['Air Programs']

['Greenhouse Gases']

05/22/2023

...

For fluorinated gas production and transformation processes, you must calculate the fluorinated GHG emissions from each process using the emission factor or emission calculation factor method specified in paragraphs (c), (d), and (e) of this section, as appropriate. For destruction processes that destroy fluorinated GHGs that were previously “produced” as defined at §98.410(b), you must calculate emissions using the procedures in paragraph (f) of this section. For venting of residual gas from containers (e.g., cylinder heels), you must calculate emissions using the procedures in paragraph (g) of this section.

(a) [Reserved]

(b) Mass balance method. The mass balance method was available for reporting years 2011, 2012, 2013, and 2014 only. See paragraph 1 of Appendix A of this subpart for the former mass balance method.

(c) Emission factor and emission calculation factor methods. To use the method in this paragraph for batch processes, you must comply with either paragraph (c)(3) of this section (Emission Factor approach) or paragraph (c)(4) of this section (Emission Calculation Factor approach). To use the method in this paragraph for continuous processes, you must first make a preliminary estimate of the emissions from each individual continuous process vent under paragraph (c)(1) of this section. If your continuous process operates under different conditions as part of normal operations, you must also define the different operating scenarios and make a preliminary estimate of the emissions from the vent for each operating scenario. Then, compare the preliminary estimate for each continuous process vent (summed across operating scenarios) to the criteria in paragraph (c)(2) of this section to determine whether the process vent meets the criteria for using the emission factor method described in paragraph (c)(3) of this section or whether the process vent meets the criteria for using the emission calculation factor method described in paragraph (c)(4) of this section. For continuous process vents that meet the criteria for using the emission factor method described in paragraph (c)(3) of this section and that have more than one operating scenario, compare the preliminary estimate for each operating scenario to the criteria in (c)(3)(ii) to determine whether an emission factor must be developed for that operating scenario.

(1) Preliminary estimate of emissions by process vent. You must estimate the annual CO2e emissions of fluorinated GHGs for each process vent within each operating scenario of a continuous process using the approaches specified in paragraph (c)(1)(i) or (c)(1)(ii) of this section, accounting for any destruction as specified in paragraph (c)(1)(iii) of this section. You must determine emissions of fluorinated GHGs by process vent by using measurements, by using calculations based on chemical engineering principles and chemical property data, or by conducting an engineering assessment. You may use previous measurements, calculations, and assessments if they represent current process operating conditions or process operating conditions that would result in higher fluorinated GHG emissions than the current operating conditions and if they were performed in accordance with paragraphs (c)(1)(i), (c)(1)(ii), and (c)(1)(iii) of this section, as applicable. You must document all data, assumptions, and procedures used in the calculations or engineering assessment and keep a record of the emissions determination as required by §98.127(a).

(i) Engineering calculations. For process vent emission calculations, you may use any of paragraphs (c)(1)(i)(A), (c)(1)(i)(B), or (c)(1)(i)(C) of this section.

(A) U.S. Environmental Protection Agency, Emission Inventory Improvement Program, Volume II: Chapter 16, Methods for Estimating Air Emissions from Chemical Manufacturing Facilities, August 2007, Final (incorporated by reference, see §98.7).

(B) You may determine the fluorinated GHG emissions from any process vent within the process using the procedures specified in §63.1257(d)(2)(i) and (d)(3)(i)(B) of this chapter, except as specified in paragraphs (c)(1)(i)(B)(1) through (c)(1)(i)(B)(4) of this section. For the purposes of this subpart, use of the term “HAP” in §63.1257(d)(2)(i) and (d)(3)(i)(B) of this chapter means “fluorinated GHG”.

(1) To calculate emissions caused by the heating of a vessel without a process condenser to a temperature lower than the boiling point, you must use the procedures in §63.1257(d)(2)(i)(C)(3) of this chapter.

(2) To calculate emissions from depressurization of a vessel without a process condenser, you must use the procedures in §63.1257(d)(2)(i)(D)(10) of this chapter.

(3) To calculate emissions from vacuum systems, the terms used in Equation 33 to §63.1257(d)(2)(i)(E) of this chapter are defined as follows:

(i) Psystem = Absolute pressure of the receiving vessel.

(ii) Pi= Partial pressure of the fluorinated GHG determined at the exit temperature and exit pressure conditions of the condenser or at the conditions of the dedicated receiver.

