['Air Programs']

['Hazardous Air Pollutants']

05/05/2022

...

(a) You must conduct each performance test in Table 5 to this subpart that applies to you.

(b) Prior to the relevant compliance date for your source as specified in §63.7083(e), each performance test must be conducted according to the requirements in §63.7(e)(1) and under the specific conditions specified in Table 5 to this subpart. On and after the relevant compliance date for your source as specified in §63.7083(e), each performance test must be conducted based on representative performance (i.e., performance based on normal operating conditions) of the affected source and under the specific conditions in Table 5 to this subpart. Representative conditions exclude periods of startup and shutdown. The owner or operator may not conduct performance tests during periods of malfunction. The owner or operator must record the process information that is necessary to document operating conditions during the test and include in such record an explanation to support that such conditions represent normal operation. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(c) Prior to the relevant compliance date for your source as specified in §63.7083(e)), you may not conduct performance tests during periods of startup, shutdown, or malfunction, as specified in §63.7(e)(1)). On and after the relevant compliance date for your source as specified in §63.7083(e), you may not conduct performance tests during periods of startup, shutdown, or malfunction, as specified in paragraph (b) of this section.

(d) Except for opacity and VE observations, you must conduct three separate test runs for each performance test required in this section, as specified in §63.7(e)(3). Each test run must last at least 1 hour.

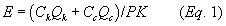

(e) The emission rate of particulate matter (PM) from each lime kiln (and each lime cooler if there is a separate exhaust to the atmosphere from the lime cooler) must be computed for each run using Equation 1 of this section:

Where:

E = Emission rate of PM, pounds per ton (lb/ton) of stone feed.

Ck = Concentration of PM in the kiln effluent, grain/dry standard cubic feet (gr/dscf).

Qk = Volumetric flow rate of kiln effluent gas, dry standard cubic feet per hour (dscf/hr).

Cc = Concentration of PM in the cooler effluent, grain/dscf. This value is zero if there is not a separate cooler exhaust to the atmosphere.

Qc = Volumetric flow rate of cooler effluent gas, dscf/hr. This value is zero if there is not a separate cooler exhaust to the atmosphere.

P = Stone feed rate, tons per hour (ton/hr).

K = Conversion factor, 7000 grains per pound (grains/lb).

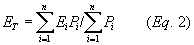

(f)(1) If you choose to meet a weighted average emission limit as specified in item 4 of Table 1 to this subpart, you must calculate a combined particulate emission rate from all kilns and coolers within your LMP using Equation 2 of this section:

Where:

ET = Emission rate of PM from all kilns and coolers, lb/ton of stone feed.

Ei = Emission rate of PM from kiln i, or from kiln/cooler combination i, lb/ton of stone feed.

Pi = Stone feed rate to kiln i, ton/hr.

n = Number of kilns you wish to include in averaging.

(2) You do not have to include every kiln in this calculation, only include kilns you wish to average. Kilns that have a PM emission limit of 0.60 lb/tsf are ineligible for any averaging.

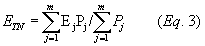

(g) The weighted average PM emission limit from all kilns and coolers for which you are averaging must be calculated using Equation 3 of this section:

Where:

ETN = Weighted average PM emission limit for all kilns and coolers being included in averaging at the LMP, lb/ton of stone feed.

Ej = PM emission limit (0.10 or 0.12) for kiln j, or for kiln/cooler combination j, lb/ton of stone feed.

Pj = Stone feed rate to kiln j, ton/hr.

m = Number of kilns and kiln/cooler combinations you are averaging at your LMP. You must include the same kilns in the calculation of ET and ETN. Kilns that have a PM emission limit of 0.60 lb/tsf are ineligible for any averaging.

(h) Performance test results must be documented in complete test reports that contain the information required by paragraphs (h)(1) through (10) of this section, as well as all other relevant information. The plan to be followed during testing must be made available to the Administrator at least 60 days prior to testing.

(1) A brief description of the process and the air pollution control system;

(2) Sampling location description(s);

(3) A description of sampling and analytical procedures and any modifications to standard procedures;

(4) Test results, including opacity;

(5) Quality assurance procedures and results;

(6) Records of operating conditions during the test, preparation of standards, and calibration procedures;

(7) Raw data sheets for field sampling and field and laboratory analyses;

(8) Documentation of calculations;

(9) All data recorded and used to establish operating limits; and

(10) Any other information required by the test method.

(i) [Reserved]

(j) You must establish any applicable 3-hour block average operating limit indicated in Table 3 to this subpart according to the applicable requirements in Table 4 to this subpart and paragraphs (j)(1) through (4) of this section.

(1) Continuously record the parameter during the PM performance test and include the parameter record(s) in the performance test report.

(2) Determine the average parameter value for each 15-minute period of each test run.

(3) Calculate the test run average for the parameter by taking the average of all the 15-minute parameter values for the run.

(4) Calculate the 3-hour operating limit by taking the average of the three test run averages.

(k) For each building enclosing any PSH operations that is subject to a VE limit, you must conduct a VE check according to item 18 in Table 5 to this subpart, and in accordance with paragraphs (k)(1) through (3) of this section.

(1) Conduct visual inspections that consist of a visual survey of the building over the test period to identify if there are VE, other than condensed water vapor.

(2) Select a position at least 15 but not more 1,320 feet from each side of the building with the sun or other light source generally at your back.

(3) The observer conducting the VE checks need not be certified to conduct EPA Method 9 in appendix A-4 to part 60 of this chapter. However, the observer must meet the training requirements as described in EPA Method 22 in appendix A-7 to part 60 of this chapter.

(l) When determining compliance with the opacity standards for fugitive emissions from PSH operations in item 8 of Table 1 to this subpart, you must conduct EPA Method 9 in appendix A-4 to part 60 of this chapter according to item 17 in Table 5 to this subpart, and in accordance with paragraphs (l)(1) through (3) of this section.

(1) The minimum distance between the observer and the emission source shall be 4.57 meters (15 feet).

(2) The observer shall, when possible, select a position that minimizes interference from other fugitive emission sources (e.g., road dust). The required observer position relative to the sun must be followed.

(3) If you use wet dust suppression to control PM from PSH operations, a visible mist is sometimes generated by the spray. The water mist must not be confused with particulate matter emissions and is not to be considered VE. When a water mist of this nature is present, you must observe emissions at a point in the plume where the mist is no longer visible.

(m) On and after the relevant compliance date for your source as specified in §63.7083(e), during startup, kilns must be tested hourly to determine when lime product meets the definition of on-specification lime product.

[85 FR 44978, July 24, 2020]

READ MORESHOW LESS

['Air Programs']

['Hazardous Air Pollutants']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.