['Air Programs']

['Ozone Layer Protection']

01/16/2025

...

This appendix is based on the Air-Conditioning and Refrigeration Institute Standard 740-1995.

Section 1. Purpose

1.1 Purpose. The purpose of this standard is to establish methods of testing for rating and evaluating the performance of refrigerant recovery, and/or recycling equipment and general equipment requirements (herein referred to as “equipment”) for contaminant or purity levels, capacity, speed and purge loss to minimize emission into the atmosphere of designated refrigerants.

Section 2. Scope

2.1 Scope. This standard applies to equipment for recovering and/or recycling single refrigerants, azeotropics, zeotropic blends, and their normal contaminants from refrigerant systems. This standard defines the test apparatus, test gas mixtures, sampling procedures and analytical techniques that will be used to determine the performance of refrigerant recovery and/or recycling equipment (hereinafter, “equipment”).

Section 3. Definitions

3.1 Definitions. All terms in this appendix will follow the definitions in §82.152 unless otherwise defined in this appendix.

3.2 Clearing Refrigerant. Procedures used to remove trapped refrigerant from equipment before switching from one refrigerant to another.

3.3 High Temperature Vapor Recovery Rate. For equipment having at least one designated refrigerant (see 11.2) with a boiling point in the range of −50 to +10°C, the rate will be measured for R-22, or the lowest boiling point refrigerant if R-22 is not a designated refrigerant.

3.4 Published Ratings. A statement of the assigned values of those performance characteristics, under stated rating conditions, by which a unit may be chosen to fit its application. These values apply to all units of like nominal size and type (identification) produced by the same manufacturer. As used herein, the term “published rating” includes the rating of all performance characteristics shown on the unit or published in specifications, advertising or other literature controlled by the manufacturer, at stated rating conditions.

3.5 Push/Pull Method. The push/pull refrigerant recovery method is defined as the process of transferring liquid refrigerant from a refrigeration system to a receiving vessel by lowering the pressure in the vessel and raising the pressure in the system, and by connecting a separate line between the system liquid port and the receiving vessel.

3.6 Recycle Flow Rate. The amount of refrigerant processed divided by the time elapsed in the recycling mode. For equipment which uses a separate recycling sequence, the recycle rate does not include the recovery rate (or elapsed time). For equipment which does not use a separate recycling sequence, the recycle rate is a rate based solely on the higher of the liquid or vapor recovery rate, by which the contaminant levels were measured.

3.7 Residual Trapped Refrigerant. Refrigerant remaining in equipment after clearing.

3.8 Shall, Should, Recommended or It Is Recommended shall be interpreted as follows:

3.8.1 Shall. Where “shall” or “shall not” is used for a provision specified, that provision is mandatory if compliance with this appendix is claimed.

3.8.2 Should, Recommended or It Is Recommended is used to indicate provisions which are not mandatory but which are desirable as good practice.

3.9 Standard Contaminated Refrigerant Sample. A mixture of new or reclaimed refrigerant and specified quantities of identified contaminants which constitute the mixture to be processed by the equipment under test. These contaminant levels are expected only from severe service conditions.

3.10 Trapped Refrigerant. The amount of refrigerant remaining in the equipment after the recovery or recovery/recycling operation but before clearing.

3.11 Vapor Recovery Rate. The average rate that refrigerant is withdrawn from the mixing chamber between two pressures as vapor recovery rate is changing pressure and temperature starting at saturated conditions either 24°C or at the boiling point 100 kPa (abs), whichever is higher. The final pressure condition is 10% of the initial pressure, but not lower than the equipment final recovery vacuum and not higher than 100 kPa (abs).

Section 4. General Equipment Requirements

4.1 Equipment Information. The equipment manufacturer shall provide operating instructions, necessary maintenance procedures and source information for replacement parts and repair.

4.2 Filter Replacement. The equipment shall indicate when any filter/drier(s) needs replacement. This requirement can be met by use of a moisture transducer and indicator light, by use of a sight glass/moisture indicator or by some measurement of the amount of refrigerant processed such as a flow meter or hour meter. Written instructions such as “to change the filter every 181 kg, or every 30 days” shall not be acceptable except for equipment in large systems where the liquid recovery rate is greater than 11.3 kg/min where the filter/drier(s) would be changed for every job.

4.3 Purge of Non-Condensable. If non-condensables are purged, the equipment shall either automatically purge non-condensables or provide indicating means to guide the purge process.