(iii) Pj= Partial pressure of condensables (including fluorinated GHG) determined at the exit temperature and exit pressure conditions of the condenser or at the conditions of the dedicated receiver.

(iv) MWFluorinated GHG = Molecular weight of the fluorinated GHG determined at the exit temperature and exit pressure conditions of the condenser or at the conditions of the dedicated receiver.

(4) To calculate emissions when a vessel is equipped with a process condenser or a control condenser, you must use the procedures in §63.1257(d)(3)(i)(B) of this chapter, except as follows:

(i) You must determine the flowrate of gas (or volume of gas), partial pressures of condensables, temperature (T), and fluorinated GHG molecular weight (MWFluorinated GHG) at the exit temperature and exit pressure conditions of the condenser or at the conditions of the dedicated receiver.

(ii) You must assume that all of the components contained in the condenser exit vent stream are in equilibrium with the same components in the exit condensate stream (except for noncondensables).

(iii) You must perform a material balance for each component, if the condensate receiver composition is not known.

(iv) For the emissions from gas evolution, the term for time, t, must be used in Equation 12 to §63.1257(d)(2)(i)(B) of this chapter.

(v) Emissions from empty vessel purging must be calculated using Equation 36 to §63.1257(d)(2)(i)(H) of this chapter and the exit temperature and exit pressure conditions of the condenser or the conditions of the dedicated receiver.

(C) Commercial software products that follow chemical engineering principles (e.g., including the calculation methodologies in paragraphs (c)(1)(i)(A) and (c)(1)(i)(B) of this section).

(ii) Engineering assessments. For process vent emissions determinations, you may conduct an engineering assessment to calculate uncontrolled emissions. An engineering assessment includes, but is not limited to, the following:

(A) Previous test results, provided the tests are representative of current operating practices of the process.

(B) Bench-scale or pilot-scale test data representative of the process operating conditions.

(C) Maximum flow rate, fluorinated GHG emission rate, concentration, or other relevant parameters specified or implied within a permit limit applicable to the process vent.

(D) Design analysis based on chemical engineering principles, measureable process parameters, or physical or chemical laws or properties.

(iii) Impact of destruction for the preliminary estimate. If the process vent is vented to a destruction device, you may reflect the impact of the destruction device on emissions. In your emissions estimate, account for the following:

(A) The destruction efficiencies of the device that have been demonstrated for the fluorinated GHGs in the vent stream for periods when the process vent is vented to the destruction device.

(B) Any periods when the process vent is not vented to the destruction device.

(iv) Use of typical recent values. In the calculations in paragraphs (c)(1)(i), (c)(1)(ii), and (c)(1)(iii) of this section, the values used for the expected process activity and for the expected fraction of that activity whose emissions will be vented to the properly functioning destruction device must be based on either typical recent values for the process or values that would overestimate emissions from the process, unless there is a compelling reason to adopt a different value (e.g., installation of a destruction device for a previously uncontrolled process). If there is such a reason, it must be documented in the GHG Monitoring Plan.

(v) GWPs. To convert the fluorinated GHG emissions to CO2e, use Equation A-1 of §98.2.

(vi) [Reserved]

(A) Contents of the request. You must include the following information in the request for each fluorinated GHG that does not have a GWP listed in Table A-1 to subpart A of this part and that constitutes more than one percent by mass of the stream emitted from the vent:

(1) The identity of the fluorinated GHG, including its chemical formula and, if available, CAS number.

(2) The estimated GWP of the fluorinated GHG.

(3) The data and analysis that supports your estimate of the GWP of the fluorinated GHG, including:

(i) Data and analysis related to the low-pressure gas phase infrared absorption spectrum of the fluorinated GHG.

(ii) Data and analysis related to the estimated atmospheric lifetime of the fluorinated GHG (reaction mechanisms and rates, including e.g., photolysis and reaction with atmospheric components such as OH, O3, CO, and water).

(iii) The radiative transfer analysis that integrates the lifetime and infrared absorption spectrum data to calculate the GWP.

(iv) Any published or unpublished studies of the GWP of the gas.

(4) The engineering calculations or assessments and underlying data that demonstrate that the process vent is calculated to emit less than 10,000 metric tons CO2e of this and other fluorinated GHGs only when the proposed provisional GWPs, not the default GWP of 2,000, are used for fluorinated GHGs whose GWPs are not listed in Table A-1 to subpart A of this part.

