['Air Programs']

['Hazardous Air Pollutants']

02/27/2022

...

§63.300 Applicability.

(a) Unless otherwise specified in §§63.306, 63.307, and 63.311, the provisions of this subpart apply to existing by-product coke oven batteries at a coke plant and to existing nonrecovery coke oven batteries at a coke plant on and after the following dates:

(1) December 31, 1995, for existing by-product coke oven batteries subject to emission limitations in §63.302(a)(1) or existing nonrecovery coke oven batteries subject to emission limitations in §63.303(a);

(2) January 1, 2003, for existing by-product coke oven batteries subject to emission limitations in §63.302(a)(2);

(3) July 14, 2005, for existing by-product coke oven batteries subject to emission limitations in §63.302(a)(3) and for nonrecovery coke oven batteries subject to the emission limitations and requirements in §63.303(b)(3) or (c);

(4) Upon startup for a new nonrecovery coke oven battery subject to the emission limitations and requirements in §63.303(b), (c), and (d). A new nonrecovery coke oven battery subject to the requirements in §63.303(d) is one for which construction or reconstruction commenced on or after August 9, 2004;

(5) November 15, 1993, for existing by-product and nonrecovery coke oven batteries subject to emission limitations in §63.304(b)(1) or 63.304(c);

(6) January 1, 1998, for existing by-product coke oven batteries subject to emission limitations in §63.304(b)(2) or 63.304(b)(7); and

(7) January 1, 2010, for existing by-product coke oven batteries subject to emission limitations in §63.304(b)(3) or 63.304(b)(7).

(b) The provisions for new sources in §§63.302(b), 63.302(c), and 63.303(b) apply to each greenfield coke oven battery and to each new or reconstructed coke oven battery at an existing coke plant if the coke oven battery results in an increase in the design capacity of the coke plant as of November 15, 1990, (including any capacity qualifying under §63.304(b)(6), and the capacity of any coke oven battery subject to a construction permit on November 15, 1990, which commenced operation before October 27, 1993.

(c) The provisions of this subpart apply to each brownfield coke oven battery, each padup rebuild, and each cold-idle coke oven battery that is restarted.

(d) The provisions of §§63.304(b)(2)(i)(A) and 63.304(b)(3)(i) apply to each foundry coke producer as follows:

(1) A coke oven battery subject to §63.304(b)(2)(i)(A) or §63.304(b)(3)(i) must be a coke oven battery that on January 1, 1992, was owned or operated by a foundry coke producer; and

(2)(i) A coke oven battery owned or operated by an integrated steel producer on January 1, 1992, and listed in paragraph (d)(2)(ii) of this section, that was sold to a foundry coke producer before November 15, 1993, shall be deemed for the purposes of paragraph (d)(1) of this section to be owned or operated by a foundry coke producer on January 1, 1992.

(ii) The coke oven batteries that may qualify under this provision are the following:

(A) The coke oven batteries at the Bethlehem Steel Corporation's Lackawanna, New York facility; and

(B) The coke oven batteries at the Rouge Steel Company's Dearborn, Michigan facility.

(e) The emission limitations set forth in this subpart shall apply at all times except during a period of startup, shutdown, or malfunction. The startup period shall be determined by the Administrator and shall not exceed 180 days.

(f) After October 28, 1992, rules of general applicability promulgated under section 112 of the Act, including the General Provisions, may apply to coke ovens provided that the topic covered by such a rule is not addressed in this subpart.

[58 FR 57911, Oct. 27, 1993, as amended at 70 FR 20012, Apr. 15, 2005]

§63.301 Definitions.

Terms used in this subpart are defined in the Act or in this section as follows:

Administrator means the Administrator of the United States Environmental Protection Agency or his or her authorized representative (e.g., a State that has been delegated the authority to implement the provisions of this subpart or its designated agent).

Brownfield coke oven battery means a new coke oven battery that replaces an existing coke oven battery or batteries with no increase in the design capacity of the coke plant as of November 15, 1990 (including capacity qualifying under §63.304(b)(6), and the capacity of any coke oven battery subject to a construction permit on November 15, 1990, which commenced operation before October 27, 1993.

Bypass/bleeder stack means a stack, duct, or offtake system that is opened to the atmosphere and used to relieve excess pressure by venting raw coke oven gas from the collecting main to the atmosphere from a by-product coke oven battery, usually during emergency conditions.

By-product coke oven battery means a source consisting of a group of ovens connected by common walls, where coal undergoes destructive distillation under positive pressure to produce coke and coke oven gas, from which by-products are recovered. Coke oven batteries in operation as of April 1, 1992, are identified in appendix A to this subpart.

Certified observer means a visual emission observer, certified under (if applicable) Method 303 and Method 9 (if applicable) and employed by the Administrator, which includes a delegated enforcement agency or its designated agent. For the purpose of notifying an owner or operator of the results obtained by a certified observer, the person does not have to be certified.

Charge or charging period means, for a by-product coke oven battery, the period of time that commences when coal begins to flow into an oven through a topside port and ends when the last charging port is recapped. For a nonrecovery coke oven battery, charge or charging period means the period of time that commences when coal begins to flow into an oven and ends when the push side door is replaced.

Coke oven battery means either a by-product or nonrecovery coke oven battery.

Coke oven door means each end enclosure on the pusher side and the coking side of an oven. The chuck, or leveler-bar, door is part of the pusher side door. A coke oven door includes the entire area on the vertical face of a coke oven between the bench and the top of the battery between two adjacent buckstays.

Cold-idle coke oven battery means an existing coke oven battery that has been shut down, but is not dismantled.

Collecting main means any apparatus that is connected to one or more offtake systems and that provides a passage for conveying gases under positive pressure from the by-product coke oven battery to the by-product recovery system.

Collecting main repair means any measure to stop a collecting main leak on a long-term basis. A repair measure in general is intended to restore the integrity of the collecting main by returning the main to approximately its design specifications or its condition before the leak occurred. A repair measure may include, but is not limited to, replacing a section of the collecting main or welding the source of the leak.

Consecutive charges means charges observed successively, excluding any charge during which the observer's view of the charging system or topside ports is obscured.

Design capacity means the original design capacity of a coke oven battery, expressed in megagrams per year of furnace coke.

Foundry coke producer means a coke producer that is not and was not on January 1, 1992, owned or operated by an integrated steel producer and had on January 1, 1992, an annual design capacity of less than 1.25 million megagrams per year (1.38 million tons per year) (not including any capacity satisfying the requirements of §63.300(d)(2) or §63.304(b)(6)).

Greenfield coke oven battery means a coke oven battery for which construction is commenced at a plant site (where no coke oven batteries previously existed) after December 4, 1992.

Integrated steel producer means a company or corporation that produces coke, uses the coke in a blast furnace to make iron, and uses the iron to produce steel. These operations may be performed at different plant sites within the corporation.

Malfunction means any sudden, infrequent, and not reasonably preventable failure of air pollution control equipment, process equipment, or a process to operate in a normal or usual manner which causes, or has the potential to cause, the emission limitations in an applicable standard to be exceeded. Failures caused in part by poor maintenance or careless operation are not malfunctions.

New shed means a shed for which construction commenced after September 15, 1992. The shed at Bethlehem Steel Corporation's Bethlehem plant on Battery A is deemed not to be a new shed.

Nonrecovery coke oven battery means a source consisting of a group of ovens connected by common walls and operated as a unit, where coal undergoes destructive distillation under negative pressure to produce coke, and which is designed for the combustion of the coke oven gas from which by-products are not recovered.

Offtake system means any individual oven apparatus that is stationary and provides a passage for gases from an oven to a coke oven battery collecting main or to another oven. Offtake system components include the standpipe and standpipe caps, goosenecks, stationary jumper pipes, mini-standpipes, and standpipe and gooseneck connections.

