Compliance Just Got Easier: Stay ahead of regulatory changes with instant notifications on updates that matter.

['Air Programs']

['Volatile Organic Compounds']

01/16/2025

...

Subpart E - National Volatile Organic Compound Emission Standards for Aerosol Coatings

§59.500 What is the purpose of this subpart?

This subpart establishes the product-weighted reactivity (PWR) limits regulated entities must meet in order to comply with the national rule for volatile organic compounds (VOC) emitted from aerosol coatings. This subpart also establishes labeling, recordkeeping, and reporting requirements for regulated entities.

§59.501 Am I subject to this subpart?

(a) The regulated entities for an aerosol coating product are the manufacturer or importer of an aerosol coating product and a distributor of an aerosol coating product if it is named on the label or if it specifies the formulation of the product. Distributors include retailers who fall within the definition of “distributor” in §59.503.

(b) Except as provided in paragraph (e) of this section, the responsibilities of each regulated entity are detailed in paragraphs (b)(1) through (b)(4) of this section.

(1) If you are a manufacturer or importer, you are a regulated entity responsible for ensuring that all aerosol coatings manufactured or imported by you meet the PWR limits presented in §59.504, even if your name is not on the label.

(2) If you are a distributor named on the label, you are a regulated entity responsible for compliance with all sections of this subpart except for the limits presented in §59.504. If you are a distributor that has specified formulations to be used by a manufacturer, then you are a regulated entity responsible for compliance with all sections of this subpart.

(3) If there is no distributor named on the label, then the manufacturer or importer is a regulated entity responsible for compliance with all sections of this subpart.

(4) If you are a manufacturer, importer, or distributor, you can choose to certify that you will provide any or all of the recordkeeping and reporting requirements of §§59.510 and 59.511 by following the procedures of §59.511(g) and (h).

(c) Except as provided in paragraph (e) of this section, the provisions of this subpart apply to aerosol coatings manufactured on or after July 1, 2009, for sale or distribution in the United States. Aerosol coatings that are registered under the Federal Insecticide, Fungicide and Rodenticide Act (7 U.S.C. 136-136y) (FIFRA). For FIFRA registered aerosol coatings, the provisions of this subpart apply to aerosol coatings manufactured on or after January 1, 2010, for sale or distribution in the United States.

(d) You are not a regulated entity under this subpart for the aerosol coatings products that you manufacture (in or outside of the United States) that are exclusively for sale outside the United States.

(e) If you meet the definition of small quantity manufacturer for a given year, the products you manufacture in that year are not subject to the PWR limits presented in §59.504 or the labeling requirements of §59.507. To qualify for this exemption, small aerosol coating manufacturers must comply with the applicable recordkeeping and reporting requirements in §§59.510 and 59.511.

(f) If you are a person who manufactures or processes aerosol coatings outside of the United States, you may qualify for the small quantity manufacturer exemption in paragraph (e) of this section if you meet the requirements of paragraphs (f)(1) through (f)(3) of this section.

(1) The total VOC by mass included in all aerosol coatings you manufacture, at all facilities, in a given calendar year, in the aggregate, is less than 7,500 kilograms.

(2) You comply with the recordkeeping and reporting requirements in §§59.510 and 59.511.

(3) You commit to and comply with the requirements of paragraphs (f)(3)(i) through (f)(3)(vii) of this section.

(i) You must submit an initial notification no later than July 31, 2009, or on or before the date that you start manufacturing aerosol coating products that are sold in the United States, whichever is later. This initial notification must state that you are a foreign manufacturer that is intending to qualify for the small quantity manufacturer exemption in paragraph (e) of this section, provide all of the information specified in §59.511(b), and provide all the information in paragraphs (f)(3)(i)(A) and (f)(3)(i)(B) of this section.

(A) The name, address, telephone number, and e-mail address of an agent located in the United States who will serve as your point of contact for communications with EPA.

(B) The address of each of your facilities that is manufacturing aerosol coatings for sale in the United States.

(ii) You must notify the Administrator of any changes in the information provided in your initial notification within 30 days following the change.

(iii) The agent identified above must maintain a copy of the compliance records specified in §59.510(b). Those records must be kept by the agent such that the agent will be able to provide the written report which must be submitted upon 60 days notice under §59.511(d) and able to make those records available for inspection and review under §59.511(e).

(iv) You must give any EPA inspector or auditor full, complete, and immediate access to your facilities and records to conduct inspections and audits of your manufacturing facilities.

(v) You must agree that United States substantive and procedural law shall apply to any civil or criminal enforcement action against you under this subpart, and that the forum for any civil or criminal enforcement action under this subpart shall be governed by the CAA, including the EPA administrative forum where allowed under the CAA.

(vi) Any person certifying any notification, report, or other communication from you to EPA must state in the certification that United States substantive and procedural law shall apply to any civil or criminal enforcement action against him or her under this subpart, and that the forum for any civil or criminal enforcement action under this section shall be governed by the CAA, including the EPA administrative forum where allowed under the CAA.

(vii) All reports and other communications with EPA must be in English. To the extent that you provide any documents as part of any report or other communication with EPA, an English language translation of that document must be provided with the report or communication.

[73 FR 15621, Mar. 24, 2008, as amended at 73 FR 15425, Mar. 24, 2008; 73 FR 78996, Dec. 24, 2008; 74 FR 29603, June 23, 2009]

§59.502 When do I have to comply with this subpart?

(a) Except as provided in §59.509 and paragraphs (b) and (c) of this section, you must be in compliance with all provisions of this subpart by July 1, 2009.

(b) The Administrator will consider issuance of a special compliance extension that extends the date of compliance until January 1, 2011, to regulated entities that have never manufactured, imported, or distributed aerosol coatings for sale or distribution in California that are in compliance with California's Regulation for Reducing Ozone Formed From Aerosol Coating Product Emissions, Title 17, California Code of Regulations, sections 94520-94528. In order to be considered for an extension of the compliance date, you must submit a special compliance extension application to the EPA Administrator no later than 90 days before the compliance date or within 90 days before the date that you first manufacture aerosol coatings, whichever is later. This application must contain the information in paragraphs (b)(1) through (b)(5) of this section. If a regulated entity remains unable to comply with the limits of this rule by January 1, 2011, the regulated entity may seek a variance in accordance with §59.509.

(1) Company name;

(2) A signed certification by a responsible company official that the regulated entity has not at any time manufactured, imported, or distributed for sale or distribution in California any product in any category listed in Table 1 of this subpart that complies with California's Regulation for Reducing Ozone Formed From Aerosol Coating Product Emissions, Title 17, California Code of Regulations, sections 94520-94528;

(3) A statement that the regulated entity will, to the extent possible within its reasonable control, take appropriate action to achieve compliance with this subpart by January 1, 2011;

(4) A list of the product categories in Table 1 of this subpart that the regulated entity manufactures, imports, or distributes; and,

(5) Name, title, address, telephone, e-mail address, and signature of the certifying company official.

(c) Except as provided in paragraph (b) of this section, the compliance date for aerosol coatings that are registered under the Federal Insecticide, Fungicide and Rodenticide Act (7 U.S.C 136-136y) (FIFRA) is January 1, 2010.

[73 FR 15621, Mar. 24, 2008, as amended at 73 FR 78997, Dec. 24, 2008]

§59.503 What definitions apply to this subpart?

The following terms are defined for the purposes of this subpart only.

Administrator means the Administrator of the United States Environmental Protection Agency (EPA) or an authorized representative.