(B) Review and completeness determination by EPA. If EPA makes a preliminary determination that the request is complete, that it substantiates each of the provisional GWPs, and that it demonstrates that the process vent is calculated to emit less than 10,000 metric tons CO2e of this and other fluorinated GHGs only when the provisional GWPs, not the default GWP of 2,000, are used for fluorinated GHGs whose GWPs are not listed in Table A-1 to subpart A of this part, then EPA will publish a notice including the data and analysis submitted under paragraphs (c)(1)(vi)(A)(1) through (c)(1)(vi)(A)(3) of this section. If, after review of public comment on the notice, EPA finalizes its preliminary determination, then EPA will permit the facility to use the provisional GWPs for the calculations in paragraph (c)(1) of this section unless and until EPA determines that one or more of the provisional GWPs is in error and provides reasonable notice to the facility.

(2) Method selection for continuous process vents.

(i) If the calculations under paragraph (c)(1) of this section, as well as any subsequent measurements and calculations under this subpart, indicate that the continuous process vent has fluorinated GHG emissions of less than 10,000 metric ton CO2e per year, summed across all operating scenarios, then you may comply with either paragraph (c)(3) of this section (Emission Factor approach) or paragraph (c)(4) of this section (Emission Calculation Factor approach).

(ii) If the continuous process vent does not meet the criteria in paragraph (c)(2)(i) of this section, then you must comply with the emission factor method specified in paragraph (c)(3) (Emission Factor approach) of this section.

(A) You must conduct emission testing for process-vent-specific emission factor development before the destruction device unless the calculations you performed under paragraph (c)(1)(iii) of this section indicate that the uncontrolled fluorinated GHG emissions that occur during periods when the process vent is not vented to the properly functioning destruction device are less than 10,000 metric tons CO2e per year. In this case, you may conduct emission testing after the destruction device to develop a process-vent-specific emission factor. If you do so, you must develop and apply an emission calculation factor under paragraph (c)(4) to estimate emissions during any periods when the process vent is not vented to the properly functioning destruction device.

(B) Regardless of the level of uncontrolled emissions, the emission testing for process-vent-specific emission factor development may be conducted on the outlet side of a wet scrubber in place for acid gas reduction, if one is in place, as long as there is no appreciable reduction in the fluorinated GHG.

(3) Process-vent-specific emission factor method. For each process vent, conduct an emission test and measure fluorinated GHG emissions from the process and measure the process activity, such as the feed rate, production rate, or other process activity rate, during the test as described in this paragraph (c)(3). Conduct the emission test according to the procedures in §98.124. All emissions test data and procedures used in developing emission factors must be documented according to §98.127. If more than one operating scenario applies to the process that contains the subject process vent, you must comply with either paragraph (3)(i) or paragraph (3)(ii) of this section.

(i) Conduct a separate emissions test for operation under each operating scenario.

(ii) Conduct an emissions test for the operating scenario that is expected to have the largest emissions in terms of CO2e (considering both activity levels and emission calculation factors) on an annual basis. Also conduct an emissions test for each additional operating scenario that is estimated to emit 10,000 metric tons CO2e or more annually from the vent and whose emission calculation factor differs by 15 percent or more from the emission calculation factor of the operating scenario that is expected to have the largest emissions (or of another operating scenario for which emission testing is performed), unless the difference between the operating scenarios is solely due to the application of a destruction device to emissions under one of the operating scenarios. For any other operating scenarios, adjust the process-vent specific emission factor developed for the operating scenario that is expected to have the largest emissions (or for another operating scenario for which emission testing is performed) using the approach in paragraph (c)(3)(viii) of this section.

(iii) You must measure the process activity, such as the process feed rate, process production rate, or other process activity rate, as applicable, during the emission test and calculate the rate for the test period, in kg (or another appropriate metric) per hour.

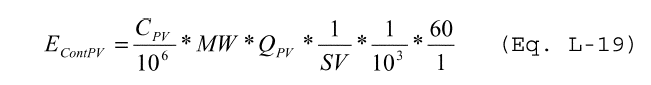

(iv) For continuous processes, you must calculate the hourly emission rate of each fluorinated GHG using Equation L-19 of this section and determine the hourly emission rate of each fluorinated GHG per process vent (and per operating scenario, as applicable) for the test run.

Where:

EContPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, during the emission test during test run r (kg/hr).

CPV = Concentration of fluorinated GHG f during test run r of the emission test (ppmv).

