['Air Programs']

['Greenhouse Gases']

05/22/2023

...

(a) You must determine annual N2O process emissions from each nitric acid train according to paragraphs (a)(1) or (a)(2) of this section.

(1) Use a site-specific emission factor and production data according to paragraphs (b) through (i) of this section.

(2) Request Administrator approval for an alternative method of determining N2O emissions according to paragraphs (a)(2)(i) through (iv) of this section.

(i) If you received Administrator approval for an alternative method of determining N2O emissions in the previous reporting year and your methodology is unchanged, your alternative method is automatically approved for the next reporting year.

(ii) You must notify the EPA of your use of a previously approved alternative method in your annual report.

(iii) Otherwise, if you have not received Administrator approval for an alternative method of determining N2O emissions in a prior reporting year or your methodology has changed, you must submit the request within the first 30 days of each subsequent reporting year.

(iv) If the Administrator does not approve your requested alternative method within 150 days of the end of the reporting year, you must determine the N2O emissions for the current reporting period using the procedures specified in paragraph (a)(1) of this section.

(b) You must conduct an annual performance test for each nitric acid train according to paragraphs (b)(1) through (3) of this section.

(1) You must conduct the performance test at the absorber tail gas vent, referred to as the test point, for each nitric acid train according to §98.224(b) through (f). If multiple nitric acid trains exhaust to a common abatement technology and/or emission point, you must sample each process in the ducts before the emissions are combined, sample each process when only one process is operating, or sample the combined emissions when multiple processes are operating and base the site-specific emission factor on the combined production rate of the multiple nitric acid trains.

(2) You must conduct the performance test under normal process operating conditions.

(3) You must measure the production rate during the performance test and calculate the production rate for the test period in tons (100 percent acid basis) per hour.

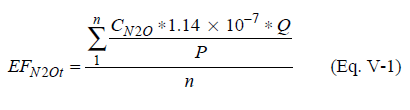

(c) Using the results of the performance test in paragraph (b) of this section, you must calculate an average site-specific emission factor for each nitric acid train “t” according to Equation V–1 of this section:

Where:

EFN2Ot = Average site-specific N2O emissions factor for nitric acid train “t” (lb N2O/ton nitric acid produced, 100 percent acid basis).

CN2O = N2O concentration for each test run during the performance test (ppm N2O).

1.14 × 10-7 = Conversion factor (lb/dscf-ppm N2O).

Q = Volumetric flow rate of effluent gas for each test run during the performance test (dscf/hr).

P = Production rate for each test run during the performance test (tons nitric acid produced per hour, 100 percent acid basis).

n = Number of test runs.

(d) If nitric acid train “t” exhausts to any N2O abatement technology “N”, you must determine the destruction efficiency for each N2O abatement technology “N” according to paragraphs (d)(1), (2), or (3) of this section.

(1) Use the manufacturer’s specified destruction efficiency.

(2) Estimate the destruction efficiency through process knowledge.

Examples of information that could constitute process knowledge include calculations based on material balances, process stoichiometry, or previous test results provided the results are still relevant to the current vent stream conditions. You must document how process knowledge (if applicable) was used to determine the destruction efficiency.

(3) Calculate the destruction efficiency by conducting an additional performance test on the emissions stream following the N2O abatement technology.

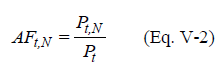

(e) If nitric acid train “t” exhausts to any N2O abatement technology “N”, you must determine the annual amount of nitric acid produced on nitric acid train “t” while N2O abatement technology “N” is operating according to §98.224(f). Then you must calculate the abatement utilization factor for each N2O abatement technology “N” for each nitric acid train “t” according to Equation V-2 of this section.

Where:

AFt,N = Abatement utilization factor of N2O abatement technology “N” at nitric acid train “t” (fraction of annual production that abatement technology is operating).

Pt = Total annual nitric acid production from nitric acid train “t” (ton acid produced, 100 percent acid basis)

Pt,N= Annual nitric acid production from nitric acid train “t” during which N2O abatement technology “N” was operational (ton acid produced, 100 percent acid basis).

(f) [Removed]

(g) You must calculate N2O emissions for each nitric acid train “t” according to paragraph (g)(1), (g)(2), (g)(3), or (g)(4) of this section.

(1) If nitric acid train “t” exhausts to one N2O abatement technology “N” after the test point, you must use the emissions factor (determined in Equation V–1 of this section), the destruction efficiency (determined in paragraph (d) of this section), the annual nitric acid production (determined in paragraph (i) of this section), and the abatement utilization factor (determined in paragraph (e) of this section) according to Equation V–3a of this section:

Where:

EN2Ot= Annual N2O mass emissions from nitric acid train “t” according to this Equation V-3a (metric tons).

EFN2Ot = Average site-specific N2O emissions factor for nitric acid train “t” (lb N2O/ton acid produced, 100 percent acid basis).