Oven means a chamber in the coke oven battery in which coal undergoes destructive distillation to produce coke.

Padup rebuild means a coke oven battery that is a complete reconstruction of an existing coke oven battery on the same site and pad without an increase in the design capacity of the coke plant as of November 15, 1990 (including any capacity qualifying under §63.304(b)(6), and the capacity of any coke oven battery subject to a construction permit on November 15, 1990, which commenced operation before October 27, 1993. The Administrator may determine that a project is a padup rebuild if it effectively constitutes a replacement of the battery above the pad, even if some portion of the brickwork above the pad is retained.

Pushing, for the purposes of §63.305, means that coke oven operation that commences when the pushing ram starts into the oven to push out coke that has completed the coking cycle and ends when the quench car is clear of the coke side shed.

Run means the observation of visible emissions from topside port lids, offtake systems, coke oven doors, or the charging of a coke oven that is made in accordance with and is valid under Methods 303 or 303A in appendix A to this part.

Shed means a structure for capturing coke oven emissions on the coke side or pusher side of the coke oven battery, which routes the emissions to a control device or system.

Short coke oven battery means a coke oven battery with ovens less than 6 meters (20 feet) in height.

Shutdown means the operation that commences when pushing has occurred on the first oven with the intent of pushing the coke out of all of the ovens in a coke oven battery without adding coal, and ends when all of the ovens of a coke oven battery are empty of coal or coke.

Standpipe cap means an apparatus used to cover the opening in the gooseneck of an offtake system.

Startup means that operation that commences when the coal begins to be added to the first oven of a coke oven battery that either is being started for the first time or that is being restarted and ends when the doors have been adjusted for maximum leak reduction and the collecting main pressure control has been stabilized. Except for the first startup of a coke oven battery, a startup cannot occur unless a shutdown has occurred.

Tall coke oven battery means a coke oven battery with ovens 6 meters (20 feet) or more in height.

Temporary seal means any measure, including but not limited to, application of luting or packing material, to stop a collecting main leak until the leak is repaired.

Topside port lid means a cover, removed during charging or decarbonizing, that is placed over the opening through which coal can be charged into the oven of a by-product coke oven battery.

[58 FR 57911, Oct. 27, 1993, as amended at 65 FR 62215, Oct. 17, 2000; 71 FR 20456, Apr. 20, 2006]

§63.302 Standards for by-product coke oven batteries.

(a) Except as provided in §63.304 or §63.305, on and after the dates specified in this paragraph, no owner or operator shall cause to be discharged or allow to be discharged to the atmosphere, coke oven emissions from each affected existing by-product coke oven battery that exceed any of the following emission limitations or requirements:

(1) On and after December 31, 1995;

(i) For coke oven doors;

(A) 6.0 percent leaking coke oven doors for each tall by-product coke oven battery, as determined according to the procedures in §63.309(d)(1); and

(B) 5.5 percent leaking coke oven doors for each short by-product coke oven battery, as determined according to the procedures in §63.309(d)(1);

(ii) 0.6 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1);

(iii) 3.0 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1); and

(iv) 12 seconds of visible emissions per charge, as determined by the procedures in §63.309(d)(2).

(2) On and after January 1, 2003, unless the Administrator promulgates more stringent limits pursuant to section 112(f) of the Act;

(i) 5.5 percent leaking coke oven doors for each tall by-product coke oven battery, as determined by the procedures in §63.309(d)(1); and

(ii) 5.0 percent leaking coke oven doors for each short by-product coke oven battery, as determined by the procedures in §63.309(d)(1).

(3) On and after July 14, 2005;

(i) 4.0 percent leaking coke oven doors for each tall by-product coke oven battery and for each by-product coke oven battery owned or operated by a foundry coke producer, as determined by the procedures in §63.309(d)(1);

(ii) 3.3 percent leaking coke oven doors for each by-product coke oven battery not subject to the emission limitation in paragraph (a)(3)(i) of this section, as determined by the procedures in §63.309(d)(1);

(iii) 0.4 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1);

(iv) 2.5 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1); and

(v) 12 seconds of visible emissions per charge, as determined by the procedures in §63.309(d)(2).

(b) Except as provided in paragraph (c) of this section, no owner or operator shall cause to be discharged or allow to be discharged to the atmosphere, coke oven emissions from a by-product coke oven battery subject to the applicability requirements in §63.300(b) that exceed any of the following emission limitations:

(1) 0.0 percent leaking coke oven doors, as determined by the procedures in §63.309(d)(1);

(2) 0.0 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1);

(3) 0.0 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1); and

(4) 34 seconds of visible emissions per charge, as determined by the procedures in §63.309(d)(2).

(c) The emission limitations in paragraph (b) of this section do not apply to the owner or operator of a by-product coke oven battery that utilizes a new recovery technology, including but not limited to larger size ovens, operation under negative pressure, and processes with emission points different from those regulated under this subpart. An owner or operator constructing a new by-product coke oven battery or reconstructing an existing by-product recovery battery that utilizes a new recovery technology shall:

(1) Notify the Administrator of the intention to do so, as required in §63.311(c); and

(2) Submit, for the determination under section 112(g)(2)(B) of the Act, and as part of the application for permission to construct or reconstruct, all information and data requested by the Administrator for the determination of applicable emission limitations and requirements for that by-product coke oven battery.

(d) Emission limitations and requirements applied to each coke oven battery utilizing a new recovery technology shall be less than the following emission limitations or shall result in an overall annual emissions rate for coke oven emissions for the battery that is lower than that obtained by the following emission limitations:

(1) 4.0 percent leaking coke oven doors on tall by-product coke oven batteries, as determined by the procedures in §63.309(d)(1);

(2) 3.3 percent leaking coke oven doors on short by-product coke oven batteries, as determined by the procedures in §63.309(d)(1);

(3) 2.5 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1);

(4) 0.4 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1); and

(5) 12 seconds of visible emissions per charge, as determined by the procedures in §63.309(d)(2).

[58 FR 57911, Oct. 27, 1993, as amended at 70 FR 20013, Apr. 15, 2005]

§63.303 Standards for nonrecovery coke oven batteries.

(a) Except as provided in §63.304, on and after December 31, 1995, no owner or operator shall cause to be discharged or allow to be discharged to the atmosphere coke oven emissions from each affected existing nonrecovery coke oven battery that exceed any of the following emission limitations or requirements:

(1) For coke oven doors;

(i) 0.0 percent leaking coke oven doors, as determined by the procedures in §63.309(d)(1); or

(ii) The owner or operator shall monitor and record, once per day for each day of operation, the pressure in each oven or in a common battery tunnel to ensure that the ovens are operated under a negative pressure.

(2) For charging operations, the owner or operator shall implement, for each day of operation, the work practices specified in §63.306(b)(6) and record the performance of the work practices as required in §63.306(b)(7).

(b) No owner or operator shall cause to be discharged or allow to be discharged to the atmosphere coke oven emissions from each affected new nonrecovery coke oven battery subject to the applicability requirements in §63.300(b) that exceed any of the following emission limitations or requirements:

(1) For coke oven doors;

(i) 0.0 percent leaking coke oven doors, as determined by the procedures in §63.309(d)(1); or

(ii) The owner or operator shall monitor and record, once per day for each day of operation, the pressure in each oven or in a common battery tunnel to ensure that the ovens are operated under a negative pressure;

(2) For charging operations, the owner or operator shall install, operate, and maintain an emission control system for the capture and collection of emissions in a manner consistent with good air pollution control practices for minimizing emissions from the charging operation;

(3) For charging operations, the owner or operator shall implement, for each day of operation, the work practices specified in §63.306(b)(6) and record the performance of the work practices as required in §63.306(b)(7).

(4) 0.0 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1) (if applicable to the new nonrecovery coke oven battery); and

(5) 0.0 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1) (if applicable to the new nonrecovery coke oven battery).