MW = Molecular weight of fluorinated GHG f (g/g-mole).

QPV = Flow rate of the process vent stream during test run r of the emission test (m3/min).

SV = Standard molar volume of gas (0.0240 m3/g-mole at 68 °F and 1 atm).

1/103 = Conversion factor (1 kilogram/1,000 grams).

60/1 = Conversion factor (60 minutes/1 hour).

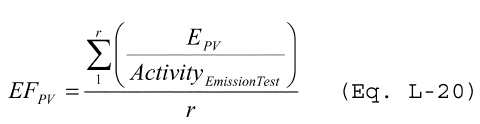

(v) You must calculate a site-specific, process-vent-specific emission factor for each fluorinated GHG for each process vent and each operating scenario, in kg of fluorinated GHG per process activity rate (e.g., kg of feed or production), as applicable, using Equation L-20 of this section. For continuous processes, divide the hourly fluorinated GHG emission rate during the test by the hourly process activity rate during the test runs.

Where:

EFPV = Emission factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j (e.g., kg emitted/kg activity).

EPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, during the emission test during test run r, for either continuous or batch (kg emitted/hr for continuous, kg emitted/batch for batch).

ActivityEmissionTest = Process feed, process production, or other process activity rate for process i, operating scenario j, during the emission test during test run r (e.g., kg product/hr).

r = Number of test runs performed during the emission test.

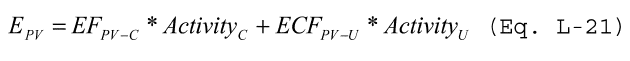

(vi) If you conducted emissions testing after the destruction device, you must calculate the emissions of each fluorinated GHG for the process vent (and operating scenario, as applicable) using Equation L-21 of this section. You must also develop a process-vent-specific emission calculation factor based on paragraph (c)(4) of this section for the periods when the process vent is not venting to the destruction device.

Where:

EPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, for the year (kg).

EFPV-C = Emission factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j, based on testing after the destruction device (kg emitted/activity) (e.g., kg emitted/kg product).

ActivityC = Total process feed, process production, or other process activity for process i, operating scenario j, during the year for which emissions are vented to the properly functioning destruction device (i.e., controlled).

ECFPV-U = Emission calculation factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j during periods when the process vent is not vented to the properly functioning destruction device (kg emitted/activity) (e.g., kg emitted/kg product).

ActivityU = Total process feed, process production, or other process activity during the year for which the process vent is not vented to the properly functioning destruction device (e.g., kg product).

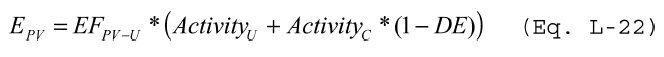

(vii) If you conducted emissions testing before the destruction device, apply the destruction efficiencies of the device that have been demonstrated for the fluorinated GHGs in the vent stream to the fluorinated GHG emissions for the process vent (and operating scenario, as applicable), using Equation L-22 of this section. You may apply the destruction efficiency only to the portion of the process activity during which emissionsare vented to the properly functioning destruction device (i.e., controlled).

ar

Where:

EPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, for the year, considering destruction efficiency (kg).

EFPV-U = Emission factor (uncontrolled) for fluorinated GHG f emitted from process vent v during process i, operating scenario j (kg emitted/kg product).

ActivityU = Total process feed, process production, or other process activity for process i, operating scenario j, during the year for which the process vent is not vented to the properly functioning destruction device (e.g., kg product).

ActivityC = Total process feed, process production, or other process activity for process i, operating scenario j, during the year for which the process vent is vented to the properly functioning destruction device (e.g., kg product).

DE = Demonstrated destruction efficiency of the destruction device (weight fraction).

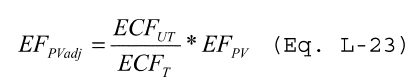

(viii) Adjusted process-vent-specific emission factors for other operating scenarios. For process vents from processes with multiple operating scenarios, use Equation L-23 of this section to develop an adjusted process-vent-specific emission factor for each operating scenario from which the vent is estimated to emit less than 10,000 metric tons CO2e annually or whose emission calculation factor differs by less than 15 percent from the emission calculation factor of the operating scenario that is expected to have the largest emissions (or of another operating scenario for which emission testing is performed).

Where:

EFPVadj = Adjusted process-vent-specific emission factor for an untested operating scenario.

ECFUT = Emission calculation factor for the untested operating scenario developed under paragraph (c)(4) of this section.