4.4 Purge Loss. The total refrigerant loss due to purging non-condensables, draining oil and clearing refrigerant (see 9.5) shall be less than 3% (by weight) of total processed refrigerant.

4.5 Permeation Rate. High pressure hose assemblies 5/8 in. [16 mm] nominal and smaller shall not exceed a permeation rate of 3.9 g/cm 2/yr (internal surface) at a temperature of 48.8°C. Hose assemblies that UL recognized as having passed ANSI/UL 1963 requirements shall be accepted without testing. See 7.1.4.

4.6 Clearing Trapped Refrigerant. For equipment rated for more than one refrigerant, the manufacturer shall provide a method and instructions which will accomplish connections and clearing within 15 minutes. Special equipment, other than a vacuum pump or manifold gauge set shall be furnished. The clearing procedure shall not rely upon the storage cylinder below saturated pressure conditions at ambient temperature.

4.7 Temperature. The equipment shall be evaluated at 24°C with additional limited evaluation at 40°C. Normal operating conditions range from 10°C to 40°C.

4.8 Exemptions. Equipment intended for recovery only shall be exempt from 4.2 and 4.3.

Section 5. Contaminated Refrigerants

5.1 Sample Characteristics. The standard contaminated refrigerant sample shall have the characteristics specified in Table 1, except as provided in 5.2.

5.2 Recovery-Only Testing. Recovery equipment not rated for any specific contaminant shall be tested with new or reclaimed refrigerant.

Section 6. Test Apparatus

6.1 General Recommendations. The recommended test apparatus is described in the following paragraphs. If alternate test apparatus are employed, the user shall be able to demonstrate that they produce results equivalent to the specified referee apparatus.