(c) Except as provided in §63.304, the owner or operator of any nonrecovery coke oven battery shall meet the work practice standards in paragraphs (c)(1) and (2) of this section.

(1) The owner or operator shall observe each coke oven door after charging and record the oven number of any door from which visible emissions occur. Emissions from coal spilled during charging or from material trapped within the seal area of the door are not considered to be a door leak if the owner or operator demonstrates that the oven is under negative pressure, and that no emissions are visible from the top of the door or from dampers on the door.

(2) Except as provided in paragraphs (c)(2)(i) and (ii) of this section, if a coke oven door leak is observed at any time during the coking cycle, the owner or operator shall take corrective action and stop the leak within 15 minutes from the time the leak is first observed. No additional leaks are allowed from doors on that oven for the remainder of that oven's coking cycle.

(i) Except as provided in paragraph (c)(2)(ii) of this section, the owner or operator may take corrective action and stop the leak within 45 minutes (instead of 15 minutes) from the time the leak is first observed for a maximum of two times per battery in any semiannual reporting period.

(ii) If a worker must enter a cokeside shed to stop a leaking door under the cokeside shed, the owner or operator shall take corrective action and stop the door leak within 45 minutes (instead of 15 minutes) from the time the leak is first observed. The evacuation system and control device for the cokeside shed must be operated at all times there is a leaking door under the cokeside shed.

(d) The owner or operator of a new nonrecovery coke oven battery shall meet the emission limitations and work practice standards in paragraphs (d)(1) through (4) of this section.

(1) The owner or operator shall not discharge or cause to be discharged to the atmosphere from charging operations any fugitive emissions that exhibit an opacity greater than 20 percent, as determined by the procedures in §63.309(j).

(2) The owner or operator shall not discharge or cause to be discharged to the atmosphere any emissions of particulate matter (PM) from a charging emissions control device that exceed 0.0081 pounds per ton (lbs/ton) of dry coal charged, as determined by the procedures in §63.309(k).

(3) The owner or operator shall observe the exhaust stack of each charging emissions control device at least once each day of operation during charging to determine if visible emissions are present and shall record the results of each daily observation or the reason why conditions did not permit a daily observation. If any visible emissions are observed, the owner or operator must:

(i) Take corrective action to eliminate the presence of visible emissions;

(ii) Record the cause of the problem creating the visible emissions and the corrective action taken;

(iii) Conduct visible emission observations according to the procedures in §63.309(m) within 24 hours after detecting the visible emissions; and

(iv) Report any 6-minute average, as determined according to the procedures in §63.309(m), that exceeds 10 percent opacity as a deviation in the semiannual compliance report required by §63.311(d).

(4) The owner or operator shall develop and implement written procedures for adjusting the oven uptake damper to maximize oven draft during charging and for monitoring the oven damper setting during each charge to ensure that the damper is fully open.

[58 FR 57911, Oct. 27, 1993, as amended at 70 FR 20013, Apr. 15, 2005]

§63.304 Standards for compliance date extension.

(a) An owner or operator of an existing coke oven battery (including a cold-idle coke oven battery), a padup rebuild, or a brownfield coke oven battery, may elect an extension of the compliance date for emission limits to be promulgated pursuant to section 112(f) of the Act in accordance with section 112(i)(8). To receive an extension of the compliance date from January 1, 2003, until January 1, 2020, the owner or operator shall notify the Administrator as described in §63.311(c) that the battery will comply with the emission limitations and requirements in this section in lieu of the applicable emission limitations in §63.302 or 63.303.

(b) Except as provided in paragraphs (b)(4), (b)(5), and (b)(7) of this section and in §63.305, on and after the dates specified in this paragraph, no owner or operator shall cause to be discharged or allow to be discharged to the atmosphere coke oven emissions from a by-product coke oven battery that exceed any of the following emission limitations:

(1) On and after November 15, 1993;

(i) 7.0 percent leaking coke oven doors, as determined by the procedures in §63.309(d)(1);

(ii) 0.83 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1);

(iii) 4.2 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1); and

(iv) 12 seconds of visible emissions per charge, as determined by the procedures in §63.309(d)(2).

(2) On and after January 1, 1998;

(i) For coke oven doors:

(A) 4.3 percent leaking coke oven doors for each tall by-product coke oven battery and for each by-product coke oven battery owned or operated by a foundry coke producer, as determined by the procedures in §63.309(d)(1); and

(B) 3.8 percent leaking coke oven doors on each by-product coke oven battery not subject to the emission limitation in paragraph (b)(2)(i)(A) of this section, as determined by the procedures in §63.309(d)(1);

(ii) 0.4 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1);

(iii) 2.5 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1); and

(iv) 12 seconds of visible emissions per charge, as determined by the procedures in §63.309(d)(2).

(3) On and after January 1, 2010, unless the Administrator promulgates more stringent limits pursuant to section 112(i)(8)(C) of the Act;

(i) 4.0 percent leaking coke oven doors on each tall by-product coke oven battery and for each by-product coke oven battery owned or operated by a foundry coke producer, as determined by the procedures in §63.309(d)(1); and

(ii) 3.3 percent leaking coke oven doors for each by-product coke oven battery not subject to the emission limitation in paragraph (b)(3)(i) of this section, as determined by the procedures in §63.309(d)(1).

(4) No owner or operator shall cause to be discharged or allow to be discharged to the atmosphere coke oven emissions from a brownfield or padup rebuild by-product coke oven battery, other than those specified in paragraph (b)(4)(v) of this section, that exceed any of the following emission limitations:

(i) For coke oven doors;

(A) 4.0 percent leaking coke oven doors for each tall by-product coke oven battery, as determined by the procedures in §63.309(d)(1); and

(B) 3.3 percent leaking coke oven doors on each short by-product coke oven battery, as determined by the procedures in §63.309(d)(1);

(ii) 0.4 percent leaking topside port lids, as determined by the procedures in §63.309(d)(1);

(iii) 2.5 percent leaking offtake system(s), as determined by the procedures in §63.309(d)(1); and

(iv) 12 seconds of visible emissions per charge, as determined by the procedures in §63.309(d)(2).

(v) The requirements of paragraph (b)(4) of this section shall not apply and the requirements of paragraphs (b)(1), (b)(2), and (b)(3) of this section do apply to the following brownfield or padup rebuild coke oven batteries:

(A) Bethlehem Steel-Burns Harbor, Battery No. 2;

(B) National Steel-Great Lakes, Battery No. 4; and

(C) Koppers-Woodward, Battery No. 3.

(vi) To retain the exclusion provided in paragraph (b)(4)(v) of this section, a coke oven battery specified in paragraph (b)(4)(v) of this section shall commence construction not later than July 1, 1996, or 1 year after obtaining a construction permit, whichever is earlier.

(5) The owner or operator of a cold-idle coke oven battery that shut down on or after November 15, 1990, shall comply with the following emission limitations:

(i) For a brownfield coke oven battery or a padup rebuild coke oven battery, coke oven emissions shall not exceed the emission limitations in paragraph (b)(4) of this section; and

(ii) For a cold-idle battery other than a brownfield or padup rebuild coke oven battery, coke oven emissions shall not exceed the emission limitations in paragraphs (b)(1) through (b)(3) of this section.

(6) The owner or operator of a cold-idle coke oven battery that shut down prior to November 15, 1990, shall submit a written request to the Administrator to include the battery in the design capacity of a coke plant as of November 15, 1990. A copy of the request shall also be sent to Director, Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency, Research Triangle Park, NC 27711. The Administrator will review and approve or disapprove a request according to the following procedures:

(i) Requests will be reviewed for completeness in the order received. A complete request shall include:

(A) Battery identification;

(B) Design information, including the design capacity and number and size of ovens; and

(C) A brief description of the owner or operator's plans for the cold-idle battery, including a statement whether construction of a padup rebuild or a brownfield coke oven battery is contemplated.