ECFT = Emission calculation for the tested operating scenario developed under paragraph (c)(4) of this section.

EFPV = Process vent specific emission factor for the tested operating scenario.

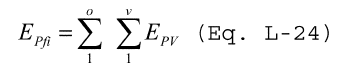

(ix) Sum the emissions of each fluorinated GHG from all process vents in each operating scenario and all operating scenarios in the process for the year to estimate the total process vent emissions of each fluorinated GHG from the process, using Equation L-24 of this section.

Where:

EPfi = Mass of fluorinated GHG f emitted from process vents for process i for the year (kg).

EPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, for the year, considering destruction efficiency (kg).

v = Number of process vents in process i, operating scenario j.

o = Number of operating scenarios for process i.

(4) Process-vent-specific emission calculation factor method. For each process vent within an operating scenario, determine fluorinated GHG emissions by calculations and determine the process activity rate, such as the feed rate, production rate, or other process activity rate, associated with the emission rate.

(i) You must calculate uncontrolled emissions of fluorinated GHG by individual process vent, EPV, by using measurements, by using calculations based on chemical engineering principles and chemical property data, or by conducting an engineering assessment. Use the procedures in paragraphs (c)(1)(i) or (ii) of this section, except paragraph (c)(1)(ii)(C) of this section. The procedures in paragraphs (c)(1)(i) and (ii) of this section may be applied either to batch process vents or to continuous process vents. The uncontrolled emissions must be based on a typical batch or production rate under a defined operating scenario. The process activity rate associated with the uncontrolled emissions must be determined. The methods, data, and assumptions used to estimate emissions for each operating scenario must be selected to yield a best estimate (expected value) of emissions rather than an over- or underestimate of emissions for that operating scenario. All data, assumptions, and procedures used in the calculations or engineering assessment must be documented according to §98.127.

(ii) You must calculate a site-specific, process-vent-specific emission calculation factor for each process vent, each operating scenario, and each fluorinated GHG, in kg of fluorinated GHG per activity rate (e.g., kg of feed or production) as applicable, using Equation L-25 of this section.

Where:

ECFPV = Emission calculation factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j, (e.g., kg emitted/kg product).

EPV = Average mass of fluorinated GHG f emitted, based on calculations, from process vent v from process i, operating scenario j, during the period or batch for which emissions were calculated, for either continuous or batch (kg emitted/hr for continuous, kg emitted/batch for batch).

ActivityRepresentative = Process feed, process production, or other process activity rate corresponding to average mass of emissions based on calculations (e.g., kg product/hr for continuous, kg product/batch for batch).

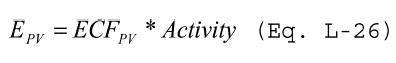

(iii) You must calculate emissions of each fluorinated GHG for the process vent (and operating scenario, as applicable) for the year by multiplyingthe process-vent-specific emission calculation factor by the total process activity, as applicable, for the year, using Equation L-26 of this section.

Where:

EPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, for the year (kg).

ECFPV = Emission calculation factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j, (kg emitted/activity) (e.g., kg emitted/kg product).

Activity = Process feed, process production, or other process activity for process i, operating scenario j, during the year.

(iv) If the process vent is vented to a destruction device, apply the demonstrated destruction efficiency of the device to the fluorinated GHG emissions for the process vent (and operating scenario, as applicable), using Equation L-27 of this section. Apply the destruction efficiency only to the portion of the process activity that is vented to the properly functioning destruction device (i.e., controlled).

Where:

EPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, for the year considering destruction efficiency (kg).

ECFPV = Emission calculation factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j, (e.g., kg emitted/kg product).

ActivityU = Total process feed, process production, or other process activity for process i, operating scenario j, during the year for which the process vent is not vented to the properly functioning destruction device (e.g., kg product).

ActivityC = Total process feed, process production, or other process activity for process i, operating scenario j, during the year for which the process vent is vented to the properly functioning destruction device (e.g., kg product).

DE = Demonstrated destruction efficiency of the destruction device (weight fraction).

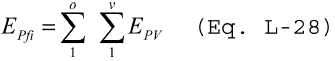

(v) Sum the emissions of each fluorinated GHG from all process vents in each operating scenario and all operating scenarios in the process for the year to estimate the total process vent emissions of each fluorinated GHG from the process, using Equation L-28 of this section.

