['Air Programs']

['Ozone Layer Protection']

01/16/2025

...

Recovery Efficiency Test Procedure for Refrigerant Recovery Equipment Used on Small Appliances

The following test procedure is utilized to evaluate the efficiency of equipment designed to recover ozone depleting refrigerants (or any substitute refrigerant subject to the recycling rules promulgated pursuant to section 608 of the Clean Air Act Amendments of 1990) from small appliances when service of those appliances requires entry into the sealed refrigeration system or when those appliances are destined for disposal. This procedure is designed to calculate on a weight or mass basis the percentage of a known charge of CFC-12 refrigerant removed and captured from a test stand refrigeration system. Captured refrigerant is that refrigerant delivered to a container suitable for shipment to a refrigerant reclaimer plus any refrigerant remaining in the recovery system in a manner that it will be transferred to a shipping container after additional recovery operations.

The test stand refrigeration system required for this procedure is constructed with standard equipment utilized in currently produced household refrigerator and freezer products. The procedure also accounts for compressor oils that might be added to or removed from the test stand compressor or any compressor used in the recovery system.

I. Test Stand

Test stands are constructed in accordance with the following standards.

1. Evaporator - 5/16 in. outside dia. with 30 cu. in. volume.

2. Condenser - 1/4 in. outside dia. with 20 cu. in volume.

3. Suction line capillary heat exchanger - appropriate for compressor used.

4. An 800-950 Btu/hr high side case (rotary) compressor; or (depending on the test senario);

5. An 800-9500 Btu/hr low side case (reciprocating) compressor.

A person seeking to have its recovery system certified shall specify the compressors by manufacturer and model that are to be used in test stands constructed for evaluation of its equipment, and the type and quantity of compressor to be used in those compressors. Only a compressor oil approved for use by the compressor's manufacturer may be specified, and the quantity of compressor oil specified shall be an appropriate quantity for the type of oil and compressor to be used. In order to reduce the cost of testing, the person seeking certification of its recovery system may supply an EPA approved third party testing laboratory with test stands meeting these standards for use in evaluating its recovery system.

II. Test Conditions

Tests are to be conducted at 75 degrees F, plus or minus 2 degrees F (23.9 C ±1.1 C). Separate tests are conducted on both high side case compressor stands and low side case compressor stands. Separate tests are also conducted with the test stand compressor running during the recovery operation, and without the test stand compressor running during the recovery operation, to calculate the system's recovery efficiency under either condition.

These tests are to be performed using a representative model of all equipment used in the recovery system to deliver recovered refrigerant to a container suitable for shipment to a refrigerant reclaimer. The test stands are to be equipped with access valves permanently installed as specific by the recovery system's vendor to represent the valves used with that system in actual field operations.

A series of five (5) recovery operations are to be performed for each compressor scenario and a recovery efficiency is calculated based on the total quantity of refrigerant captured during all five (5) recoveries. Alternatively, at the request of the recovery system's vendor, a recovery efficiency is to be calculated for each recovery event. In this case, a statistically significant number of recovery operations are to be performed. Determination of what is a statistically significant number of recoveries is to be calculated as set out below. These individual recovery efficiencies are then averaged.

There are four (4) compressor scenarios to be tested. These are a high side case compressor in working condition; a high side case compressor in nonworking condition; a low side case compressor in working condition; and a low side case compressor in nonworking condition. Recovery efficiencies calculated for the two working compressor scenarios are to be averaged to report a working compressor performance. The two nonworking compressor efficiencies are also to be averaged to report a nonworking compressor performance.

If large scale equipment is required in the system to deliver recovered refrigerant to a refrigerant reclaimer (eg. carbon desorption equipment) and it is not possible to have that equipment evaluated under the procedure, the system's vendor shall obtain engineering data on the performance of that large scale equipment that will reasonably demonstrate the percentage refrigerant lost when processed by that equipment. That data will be supplied to any person required to evaluate the performance of those systems. The following procedure will also be modified as needed to determine the weight of refrigerant recovered from a test stand and delivered to a container for shipment to the large process equipment for further processing. The percentage loss documented to occur during processing is then to be applied to the recovery efficiencies calculated in this modified procedure to determine the overall capture efficiency for the entire system.

The following are definitions of symbols used in the test procedure.

Test Stand:

“TSO” means an original test stand weight.

“TSC” means a charged test stand weight.

Shipping Containers:

“SCO” means the original or empty weight of shipping container(s).

“SCF” means the final or full weight of shipping container(s).

Recover/Transfer System:

“RSO” means the original weight of a recovery/transfer system.

“RSF” means the final weight of a recovery/transfer system.

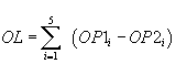

“OL” means the net amount of oil added/removed from the recovery device and/or transfer device between the beginning and end of the test for one compressor scenario.