(ii) A complete request shall be approved if the design capacity of the battery and the design capacity of all previous approvals does not exceed the capacity limit in paragraph (b)(6)(iii) of this section.

(iii) The total nationwide coke capacity of coke oven batteries that receive approval under paragraph (b)(6) of this section shall not exceed 2.7 million Mg/yr (3.0 million ton/yr).

(iv) If a construction permit is required, an approval shall lapse if a construction permit is not issued within 3 years of the approval date, or if the construction permit lapses.

(v) If a construction permit is not required, an approval will lapse if the battery is not restarted within 2 years of the approval date.

The owner or operator of a by-product coke oven battery with fewer than 30 ovens may elect to comply with an emission limitation of 2 or fewer leaking coke oven doors, as determined by the procedures in §63.309(d)(4), as an alternative to the emission limitation for coke oven doors in paragraphs (b)(2)(i), (b)(3) (i) through (ii), (b)(4)(i), (b)(5), and (b)(6) of this section.

(c) On and after November 15, 1993, no owner or operator shall cause to be discharged or allow to be discharged to the atmosphere coke oven emissions from an existing nonrecovery coke oven battery that exceed any of the emission limitations or requirements in §63.303(a).

(d) Each owner or operator of an existing coke oven battery qualifying for a compliance date extension pursuant to this section shall make available, no later than January 1, 2000, to the surrounding communities the results of any risk assessment performed by the Administrator to determine the appropriate level of any emission standard established by the Administrator according to section 112(f) of the Act.

[58 FR 57911, Oct. 27, 1993, as amended at 65 FR 62215, Oct. 17, 2000]

§63.305 Alternative standards for coke oven doors equipped with sheds.

(a) The owner or operator of a new or existing coke oven battery equipped with a shed for the capture of coke oven emissions from coke oven doors and an emission control device for the collection of the emissions may comply with an alternative to the applicable visible emission limitations for coke oven doors in §§63.302 and 63.304 according to the procedures and requirements in this section.

(b) To qualify for approval of an alternative standard, the owner or operator shall submit to the Administrator a test plan for the measurement of emissions. A copy of the request shall also be sent to the Director, Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency, Research Triangle Park, NC 27711. The plan shall describe the procedures to be used for the measurement of particulate matter; the parameters to be measured that affect the shed exhaust rate (e.g., damper settings, fan power) and the procedures for measuring such parameters; and if applicable under paragraph (c)(5)(ii) of this section, the procedures to be used for the measurement of benzene soluble organics, benzene, toluene, and xylene emitted from the control device for the shed. The owner or operator shall notify the Administrator at least 30 days before any performance test is conducted.

(c) A complete test plan is deemed approved if no disapproval is received within 60 days of the submittal to the Administrator. After approval of the test plan, the owner or operator shall;

(1) Determine the efficiency of the control device for removal of particulate matter by conducting measurements at the inlet and the outlet of the emission control device using Method 5 in appendix A to part 60 of this chapter, with the filter box operated at ambient temperature and in a manner to avoid condensation, with a backup filter;

(2) Measure the visible emissions from coke oven doors that escape capture by the shed using Method 22 in appendix A to part 60 of this chapter. For the purpose of approval of an alternative standard, no visible emissions may escape capture from the shed.

(i) Visible emission observations shall be taken during conditions representative of normal operations, except that pushing shall be suspended and pushing emissions shall have cleared the shed; and

(ii) Method 22 observations shall be performed by an observer certified according to the requirements of Method 9 in appendix A to part 60 of this chapter. The observer shall allow pushing emissions to be evacuated (typically 1 to 2 minutes) before making observations;

(3) Measure the opacity of emissions from the control device using Method 9 in appendix A to part 60 of this chapter during conditions representative of normal operations, including pushing; and

(i) If the control device has multiple stacks, the owner or operator shall use an evaluation based on visible emissions and opacity to select the stack with the highest opacity for testing under this section;

(ii) The highest opacity, expressed as a 6-minute average, shall be used as the opacity standard for the control device.

(4) Thoroughly inspect all compartments of each air cleaning device prior to the performance test for proper operation and for changes that signal the potential for malfunction, including the presence of tears, holes, and abrasions in filter bags; damaged seals; and for dust deposits on the clean side of bags; and

(5) Determine the allowable percent leaking doors under the shed using either of the following procedures:

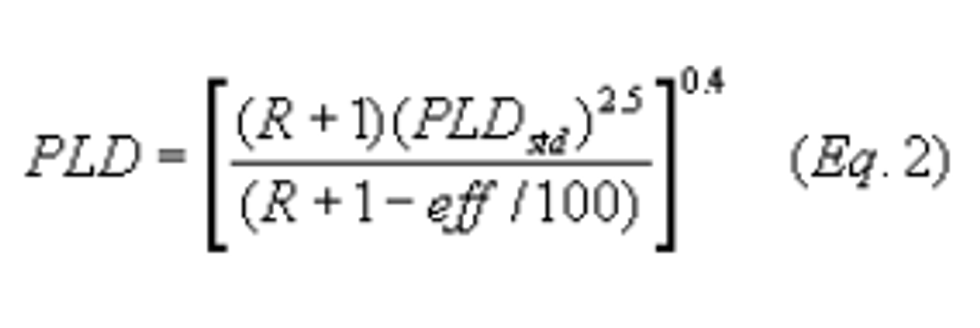

(i) Calculate the allowable percent leaking doors using the following equation:

where

PLD = Allowable percent leaking doors for alternative standard.

PLDstd = Applicable visible emission limitation of percent leaking doors under this subpart that would otherwise apply to the coke oven battery, converted to the single-run limit according to Table 1.

eff = Percent control efficiency for particulate matter for emission control device as determined according to paragraph (c)(1) of this section.

| 30-run limit | Single-pass limit (98 percent level) |

|---|---|

| 7.0 | 11.0 |

| 6.0 | 9.5 |

| 5.5 | 8.7 |

| 5.0 | 8.1 |

| 4.3 | 7.2 |

| 4.0 | 6.7 |

| 3.8 | 6.4 |

| 3.3 | 5.8 |

or;

(ii) Calculate the allowable percent leaking doors using the following procedures:

(A) Measure the total emission rate of benzene, toluene, and xylene exiting the control device using Method 18 in appendix A to part 60 of this chapter and the emission rate of benzene soluble organics entering the control device as described in the test plan submitted pursuant to paragraph (b) of this section; or

(B) Measure benzene, toluene, xylene, and benzene soluble organics in the gas in the collector main as described in the test plan submitted pursuant to paragraph (b) of this section; and

(C) Calculate the ratio (R) of benzene, toluene, and xylene to benzene soluble organics for the gas in the collector main, or as the sum of the outlet emission rates of benzene, toluene, and xylene, divided by the emission rate of benzene soluble organics as measured at the inlet to the control device; and

(D) Calculate the allowable percent leaking doors limit under the shed using the following equation:

where

R = Ratio of measured emissions of benzene, toluene, and xylene to measured emissions of benzene soluble organics.

(iii) If the allowable percent leaking coke oven doors is calculated to exceed 15 percent leaking coke oven doors under paragraphs (c)(5)(i) or (c)(5)(ii) of this section, the owner or operator shall use 15 percent leaking coke oven doors for the purposes of this section.

(6) Monitor the parameters that affect the shed exhaust flow rate.

(7) The owner or operator may request alternative sampling procedures to those specified in paragraph (c)(5)(ii) (A) and (B) of this section by submitting details on the procedures and the rationale for their use to the Administrator. Alternative procedures shall not be used without approval from the Administrator.

(8) The owner or operator shall inform the Administrator of the schedule for conducting testing under the approved test plan and give the Administrator the opportunity to observe the tests.

