selected under §98.94(c)(2)(ii) for each fab corresponds to the largest quantity(ies) consumed, on a mass basis, of fluorinated GHG used at your fab during the reporting year for which you are required to apportion.

(4) The result of the calculation comparing the actual and modeled gas consumption under §98.94(c)(2)(iii) and (iv), as applicable.

(5) If you are required to apportion fluorinated GHG consumption between fabs as required by §98.94(c)(2)(v), certification that the gas(es) you selected under §98.94(c)(2)(ii) corresponds to the largest quantity(ies) consumed on a mass basis, of fluorinated GHG used at your facility during the reporting year for which you are required to apportion.

(n) [Reserved]

(o) [Reserved]

(p) Inventory and description of all abatement systems through which fluorinated GHGs or N2O flow at your facility and for which you are claiming destruction or removal efficiency, including:

(1) The number of abatement systems controlling emissions for each process sub-type, or process type, as applicable, for each gas used in the process sub-type or process type.

(2) The basis of the destruction or removal efficiency being used (default or site specific measurement according to §98.94(f)(4)(i)) for each process sub-type or process type and for each gas.

(q) For all abatement systems through which fluorinated GHGs or N2O flow at your facility, for which you are reporting controlled emissions, the following:

(1) Certification that all abatement systems at the facility have been installed, maintained, and operated in accordance with the site maintenance plan for abatement systems that is developed and maintained in your records as specified in §98.97(d)(9).

(2) If you use default destruction or removal efficiency values in your emissions calculations under §98.93(a), (b), or (i), certification that the site maintenance plan for abatement systems for which emissions are being reported contains manufacturer's recommendations and specifications for installation, operation, and maintenance for each abatement system.

(3) If you use default destruction or removal efficiency values in your emissions calculations under §98.93(a), (b), and/or (i), certification that the abatement systems for which emissions are being reported were specifically designed for fluorinated GHG or N2O abatement, as applicable. You must support this certification by providing abatement system supplier documentation stating that the system was designed for fluorinated GHG or N2O abatement, as applicable.

(4) For all stack systems for which you calculate fluorinated GHG emissions according to the procedures specified in §98.93(i)(3), certification that you have included and accounted for all abatement systems and any respective downtime in your emissions calculations under §98.93(i)(3).

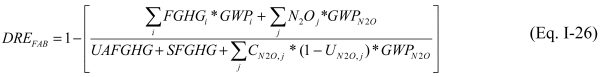

(r) You must report an effective fab-wide destruction or removal efficiency value for each fab at your facility calculated using Equation I-26, I-27, and I-28 of this subpart, as appropriate.

Where:

DREFAB= Fab-wide effective destruction or removal efficiency value, expressed as a decimal fraction.

FGHGi= Total emissions of each fluorinated GHG i emitted from electronics manufacturing processes in the fab, calculated according to the procedures in §98.93.

N2Oj= Emissions of N2O from each N2O-emitting electronics manufacturing process j in the fab, expressed in metric ton CO2equivalents, calculated according to the procedures in §98.93.

UAFGHG = Total unabated emissions of fluorinated GHG emitted from electronics manufacturing processes in the fab, expressed in metric ton CO2equivalents as calculated in Equation I-27 of this subpart.

SFGHG = Total unabated emissions of fluorinated GHG emitted from electronics manufacturing processes in the fab, expressed in metric ton CO2equivalents, as calculated in Equation I-28 of this subpart.

CNO,j= Consumption of N2O in each N2O emitting process j, expressed in metric ton CO2equivalents.

1-UNO,j= N2O emission factor for each N2O emitting process j from Table I-8 of this subpart.

GWPi= GWP of emitted fluorinated GHG i from Table A-1 of this part.

GWPNO= GWP of N2O from Table A-1 of this part.

i = Fluorinated GHG.

j = Process Type.

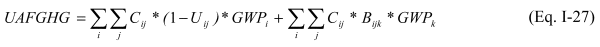

(1) Use Equation I-27 of this subpart to calculate total unabated emissions, in metric tons CO2e, of all fluorinated GHG emitted from electronics manufacturing processes whose emissions of fluorinated GHG you calculated according to the default utilization and by-product formation rate procedures in §98.93(a) or §98.93(i)(4). For each fluorinated GHG i in process j, use the same consumption (Cij), emission factors (1?Uij), and by-product formation rates (Bijk) to calculate unabated emissions as you used to calculate emissions in §98.93(a) or §98.93(i)(4).