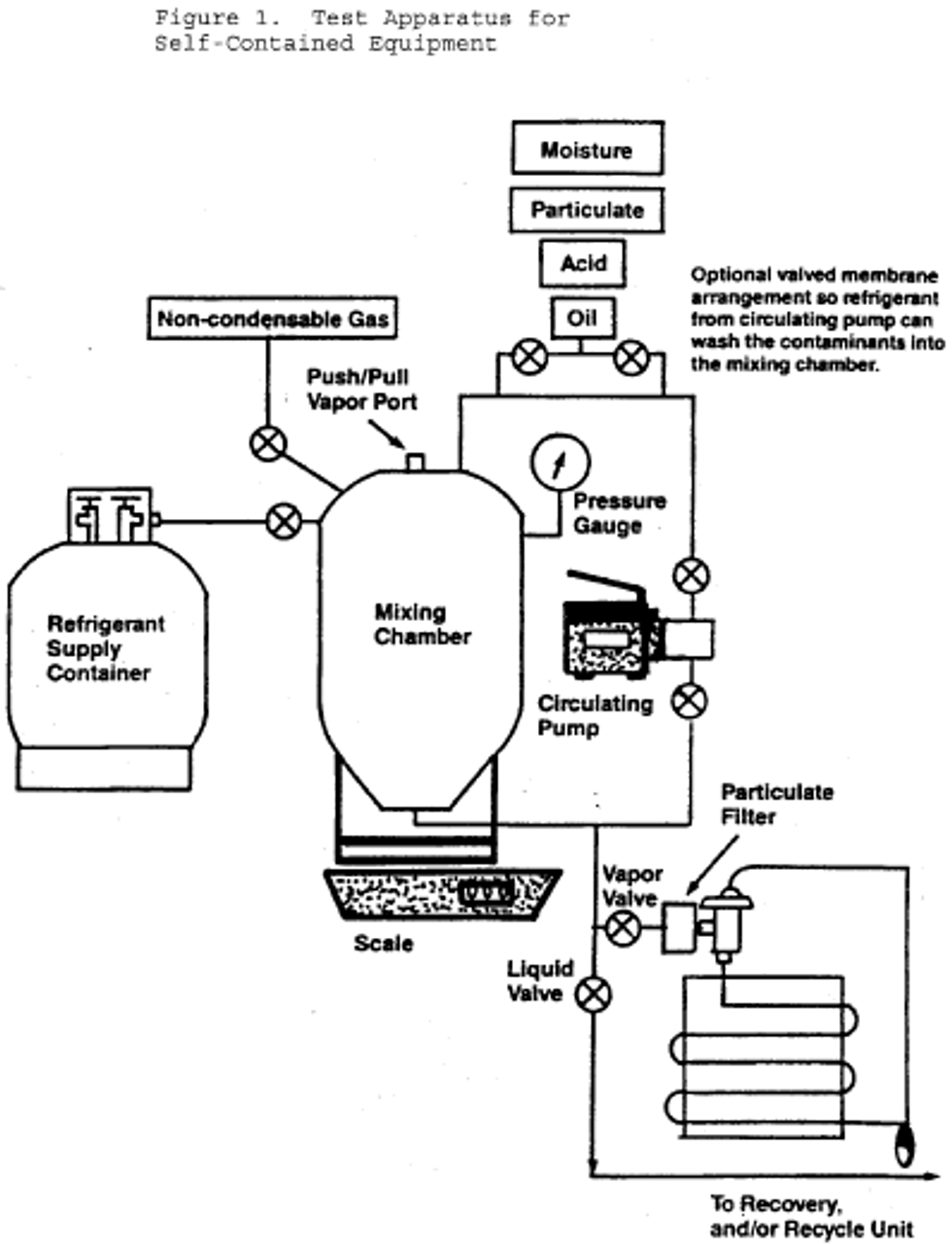

6.2 Self-Contained Equipment Test Apparatus. The apparatus, shown in Figure 1, shall consist of:

6.2.1 Mixing Chamber. A mixing chamber consisting of a tank with a conical-shaped bottom, a bottom port and piping for delivering refrigerant to the equipment, various ports and valves for adding refrigerant to the chamber and stirring means for mixing.

6.2.2 Filling Storage Cylinder. The storage cylinder to be filled by the refrigerant transferred shall be cleaned and at the pressure of the recovered refrigerant at the beginning of the test. It will not be filled over 80%, by volume.

6.2.3 Vapor Feed. Vapor refrigerant feed consisting of evaporator, control valves and piping to create a 3.0°C superheat condition at an evaporating temperature of 21°C ±2K.

6.2.4 Alternative Vapor Feed. An alternative method for vapor feed shall be to pass the refrigerant through a boiler and then through an automatic pressure regulating valve set at different saturation pressures, moving from saturated pressure at 24°C to final pressure of recovery.

6.2.5 Liquid Feed. Liquid refrigerant feed consisting of control valves, sampling port and piping.

6.2.6 Instrumentation. Instrumentation capable of measuring weight, temperature, pressure and refrigerant loss, as required.

| R11 | R12 | R13 | R22 | R113 | R114 | R123 | R134a | R500 | R502 | R503 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Moisture Content: ppm by Weight of Pure refrigerant | 100 | 80 | 30 | 200 | 100 | 85 | 200 | 200 | 200 | 200 | 30 |

| Particulate Content: ppm by Weight of Pure Refrigerant Characterized by 1 | 80 | 80 | NA | 80 | 80 | 80 | 80 | 80 | 80 | 80 | NA |

| Acid Content: ppm by Weight of Pure Refrigerant - (mg KOH per kg Refrigerant) Characterized by 2 | 500 | 100 | NA | 500 | 400 | 200 | 500 | 100 | 100 | 100 | NA |

| Mineral Oil Content: | |||||||||||

| % by Weight of Pure Refrigerant | 20 | 5 | NA | 5 | 20 | 20 | 20 | 5 | 5 | 5 | NA |

| Viscosity (SUS) | 300 | 150 | 300 | 300 | 300 | 300 | 150 3 | 150 | 150 | ||

| Non-Condensable Gases (Air Content): % by Volume | NA | 3 | 3 | 3 | NA | 3 | NA | 3 | 3 | 3 | 3 |

| 1 Particulate content shall consist of inert materials and shall comply with particulate requirements in appendix B. 2 Acid consists of 60% oleic acid and 40% hydrochloric acid on a total number basis. 3 Synthetic ester-based oil. | |||||||||||

6.3 Size. The size of the mixing chamber shall be a minimum of .09 m 3. The bottom port and the refrigerant feed shall depend on the size of the equipment. Typically, the mixing valves and piping shall be 9.5 mm. For large equipment to be used on chillers, the minimum inside diameter of ports, valves and pipings shall be the smaller of the manufacturer's recommendation or 37 mm.