Aerosol Coating Product means a pressurized coating product containing pigments or resins that is dispensed by means of a propellant and is packaged in a disposable can for hand-held application, or for use in specialized equipment for ground traffic/marking applications. For the purpose of this regulation, applicable aerosol coatings categories are listed in Table 1 of this subpart.

Art Fixative or Sealant means a clear coating, including art varnish, workable art fixative and ceramic coating, which is designed and labeled exclusively for application to paintings, pencil, chalk, or pastel drawings, ceramic art pieces or other closely related art uses, in order to provide a final protective coating or to fix preliminary stages of artwork while providing a workable surface for subsequent revisions.

ASTM means the American Society for Testing and Materials.

Autobody Primer means an automotive primer or primer surfacer coating designed and labeled exclusively to be applied to a vehicle body substrate for the purposes of corrosion resistance and building a repair area to a condition in which, after drying, it can be sanded to a smooth surface.

Automotive Bumper and Trim Product means a product, including adhesion promoters and chip sealants, designed and labeled exclusively to repair and refinish automotive bumpers and plastic trim parts.

Aviation Propeller Coating means a coating designed and labeled exclusively to provide abrasion resistance and corrosion protection for aircraft propellers.

Aviation or Marine Primer means a coating designed and labeled exclusively to meet federal specification TT-P-1757.

Clear Coating means a coating which is colorless, containing resins but no pigments except flatting agents, and is designed and labeled to form a transparent or translucent solid film.

Coating Solids means the nonvolatile portion of an aerosol coating product, consisting of the film-forming ingredients, including pigments and resins.

Commercial Application means the use of aerosol coating products in the production of goods, or the providing of services for profit, including touch-up and repair.

Corrosion Resistant Brass, Bronze, or Copper Coating means a clear coating designed and labeled exclusively to prevent tarnish and corrosion of uncoated brass, bronze, or copper metal surfaces.

Distributor means any person who purchases or is supplied aerosol coating product for the purposes of resale or distribution in commerce. Retailers who fall within this definition are distributors. Importers are not distributors.

Enamel means a coating which cures by chemical cross-linking of its base resin and is not resoluble in its original solvent.

Engine Paint means a coating designed and labeled exclusively to coat engines and their components.

Exact Match Finish, Engine Paint means a coating which meets all of the following criteria:

(1) The product is designed and labeled exclusively to exactly match the color of an original, factory-applied engine paint;

(2) The product is labeled with the manufacturer's name for which they were formulated; and

(3) The product is labeled with one of the following:

(i) The original equipment manufacturer's (O.E.M.) color code number;

(ii) The color name; or

(iii) Other designation identifying the specific O.E.M. color to the purchaser.

Exact Match Finish, Automotive means a topcoat which meets all of the following criteria:

(1) The product is designed and labeled exclusively to exactly match the color of an original, factory-applied automotive coating during the touch-up of automobile finishes;

(2) The product is labeled with the manufacturer's name for which they were formulated; and

(3) The product is labeled with one of the following:

(i) The original equipment manufacturer's (O.E.M.) color code number;

(ii) The color name; or

(iii) Other designation identifying the specific O.E.M. color to the purchaser. Notwithstanding the foregoing, automotive clear coatings designed and labeled exclusively for use over automotive exact match finishes to replicate the original factory-applied finish shall be considered to be automotive exact match finishes.

Exact Match Finish, Industrial means a coating which meets all of the following criteria:

(1) The product is designed and labeled exclusively to exactly match the color of an original, factory-applied industrial coating during the touch-up of manufactured products;

(2) The product is labeled with the manufacturer's name for which they were formulated; and

(3) The product is labeled with one of the following:

(i) O.E.M. color code number;

(ii) The color name; or

(iii) Other designation identifying the specific O.E.M. color to the purchaser.

Flat Paint Products means a coating which, when fully dry, registers specular gloss less than or equal to 15 on an 85° gloss meter, or less than or equal to 5 on a 60° gloss meter, or which is labeled as a flat coating.

Flatting Agent means a compound added to a coating to reduce the gloss of the coating without adding color to the coating.

Floral Spray means a coating designed and labeled exclusively for use on fresh flowers, dried flowers, or other items in a floral arrangement for the purposes of coloring, preserving or protecting their appearance.

Formulation Data, unless otherwise specified, means the recipe used to formulate or manufacture a coating product in terms of the weight fraction (g compound/g product) of each individual VOC in the product.

Fluorescent Coating means a coating labeled as such, which converts absorbed incident light energy into emitted light of a different hue.

Glass Coating means a coating designed and labeled exclusively for use on glass or other transparent material to create a soft, translucent light effect, or to create a tinted or darkened color while retaining transparency.

Ground Traffic/Marking Coating means a coating designed and labeled exclusively to be applied to dirt, gravel, grass, concrete, asphalt, warehouse floors, or parking lots. Such coatings must be in a container equipped with a valve and spray head designed to direct the spray toward the surface when the can is held in an inverted vertical position.

High Temperature Coating means a coating, excluding engine paint, which is designed and labeled exclusively for use on substrates which will, in normal use, be subjected to temperatures in excess of 400°F.

Hobby/Model/Craft Coating means a coating which is designed and labeled exclusively for hobby applications and is sold in aerosol containers of 6 ounces by weight or less.

Importer means any person who brings an aerosol coating product that was manufactured, filled, or packaged at a location outside of the United States into the United States for sale or distribution in the United States.

Ingredient means a component of an aerosol coating product.

Impurity means an individual chemical compound present in a raw material which is incorporated in the final aerosol coatings formulation, if the compound is present in amounts below the following in the raw material:

(1) For individual compounds that are carcinogens each compound must be present in an amount less than 0.1 percent by weight;

(2) For all other compounds present in a raw material, a compound must be present in an amount less than 1 percent by weight.

Lacquer means a thermoplastic film-forming material dissolved in organic solvent, which dries primarily by solvent evaporation, and is resoluble in its original solvent.

Manufacturer means any person who manufactures or processes an aerosol coating product for sale or distribution within the United States. Manufacturers include:

(1) Processors who blend and mix aerosol coatings;

(2) Contract fillers who develop formulas and package these formulations under a distributor's name; and

(3) Contract fillers who manufacture products using formulations provided by a distributor.

Marine Spar Varnish means a coating designed and labeled exclusively to provide a protective sealant for marine wood products.

Metallic Coating means a topcoat which contains at least 0.5 percent by weight elemental metallic pigment in the formulation, including propellant, and is labeled as “metallic,” or with the name of a specific metallic finish such as “gold,” “silver,” or “bronze.”

Multi-Component Kit means an aerosol spray paint system which requires the application of more than one component (e.g. foundation coat and topcoat), where both components are sold together in one package.

Nonflat Paint Product means a coating which, when fully dry, registers a specular gloss greater than 15 on an 85° gloss meter or greater than five on a 60° gloss meter.

Ozone means a colorless gas with a pungent odor, having the molecular form O3.

Person means an individual, corporation, partnership, association, state, any agency, department, or instrumentality of the United States, and any officer, agent, or employee thereof.

Photograph Coating means a coating designed and labeled exclusively to be applied to finished photographs to allow corrective retouching, protection of the image, changes in gloss level, or to cover fingerprints.

Pleasure Craft means privately owned vessels used for noncommercial purposes.

Pleasure Craft Finish Primer/Surfacer/Undercoater means a coating designed and labeled exclusively to be applied prior to the application of a pleasure craft topcoat for the purpose of corrosion resistance and adhesion of the topcoat, and which promotes a uniform surface by filling in surface imperfections.

Pleasure Craft Topcoat means a coating designed and labeled exclusively to be applied to a pleasure craft as a final coat above the waterline and below the waterline when stored out of water. This category does not include clear coatings.