Where:

UAFGHG = Total unabated emissions of fluorinated GHG emitted from electronics manufacturing processes in the fab, expressed in metric ton CO2e for which you calculated total emission according to the procedures in §98.93(a) or §98.93(i)(4).

Cij= Total consumption of fluorinated GHG i, apportioned to process j, expressed in metric ton CO2e, which you used to calculate total emissions according to the procedures in §98.93(a) or §98.93(i)(4).

Uij= Process utilization rate for fluorinated GHG i, process type j, which you used to calculate total emissions according to the procedures in §98.93(a) or §98.93(i)(4).

GWPi= GWP of emitted fluorinated GHG i from Table A-1 of this part.

GWPk= GWP of emitted fluorinated GHG by-product k from Table A-1 of this part.

Bijk= By-product formation rate of fluorinated GHG k created as a by-product per amount of fluorinated GHG input gas i (kg) consumed by process type j (kg).

i = Fluorinated GHG.

j = Process Type.

k = Fluorinated GHG by-product.

(2) Use Equation I-28 to calculate total unabated emissions, in metric ton CO2e, of all fluorinated GHG emitted from electronics manufacturing processes whose emissions of fluorinated GHG you calculated according to the stack testing procedures in §98.93(i)(3). For each set of processes, use the same input gas consumption (Cif), input gas emission factors (EFif), by-product gas emission factors (EFkf), fractions of tools abated (aif and af), and destruction efficiencies (dif and dkf) to calculate unabated emissions as you used to calculate emissions.

Where:

SFGHG = Total unabated emissions of fluorinated GHG emitted from electronics manufacturing processes in the fab, expressed in metric ton CO2e for which you calculated total emission according to the procedures in §98.93(i)(3).

EFif= Emission factor for fluorinated GHG input gas i, emitted from fab f, as calculated in Equation I-19 of this subpart (kg emitted/kg input gas consumed).

aif= Fraction of fluorinated GHG input gas i used in fab f in tools with abatement systems (expressed as a decimal fraction).

dif = Fraction of fluorinated GHG i destroyed or removed in abatement systems connected to process tools in fab f, as calculated from Equation I-24A of this subpart, which you used to calculate total emissions according to the procedures in §98.93(i)(3) (expressed as a decimal fraction).

Cif= Total consumption of fluorinated GHG input gas i, of tools vented to stack systems that are tested, for fab f, for the reporting year, expressed in metric ton CO2e, which you used to calculate total emissions according to the procedures in §98.93(i)(3) (expressed as a decimal fraction).

EFkf= Emission factor for fluorinated GHG by-product gas k, emitted from fab f, as calculated in Equation I-20 of this subpart (kg emitted/kg of all input gases consumed in tools vented to stack systems that are tested).

af= Fraction of input gases used in fab f in tools with abatement systems (expressed as a decimal fraction).

dkf = Fraction of fluorinated GHG byproduct k destroyed or removed in abatement systems connected to process tools in fab f, as calculated from Equation I-24B of this subpart, which you used to calculate total emissions according to the procedures in §98.93(i)(3) (expressed as a decimal fraction).

GWPi= GWP of emitted fluorinated GHG i from Table A-1 of this part.

GWPk= GWP of emitted fluorinated GHG by-product k from Table A-1 of this part.

i = Fluorinated GHG.

k = Fluorinated GHG by-product.

(s) Where missing data procedures were used to estimate inputs into the fluorinated heat transfer fluid mass balance equation under §98.95(b), the number of times missing data procedures were followed in the reporting year and the method used to estimate the missing data.

(t) [Reserved]

(u) [Reserved]

(v) [Reserved]

(w) If you elect to calculate fab-level emissions of fluorinated GHG using the stack test methods specified in §98.93(i), you must report the following in paragraphs (w)(1) and (2) for each stack system, in addition to the relevant data in paragraphs (a) through (v) of this section:

(1) The date of any stack testing conducted during the reporting year, and the identity of the stack system tested.

(2) An inventory of all stack systems from which process fluorinated GHG are emitted. For each stack system, indicate whether the stack system is among those for which stack testing was performed as per §98.93(i)(3) or not performed as per §98.93(i)(2).

(x) If the emissions you report under paragraph (c) of this section include emissions from research and development activities, as defined in §98.6, report the approximate percentage of total GHG emissions, on a metric ton CO2e basis, that are attributable to research and development activities, using the following ranges: less than 5 percent, 5 percent to less than 10 percent, 10 percent to less than 25 percent, 25 percent to less than 50 percent, 50 percent and higher.