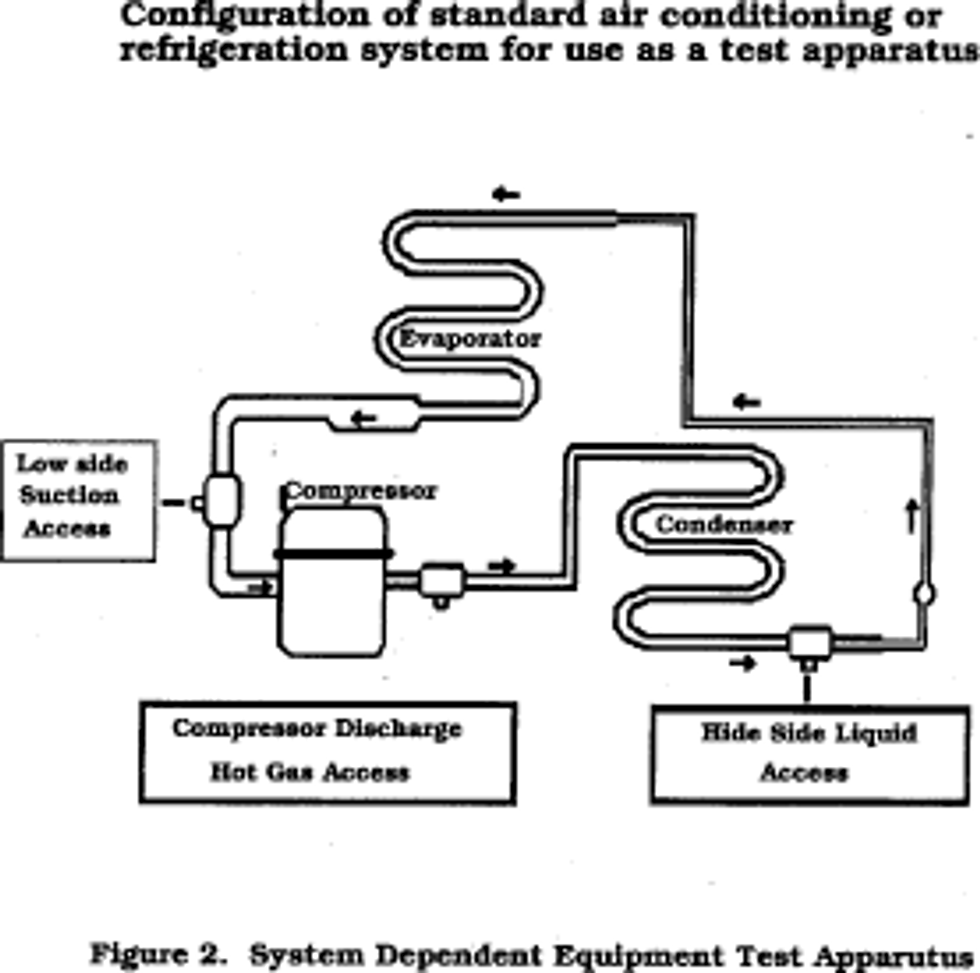

6.4 System Dependent Equipment Test Apparatus. This test apparatus is to be used for final recovery vacuum rating of all system dependent equipment.

6.4.1 Test Setup. The test apparatus shown in Figure 2 consists of a complete refrigeration system. The manufacturer shall identify the refrigerants to be tested. The test apparatus can be modified to facilitate operation or testing of the system dependent equipment if the modifications to the apparatus are specifically described within the manufacturer's literature. (See Figure 2.) A 6.3 mm balance line shall be connected across the test apparatus between the high and low-pressure sides, with an isolation valve located at the connection to the compressor high side. A 6.3 mm access port with a valve core shall be located in the balance line for the purpose of measuring final recovery vacuum at the conclusion of the test.

Section 7. Performance Testing

7.1 General Testing.

7.1.1 Temperatures. Testing shall be conducted at an ambient temperature of 24°C ±1K except high temperature vapor recovery shall be at 40°C ±1K. The evaporator conditions of 6.2.3 shall be maintained as long as liquid refrigerant remains in the mixing chamber.

7.1.2 Refrigerants. The equipment shall be tested for all designated refrigerants (see 11.2). All tests in Section 7 shall be completed for each refrigerant before starting tests with the next refrigerant.

7.1.3 Selected Tests. Tests shall be as appropriate for the equipment type and ratings parameters selected (see 9.9, 11.1 and 11.2).