Polyolefin Adhesion Promoter means a coating designed and labeled exclusively to be applied to a polyolefin or polyolefin copolymer surface of automotive body parts, bumpers, or trim parts to provide a bond between the surface and subsequent coats.

Primer means a coating labeled as such, which is designed to be applied to a surface to provide a bond between that surface and subsequent coats.

Product-Weighted Reactivity (PWR) Limit means the maximum allowed “product-weighted reactivity,” as calculated in §59.505, of an aerosol coating product that is subject to the limits specified in §59.504 for a specific category, expressed as grams of ozone per gram (g O3/g of product).

Propellant means a liquefied or compressed gas that is used in whole or in part, such as a co-solvent, to expel a liquid or any other material from the same self-pressurized container or from a separate container.

Reactivity Factor (RF) is a measure of the change in mass of ozone formed by adding a gram of a VOC to the ambient atmosphere, expressed to hundredths of a gram (g O3/g VOC). The RF values for individual compounds and hydrocarbon solvent mixtures are specified in Tables 2A, 2B, and 2C of this subpart.

Retailer means any person who sells, supplies, or offers aerosol coating products for sale directly to consumers. Retailers who fall within the definition of “distributor” in this section are distributors.

Retail Outlet means any establishment where consumer products are sold, supplied, or offered for sale, directly to consumers.

Shellac Sealer means a clear or pigmented coating formulated solely with the resinous secretion of the lac beetle (Laccifer lacca), thinned with alcohol, and formulated to dry by evaporation without a chemical reaction.

Slip-Resistant Coating means a coating designed and labeled exclusively as such, which is formulated with synthetic grit and used as a safety coating.

Small quantity manufacturer means a manufacturer whose total VOC by mass included in all aerosol coatings manufactured at all facilities in a given calendar year, in the aggregate, is less than 7,500 kilograms.

Spatter Coating/Multicolor Coating means a coating labeled exclusively as such wherein spots, globules, or spatters of contrasting colors appear on or within the surface of a contrasting or similar background.

Stain means a coating which is designed and labeled to change the color of a surface but not conceal the surface.

United States means the United States of America, including the District of Columbia, the Commonwealth of Puerto Rico, the Virgin Islands, Guam, American Samoa, and the Commonwealth of the Northern Mariana Islands.

Vinyl/Fabric/Leather/Polycarbonate Coating means a coating designed and labeled exclusively to coat vinyl, fabric, leather, or polycarbonate substrates or to coat flexible substrates including rubber or thermoplastic substrates.

Volatile Organic Compound (VOC) means any organic compound as defined in §51.100(s) of this chapter. As provided in 40 CFR 51.100(s)(7), exemptions from the definition of VOC in 40 CFR 51.100(s) for certain compounds that are used in aerosol coatings are inapplicable for purposes of this subpart.

Webbing/Veiling Coating means a coating designed and labeled exclusively to provide a stranded to spider webbed appearance when applied.

Weight Fraction means the weight of an ingredient divided by the total net weight of the product, expressed to thousandths of a gram of ingredient per gram of product (excluding container and packaging).

Weld-Through Primer means a coating designed and labeled exclusively to provide a bridging or conducting effect for corrosion protection following welding.

Wood Stain means a coating which is formulated to change the color of a wood surface but not conceal the surface.

Wood Touch-Up/Repair/Restoration means a coating designed and labeled exclusively to provide an exact color or sheen match on finished wood products.

Working Day means any day from Monday through Friday, inclusive, except for days that are Federal holidays.

§59.504 What limits must I meet?

(a) Except as provided in §59.509, each aerosol coating product you manufacture, distribute or import for sale or use in the United States must meet the PWR limits presented in Table 1 of this subpart. These limits apply to the final aerosol coating, including the propellant. The PWR limits specified in Table 1 of this subpart are also applicable to any aerosol coating product that is assembled by adding bulk coating to aerosol containers of propellant.

(b) If a product can be included in both a general coating category and a specialty coating category and the product meets all of the criteria of the specialty coating category, then the specialty coating limit will apply instead of the general coating limit, unless the product is a high temperature coating. High-temperature coatings that contain at least 0.5 percent by weight of an elemental metallic pigment in the formulation, including propellant, are subject to the limit specified for metallic coatings.

(c) Except as provided in paragraph (b) of this section, if anywhere on the container of any aerosol coating product subject to the limits in Table 1 of this subpart, or on any sticker or label affixed to such product, or in any sales or advertising literature, the manufacturer, importer or distributor of the product makes any representation that the product may be used as, or is suitable for use as a product for which a lower limit is specified, then the lowest applicable limit will apply.

§59.505 How do I demonstrate compliance with the reactivity limits?

(a) To demonstrate compliance with the PWR limits presented in Table 1 of this subpart, you must calculate the PWR for each coating as described in paragraphs (a)(1) through (2) of this section:

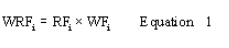

(1) Calculate the weighted reactivity factor (WRF) for each propellant and coating component using Equation 1:

Where:

WRFi = weighted reactivity factor of component i, g O3/g component i.

RFi = reactivity factor of component i, g O3/g component i, from Table 2A, 2B, or 2C.

WFi = weight fraction of component i in the product,

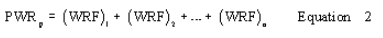

(2) Calculate the PWR of each product using Equation 2:

Where:

PWRp = PWR for product P, g O3/g product.

WRF1 = weighted reactivity factor for component 1, g O3/g component.

WRF2 = weighted reactivity factor for component 2, g O3/g component.

WRFn = weighted reactivity factor for component n, g O3/g component.

(b) In calculating the PWR, you must follow the guidelines in paragraphs (b)(1) through (b)(4) of this section.

(1) Any ingredient which does not contain carbon is assigned a RF value of 0.

(2) Any aerosol coating solid, including but not limited to resins, pigments, fillers, plasticizers, and extenders is assigned a RF of 0. These items do not have to be identified individually in the calculation.

(3) All individual compounds present in the coating in an amount equal to or exceeding 0.1 percent will be considered ingredients regardless of whether or not the ingredient is reported to the manufacturer.

(4) All individual compounds present in the coating in an amount less than 0.1 percent will be assigned an RF value of 0.

(5) Any component that is a VOC but is not listed in Table 2A, 2B, or 2C of this subpart is assigned an RF value as detailed in paragraph (e) of this section.

(c) You may use either formulation data (including information for both the liquid and propellant phases), California Air Resources Board Method 310 - Determination of Volatile Organic Compounds (VOC) in Consumer Products and Reactive Organic Compounds in Aerosol Coating Products (May 5, 2005) (incorporated by reference in 59.515), or EPA's Method 311 - Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (40 CFR part 63, appendix A), to calculate the PWR. However, if there are inconsistencies between the formulation data and the California Air Resources Board Method 310 (May 5, 2005) (incorporated by reference in 59.515), or EPA Method 311 - Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (40 CFR part 63, appendix A) results, the California Air Resources Board Method 310 (May 5, 2005) (incorporated by reference in 59.515), or EPA Method 311 - Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (40 CFR part 63, appendix A) results will govern.

(d) If you manufacture a coating containing either an aromatic or aliphatic hydrocarbon solvent mixture, you must use the appropriate RF for that mixture provided in Table 2B or 2C of this subpart when calculating the PWR using formulation data. However, when calculating the PWR for a coating containing these mixtures using data from California Air Resources Board Method 310 (May 5, 2005) (incorporated by reference in 59.515), or EPA Method 311 - Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (40 CFR part 63, appendix A), you must identify the individual compounds that are present in the solvent mixture and use the weight fraction of those individual compounds and their RF from Table 2A of this subpart in the calculation.