Weighing steps are conducted with precision and accuracy of plus or minus 1.0 gram.

III. Test Procedure

1. Evacuate the test stand to 20 microns vacuum (pressure measured at a vacuum pump) for 12 hours.

2. Weigh the test stand (TSO).

3. If this is the first recovery operation being performed for a compressor scenario (or if a recovery efficiency is to be calculated for each recovery event), then weigh all devices used in the recovery system to deliver recovered refrigerant to a container suitable for shipment or delivery to a refrigerant reclaimer. Weigh only devices that can retain refrigerant in a manner that it will ultimately be transferred to a shipping container without significant release to the atmosphere (RSO).

4. Weigh final shipping containers (SCO).

5. Charge the test stand with an appropriate CFC-12 charge (either 6 oz. or 9 oz.).

6. Run the test stand for four (4) hours with 100% run time.

7. Turn off the test stand for twelve (12) hours. During this period evaporate all condensation that has collected on the test stand during step 6.

8. Weigh the test stand (TSC).

9. Recover CFC-12 from the test stand and perform all operations needed to transfer the recovered refrigerant to one of the shipping containers weighed in step 4. All recovery and transfer operations are to be performed in accordance with the operating instructions provided by the system's vendor. The compressor in the test stand is to remain “off” or be turned “on” during the recovery operation depending on whether the test is for a nonworking or working compressor performance evaluation. If a recovery efficiency is to be calculated for each recovery event, transfer the captured refrigerant to a shipping container and then skip to step 13. Otherwise continue. If the system allows for multiple recovery operations to be performed before transferring recovered refrigerant to a shipping container, the transfer operation can be delayed until either the maximum number of recovery operations allowed before a transfer is required have been performed, or the last of the five (5) recovery operations has been performed.

10. Perform any oil removal or oil addition operations needed to properly maintain the test stand and the devices used for recovery or transfer operations. Determine the net weight of the oil added or removed from the recovery device and/or transfer device. (OP1 for oil added, OP2 for oil removed).

11. Evacuate the test stand to 20 microns vacuum for 4 hours.

12. Return to step 2 unless five (5) recovery operations have been performed.

13. Weigh all final shipping containers that received recovered refrigerant (SCF).

14. Weigh the equipment weighed in step three (3) above (RSF). If a recovery efficiency is to be calculated for each recovery event, perform calculations and return to step one (1) for additional recoveries.

IV. Calculations

A. For Five (5) Consecutive Recoveries

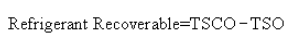

Refrigerant Recoverable equals the summation of charged test stand weights minus original test stand weights.

Oil Loss equals the net weight of oil added to and removed from the recovery device and/or transfer device.

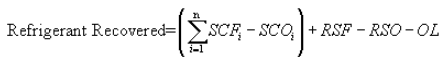

Refrigerant Recovered equals the final weight of shipping containers minus the initial weight of final shipping containers, plus final recovery system weight, minus original recovery system weight, plus the net value of all additions and removals of oil from the recovery and transfer devices.

n = number of shipping containers used.

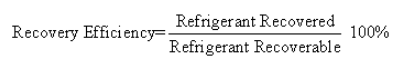

Recovery Efficiency equals Refrigerant Recovered divided by Refrigerant Recoverable times 100%.

B. For Individual Recoveries

Refrigerant Recoverable equals the charged test stand weight minus the original test stand weight.

Refrigerant Recovered equals the final weight of the shipping container minus the initial weight of the shipping container plus the final weight of the recovery system minus the original recovery system weight.

Recovery Efficiency equals Refrigerant Recovered divided by Refrigerant Recoverable times 100 percent.

C. Calculation of a Statistically Significant Number of Recoveries

Where:

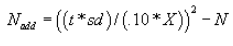

Nadd = the number of additional samples required to achieve 90% confidence.

sd = Standard deviation, or (X/(N−1) 5)

X = Sample average

N = Number of samples tested

| Number of samples | t for 90% confidence |

|---|---|

| 2 | 6.814 |

| 3 | 2.920 |

| 4 | 2.353 |

| 5 | 2.132 |

| 6 | 2.015 |

| 7 | 1.943 |

| 8 | 1.895 |

| 9 | 1.860 |

| 10 | 1.833 |

Procedure:

1. Compute Nadd after completing two recoveries.

2. If Nadd>0, then run an additional test.

3. Re-compute Nadd. Continue to test additional samples until Nadd<0.

V. Test Procedure Approval and Certification

Each vendor of capture equipment for small appliances desiring certification will provide a representative model of its capture system and its recommended recovery procedures to an EPA approved third party laboratory for testing in accordance with this procedure. The third party laboratory will certify recovery systems that when tested in accordance with this procedure demonstrate a sufficient recovery efficiency to meet EPA regulatory requirements.

['Air Programs']

['Ozone Layer Protection']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.