Where:

EPfi = Mass of fluorinated GHG f emitted from process vents for process i for the year (kg).

EPV = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, for the year, considering destruction efficiency (kg).

v = Number of process vents in process i, operating scenario j.

o = Number of operating scenarios in process i.

(d) Calculate fluorinated GHG emissions for equipment leaks (EL). If you comply with paragraph (c) of this section, you must calculate the fluorinated GHG emissions from pieces of equipment associated with processes covered under this subpart and in fluorinated GHG service. If you conduct monitoring of equipment in fluorinated GHG service, monitoring must be conducted for those in light liquid and in gas and vapor service. If you conduct monitoring of equipment in fluorinated GHG service, you may exclude from monitoring each piece of equipment that is difficult-to-monitor, that is unsafe-to-monitor, that is insulated, or that is in heavy liquid service; you may exclude from monitoring each pump with dual mechanical seals, agitator with dual mechanical seals, pump with no external shaft, agitator with no external shaft; you may exclude from monitoring each pressure relief device in gas and vapor service with upstream rupture disk, each sampling connection system with closed-loop or closed-purge systems, and any pieces of equipment where leaks are routed through a closed vent system to a destruction device. You must estimate emissions using another approach for those pieces of equipment excluded from monitoring. Equipment that is in fluorinated GHG service for less than 300 hr/yr; equipment that is in vacuum service; pressure relief devices that are in light liquid service; and instrumentation systems are exempted from these requirements.

(1) The emissions from equipment leaks must be calculated using any of the procedures in paragraphs (d)(1)(i), (d)(1)(ii), (d)(1)(iii), or (d)(1)(iv) of this section.

(i) Use of Average Emission Factor Approach in EPA Protocol for Equipment Leak Emission Estimates. The emissions from equipment leaks may be calculated using the default Average Emission Factor Approach in EPA-453/R-95-017 (incorporated by reference, see §98.7).

(ii) Use of Other Approaches in EPA Protocol for Equipment Leak Emission Estimates in conjunction with EPA Method 21 at 40 CFR part 60, appendix A-7. The emissions from equipment leaks may be calculated using one of the following methods in EPA-453/R-95-017 (incorporated by reference, see §98.7): The Screening Ranges Approach; the EPA Correlation Approach; or the Unit-Specific Correlation Approach. If you determine that EPA Method 21 at 40 CFR part 60, appendix A-7 is appropriate for monitoring a fluorinated GHG, and if you calibrate your instrument with a compound different from one or more of the fluorinated GHGs or surrogates to be measured, you must develop response factors for each fluorinated GHG or for each surrogate to be measured using EPA Method 21 at 40 CFR part 60, appendix A-7. For each fluorinated GHG or surrogate measured, the response factor must be less than 10. The response factor is the ratio of the known concentration of a fluorinated GHG or surrogate to the observed meter reading when measured using an instrument calibrated with the reference compound.

(iii) Use of Other Approaches in EPA Protocol for Equipment Leak Emission Estimates in conjunction with site-specific leak monitoring methods. The emissions from equipment leaks may be calculated using one of the following methods in EPA-453/R-95-017 (incorporated by reference, see §98.7): The Screening Ranges Approach; the EPA Correlation Approach; or the Unit-Specific Correlation Approach. You may develop a site-specific leak monitoring method appropriate for monitoring fluorinated GHGs or surrogates to use along with these three approaches. The site-specific leak monitoring method must meet the requirements in §98.124(f)(1).

(iv) Use of site-specific leak monitoring methods. The emissions from equipment leaks may be calculated using a site-specific leak monitoring method. The site-specific leak monitoring method must meet the requirements in §98.124(f)(1).

(2) You must collect information on the number of each type of equipment; the service of each piece of equipment (gas, light liquid, heavy liquid); the concentration of each fluorinated GHG in the stream; and the time period each piece of equipment was in service. Depending on which approach you follow, you may be required to collect information for equipment on the associated screening data concentrations for greater than or equal to 10,000 ppmv and associated screening data concentrations for less than 10,000 ppmv; associated actual screening data concentrations; or associated screening data and leak rate data (i.e., bagging) used to develop a unit-specific correlation.