(e) If a VOC is used in a product but not listed in Table 2A of this subpart, the Reactivity Factor (RF) is assigned according to paragraphs (e)(1), (e)(2), (e)(3) or (e)(4) of this section.

(1) If the VOC is not listed in Table 2A of this subpart, but has an RF greater than 0.3, the regulated entity may petition EPA to add the VOC to Table 2A, as described in §59.511(j). Based on these petitions, EPA will periodically update the appropriate table. Once an RF for a VOC is listed on the appropriate table, that RF will be used for that VOC for the purposes of this rule. As provided in §59.511(j), any petitions submitted to EPA on or before June 1, 2008, will be considered, and if appropriate, incorporated into Table 2A on or before January 1, 2009.

(2) If the VOC is used in a product but not listed in Table 2A of this regulation, and has an RF less than or equal to 0.3, and will be used at a level greater than or equal to 7.3 weight percent (g of compound/g product) in any of the regulated entity's formulations, the regulated entity may petition EPA as described in §59.511(j). Based on these petitions, EPA will periodically update the appropriate table. Once an RF for a VOC is listed on the appropriate table, that RF will be used for that VOC for the purposes of this rule. As provided in §59.511(j), any petition submitted to EPA on or before June 1, 2008 will be considered, and if appropriate, incorporated into Table 2A on or before January 1, 2009.

(3) If a compound has an RF less than or equal to 0.3, and will not be used at a level greater than or equal to 7.3 weight percent (g of compound/g product) in any of the regulated entity's formulations, the RF to be used in all calculations by that entity for this subpart is 0.

(4) Except as provided in paragraph (e)(1), (e)(2) and (e)(3) of this section, if a VOC is not listed in Table 2A of this subpart, it is assigned a default RF factor of 22.04 g O3/g VOC. As described in §59.511(j), regulated entities may petition the Administrator to add a compound or mixture to Table 2A, 2B, or 2C of this subpart.

(f) In calculating the PWR value for a coating containing an aromatic hydrocarbon solvent with a boiling range different from the ranges specified in Table 2C of this subpart, you must assign an RF as described in paragraphs (f)(1) and (f)(2) of this section:

(1) If the solvent boiling point is lower than or equal to 420 degrees F, then you must use the RF in Table 2C of this subpart specified for bin 23;

(2) If the solvent boiling point is higher than 420 degrees F, then you must use the RF specified in Table 2C of this subpart for bin 24.

(g) For purposes of compliance with the PWR limits, all compounds listed in Tables 2A, 2B, or 2C that are used in the aerosol coating products must be included in the calculation. This includes compounds that may otherwise be exempted from the definition of VOC in §59.100(s).

§59.506 How do I demonstrate compliance if I manufacture multi-component kits?

(a) If you manufacture multi-component kits as defined in §59.503, then the Kit PWR must not exceed the Total Reactivity Limit.

(b) You must calculate the Kit PWR and the Total Reactivity Limit as follows:

(1) KIT PWR = (PWR(1) × W1) (PWR(2) × W2) . ... (PWR(n) × Wn)

(2) Total Reactivity Limit = (RL1 × W1) (RL2 × W2) ... (RLn × Wn).

(3) Kit PWR ≤Total Reactivity Limit.

Where:

W = the weight of the product contents (excluding container).

RL = the PWR Limit specified in Table 1 of this subpart.

Subscript 1 denotes the first component product in the kit.

Subscript 2 denotes the second component product in the kit.

Subscript n denotes any additional component product.

§59.507 What are the labeling requirements for aerosol coatings?

(a) The labels of all aerosol products manufactured on and after the applicable compliance date listed in §59.502 must contain the information listed in paragraphs (a)(1) through (4) of this section.

(1) The aerosol coating category code for the coating, based on the category definitions in §59.503. This code can be the default category code shown in Table 1 of this subpart or a company-specific code, if that code is explained as required by §59.511(a);

(2) The applicable PWR limit for the product specified in Table 1 of this subpart;

(3) The day, month, and year on which the product was manufactured, or a code indicating such date;

(4) The name and a contact address for the manufacturer, distributor, or importer that is the regulated entity under this subpart.

(b) The label on the product must be displayed in such a manner that it is readily observable without removing or disassembling any portion of the product container or packaging. The information may be displayed on the bottom of the container as long as it is clearly legible without removing any product packaging.

§59.508 What test methods must I use?

(a) Except as provided in §59.505(c), you must use the procedures in California Air Resource Board Method 310 - Determination of Volatile Organic Compounds (VOC) in Consumer Products and Reactive Organic Compounds in Aerosol Coating Products (May 5, 2005) (incorporated by reference in §59.515) or EPA's Method 311 - Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (40 CFR part 63, appendix A) to determine the speciated ingredients and weight percentage of each ingredient of each aerosol coating product. EPA Method 311 - Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (40 CFR part 63, appendix A) must be used in conjunction with ASTM Method D3063-94 or D3074-94 for analysis of the propellant portion of the coating. Those choosing to use California Air Resources Board Method 310 (May 5, 2005) (incorporated by reference in §59.515) must follow the procedures specified in section 5.0 of that method with the exception of section 5.3.1, which requires the analysis of the VOC content of the coating. For the purposes of this subpart, you are not required to determine the VOC content of the aerosol coating. For both California Air Resources Board Method 310 (May 5, 2005) (incorporated by reference in §59.515) and EPA Method 311 - Analysis of Hazardous Air Pollutant Compounds in Paints and Coatings by Direct Injection into a Gas Chromatograph (40 CFR part 63, appendix A), you must have a listing of the VOC ingredients in the coating before conducting the analysis.

(b) To determine the metal content of metallic aerosol coating products, you must use South Coast Air Quality Management District (SCAQMD) Method 318-95, Determination of Weight Percent Elemental Metal in Coatings by X-ray Diffraction, July, 1996, in 40 CFR part 59 (incorporated by reference in §59.515).

To determine the specular gloss of flat and nonflat coatings you must use ASTM Method D523-89 (Reapproved 1999), Standard Test Method for Specular Gloss, in 40 CFR part 59 (incorporated by reference in §59.515).

§59.509 Can I get a variance?

(a) Any regulated entity that cannot comply with the requirements of this subpart because of circumstances beyond its reasonable control may apply in writing to the Administrator for a temporary variance. The variance application must include the information specified in paragraphs (a)(1) through (a)(5) of this section.

(1) The specific products for which the variance is sought.

(2) The specific provisions of the subpart for which the variance is sought.

(3) The specific grounds upon which the variance is sought.

(4) The proposed date(s) by which the regulated entity will achieve compliance with the provisions of this subpart. This date must be no later than 3 years after the issuance of a variance.

(5) A compliance plan detailing the method(s) by which the regulated entity will achieve compliance with the provisions of this subpart.

(b) Within 30 days of receipt of the original application and within 30 days of receipt of any supplementary information that is submitted, the Administrator will send a regulated entity written notification of whether the application contains sufficient information to make a determination. If an application is incomplete, the Administrator will specify the information needed to complete the application, and provide the opportunity for the regulated entity to submit written supplementary information or arguments to the Administrator to enable further action on the application. The regulated entity must submit this information to the Administrator within 30 days of being notified that its application is incomplete.

(c) Within 60 days of receipt of sufficient information to evaluate the application, the Administrator will send a regulated entity written notification of approval or disapproval of a variance application. This 60-day period will begin after the regulated entity has been sent written notification that its application is complete.

(d) The Administrator will issue a variance if the criteria specified in paragraphs (d)(1) and (d)(2) of this section are met to the satisfaction of the Administrator.