(y) If your semiconductor manufacturing facility emits more than 40,000 metric ton CO2e of GHG emissions, based on your most recently submitted annual report (beginning with the 2015 reporting year) as required in paragraph (c) of this section, from the electronics manufacturing processes subject to reporting under this subpart, you must prepare and submit a triennial (every 3 years) technology assessment report to the Administrator (or an authorized representative) that meets the requirements specified in paragraphs (y)(1) through (6) of this section. Any other semiconductor manufacturing facility may voluntarily submit this report to the Administrator.

(1) The first report must be submitted with the annual GHG emissions report that is due no later than March 31, 2017, and subsequent reports must be delivered every 3 years no later than March 31 of the year in which it is due.

(2) The report must include the information described in paragraphs (y)(2)(i) through (v) of this section.

(i) It must describe how the gases and technologies used in semiconductor manufacturing using 200 mm and 300 mm wafers in the United States have changed in the past 3 years and whether any of the identified changes are likely to have affected the emissions characteristics of semiconductor manufacturing processes in such a way that the default utilization and by-product formation rates or default destruction or removal efficiency factors of this subpart may need to be updated.

(ii) It must describe the effect on emissions of the implementation of new process technologies and/or finer line width processes in 200 mm and 300 mm technologies, the introduction of new tool platforms, and the introduction of new processes on previously tested platforms.

(iii) It must describe the status of implementing 450 mm wafer technology and the potential need to create or update default emission factors compared to 300 mm technology.

(iv) It must provide any utilization and byproduct formation rates and/or destruction or removal efficiency data that have been collected in the previous 3 years that support the changes in semiconductor manufacturing processes described in the report. For any utilization or byproduct formation rate data submitted, the report must include the input gases used and measured, the utilization rates measured, the byproduct formation rates measured, the process type, the process subtype for chamber clean processes, the wafer size, and the methods used for the measurements. For any destruction or removal efficiency data submitted, the report must include the input gases used and measured, the destruction and removal efficiency measured, the process type, and the methods used for the measurements.

(v) It must describe the use of a new gas, use of an existing gas in a new process type or sub-type, or a fundamental change in process technology.

(3) If, on the basis of the information reported in paragraph (y)(2) of this section, the report indicates that GHG emissions from semiconductor manufacturing may have changed from those represented by the default utilization and by-product formation rates in Tables I-3 or I-4, or the default destruction or removal efficiency values in Table I-16 of this subpart, the report must lay out a data gathering and analysis plan focused on the areas of potential change. The plan must describe the elements in paragraphs (y)(3)(i) and (ii).

(i) The testing of tools to determine the potential effect on current utilization and by-product formation rates and destruction or removal efficiency values under the new conditions.

(ii) A planned analysis of the effect on overall facility emissions using a representative gas-use profile for a 200 mm, 300 mm, or 450 mm fab (depending on which technology is under consideration).

(4) Multiple semiconductor manufacturing facilities may submit a single consolidated 3-year report as long as the facility identifying information in §98.3(c)(1) and the certification statement in §98.3(c)(9) is provided for each facility for which the consolidated report is submitted.

(5) The Administrator will review the report received and determine whether it is necessary to update the default utilization rates and by-product formation rates in Tables I-3, I-4, I-11, and I-12 of this subpart and default destruction or removal efficiency values in Table I-16 of this subpart based on the following:

(i) Whether the revised default utilization and by-product formation rates and destruction or removal efficiency values will result in a projected shift in emissions of 10 percent or greater.

(ii) Whether new platforms, processes, or facilities that are not captured in current default utilization and by-product formation rates and destruction or removal efficiency values should be included in revised values.

(iii) Whether new data are available that could expand the existing data set to include new gases, tools, or processes not included in the existing data set (i.e. gases, tools, or processes for which no data are currently available).

(6) The Administrator will review the reports within 120 days and will notify you of a determination whether it is necessary to update any default utilization and by-product formation rates and/or destruction or removal efficiency values. If the Administrator determines it is necessary to update default utilization and by-product formation rates and/or destruction or removal efficiency values, you will then have 180 days from the date you receive notice of the determination to execute the data collection and analysis plan described in the report and submit those data to the Administrator.

[75 FR 74826, Dec. 1, 2010; 77 FR 10381, Feb. 22, 2012; 78 FR 68215, Nov. 13, 2013; 78 FR 71954, Nov. 29, 2013; 79 FR 73785, Dec. 11, 2014; 81 FR 89255, Dec. 9, 2016]

READ MORESHOW LESS

['Air Programs']

['Greenhouse Gases']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.