(3) Calculate and sum the emissions of each fluorinated GHG in metric tons per year for equipment pieces for each process, EELf, annually. You must include and estimate emissions for types of equipment that are excluded from monitoring, including difficult-to-monitor, unsafe-to-monitor and insulated pieces of equipment, pieces of equipment in heavy liquid service, pumps with dual mechanical seals, agitators with dual mechanical seals, pumps with no external shaft, agitators with no external shaft, pressure relief devices in gas and vapor service with upstream rupture disk, sampling connection systems with closed-loop or closed purge systems, and pieces of equipment where leaks are routed through a closed vent system to a destruction device.

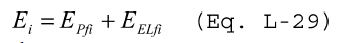

(e) Calculate total fluorinated GHG emissions for each process and for production or transformation processes at the facility.

(1) Estimate annually the total mass of each fluorinated GHG emitted from each process, including emissions from process vents in paragraphs (c)(3) and (c)(4) of this section, as appropriate, and from equipment leaks in paragraph (d), using Equation L-29 of this section.

Where:

Ei = Total mass of each fluorinated GHG f emitted from process i, annual basis (kg/year).

EPfi = Mass of fluorinated GHG f emitted from all process vents and all operating scenarios in process i, annually (kg/year, calculated in Equation L-24 or L-28 of this section, as appropriate).

EELfi = Mass of fluorinated GHG f emitted from equipment leaks for pieces of equipment for process i, annually (kg/year, calculated in paragraph (d)(3) of this section).

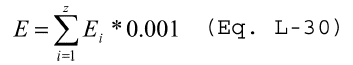

(2) Estimate annually the total mass of each fluorinated GHG emitted from each type of production or transformation process at the facility using Equation L-30 of this section. Develop separate totals for fluorinated gas production processes, transformation processes that transform fluorinated gases produced at the facility, and transformation processes that transform fluorinated gases produced at another facility.

Where:

E = Total mass of each fluorinated GHG f emitted from all fluorinated gas production processes, all transformation processes that transform fluorinated gases produced at the facility, or all transformation processes that transform fluorinated gases produced at another facility, as appropriate (metric tons).

Ei = Total mass of each fluorinated GHG f emitted from each production or transformation process, annual basis (kg/year, calculated in Equation L-29 of this section).

0.001 = Conversion factor from kg to metric tons.

z = Total number of fluorinated gas production processes, fluorinated gas transformation processes that transform fluorinated gases produced at the facility, or transformation processes that transform fluorinated gases produced at another facility, as appropriate.

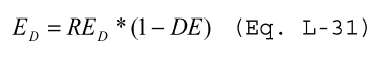

(f) Calculate fluorinated GHG emissions from destruction of fluorinated GHGs that were previously “produced”. Estimate annually the total mass of fluorinated GHGs emitted from destruction of fluorinated GHGs that were previously “produced” as defined at §98.410(b) using Equation L-31 of this section:

Where:

ED = The mass of fluorinated GHGs emitted annually from destruction of fluorinated GHGs that were previously “produced” as defined at §98.410(b) (metric tons).

RED = The mass of fluorinated GHGs that were previously “produced” as defined at §98.410(b) and that are fed annually into the destruction device (metric tons).

DE = Destruction efficiency of the destruction device (fraction).

(g) Emissions from venting of residual fluorinated GHGs in containers. If you vent residual fluorinated GHGs from containers, you must either measure the residual fluorinated GHGs vented from each container or develop a heel factor for each combination of fluorinated GHG, container size, and container type that you vent. You do not need to estimate de minimis emissions associated with good-faith attempts to recycle or recover residual fluorinated GHGs in or from containers.

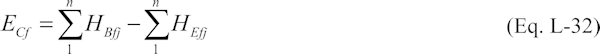

(1) Measuring contents of each container. If you weigh or otherwise measure the contents of each container before venting the residual fluorinated GHGs, use Equation L-32 of this section to calculate annual emissions of each fluorinated GHG from venting of residual fluorinated GHG from containers. Convert pressures to masses as directed in paragraph (g)(2)(ii) of this section.

Where:

ECf = Total mass of each fluorinated GHG f emitted from the facility through venting of residual fluorinated GHG from containers, annual basis (metric tons/year).

HBfj = Mass of residual fluorinated GHG f in container j when received by facility (metric tons).

HEfj = Mass of residual fluorinated GHG f in container j after evacuation by facility (metric tons). (Facility may equate to zero.)

n = Number of vented containers for each fluorinated GHG f.

(2) Developing and applying heel factors. If you use heel factors to estimate emissions of residual fluorinated GHGs vented from containers, you must annually develop these factors based on representative samples of the containers received by your facility from fluorinated GHG users.