(1) Complying with the provisions of this subpart would not be technologically or economically feasible.

(2) The compliance plan proposed by the applicant can reasonably be implemented and will achieve compliance as expeditiously as possible.

(e) A variance must specify dates by which the regulated entity will achieve increments of progress towards compliance, and will specify a final compliance date by which the regulated entity will achieve compliance with this subpart.

(f) A variance will cease to be effective upon failure of the party to whom the variance was issued to comply with any term or condition of the variance.

§59.510 What records am I required to maintain?

(a) If you are the regulated entity identified in §59.501(a) as being responsible for recordkeeping for a product, and no other person has certified that they will fulfill your recordkeeping responsibilities as provided in §59.511(g), you must comply with paragraphs (a)(1) through (a)(5) of this section:

(1) All records must be maintained on and after the applicable compliance date listed in §59.502.

(2) You are required to maintain records of the following at the location specified in §59.511(b)(4) for each product subject to the PWR limits in Table 1 of this subpart: The product category, all product calculations, the PWR, and the weight fraction of all ingredients including: Water, total solids, each VOC, and any other compounds assigned a RF of zero as specified in §59.505. Solids do not have to be listed individually in these records. If an individual VOC is present in an amount less than 0.1 percent by weight, then it does not need to be reported as an ingredient. An impurity that meets the definition provided in §59.503 does not have to be reported as an ingredient. For each batch of each product subject to the PWR limits, you must maintain records of the date the batch was manufactured, the volume of the batch, the recipe used for formulating the batch, and the number of cans manufactured in each batch and each formulation.

(3) You must maintain a copy of each notification and report that you submit to comply with this subpart, the documentation supporting each notification, and a copy of the label for each product.

(4) If you claim the exemption under §59.501(e), you must maintain a copy of the initial report and each annual report that you submit to EPA, and the documentation supporting such report.

(5) You must maintain all records required by this subpart for a minimum of 5 years. The records must be in a form suitable and readily available for inspection and review.

(b) By providing the written certification to the Administrator in accordance with §59.511(g), the certifying entity accepts responsibility for compliance with the recordkeeping requirements of this section with respect to any products covered by the written certification, as detailed in the written certification. Failure to maintain the required records may result in enforcement action by EPA against the certifying entity in accordance with the enforcement provisions applicable to violation of these provisions by regulated entities. If the certifying entity revokes its certification, as allowed by §59.511(h), the regulated entity must assume responsibility for maintaining all records required by this section.

[73 FR 15621, Mar. 24, 2008, as amended at 74 FR 29603, June 23, 2009]

§59.511 What notifications and reports must I submit?

(a) If you are the regulated entity identified in §59.501(a) and (b) as being responsible for notifications and reporting for a product, and no other person has certified that they will fulfill your notification and reporting responsibilities as provided in paragraph (g) of this section, you are responsible for all notifications and reports included in this section. If no distributor is named on the label, the manufacturer or importer of the aerosol coating is responsible for all requirements of this section, even if not listed on the label.

(b) You must submit an initial notification no later than July 31, 2009, or on or before the date that you first manufacture, distribute, or import aerosol coatings, whichever is later. The initial notification must include the information in paragraphs (b)(1) through (b)(11) of this section.

(1) Company name;

(2) Name, title, address, telephone number, e-mail address and signature of certifying company official;

(3) A list of the product categories from Table 1 of this subpart that you manufacture, import, or distribute;

(4) The street address of each of your facilities in the United States that is manufacturing, packaging, or importing aerosol coatings that are subject to the provisions of this subpart, and the street address where compliance records are maintained for each site, if different;

(5) A description of date coding systems, clearly explaining how the date of manufacture is marked on each sales unit;

(6) An explanation of the product category codes that will be used on all required labels, or a statement that the default category codes in Table 1 of this subpart will be used;

(7) For each product category, an explanation of how the manufacturer, distributor, or importer will define a batch for the purpose of the recordkeeping requirements;

(8) A list of any compounds or mixtures that will be used in aerosol coatings that are not included in Table 2A, 2B, or 2C of this subpart;

(9) For each product category, VOC formulation data for each formulation that you anticipate manufacturing, importing, or distributing for calendar year 2009 or for the first year that includes your compliance date, if different than 2009. If a regulated entity can certify that the reporting is being completed by another regulated entity for any product, no second report is required. The formulation data must include the weight fraction (g compound/g product) for each VOC ingredient used in the product in an amount greater than or equal to 0.1 percent. The formulation data must also include the information in either paragraph (b)(9)(i) or (b)(9)(ii) of this section for each VOC ingredient reported.

(i) For compounds listed in Table 2A of this regulation, the chemical name, CAS number, and the applicable reactivity factor; or

(ii) For hydrocarbon solvent mixtures listed in either 2B or 2C or this subpart, the trade name, solvent mixture manufacturer, bin number, and the applicable reactivity factor.

(10) For each product formulation, a list of the unique product codes by Universal Product Code (UPC), or other unique identifier; and

(11) A statement certifying that all products manufactured by the company that are subject to the limits in Table 1 of this subpart will be in compliance with those limits.

(c) If you change any information included in the initial notification required by paragraph (b) of this section, including the list of aerosol categories, contact information, records location, the category or date coding system, or the list required under paragraph (b)(8) of this section, you must notify the Administrator of such changes within 30 days following the change. You are also required to notify the Administrator within 30 days of the date that you begin using an organic compound in any of your aerosol coating products if that compound has an RF less than or equal to 0.3, and is used at a level greater than or equal to 7.3 weight percent (g of compound/g product) in any of your formulations. You are not required to notify the Administrator within 30 days of changes to the information provided as required by paragraph (b)(9) of this section. Changes in formulation are to be reported in the triennial reporting required by paragraph (i) of this section.

(d) Upon 60 days written notice, you must submit to the Administrator a written report with all the information in paragraphs (d)(1) through (d)(5) of this section for each product you manufacture, distribute, or import under your name or another company's name.

(1) The brand name of the product;

(2) A copy of the product label;

(3) The owner of the trademark or brand names;

(4) The product category as defined in §59.503;

(5) For each product, formulation data for each formulation that manufactured, imported, or distributed in the requested time period. The formulation data must include the weight fraction (g compound/g product) for each VOC ingredient used in the product in an amount greater than or equal to 0.1 percent, plus the weight fraction of all other ingredients including: Water, total solids, and any other compounds assigned an RF of zero. The formulation data must also include the information in either paragraph (d)(5)(i) or (ii) of this section.

(i) For compounds listed in Table 2A of this subpart, the chemical name, CAS number, and the applicable reactivity factor.

(ii) For hydrocarbon solvent mixtures listed in either 2B or 2C or this table, the trade name, solvent mixture manufacturer, bin number, and the applicable reactivity factor.

(e) If you claim the exemption under §59.501(e), you must submit an initial notification no later than July 31, 2009, or on or before the date that you first manufacture aerosol coatings, whichever is later.The initial notification must include the information in paragraphs (e)(1) through (e)(6) of this section.

(1) Company name;

(2) Name, title, number, address, telephone number, e-mail address, and signature of certifying company official;

(3) A list of the product categories from Table 1 of this subpart that you manufacture;

(4) The total amount of product you manufacture in each category and the total VOC mass content of such products for the preceding calendar year;

(5) The street address of each of your facilities in the United States that is manufacturing aerosol coatings that are subject to the provisions of this subpart and the street address where compliance records are maintained for each site, if different; and

(6) A list of the States in which you sell or otherwise distribute the products you manufacture.