7.1.4 Hose Assemblies. For the purpose of limiting refrigerant emissions to the atmosphere, hose assemblies shall be tested for permeation according to ANSI/UL Standard 1963, Section 40.10.

7.2 Equipment Preparation and Operation. The equipment shall be prepared and operated per the operating instructions.

7.3 Test Batch. The test batch consisting of refrigerant sample (see Section 5) of the test refrigerant shall be prepared and thoroughly mixed. Continued mixing or stirring shall be required during the test while liquid refrigerant remains in the mixing chamber. The mixing chamber shall be filled to 80% level by volume.

7.3.1 Control Test Batch. Prior to starting the test for the first batch for each refrigerant, a liquid sample will be drawn from the mixing chamber and analyzed per Section 8 to assure that contaminant levels match Table 1 within ±10 ppm for moisture, ±20 ppm for particulate, ±20 ppm for oleic acid and ±0.5% for oil.

7.4 Recovery Tests (Recovery and Recovery/Recycle Equipment).

7.4.1 Determining Recovery Rates. The liquid and vapor refrigerant recovery rates shall be measured during the first test batch for each refrigerant (see 9.1, 9.2 and 9.4). Equipment preparation and recovery cylinder changeover shall not be included in elapsed time measurements for determining vapor recovery rate and liquid refrigerant recovery rate. Operations such as subcooling the recovery cylinder shall be included. Recovery cylinder shall be the same size as normally furnished or specified in the instructions by the equipment manufacturer. Oversized tanks shall not be permitted.

7.4.1.1 Liquid Refrigerant Recovery Rate. If elected, the recovery rate using the liquid refrigerant feed means (see 6.2.5) shall be determined. After the equipment reaches stabilized conditions of condensing temperature and/or recovery cylinder pressure, the recovery process shall be stopped and an initial weight shall be taken of the mixing chamber (see 9.2). The recovery process shall be continued for a period of time sufficient to achieve the accuracy in 9.4. The recovery process shall be stopped and a final weight shall be taken of the mixing chamber.

7.4.1.2 Vapor Refrigerant Recovery Rate. If elected, the average vapor flow rate shall be measured to accuracy requirements in clause 9.4 under conditions with no liquid refrigerant in the mixing chamber. The liquid recovery feed means shall be used. At initial conditions of saturated vapor at the higher of 24°C or the boiling temperature (100 kPa absolute pressure), the weight of the mixing chamber and the pressure shall be recorded. At final conditions representing pressure in the mixing chamber of 10% of the initial condition, but not less than the final recovery vacuum (see 9.6) nor more than 100 kPa, measure the weight of the mixing chamber and the elapsed time.

7.4.1.3 High Temperature Vapor Recovery Rate. Applicable for equipment having at least one designated refrigerant (see 11.2) with a boiling point between −50°C and +10°C. Measure the rate for R-22, or the refrigerant with the lowest boiling point if R-22 is not a designated refrigerant. Repeat the test in 7.4.1.2 at saturated conditions at 40°C and continue to operate equipment to assure it will achieve the final recovery vacuum (see 7.4.3).

7.4.2 Recovery Operation. This test is for determining the final recovery vacuum and the ability to remove contaminants as appropriate. If equipment is rated for liquid recovery (see 7.4.1.3), liquid recovery feed means described in 6.2.5 shall be used. If not, vapor recovery means described in 6.2.3 or 6.2.4 shall be used. Continue recovery operation until all liquid is removed from the test apparatus and vapor is removed to the point where equipment shuts down by automatic means or is manually shut off per operating instructions.

7.4.2.1 Oil Draining. Capture oil from the equipment at intervals as required in the instructions. Record the weight of the container. Completely remove refrigerant from oil by evacuation or other appropriate means. The weight difference shall be used in 9.5.2.

7.4.3 Final Recovery Vacuum. At the end of the first test batch for each refrigerant, the liquid valve and vapor valve of the apparatus shall be closed. After waiting 1 minute, the mixing chamber pressure shall be recorded (see 9.6).

7.4.4 Residual Refrigerant. This test will measure the mass of remaining refrigerant in the equipment after clearing and therefore the potential for mixing refrigerants (see 4.6).

7.4.4.1 Initial Conditions. At the end of the last test for each batch for each refrigerant, the equipment shall be disconnected from the test apparatus (Figure 1). Recycle per 7.5, if appropriate. Perform refrigerant clearing operations as called for in the instruction manual. Capture and record the weight of any refrigerant which would have been emitted to the atmosphere during the clearing process for use in 9.5. If two loops are used for recycling, trapped refrigerant shall be measured for both.