(i) Sample size. For each combination of fluorinated GHG, container size, and container type that you vent, select a representative sample of containers that reflects the full range of quantities of residual gas returned in that container size and type. This sample must reflect the full range of the industries and a broad range of the customers that use and return the fluorinated GHG, container size, and container type. The minimum sample size for each combination of fluorinated GHG, container size, and container type must be 30, unless this is greater than the number of containers returned within that combination annually, in which case the contents of every container returned must be measured.

(ii) Measurement of residual gas. The residual weight or pressure you use for paragraph (g)(1) of this section must be determined by monitoring the mass or the pressure of your cylinders/containers according to §98.124(k). If you monitor the pressure, convert the pressure to mass using a form of the ideal gas law, as displayed in Equation L-33 of this section, with an appropriately selected Z value.

Where:

mR = Mass of residual gas in the container (metric ton).

p = Absolute pressure of the gas (Pa).

V = Volume of the gas (m3).

MW = Molecular weight of the fluorinated GHG f (g/gmole).

Z = Compressibility factor.

R = Gas constant (8.314 Pa m3/Kelvin mole).

T = Absolute temperature (K).

106 = Conversion factor (106g/metric ton).

(iii) Heel factor calculation. To determine the heel factor hfj for each combination of fluorinated GHG, container size, and container type, use paragraph (g)(1) of this section to calculate the total heel emissions for each sample selected under paragraph (g)(2)(i) of this section. Divide this total by the number of containers in the sample. Divide the result by the full capacity (the mass of the contents of a full container) of that combination of fluorinated GHG, container size, and container type. The heel factor is expressed as a fraction of the full capacity.

(iv) Calculate annual emissions of each fluorinated GHG from venting of residual fluorinated GHG from containers using Equation L-34 of this section.

Where:

ECf = Total mass of each fluorinated GHG f emitted from the facility through venting of residual fluorinated GHG from containers, annual basis (metric tons/year).

hfj = Facility-wide gas-specific heel factor for fluorinated GHG f (fraction) and container size and type j, as determined in paragraph (g)(2)(iii) of this section.

Nfj = Number of containers of size and type j returned to the fluorinated gas production facility.

Ffj = Full capacity of containers of size and type j containing fluorinated GHG f (metric tons).

n = Number of combinations of container sizes and types for fluorinated GHG f.

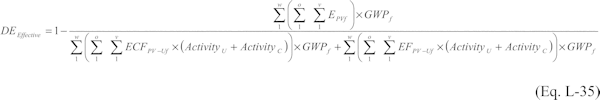

(h) Effective destruction efficiency for each process. If you used the emission factor or emission calculation factor method to calculate emissions from the process, use Equation L-35 to calculate the effective destruction efficiency for the process, including each process vent:

Where:

DEEffective = Effective destruction efficiency for process i (fraction).

EPVf = Mass of fluorinated GHG f emitted from process vent v from process i, operating scenario j, for the year, calculated in Equation L-21, L-22, L-26, or L-27 of this section (kg).

GWPf = Global warming potential for each greenhouse gas from Table A-1 of subpart A of this part.

ECFPV-Uf = Emission calculation factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j during periods when the process vent is not vented to the properly functioning destruction device, as used in Equation L-21; or emission calculation factor for fluorinated GHG f emitted from process vent v during process i, operating scenario j, as used in Equation L-26 or L-27 (kg emitted/activity) (e.g., kg emitted/kg product), denoted as “ECFPV” in those equations.

EFPV-Uf = Emission factor (uncontrolled) for fluorinated GHG f emitted from process vent v during process i, operating scenario j, as used in Equation L-22 (kg emitted/activity) (e.g., kg emitted/kg product), denoted as “EFPV-U” in that equation.

ActivityU = Total process feed, process production, or other process activity for process i, operating scenario j during the year, for which the process vent is not vented to the properly functioning destruction device (i.e., uncontrolled).

ActivityC = Total process feed, process production, or other process activity for process i, operating scenario j during the year, for which emissions are vented to the properly functioning destruction device (i.e., controlled).

o = Number of operating scenarios for process i.

v = Number of process vents in process i, operating scenario j.

w = Number of fluorinated GHGs emitted from the process.

[75 FR 74832, Dec. 1, 2010; 79 FR 73785, Dec. 11, 2014]

READ MORESHOW LESS

['Air Programs']

['Greenhouse Gases']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.