(f) If you claim the exemption under §59.501(e), you must file an annual report for each year in which you claim an exemption from the limits of this subpart. Such annual report must be filed by March 1 of the year following the year in which you manufactured the products. The annual report shall include the same information required in paragraphs (e)(1) through (e)(6) of this section.

(g) If you are a manufacturer, importer, or distributor who chooses to certify that you will maintain records for a regulated entity for all or part of the purposes of §59.510 and this section, you must submit a notice to the appropriate EPA Regional Office listed in §59.512. At the same time that this notice is sent to the appropriate EPA Regional Office, a copy of the notice must be sent to the regulated entity for which you are accepting responsibility for recordkeeping and reporting requirements. After the certifying entity submits this notice to the appropriate EPA Regional Office, both the certifying entity and the regulated entity are liable for any failure to keep records or submit records and for any inaccurate records or reports covered by the notice, and one or both may be subject to an enforcement action in accordance with the enforcement provisions applicable to violation of these provisions. This notice must include the information contained in paragraphs (g)(1) though (g)(5) of this section.

(1) Name and address of certifying entity;

(2) Name and address(es) of the regulated entity for which you are accepting responsibility;

(3) Description of specific requirements in §59.510 and this section for which you are assuming responsibility and explanation of how all required information under this subpart will be maintained and submitted, as required, by you or the regulated entity; including identification of the products covered by the notice and the location or locations where the records will be maintained;

(4) A statement that the certifying entity understands that the failure to fulfill the responsibilities that it is assuming may result in an enforcement action against it in accordance with the enforcement provisions applicable to violation of these provisions by regulated entities; and

(5) The signature of the responsible official for the certifying entity.

(h) An entity that has provided certification under paragraph (g) of this section (the “certifying entity”) may revoke the written certification by sending a written statement to the appropriate Regional Office listed in §59.512 and to the regulated entity for which the certifying had accepted responsibility, giving a minimum of 90 days notice that the certifying entity is rescinding acceptance of responsibility for compliance with the requirements outlined in the certification letter. Upon expiration of the notice period, the regulated entity must assume responsibility for all applicable requirements.

(i) As a regulated entity in accordance with paragraph (a) of this section, you must provide the information requested in paragraphs (i)(1) through (i)(4) of this section every three years beginning in 2011 for reporting year 2010. The report shall be submitted by March 31 of the year following the reporting year to the appropriate Regional Office listed in §59.512. The first report is due March 31, 2011, for calendar year 2010.

(1) All identification information included in paragraphs (b)(1), (b)(2), and (b)(4) of this section;

(2) For each product category, VOC formulation data for each formulation that was manufactured, imported, or distributed in the reporting year. The formulation data must include the weight fraction (g compound/g product) for each VOC ingredient used in the product in an amount equal to or greater than 0.1 percent. If a regulated entity can certify that the reporting is being completed by another regulated entity for any product, no second report is required. The formulation data must include the information in either paragraph (i)(2)(i) or (i)(2)(ii) of this section for each VOC present in an amount greater than or equal to 0.1 percent.

(i) For compounds listed in Table 2A of this subpart, the chemical name, CAS number, and the applicable reactivity factor; or

(ii) For hydrocarbon solvent mixtures listed in either 2B or 2C of this subpart, the trade name, solvent mixture manufacturer, bin number, and the applicable reactivity factor.

(3) For each formulation, the total mass of each individual VOC species present in an amount greater than or equal to 0.1 percent of the formulation, that was manufactured, imported, or distributed in the reporting year; and

(4) For each formulation, a list of the individual product codes by UPC or other unique identifier.

(j) If a regulated entity identifies a VOC that is needed for an aerosol formulation that is not listed in Tables 2A, 2B, or 2C of this subpart, it is assigned a default RF factor of 22.04 g O3/g VOC. Regulated entities may petition the Administrator to add a compound to Table 2A, 2B, or 2C of this subpart. Petitions must include the chemical name, CAS number, a statement certifying the intent to use the compound in an aerosol coatings product, and adequate information for the Administrator to evaluate the reactivity of the compound and assign a RF value consistent with the values for the other compounds listed in Table 2A of this subpart. Any requests submitted to EPA on or before June 1, 2008 will be considered and, if appropriate, incorporated into Table 2A, 2B, or 2C of this subpart on or before January 1, 2009.

[73 FR 15621, Mar. 24, 2008, as amended at 73 FR 78997, Dec. 24, 2008; 74 FR 29604, June 23, 2009]

§59.512 Addresses of EPA regional offices.

All requests (including variance requests), reports, submittals, and other communications to the Administrator pursuant to this regulation shall be submitted to the Regional Office of the EPA which serves the State or territory for the address that is listed on the aerosol coating product in question. These areas are indicated in the following list of EPA Regional Offices.

EPA Region I (Connecticut, Maine, Massachusetts, New Hampshire, Rhode Island, Vermont) Director, Enforcement and Compliance Assurance Division, U.S. EPA Region I, 5 Post Office Square—Suite 100 (04-2), Boston, MA 02109-3912, Attn: Air Compliance Clerk.

EPA Region II (New Jersey, New York, Puerto Rico, Virgin Islands), Director, Division of Enforcement and Compliance Assistance, 290 Broadway, New York, NY 10007-1866.

EPA Region III (Delaware, District of Columbia, Maryland, Pennsylvania, Virginia, West Virginia), Air Protection Division, 1650 Arch Street, Philadelphia, PA 19103.

EPA Region IV (Alabama, Florida, Georgia, Kentucky, Mississippi, North Carolina, South Carolina, Tennessee), Director, Air Pesticides and Toxics, Management Division, Atlanta Federal Center, 61 Forsyth Street, SW., Atlanta, GA 30303-3104.

EPA Region V (Illinois, Indiana, Michigan, Minnesota, Ohio, Wisconsin), Director, Air and Radiation Division, 77 West Jackson Blvd., Chicago, IL 60604-3507.

EPA Region VI (Arkansas, Louisiana, New Mexico, Oklahoma, Texas), Director, Air, Pesticides and Toxics Division, 1445 Ross Avenue, Dallas, TX 75202-2733.

EPA Region VII (Iowa, Kansas, Missouri, Nebraska), Director, Air and Waste Management Division, 11201 Renner Boulevard, Lenexa, Kansas 66219.

EPA Region VIII (Colorado, Montana, North Dakota, South Dakota, Utah, Wyoming), Director, Air and Toxics Division, 1595 Wynkoop Street, Denver, CO 80202-1129.

EPA Region IX (American Samoa, Arizona, California, Guam, Hawaii, Nevada), Director, Air Division, 75 Hawthorne Street, San Francisco, CA 94105.

EPA Region X (Alaska, Oregon, Idaho, Washington), Director, Air and Toxics Division, 1200 Sixth Avenue, Seattle, WA 98101.

[73 FR 15621, Mar. 24, 2008, as amended at 74 FR 29604, June 23, 2009; 76 FR 49672, Aug. 11, 2011; 78 FR 37976, June 25, 2013; 84 FR 34068, July 17, 2019]

§59.513 State authority.

The provisions in this regulation will not be construed in any manner to preclude any State or political subdivision thereof from:

(a) Adopting and enforcing any emission standard or limitation applicable to a manufacturer, distributor or importer of aerosol coatings or components in addition to the requirements of this subpart.

(b) Requiring the manufacturer, distributor or importer of aerosol coatings or components to obtain permits, licenses, or approvals prior to initiating construction, modification, or operation of a facility for manufacturing an aerosol coating or component.

§59.514 Circumvention.