7.4.4.2 Residual Trapped Refrigerant. Evacuate an empty test cylinder to 1.0 kPa absolute. Record the empty weight of the test cylinder. Open all valves to the equipment so as to provide access to all trapped refrigerant. Connect the equipment to the test cylinder and operate valves to recover the residual refrigerant. Record the weight of the test cylinder using a recovery cylinder pressure no less than specified in 6.2.2. Place the test cylinder in liquid nitrogen for a period of 30 minutes or until a vacuum of 1000 microns is reached, whichever occurs first.

7.5 Recycling Tests (Recovery/Recycle Equipment).

7.5.1 Recycling Operation. As each recovery cylinder is filled in 7.4.2, recycle according to operating instructions. There will not necessarily be a separate recycling sequence. Note non-condensable purge measurement in 9.5.

7.5.1.1 Recycle Flow Rate. While recycling the first recovery cylinder for each refrigerant, determine the recycling flow rate by appropriate means (see 9.3) to achieve the accuracy required in 9.4.

7.5.2 Non-Condensable Sample. After completing 7.4.3, prepare a second test batch (7.3). Recover per 7.4.2 until the current recovery cylinder is filled to 80% level by volume. Recycle per 7.5.1. Mark this cylinder and set aside for taking the vapor sample. For equipment having both an internal tank of at least 3 kg refrigerant capacity and an external recovery cylinder, two recovery cylinders shall be marked and set aside. The first is the cylinder described above. The second cylinder is the final recovery cylinder after filling it to 80% level by volume and recycling.

7.5.3 Liquid Sample for Analysis. Repeat steps 7.3, 7.4.2 and 7.5.1 with further test batches until indication means in 4.2 show the filter/drier(s) need replacing.

7.5.3.1 Multiple Pass. For equipment with a separate recycling circuit (multiple pass), set aside the current cylinder and draw the liquid sample (see 7.4) from the previous cylinder.

7.5.3.2 Single Pass. For equipment with the single pass recycling circuit, draw the liquid sample (see 7.4) from the current cylinder.

7.6 Measuring Refrigerant Loss. Refrigerant loss due to non-condensables shall be determined by appropriate means (see 9.5.1). The loss could occur in 7.4.1, 7.4.2 and 7.5.1.

Section 8. Sampling and Chemical Analysis Methods

8.1 Chemical Analysis. Chemical analysis methods shall be specified in appropriate standards such as ARI 700-95 and Appendix C to ARI Standard 700-95.

8.2 Refrigerant Sampling.

8.2.1 Water Content. The water content in refrigerant shall be measured by the Karl Fischer Analytical Method or by the Karl Fischer Coulometric techniques. Report the moisture level in parts per million by weight.

8.2.2 Chloride Ions. Chloride ions shall be measured by turbidity tests. At this time, quantitative results have not been defined. Report chloride content as “pass” or “fail.” In the future, when quantitative results are possible, report chloride content as parts per million by weight.

8.2.3 Acidity. The acidity test uses the titration principle. Report the acidity in parts per million by weight (mg KOH/kg) of sample.

8.2.4 High Boiling Residue. High boiling residues shall use measurement of the volume of residue after evaporating a standard volume of refrigerant. Using weight measurement and converting to volumetric units is acceptable. Report high boiling residues as percent by volume.

8.2.5 Particulates/Solids. The particulates/solids measurement employs visual examination. Report results as “pass” or “fail.”

8.2.6 Non-condensables. The level of contamination by non-condensable gases in the base refrigerant being recycled shall be determined by gas chromatography. Report results as percent by volume.

Section 9. Performance Calculation and Rating

9.1 Vapor Refrigerant Recovery Rate. This rate shall be measured by weight change of the mixing chamber divided by elapsed time (see 7.4.1.2). The units shall be kg/min and the accuracy shall be per 9.4.

9.1.1 High Temperature Vapor Recovery Rate.

9.2 Liquid Refrigerant Recovery Rate. This rate shall be measured by weight change of the mixing chamber divided by elapsed time (see 7.4.1.3). The units shall be kg/min and the accuracy shall be per 9.4.