Pt= Annual nitric acid production from nitric acid train “t” (ton acid produced, 100 percent acid basis).

DF = Destruction efficiency of N2O abatement technology N that is used on nitric acid train “t” (decimal fraction of N2O removed from vent stream).

AF = Abatement utilization factor of N2O abatement technology “N” for nitric acid train “t” (decimal fraction of annual production during which abatement technology is operating).

2205 = Conversion factor (lb/metric ton).

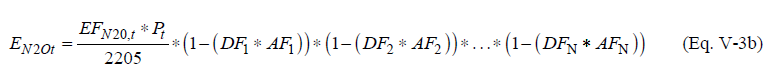

(2) If multiple N2O abatement technologies are located in series after your test point, you must use the emissions factor (determined in Equation V-1 of this section), the destruction efficiency (determined in paragraph (d) of this section), the annual nitric acid production (determined in paragraph (i) of this section), and the abatement utilization factor (determined in paragraph (e) of this section), according to Equation V-3b of this section:

Where:

EN2Ot= Annual N2O mass emissions from nitric acid train “t” according to this Equation V-3b (metric tons).

EFN2O,t= N2O emissions factor for nitric acid train “t” (lb N2O/ton nitric acid produced).

Pt= Annual nitric acid produced from nitric acid train “t” (ton acid produced, 100 percent acid basis).

DF1= Destruction efficiency of N2O abatement technology 1 (decimal fraction of N2O removed from vent stream).

AF1= Abatement utilization factor of N2O abatement technology 1 (decimal fraction of time that abatement technology 1 is operating).

DF2= Destruction efficiency of N2O abatement technology 2 (decimal fraction of N2O removed from vent stream).

AF2= Abatement utilization factor of N2O abatement technology 2 (decimal fraction of time that abatement technology 2 is operating).

DFN= Destruction efficiency of N2O abatement technology N (decimal fraction of N2O removed from vent stream).

AFN= Abatement utilization factor of N2O abatement technology N (decimal fraction of time that abatement technology N is operating).

2205 = Conversion factor (lb/metric ton).

N = Number of different N2O abatement technologies.

(3) If multiple N2O abatement technologies are located in parallel after your test point, you must use the emissions factor (determined in Equation V-1 of this section), the destruction efficiency (determined in paragraph (d) of this section), the annual nitric acid production (determined in paragraph (i) of this section), and the abatement utilization factor (determined in paragraph (e) of this section), according to Equation V-3c of this section:

Where:

EN2Ot= Annual N2O mass emissions from nitric acid train “t” according to this Equation V-3c (metric tons).

EFN2O,t= N2O emissions factor for nitric acid train “t” (lb N2O/ton nitric acid produced).

Pt= Annual nitric acid produced from nitric acid train “t” (ton acid produced, 100 percent acid basis).

DFN= Destruction efficiency of N2O abatement technology “N” (decimal fraction of N2O removed from vent stream).

AFN= Abatement utilization factor of N2O abatement technology “N” (decimal fraction of time that abatement technology “N” is operating).

FCN= Fraction control factor of N2O abatement technology “N” (decimal fraction of total emissions from nitric acid train “t” that are sent to abatement technology “N”).

2205 = Conversion factor (lb/metric ton).

N = Number of different N2O abatement technologies with a fraction control factor.

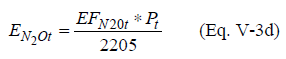

(4) If nitric acid train “t” does not exhaust to any N2O abatement technology after the test point, you must use the emissions factor (determined in Equation V-1 of this section), and the annual nitric acid production (determined in paragraph (i) of this section) according to Equation V-3b of this section:

Where:

EN2Ot= Annual N2O mass emissions from nitric acid train “t” according to this Equation V-3d (metric tons).

EFN2Ot = Average site-specific N2O emissions factor for nitric acid train “t” (lb N2O/ton acid produced, 100 percent acid basis).

Pt = Annual nitric acid production from nitric acid train “t” (ton acid produced, 100 percent acid basis).

2205 = Conversion factor (lb/metric ton).

(h) You must determine the annual nitric acid production emissions combined from all nitric acid trains at your facility using Equation V-4 of this section:

Where:

N2O = Annual process N2O emissions from nitric acid production facility (metric tons).

EN2Ot = N2O mass emissions per year for nitric acid train “t” (metric tons).

m = Number of nitric acid trains.

(i) You must determine the total annual amount of nitric acid produced on each nitric acid train “t” (tons acid produced, 100 percent acid basis), according to §98.224(f).

[74 FR 56444, Oct. 30, 2009; 75 FR 66467, Oct. 28, 2010; 78 FR 71959, Nov. 29, 2013; 81 FR 89260, Dec. 9, 2016]

READ MORESHOW LESS

['Air Programs']

['Greenhouse Gases']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.