Each manufacturer, distributor, and importer of an aerosol coating or component subject to the provisions of this subpart must not alter, destroy, or falsify any record or report, to conceal what would otherwise be noncompliance with this subpart. Such concealment includes, but is not limited to, refusing to provide the Administrator access to all required records and date-coding information, misstating the PWR content of a coating or component batch, or altering the results of any required tests to determine the PWR.

§59.515 Incorporations by reference.

(a) The following material is incorporated by reference (IBR) in the paragraphs noted in §59.508. These incorporations by reference were approved by the Director of the Federal Register in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. These materials are incorporated as they exist on the date of approval, and notice of any changes in these materials will be published in the Federal Register.

(1) California Air Resources Board Method 310 - Determination of Volatile Organic Compounds (VOC) in Consumer Products and Reactive Organic Compounds in Aerosol Coating Products (May 5, 2005), IBR approved for §59.508.

(2) South Coast Air Quality Management District (SCAQMD) Test Method 318-95, Determination of Weight Percent Elemental Metal in Coatings by X-ray Diffraction, (July, 1996), IBR approved for §59.508.

(3) ASTM Method D523-89 (Reapproved 1999), Standard Test Method for Specular Gloss, IBR approved for §59.508.

(b) You may obtain and inspect the materials at the Air and Radiation Docket and Information Center, U.S. EPA, 401 M Street, SW., Washington, DC; the EPA Library, 109 T.W. Alexander Drive, U.S. EPA, Research Triangle Park, North Carolina; you may inspect the materials at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030, or go to http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

[73 FR 15621, Mar. 24, 2008, as amended at 77 FR 14283, Mar. 9, 2012]

§59.516 Availability of information and confidentiality.

(a) Availability of information. The availability to the public of information provided to or otherwise obtained by the Administrator under this part shall be governed by part 2 of this chapter.

(b) Confidentiality. All confidential business information entitled to protection under section 114(c) of the Clean Air Act (CAA) that must be submitted or maintained by each regulated entity pursuant to this subpart shall be treated in accordance with 40 CFR part 2, subpart B.

(c) Reports and Applications. The content of all reports and applications required to be submitted to the Agency under §59.511, §59.509, or §59.502 are not entitled to protection under Section 114(c) of the CAA.

Table 1 to Subpart E of Part 59 - Product-Weighted Reactivity Limits by Coating Category

| Coating category | Category code a | Reactivity limit (g O3/g product) |

|---|---|---|

| a Regulated entities may use these category codes or define their own in accordance with §59.511(b)(6). | ||

| Clear Coatings | CCP | 1.50 |

| Flat Coatings | FCP | 1.20 |

| Fluorescent Coatings | FLP | 1.75 |

| Metallic Coatings | MCP | 1.90 |

| Non-Flat Coatings | NFP | 1.40 |

| Primers | PCP | 1.20 |

| Ground Traffic/Marking | GTM | 1.20 |

| Art Fixatives or Sealants | AFS | 1.80 |

| Auto Body Primers | ABP | 1.55 |

| Automotive Bumper and Trim Products | ABT | 1.75 |

| Aviation or Marine Primers | AMP | 2.00 |

| Aviation Propellor Coatings | APC | 2.50 |

| Corrosion Resistant Brass, Bronze, or Copper Coatings | CRB | 1.80 |

| Exact Match Finish - Engine Enamel | EEE | 1.70 |

| Exact Match Finish - Automotive | EFA | 1.50 |

| Exact Match Finish - Industrial | EFI | 2.05 |

| Floral Sprays | FSP | 1.70 |

| Glass Coatings | GCP | 1.40 |

| High Temperature Coatings | HTC | 1.85 |

| Hobby/Model/Craft Coatings, Enamel | HME | 1.45 |

| Hobby/Model/Craft Coatings, Lacquer | HML | 2.70 |

| Hobby/Model/Craft Coatings, Clear or Metallic | HMC | 1.60 |

| Marine Spar Varnishes | MSV | 0.90 |

| Photograph Coatings | PHC | 1.00 |

| Pleasure Craft Primers, Surfacers or Undercoaters | PCS | 1.05 |

| Pleasure Craft Topcoats | PCT | 0.60 |

| Polyolefin Adhesion Promoters | PAP | 2.50 |

| Shellac Sealers, Clear | SSC | 1.00 |

| Shellac Sealers, Pigmented | SSP | 0.95 |

| Slip-Resistant Coatings | SRC | 2.45 |

| Spatter/Multicolor Coatings | SMC | 1.05 |

| Vinyl/Fabric/Leather/Polycarbonate Coatings | VFL | 1.55 |

| Webbing/Veiling Coatings | WFC | 0.85 |

| Weld-Through Primers | WTP | 1.00 |

| Wood Stains | WSP | 1.40 |

| Wood Touch-up/Repair or Restoration Coatings | WTR | 1.50 |

[77 FR 14283, Mar. 9, 2012]