9.3 Recycle Flow Rate. The recycle flow rate shall be as defined in 3.10, expressed in kg/min, and the accuracy shall be per 9.4.

9.3.1 For equipment using multi-pass recycling or a separate sequence, the recycle rate shall be determined by dividing the net weight W of the refrigerant to be recycled by the actual time T required to recycle. Any set-up or operator interruptions shall not be included in the time T.

9.3.2 If no separate recycling sequence is used, the recycle rate shall be the higher of the vapor refrigerant recovery rate or the liquid refrigerant recovery rate. The recycle rate shall match a process which leads to contaminant levels in 9.9. Specifically, a recovery rate determined from bypassing a contaminant removal device cannot be used as a recycle rate when the contaminant levels in 9.9 are determined by passing the refrigerant through the contaminant removal device.

9.4 Accuracy of Flow Rates. The accuracy of test measurements in 9.1, 9.2 and 9.3 shall be ±008 kg/min or flow rates up to .42 kg/min and ±2.0% for flow rates larger than .42 kg/min. Ratings shall be expressed to the nearest .02 kg/min.

9.5 Refrigerant Loss. This calculation will be based upon the net loss of refrigerant which would have been eliminated in the non-condensable purge process (see 7.5.1), the oil draining process (see 7.4.2.1) and the refrigerant clearing process (see 7.4.4.1), all divided by the net refrigerant content of the test batches. The refrigerant loss shall not exceed 3% by weight.

9.5.1 Non-Condensable Purge. Evacuate an empty container to 2 kPa absolute. Record the empty weight of the container. Place the container in a dry ice bath. Connect the equipment purge connection to the container and operate purge according to operating instructions so as to capture the non-condensables and lost refrigerant. Weigh the cylinder after the recycling is complete. Equivalent means are permissible.

9.5.2 Oil Draining. Refrigerant removed from the oil after draining shall be collected and measured in accordance with 7.4.2.1.

9.5.3 Clearing Unit. Refrigerant captured during the clearing process shall be measured in accordance with 7.4.4.1.

9.6 Final Recovery Vacuum. The final recovery vacuum shall be the mixing chamber pressure in 7.4.3 expressed in kPa. The accuracy of the measurement shall be within 0.33 kPa.

9.7 Residual Trapped Refrigerant. The amount of residual trapped refrigerant shall be the final weight minus the initial weight of the test cylinder in 7.4.4.2, expressed in kg. The accuracy shall be ±0.02 kg and reported to the nearest 0.05 kg.

9.8 Quantity Recycled. The amount of refrigerant processed before changing filters (see 7.5.3) shall be expressed in kg to an accuracy of ±1%.

9.9 Contaminant Levels. The contaminant levels remaining after testing shall be published as follows:

Moisture content, ppm by weight

Chloride ions, pass/fail

Acidity, ppm by weight

High boiling residue, % (by volume)

Particulates-solid, pass/fail (visual examination)

Non-condensables, % (by volume)

9.10 Minimum Data Requirements for Published Ratings. Published ratings shall include all of the parameters as shown in Tables 2 and 3 for each refrigerant designated by the manufacturer.

Section 10. Tolerances

10.1 Tolerances. Performance related parameters shall not be less favorable than the published ratings.

Section 11. Marking and Nameplate Data

11.1 Marking and Nameplate Data. The nameplate shall display the manufacturer's name, model designation, type of equipment, designated refrigerants, capacities and electrical characteristics where applicable. The nameplate shall also conform to the labeling requirements established for certified recycling and recovery equipment established at 40 CFR 82.158(h).

Recommended nameplate voltages for 60 Hertz systems shall include one or more of the utilization voltages shown in Table 1 of ARI Standard 110-90. Recommended nameplate voltages for 50 Hertz systems shall include one or more of the utilization voltages shown in Table 1 of IEC Standard Publication 38, IEC Standard Voltages.