(d) After calculating the alternative standard for allowable percent leaking coke oven doors, the owner or operator shall submit the following information to the Administrator:

(1) Identity of the coke oven battery;

(2) Visible emission limitation(s) for percent leaking doors currently applicable to the coke oven battery under this subpart and known future limitations for percent leaking coke oven doors;

(3) A written report including:

(i) Appropriate measurements and calculations used to derive the allowable percent leaking coke oven doors requested as the alternative standard;

(ii) Appropriate visible emission observations for the shed and opacity observations for the control device for the shed, including an alternative opacity standard, if applicable, as described in paragraph (c)(3) of this section based on the highest 6-minute average; and

(iii) The parameter or parameters (e.g., fan power, damper position, or other) to be monitored and recorded to demonstrate that the exhaust flow rate measured during the test required by paragraph (c)(1) of this section is maintained, and the monitoring plan for such parameter(s).

(iv) If the application is for a new shed, one of the following demonstrations:

(A) A demonstration, using modeling procedures acceptable to the Administrator, that the expected concentrations of particulate emissions (including benzene soluble organics) under the shed at the bench level, when the proposed alternative standard was being met, would not exceed the expected concentrations of particulate emissions (including benzene soluble organics) if the shed were not present, the regulations under this subpart were met, and the battery was in compliance with federally enforceable limitations on pushing emissions; or

(B) A demonstration that the shed (including the evacuation system) has been designed in accordance with generally accepted engineering principles for the effective capture and control of particulate emissions (including benzene soluble organics) as measured at the shed's perimeter, its control device, and at the bench level.

(e) The Administrator will review the information and data submitted according to paragraph (d) of this section and may request additional information and data within 60 days of receipt of a complete request.

(1) Except for applications subject to paragraph (e)(3) of this section, the Administrator shall approve or disapprove an alternative standard as expeditiously as practicable. The Administrator shall approve an alternative standard, unless the Administrator determines that the approved test plan has not been followed, or any required calculations are incorrect, or any demonstration required under paragraph (d)(3)(iv) of this section does not satisfy the applicable criteria under that paragraph. If the alternative standard is disapproved, the Administrator will issue a written notification to the owner or operator within the 60-day period.

(2) The owner or operator shall comply with the applicable visible emission limitation for coke oven doors and all other requirements in this subpart prior to approval of an alternative standard. The owner or operator may apply for an alternative standard at any time after December 4, 1992.

(3) An application for an alternative standard to the standard in §63.304(b)(1)(i) for any shed that is not a new shed that is filed on or before June 15, 1993, is deemed approved if a notice of disapproval has not been received 60 days after submission of a complete request. An approval under paragraph (e)(3) of this section shall be valid for a period of 1 year.

(4) Notwithstanding the provisions of paragraph (e) of this section, no alternative standard shall be approved that exceeds 15 percent leaking coke oven doors (yard equivalent).

(f) After approval of an alternative standard, the owner or operator shall comply with the following requirements:

(1) The owner or operator shall not discharge or allow to be discharged to the atmosphere coke oven emissions from coke oven doors under sheds that exceed an approved alternative standard for percent leaking coke oven doors under sheds.

(i) All visible emission observations for compliance determinations shall be performed by a certified observer.

(ii) Compliance with the alternative standard for doors shall be determined by a weekly performance test conducted according to the procedures and requirements in §63.309(d)(5) and Method 303 in appendix A to this part.

(iii) If the visible emission limitation is achieved for 12 consecutive observations, compliance shall be determined by monthly rather than weekly performance tests. If any exceedance occurs during a performance test, weekly performance tests shall be resumed.

(iv) Observations taken at times other than those specified in paragraphs (f)(1)(ii) and (f)(1)(iii) of this section shall be subject to the provisions of §63.309(f).

(2) The certified observer shall monitor the visible coke oven emissions escaping capture by the shed on a weekly basis. The provision in paragraph (f)(6) of this section is applicable if visible coke oven emissions are observed during periods when pushing emissions have cleared the shed.

(3) The owner or operator shall not discharge or allow to be discharged to the atmosphere any visible emissions from the shed's control device exhibiting more than 0 percent opacity unless an alternative limit has been approved under paragraph (e) of this section.

(4) The opacity of emissions from the control device for the shed shall be monitored in accordance with the requirements of either paragraph (f)(4)(i) or (f)(4)(ii) of this section, at the election of the owner or operator.

(i) The owner or operator shall install, operate, and maintain a continuous opacity monitor, and record the output of the system, for the measurement of the opacity of emissions discharged from the emission control system.

(A) Each continuous opacity monitoring system shall meet the requirements of Performance Specification 1 in appendix B to part 60 of this chapter; and

(B) Each continuous opacity monitoring system shall be operated, calibrated, and maintained according to the procedures and requirements specified in part 52 of this chapter; or

(ii) A certified observer shall monitor and record at least once each day during daylight hours, opacity observations for the control device for the shed using Method 9 in appendix A to part 60 of this chapter.

(5) The owner or operator shall visually inspect the structural integrity of the shed at least once a quarter for defects, such as deterioration of sheet metal (e.g., holes in the shed), that may allow the escape of visible emissions.

(i) The owner or operator shall record the time and date a defect is first observed, the time and date the defect is corrected or repaired, and a brief description of repairs or corrective actions taken;

(ii) The owner or operator shall temporarily repair the defect as soon as possible, but no later than 5 days after detection of the defect;

(iii) Unless a major repair is required, the owner or operator shall perform a complete repair of the defect within 15 days of detection of the defect. If a major repair is required (e.g., replacement of large sections of the shed), the owner or operator shall submit a repair schedule to the enforcement agency.

(6) If the no visible emission limit for the shed specified in paragraph (f)(2) of this section is exceeded, the Administrator may require another test for the shed according to the approved test plan as specified in paragraph (c) of this section. If the certified observer observes visible coke oven emissions from the shed, except during periods of pushing or when pushing emissions have not cleared the shed, the owner or operator shall check to ensure that the shed and control device are working properly.

(7) The owner or operator shall monitor the parameter(s) affecting shed exhaust flow rate, and record data, in accordance with the approved monitoring plan for these parameters.

(8) The owner or operator shall not operate the exhaust system of the shed at an exhaust flow rate lower than that measured during the test required under paragraph (c)(1) of this section, as indicated by the monitored parameters.

(g) Each side of a battery subject to an alternative standard for doors under this section shall be treated separately for purposes of §§63.306(c) (plan implementation) and 63.306(d) (plan revisions) of this subpart. In making determinations under these provisions for the side of the battery subject to an alternative standard, the requirement that exceedances be independent shall not apply. During any period when work practices for doors for both sides of the battery are required to be implemented, §63.306(a)(3) shall apply in the same manner as if the provisions of a plan for a single emissions point were required to be implemented. Exceedances of the alternative standard for percent leaking doors under a shed is the only provision in this section implicating implementation of work practice requirements.

(h) Multiple exceedances of the visible emission limitation for door leaks and/or the provisions of an alternative standard under this section for door leaks at a battery on a single day shall be considered a single violation.

§63.306 Work practice standards.

(a) Work practice plan. On or before November 15, 1993, each owner or operator shall prepare and submit a written emission control work practice plan for each coke oven battery. The plan shall be designed to achieve compliance with visible emission limitations for coke oven doors, topside port lids, offtake systems, and charging operations under this subpart, or, for a coke oven battery not subject to visible emission limitations under this subpart, other federally enforceable visible emission limitations for these emission points.

(1) The work practice plan must address each of the topics specified in paragraph (b) of this section in sufficient detail and with sufficient specificity to allow the reviewing authority to evaluate the plan for completeness and enforceability.