11.2 Data for Designated Refrigerants. For each refrigerant designated, the manufacturer shall include all the following that are applicable per Table 2:

a. Liquid Recovery Rate

b. Vapor Recovery Rate

c. High Temperature Vapor Recovery Rate

d. Final Recovery Vacuum

e. Recycle Flow Rate

f. Residual Trapped Refrigerant

g. Quantity Recycled

| Parameter/Type of equipment | Recovery | Recovery/Recycle | Recycle | System

dependent equipment |

|---|---|---|---|---|

| Liquid Refrigerant Recovery Rate | ( 1) | ( 1) | N/A | N/A |

| Vapor Refrigerant Recovery Rate | ( 1) | ( 1) | N/A | N/A |

| High Temp. Vapor Recovery Rate | ( 1) | ( 1) | N/A | N/A |

| Final Recovery Vacuum | ( X) | ( X) | N/A | ( X) |

| Recycle Flow Rate | N/A | ( X) | ( X) | N/A |

| Refrigerant Loss | ( 3) | ( X) | ( X) | ( 3) |

| Residual Trapped Refrigerant | ( 2) | ( 2) | ( 2) | ( 2) |

| Quantity Recycled | N/A | ( X) | ( X) | N/A |

| X Mandatory rating. 1 For a recovery or recovery/recycle unit, one must rate either liquid refrigerant recovery rate or vapor refrigerant recovery rate or one can rate for both. If rating only the one, the other shall be indicated by N/A, “not applicable.” 2 Mandatory rating for equipment tested for multiple refrigerants. 3 Mandatory rating if multiple refrigerants, oil separation or non-condensable purge are rated. Note: For recovery equipment, these parameters are optional. If not rated use N/A, “not applicable.” | ||||

| Contaminant/Type of equipment | Recovery | Recovery/Recycle | Recycle | System

dependent equipment |

|---|---|---|---|---|

| Moisture Content | (*) | ( X) | ( X) | N/A |

| Chloride Ions | (*) | ( X) | ( X) | N/A |

| Acidity | (*) | ( X) | ( X) | N/A |

| High Boiling Residue | (*) | ( X) | ( X) | N/A |

| Particulates | (*) | ( X) | ( X) | N/A |

| Non-Condensables | (*) | ( X) | ( X) | N/A |

| * For recovery equipment, these parameters are optional. If not rated, use N/A, “not applicable.” X Mandatory rating. | ||||

Attachment 1 to Appendix B2 to Subpart F of Part 82 - References

Listed here are all standards, handbooks, and other publications essential to the formation and implementation of the standard. All references in this appendix are considered as part of this standard.

ANSI/UL Standard 1963, Refrigerant Recovery/Recycling Equipment, First Edition, 1989, American National Standards Institute/Underwriters Laboratories, Inc.

ARI Standard 110-90, Air-Conditioning and Refrigerating Equipment Nameplate Voltages, Air-Conditioning and Refrigeration Institute

ARI Standard 700-95, Specifications for Fluorocarbon and Other Refrigerants, Air-Conditioning and Refrigeration Institute

ASHRAE Terminology of Heating, Ventilation, Air Conditioning, Refrigeration, & Refrigeration, American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc., 1991

IEC Standard Publication 38, IEC Standard Voltages, International Electrotechnical Commission, 1983

Attachment 2 to Appendix B2 to Subpart F of Part 82-Particulate Used in Standard Contaminated Refrigerant Sample

1. Particulate Specification

B1.1 The particulate material (pm) will be a blend of 50% coarse air cleaner dust as received, and 50% retained on a 200-mesh screen. The coarse air cleaner dust is available from: AC Spark Plug Division; General Motors Corporation; Flint, Michigan.

B1.2 Preparation of Particulate Materials.

To prepare the blend of contaminant, first wet screen a quantity of coarse air cleaner dust on a 200-mesh screen (particle retention 74 pm). This is done by placing a portion of the dust on a 200-mesh screen and running water through the screen while stirring the dust with the fingers. The fine contaminant particles passing through the screen are discarded. The +200-mesh particles collected on the screen are removed and dried for one hour at 110°C. The blend of standard contaminant is prepared by mixing 50% by weight of coarse air cleaner dust as received (after drying for one hour at 110°C) with 50% by weight of the +200 mesh screened dust.

B1.3 Particle Size Analysis.

The coarse air cleaner dust as received and the blend used as the standard contaminant have the following approximate particle size analysis:

Wt. % in various size ranges, pm.

| Size range | As received | Blend |

|---|---|---|

| 0-5 | 12 | 6 |

| 5-10 | 12 | 6 |

| 10-20 | 14 | 7 |

| 20-40 | 23 | 11 |

| 40-80 | 30 | 32 |

| 80-200 | 9 | 38 |

[68 FR 43815, July 24, 2003; 68 FR 54678, Sept. 18, 2003]

['Air Programs']

['Ozone Layer Protection']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.