(2) The initial plan and any revisions shall be submitted to the Administrator or the delegated State, local, or Tribal authority. The Administrator (or delegated State, local, or Tribal authority) may require revisions to the initial plan only where the Administrator (or delegated State, local, or Tribal authority) finds either that the plan does not address each subject area listed in paragraph (b) of this section for each emission point subject to a visible emission standard under this subpart, or that the plan in unenforceable because it contains requirements that are unclear.

(3) During any period of time that an owner or operator is required to implement the provisions of a plan for a particular emission point, the failure to implement one or more obligations under the plan and/or any recordkeeping requirement(s) under §63.311(f)(4) for the emission point during a particular day is a single violation.

(b) Plan components. The owner or operator shall organize the work practice plan to indicate clearly which parts of the plan pertain to each emission point subject to visible emission standards under this subpart. Each of the following provisions, at a minimum, shall be addressed in the plan:

(1) An initial and refresher training program for all coke plant operating personnel with responsibilities that impact emissions, including contractors, in job requirements related to emission control and the requirements of this subpart, including work practice requirements. Contractors with responsibilities that impact emission control may be trained by the owner or operator or by qualified contractor personnel; however, the owner or operator shall ensure that the contractor training program complies with the requirements of this section. The training program in the plan must include:

(i) A list, by job title, of all personnel that are required to be trained and the emission point(s) associated with each job title;

(ii) An outline of the subjects to be covered in the initial and refresher training for each group of personnel;

(iii) A description of the training method(s) that will be used (e.g., lecture, video tape);

(iv) A statement of the duration of initial training and the duration and frequency of refresher training;

(v) A description of the methods to be used at the completion of initial or refresher training to demonstrate and document successful completion of the initial and refresher training; and

(vi) A description of the procedure to be used to document performance of plan requirements pertaining to daily operation of the coke oven battery and its emission control equipment, including a copy of the form to be used, if applicable, as required under the plan provisions implementing paragraph (b)(7) of this section.

(2) Procedures for controlling emissions from coke oven doors on by-product coke oven batteries, including:

(i) A program for the inspection, adjustment, repair, and replacement of coke oven doors and jambs, and any other equipment for controlling emissions from coke oven doors, including a defined frequency of inspections, the method to be used to evaluate conformance with operating specifications for each type of equipment, and the method to be used to audit the effectiveness of the inspection and repair program for preventing exceedances;

(ii) Procedures for identifying leaks that indicate a failure of the emissions control equipment to function properly, including a clearly defined chain of command for communicating information on leaks and procedures for corrective action;

(iii) Procedures for cleaning all sealing surfaces of each door and jamb, including identification of the equipment that will be used and a specified schedule or frequency for the cleaning of sealing surfaces;

(iv) For batteries equipped with self-sealing doors, procedures for use of supplemental gasketing and luting materials, if the owner or operator elects to use such procedures as part of the program to prevent exceedances;

(v) For batteries equipped with hand-luted doors, procedures for luting and reluting, as necessary to prevent exceedances;

(vi) Procedures for maintaining an adequate inventory of the number of spare coke oven doors and jambs located onsite; and

(vii) Procedures for monitoring and controlling collecting main back pressure, including corrective action if pressure control problems occur.

(3) Procedures for controlling emissions from charging operations on by-product coke oven batteries, including:

(i) Procedures for equipment inspection, including the frequency of inspections, and replacement or repair of equipment for controlling emissions from charging, the method to be used to evaluate conformance with operating specifications for each type of equipment, and the method to be used to audit the effectiveness of the inspection and repair program for preventing exceedances;

(ii) Procedures for ensuring that the larry car hoppers are filled properly with coal;

(iii) Procedures for the alignment of the larry car over the oven to be charged;

(iv) Procedures for filling the oven (e.g., procedures for staged or sequential charging);

(v) Procedures for ensuring that the coal is leveled properly in the oven; and

(vi) Procedures and schedules for inspection and cleaning of offtake systems (including standpipes, standpipe caps, goosenecks, dampers, and mains), oven roofs, charging holes, topside port lids, the steam supply system, and liquor sprays.

(4) Procedures for controlling emissions from topside port lids on by-product coke oven batteries, including:

(i) Procedures for equipment inspection and replacement or repair of topside port lids and port lid mating and sealing surfaces, including the frequency of inspections, the method to be used to evaluate conformance with operating specifications for each type of equipment, and the method to be used to audit the effectiveness of the inspection and repair program for preventing exceedances; and

(ii) Procedures for sealing topside port lids after charging, for identifying topside port lids that leak, and procedures for resealing.

(5) Procedures for controlling emissions from offtake system(s) on by-product coke oven batteries, including:

(i) Procedures for equipment inspection and replacement or repair of offtake system components, including the frequency of inspections, the method to be used to evaluate conformance with operating specifications for each type of equipment, and the method to be used to audit the effectiveness of the inspection and repair program for preventing exceedances;

(ii) Procedures for identifying offtake system components that leak and procedures for sealing leaks that are detected; and

(iii) Procedures for dampering off ovens prior to a push.

(6) Procedures for controlling emissions from nonrecovery coke oven batteries including:

(i) Procedures for charging coal into the oven, including any special procedures for minimizing air infiltration during charging, maximizing the draft on the oven, and for replacing the door promptly after charging;

(ii) If applicable, procedures for the capture and control of charging emissions;

(iii) Procedures for cleaning coke from the door sill area for both sides of the battery after completing the pushing operation and before replacing the coke oven door;

(iv) Procedures for cleaning coal from the door sill area after charging and before replacing the push side door;

(v) Procedures for filling gaps around the door perimeter with sealant material, if applicable; and

(vi) Procedures for detecting and controlling emissions from smoldering coal.

(7) Procedures for maintaining, for each emission point subject to visible emission limitations under this subpart, a daily record of the performance of plan requirements pertaining to the daily operation of the coke oven battery and its emission control equipment, including:

(i) Procedures for recording the performance of such plan requirements; and

(ii) Procedures for certifying the accuracy of such records by the owner or operator.

(8) Any additional work practices or requirements specified by the Administrator according to paragraph (d) of this section.

(c) Implementation of work practice plans. On and after November 15, 1993, the owner or operator of a coke oven battery shall implement the provisions of the coke oven emission control work practice plan according to the following requirements:

(1) The owner or operator of a coke oven battery subject to visible emission limitations under this subpart on and after November 15, 1993, shall:

(i) Implement the provisions of the work practice plan pertaining to a particular emission point following the second independent exceedance of the visible emission limitation for the emission point in any consecutive 6-month period, by no later than 3 days after receipt of written notification of the second such exceedance from the certified observer. For the purpose of this paragraph (c)(1)(i), the second exceedance is “independent” if either of the following criteria is met:

(A) The second exceedance occurs 30 days or more after the first exceedance;

(B) In the case of coke oven doors, topside port lids, and offtake systems, the 29-run average, calculated by excluding the highest value in the 30-day period, exceeds the value of the applicable emission limitation; or

(C) In the case of charging emissions, the 29-day logarithmic average, calculated in accordance with Method 303 in appendix A to this part by excluding the valid daily set of observations in the 30-day period that had the highest arithmetic average, exceeds the value of the applicable emission limitation.

(ii) Continue to implement such plan provisions until the visible emission limitation for the emission point is achieved for 90 consecutive days if work practice requirements are implemented pursuant to paragraph (c)(1)(i) of this section. After the visible emission limitation for a particular emission point is achieved for 90 consecutive days, any exceedances prior to the beginning of the 90 days are not included in making a determination under paragraph (c)(1)(i) of this section.

(2) The owner or operator of a coke oven battery not subject to visible emission limitations under this subpart until December 31, 1995, shall:

(i) Implement the provisions of the work practice plan pertaining to a particular emission point following the second exceedance in any consecutive 6-month period of a federally enforceable emission limitation for that emission point for coke oven doors, topside port lids, offtake systems, or charging operations by no later than 3 days after receipt of written notification from the applicable enforcement agency; and

(ii) Continue to implement such plan provisions for 90 consecutive days after the most recent written notification from the enforcement agency of an exceedance of the visible emission limitation.

(d) Revisions to plan. Revisions to the work practice emission control plan will be governed by the provisions in this paragraph (d) and in paragraph (a)(2) of this section. The reviewing authority is the Administrator or the delegated State, local, or Tribal authority.

(1) The reviewing authority may request the owner or operator to review and revise as needed the work practice emission control plan for a particular emission point if there are 2 exceedances of the applicable visible emission limitation in the 6-month period that starts 30 days after the owner or operator is required to implement work practices under paragraph (c) of this section. In the case of a coke oven battery subject to visual emission limitations under this subpart, the second exceedance must be independent of the criteria in paragraph (c)(1)(i) of this section.

(2) The reviewing authority may not request the owner or operator to review and revise the plan more than twice in any 12 consecutive month period for any particular emission point unless the reviewing authority disapproves the plan according to the provisions in paragraph (d)(6) of this section.

(3) If the certified observer calculates that a second exceedance (or, if applicable, a second independent exceedance) has occurred, the certified observer shall notify the owner or operator. No later than 10 days after receipt of such a notification, the owner or operator shall notify the reviewing authority of any finding of whether work practices are related to the cause or the solution of the problem. The notification is subject to review by the reviewing authority according to the provisions in paragraph (d)(6) of this section.

(4) The owner or operator shall submit a revised work practice plan within 60 days of notification from the reviewing authority under paragraph (d)(1) of this section, unless the reviewing authority grants an extension of time to submit the revised plan.

(5) If the reviewing authority requires a plan revision, the reviewing authority may require the plan to address a subject area or areas in addition to those in paragraph (b) of this section, if the reviewing authority determines that without plan coverage of such an additional subject area, there is a reasonable probability of further exceedances of the visible emission limitation for the emission point for which a plan revision is required.

(6) The reviewing authority may disapprove a plan revision required under paragraph (d) of this section if the reviewing authority determines that the revised plan is inadequate to prevent exceedances of the visible emission limitation under this subpart for the emission point for which a plan revision is required or, in the case of a battery not subject to visual emission limitations under this subpart, other federally enforceable emission limitations for such emission point. The reviewing authority may also disapprove the finding that may be submitted pursuant to paragraph (d)(3) of this section if the reviewing authority determines that a revised plan is needed to prevent exceedances of the applicable visible emission limitations.

[58 FR 57911, Oct. 27, 1993, as amended at 68 FR 37345, June 23, 2003]

§63.307 Standards for bypass/bleeder stacks.

(a)(1) Except as otherwise provided in this section, on or before March 31, 1994, the owner or operator of an existing by-product recovery battery for which a notification was not submitted under paragraph (e)(1) of this section shall install a bypass/bleeder stack flare system that is capable of controlling 120 percent of the normal gas flow generated by the battery, which shall thereafter be operated and maintained.

(2) Coke oven emissions shall not be vented to the atmosphere through bypass/bleeder stacks, except through the flare system or the alternative control device as described in paragraph (d) of this section.

(3) The owner or operator of a brownfield coke oven battery or a padup rebuild shall install such a flare system before startup, and shall properly operate and maintain the flare system.

(b) Each flare installed pursuant to this section shall meet the following requirements:

(1) Each flare shall be designed for a net heating value of 8.9 MJ/scm (240 Btu/scf) if a flare is steam-assisted or air-assisted, or a net value of 7.45 MJ/scm (200 Btu/scf) if the flare is non-assisted.

(2) Each flare shall have either a continuously operable pilot flame or an electronic igniter that meets the requirements of paragraphs (b)(3) and (b)(4) of this section.

(3) Each electronic igniter shall meet the following requirements:

(i) Each flare shall be equipped with at least two igniter plugs with redundant igniter transformers;

(ii) The ignition units shall be designed failsafe with respect to flame detection thermocouples (i.e., any flame detection thermocouples are used only to indicate the presence of a flame, are not interlocked with the ignition unit, and cannot deactivate the ignition system); and

(iii) Integral battery backup shall be provided to maintain active ignition operation for a minimum of 15 minutes during a power failure.

(iv) Each electronic igniter shall be operated to initiate ignition when the bleeder valve is not fully closed as indicated by an “OPEN” limit switch.

(4) Each flare installed to meet the requirements of this paragraph (b) that does not have an electronic igniter shall be operated with a pilot flame present at all times as determined by §63.309(h)(2).

(c) Each flare installed to meet the requirements of this section shall be operated with no visible emissions, as determined by the methods specified in §63.309(h)(1), except for periods not to exceed a total of 5 minutes during any 2 consecutive hours.

(d) As an alternative to the installation, operation, and maintenance of a flare system as required in paragraph (a) of this section, the owner or operator may petition the Administrator for approval of an alternative control device or system that achieves at least 98 percent destruction or control of coke oven emissions vented to the alternative control device or system.

(e) The owner or operator of a by-product coke oven battery is exempt from the requirements of this section if the owner or operator:

(1) Submits to the Administrator, no later than November 10, 1993, a formal commitment to close the battery permanently; and

(2) Closes the battery permanently no later than December 31, 1995. In no case may the owner or operator continue to operate a battery for which a closure commitment is submitted, past December 31, 1995.

(f) Any emissions resulting from the installation of flares (or other pollution control devices or systems approved pursuant to paragraph (d) of this section) shall not be used in making new source review determinations under part C and part D of title I of the Act.

§63.308 Standards for collecting mains.

(a) On and after November 15, 1993, the owner or operator of a by-product coke oven battery shall inspect the collecting main for leaks at least once daily according to the procedures in Method 303 in appendix A to this part.

(b) The owner or operator shall record the time and date a leak is first observed, the time and date the leak is temporarily sealed, and the time and date of repair.

(c) The owner or operator shall temporarily seal any leak in the collecting main as soon as possible after detection, but no later than 4 hours after detection of the leak.

(d) The owner or operator shall initiate a collecting main repair as expeditiously as possible, but no later than 5 calendar days after initial detection of the leak. The repair shall be completed within 15 calendar days after initial detection of the leak unless an alternative schedule is approved by the Administrator.

§63.309 Performance tests and procedures.

(a) Except as otherwise provided, a daily performance test shall be conducted each day, 7 days per week for each new and existing coke oven battery, the results of which shall be used in accordance with procedures specified in this subpart to determine compliance with each of the applicable visible emission limitations for coke oven doors, topside port lids, offtake systems, and charging operations in this subpart. If a facility pushes and charges only at night, then that facility must, at its option, change their schedule and charge during daylight hours or provide adequate lighting so that visible emission inspections can be made at night. “Adequate lighting” will be determined by the enforcement agency.

(1) Each performance test is to be conducted according to the procedures and requirements in this section and in Method 303 or 303A in appendix A to this part or Methods 9 and 22 in appendix A to part 60 of this chapter (where applicable).

(2) Each performance test is to be conducted by a certified observer.

(3) The certified observer shall complete any reasonable safety training program offered by the owner or operator prior to conducting any performance test at a coke oven battery.

(4) Except as otherwise provided in paragraph (a)(5) of this section, the owner or operator shall pay an inspection fee to the enforcement agency each calendar quarter to defray the costs of the daily performance tests required under paragraph (a) of this section.

(i) The inspection fee shall be determined according to the following formula:

where

F = Fees to be paid by owner or operator.

H = Total person hours for inspections: 4 hours for 1 coke oven battery, 6.25 hours for 2 coke oven batteries, 8.25 hours for 3 coke oven batteries. For more than 3 coke oven batteries, use these hours to calculate the appropriate estimate of person hours.

S = Current average hourly rate for private visible emission inspectors in the relevant market.

(ii) The enforcement agency may revise the value for H in equation 3 within 3 years after October 27, 1993 to reflect the amount of time actually required to conduct the inspections required under paragraph (a) of this section.

(iii) The owner or operator shall not be required to pay an inspection fee (or any part thereof) under paragraph (a)(4) of this section, for any monitoring or inspection services required by paragraph (a) of this section that the owner or operator can demonstrate are covered by other fees collected by the enforcement agency.

(iv) Upon request, the enforcement agency shall provide the owner or operator information concerning the inspection services covered by any other fees collected by the enforcement agency, and any information relied upon under paragraph (a)(4)(ii) of this section.

(5)(i) The EPA shall be the enforcement agency during any period of time that a delegation of enforcement authority is not in effect or a withdrawal of enforcement authority under §63.313 is in effect, and the Administrator is responsible for performing the inspections required by this section, pursuant to §63.313(c).

(ii) Within thirty (30) days of receiving notification from the Administrator that the EPA is the enforcement agency for a coke oven battery, the owner or operator shall enter into a contract providing for the inspections and performance tests required under this section to be performed by a Method 303 certified observer. The inspections and performance tests will be conducted at the expense of the owner or operator, during the period that the EPA is the implementing agency.

(b) The enforcement agency shall commence daily performance tests on the applicable date specified in §63.300 (a) or (c).

(c) The certified observer shall conduct each performance test according to the requirements in this paragraph:

(1) The certified observer shall conduct one run each day to observe and record visible emissions from each coke oven door (except for doors covered by an alternative standard under §63.305), topside port lid, and offtake system on each coke oven battery. The certified observer also shall conduct five runs to observe and record the seconds of visible emissions per charge for five consecutive charges from each coke oven battery. The observer may perform additional runs as needed to obtain and record a visible emissions value (or set of values) for an emission point that is valid under Method 303 or Method 303A in appendix A to this part. Observations from fewer than five consecutive charges shall constitute a valid set of charging observations only in accordance with the procedures and conditions specified in sections 3.8 and 3.9 of Method 303 in appendix A to this part.

(2) If a valid visible emissions value (or set of values) is not obtained for a performance test, there is no compliance determination for that day. Compliance determinations will resume on the next day that a valid visible emissions value (or set of values) is obtained.

(3) After each performance test for a by-product coke oven battery, the certified observer shall check and record the collecting main pressure according to the procedures in section 6.3 of Method 303 in appendix A to this part.

(i) The owner or operator shall demonstrate pursuant to Method 303 in appendix A to this part the accuracy of the pressure measurement device upon request of the certified observer;

(ii) The owner or operator shall not adjust the pressure to a level below the range of normal operation during or prior to the inspection;

(4) The certified observer shall monitor visible emissions from coke oven doors subject to an alternative standard under §63.305 on the schedule specified in §63.305(f).

(5) If applicable, the certified observer shall monitor the opacity of any emissions escaping the control device for a shed covering doors subject to an alternative standard under §63.305 on the schedule specified in §63.305(f).

(6) In no case shall the owner or operator knowingly block a coke oven door, or any portion of a door for the purpose of concealing emissions or preventing observations by the certified observer.

(d) Using the observations obtained from each performance test, the enforcement agency shall compute and record, in accordance with the procedures and requirements of Method 303 or 303A in appendix A to this part, for each day of operations on which a valid emissions value (or set of values) is obtained:

(1) The 30-run rolling average of the percent leaking coke oven doors, topside port lids, and offtake systems on each coke oven battery, using the equations in sections 4.5.3.2, 5.6.5.2, and 5.6.6.2 of Method 303 (or section 3.4.3.2 of Method 303A) in appendix A to this part;

(2) For by-product coke oven battery charging operations, the logarithmic 30-day rolling average of the seconds of visible emissions per charge for each battery, using the equation in section 3.9 of Method 303 in appendix A to this part;

(3) For a battery subject to an alternative emission limitation for coke oven doors on by-product coke oven batteries pursuant to §63.305, the 30-run rolling average of the percent leaking coke oven doors for any side of the battery not subject to such alternative emission limitation;

(4) For a by-product coke oven battery subject to the small battery emission limitation for coke oven doors pursuant to §63.304(b)(7), the 30-run rolling average of the number of leaking coke oven doors;

(5) For an approved alternative emission limitation for coke oven doors according to §63.305, the weekly or monthly observation of the percent leaking coke oven doors using Method 303 in appendix A to this part, the percent opacity of visible emissions from the control device for the shed using Method 9 in appendix A to part 60 of this chapter, and visible emissions from the shed using Method 22 in appendix A to part 60 of this chapter;

(e) The certified observer shall make available to the implementing agency as well as to the owner or operator, a copy of the daily inspection results by the end of the day and shall make available the calculated rolling average for each emission point to the owner or operator as soon as practicable following each performance test. The information provided by the certified observer is not a compliance determination. For the purpose of notifying an owner or operator of the results obtained by a certified observer, the person does not have to be certified.

(f) Compliance shall not be determined more often than the schedule provided for performance tests under this section. If additional valid emissions observations are obtained (or in the case of charging, valid sets of emission observations), the arithmetic average of all valid values (or valid sets of values) obtained during the day shall be used in any computations performed to determine compliance under paragraph (d) of this section or determinations under §63.306.

(g) Compliance with the alternative standards for nonrecovery coke oven batteries in §63.303; shed inspection, maintenance requirements, and monitoring requirements for parameters affecting the shed exhaust flow rate for batteries subject to alternative standards for coke oven doors under §63.305; work practice emission control plan requirements in §63.306; standards for bypass/bleeder stacks in §63.307; and standards for collecting mains in §63.308 is to be determined by the enforcement agency based on review of records and inspections.

(h) For a flare installed to meet the requirements of §63.307(b):

(1) Compliance with the provisions in §63.307(c) (visible emissions from flares) shall be determined using Method 22 in appendix A to part 60 of this chapter, with an observation period of 2 hours; and

(2) Compliance with the provisions in §63.307(b)(4) (flare pilot light) shall be determined using a thermocouple or any other equivalent device.

(i) No observations obtained during any program for training or for certifying observers under this subpart shall be used to determine compliance with the requirements of this subpart or any other federally enforceable standard.

(j) The owner or operator of a new nonrecovery coke oven battery shall conduct a performance test once each week to demonstrate compliance with the opacity limit in §63.303(d)(1). The owner or operator shall conduct each performance test according to the procedures and requirements in paragraphs (j)(1) through (3) of this section.

(1) Using a certified observer, determine the average opacity of five consecutive charges per week for each charging emissions capture system if charges can be observed according to the requirements of Method 9 (40 CFR part 60, appendix A), except as specified in paragraphs (j)(1)(i) and (ii) of this section.

(i) Instead of the procedures in section 2.4 of Method 9 (40 CFR part 60, appendix A), record observations to the nearest 5 percent at 15-second intervals for at least five consecutive charges.

(ii) Instead of the procedures in section 2.5 of Method 9 (40 CFR part 60, appendix A), determine and record the highest 3-minute average opacity for each charge from the consecutive observations recorded at 15-second intervals.

(2) Opacity observations are to start when the door is removed for charging and end when the door is replaced.

(3) Using the observations recorded from each performance test, the certified observer shall compute and record the average of the highest 3-minute averages for five consecutive charges.

(k) The owner or operator of a new nonrecovery coke oven battery shall conduct a performance test to demonstrate initial compliance with the emission limitations for a charging emissions control device in §63.303(d)(2) within 180 days of the compliance date that is specified for the affected source in §63.300(a)(4) and report the results in the notification of compliance status. The owner or operator shall prepare a site-specific test plan according to the requirements in §63.7(c) and shall conduct each performance test according to the requirements in §63.7(e)(1) and paragraphs (k)(1) through (4) of this section.

(1) Determine the concentration of PM according to the following test methods in appendix A to 40 CFR part 60.