Table 2A to Subpart E of Part 59 - Reactivity Factors

| Compound | CAS No. | Reactivity factor (g O3/g VOC) |

|---|---|---|

| Formaldehyde | 50-00-0 | 8.97 |

| Glycerol (1,2,3-Propanetriol) | 56-81-5 | 3.27 |

| Propylene Glycol | 57-55-6 | 2.75 |

| Ethanol | 64-17-5 | 1.69 |

| Formic Acid | 64-18-6 | 0.08 |

| Acetic Acid | 64-19-7 | 0.71 |

| Methanol | 67-56-1 | 0.71 |

| Isopropyl Alcohol (2-Propanol) | 67-63-0 | 0.71 |

| Acetone (Propanone) | 67-64-1 | 0.43 |

| n-Propanol (n-Propyl Alcohol) | 71-23-8 | 2.74 |

| n-Butyl Alcohol (Butanol) | 71-36-3 | 3.34 |

| n-Pentanol (Amyl Alcohol) | 71-41-0 | 3.35 |

| Benzene | 71-43-2 | 0.81 |

| 1,1,1-Trichloroethane | 71-55-6 | 0.00 |

| Propane | 74-98-6 | 0.56 |

| Vinyl Chloride | 75-01-4 | 2.92 |

| Acetaldehyde | 75-07-0 | 6.84 |

| Methylene Chloride (Dichloromethane) | 75-09-2 | 0.07 |

| Ethylene Oxide | 75-21-8 | 0.05 |

| Isobutane | 75-28-5 | 1.35 |

| HFC-152A (1,1-Difluoroethane) | 75-37-6 | 0.00 |

| Propylene Oxide | 75-56-9 | 0.32 |

| t-Butyl Alcohol | 75-65-0 | 0.45 |

| Methyl t-Butyl Ketone | 75-97-8 | 0.78 |

| Isophorone (3,5,5-Trimethyl-2-Cyclohexenone) | 78-59-1 | 10.58 |

| Isopentane | 78-78-4 | 1.68 |

| Isobutanol | 78-83-1 | 2.24 |

| 2-Butanol (s-Butyl Alcohol) | 78-92-2 | 1.60 |

| Methyl Ethyl Ketone (2-Butanone) | 78-93-3 | 1.49 |

| Monoisopropanol Amine (1-Amino-2-Propanol) | 78-96-6 | 13.42 |

| Trichloroethylene | 79-01-6 | 0.60 |

| Propionic Acid | 79-09-4 | 1.16 |

| Acrylic Acid | 79-10-7 | 11.66 |

| Methyl Acetate | 79-20-9 | 0.07 |

| Nitroethane | 79-24-3 | 12.79 |

| Methacrylic Acid | 79-41-4 | 18.78 |

| a-Pinene (Pine Oil) | 80-56-8 | 4.29 |

| Methyl Methacrylate | 80-62-6 | 15.84 |

| Naphthalene | 91-20-3 | 3.26 |

| Xylene, ortho- | 95-47-6 | 7.49 |

| o-Cresol | 95-48-7 | 2.34 |

| 1,2,4-Trimethylbenzene | 95-63-6 | 7.18 |

| 3-Pentanone | 96-22-0 | 1.45 |

| Methyl Ethyl Ketoxime (Ethyl Methyl Ketone Oxime) | 96-29-7 | 22.04 |

| gamma-Butyrolactone | 96-48-0 | 1.15 |

| Ethyl Lactate | 97-64-3 | 2.71 |

| Isobutyl Isobutyrate | 97-85-8 | 0.61 |

| Isobutyl Methacrylate | 97-86-9 | 8.99 |

| Butyl Methacrylate | 97-88-1 | 9.09 |

| Benzotrifluoride | 98-08-8 | 0.26 |

| PCBTF (p-Trifluoromethyl-Cl-Benzene) | 98-56-6 | 0.11 |

| Cumene (Isopropyl Benzene) | 98-82-8 | 2.32 |

| a-Methyl Styrene | 98-83-9 | 1.72 |

| Ethyl Benzene | 100-41-4 | 2.79 |

| Styrene | 100-42-5 | 1.95 |

| Benzaldehyde | 100-52-7 | 0.00 |

| Triethanolamine | 102-71-6 | 2.76 |

| 2-Ethyl-Hexyl Acetate | 103-09-3 | 0.79 |

| 2-Ethyl-Hexyl Acrylate | 103-11-7 | 2.42 |

| 2-Ethyl-1-Hexanol (Ethyl Hexyl Alcohol) | 104-76-7 | 2.20 |

| Ethyl Propionate | 105-37-3 | 0.79 |

| s-Butyl Acetate | 105-46-4 | 1.43 |

| n-Propyl Propionate | 106-36-5 | 0.93 |

| Xylene, para- | 106-42-3 | 4.25 |

| p-Dichlorobenzene | 106-46-7 | 0.20 |

| Dimethyl Succinate | 106-65-0 | 0.23 |

| 1,2-Epoxybutane (Ethyl Oxirane) | 106-88-7 | 1.02 |

| n-Propyl Bromide | 106-94-5 | 0.35 |

| Butane | 106-97-8 | 1.33 |

| 1,3-Butadiene | 106-99-0 | 13.58 |

| Ethylene Glycol | 107-21-1 | 3.36 |

| 2-Methyl-2,4-Pentanediol | 107-41-5 | 1.04 |

| Hexamethyldisiloxane | 107-46-0 | 0.00 |

| Isohexane Isomers | 107-83-5 | 1.80 |

| Methyl n-Propyl Ketone (2-Pentanone) | 107-87-9 | 3.07 |

| Propylene Glycol Monmethyl Ether (1-Methoxy-2-Propanol) | 107-98-2 | 2.62 |

| n,n-Dimethylethanolamine | 108-01-0 | 4.76 |

| 1-Nitropropane | 108-03-2 | 16.16 |

| Vinyl Acetate | 108-05-4 | 3.26 |

| Methyl Isobutyl Ketone | 108-10-1 | 4.31 |

| Isopropyl Acetate | 108-21-4 | 1.12 |

| Propylene Carbonate (4-Methyl-1,3-Dioxolan-2one) | 108-32-7 | 0.25 |

| Xylene, meta- | 108-38-3 | 10.61 |

| Propylene Glycol Monomethyl Ether Acetate (1-Methoxy-2-Propyl Acetate) | 108-65-6 | 1.71 |

| 1,3,5-Trimethyl Benzene | 108-67-8 | 11.22 |

| Di-Isobutyl Ketone (2,6-Dimethyl-4-Heptanone) | 108-83-8 | 2.94 |

| Methylcyclohexane | 108-87-2 | 1.99 |

| Toluene | 108-88-3 | 3.97 |

| Monochlorobenzene | 108-90-7 | 0.36 |

| Cyclohexanol | 108-93-0 | 2.25 |

| Cyclohexanone | 108-94-1 | 1.61 |

| n-Butyl Butyrate | 109-21-7 | 1.12 |

| Propyl Acetate | 109-60-4 | 0.87 |

| Pentane | 109-66-0 | 1.54 |

| Ethylene Glycol Monomethyl Ether (2-Methoxyethanol) | 109-86-4 | 2.98 |

| Tetrahydrofuran | 109-99-9 | 4.95 |

| Methyl Isoamyl Ketone (5-Methyl-2-Hexanone) | 110-12-3 | 2.10 |

| Isobutyl Acetate | 110-19-0 | 0.67 |

| Methyl Amyl Ketone | 110-43-0 | 2.80 |

| Hexane | 110-54-3 | 1.45 |

| n-Propyl Formate | 110-74-7 | 0.93 |

| 2-Ethoxyethanol | 110-80-5 | 3.78 |

| Cyclohexane | 110-82-7 | 1.46 |

| Morpholine | 110-91-8 | 15.43 |

| Dipropylene Glycol | 110-98-5 | 2.48 |

| Ethylene Glycol Monoethyl Ether Acetate (2-Ethoxyethyl Acetate) | 111-15-9 | 1.90 |

| Diethylenetriamine | 111-40-0 | 13.03 |

| Diethanolamine | 111-42-2 | 4.05 |

| Diethylene Glycol | 111-46-6 | 3.55 |

| n-Octane | 111-65-9 | 1.11 |

| 2-Butoxy-1-Ethanol (Ethylene Glycol Monobutyl Ether) | 111-76-2 | 2.90 |

| Diethylene Glycol Methyl Ether (2-(2-Methoxyethoxy) Ethanol) | 111-77-3 | 2.90 |

| n-Nonane | 111-84-2 | 0.95 |

| 2-(2-Ethoxyethoxy) Ethanol | 111-90-0 | 3.19 |

| Ethylene Glycol Monobutyl Ether Acetate (2-Butoxyethyl Acetate) | 112-07-2 | 1.67 |

| 2-(2-Ethoxyethoxy) Ethyl Acetate | 112-15-2 | 1.50 |

| 2-(2-Butoxyethoxy)-Ethanol | 112-34-5 | 2.70 |

| Dimethyl Ether | 115-10-6 | 0.93 |

| Triethylamine | 121-44-8 | 16.60 |

| 2-Phenoxyethanol; Ethylene Glycol Phenyl Ether | 122-99-6 | 3.61 |

| Diacetone Alcohol | 123-42-2 | 0.68 |

| 2,4-Pentanedione | 123-54-6 | 1.02 |

| Butanal | 123-72-8 | 6.74 |

| Butyl Acetate, n | 123-86-4 | 0.89 |

| 2-(2-Butoxyethoxy) Ethyl Acetate | 124-17-4 | 1.38 |

| 2-Amino-2-Methyl-1-Propanol | 124-68-5 | 15.08 |

| Perchloroethylene | 127-18-4 | 0.04 |

| Ethanolamine | 141-43-5 | 5.97 |

| Ethyl acetate | 141-78-6 | 0.64 |

| Heptane | 142-82-5 | 1.28 |

| n-Hexyl Acetate (Hexyl Acetate) | 142-92-7 | 0.87 |

| 2-Ethyl Hexanoic Acid | 149-57-5 | 4.41 |

| 1,2,3-Trimethyl Benzene | 526-73-8 | 11.26 |

| t-Butyl Acetate | 540-88-5 | 0.20 |

| Methyl Isobutyrate | 547-63-7 | 0.70 |

| Methyl Lactate | 547-64-8 | 2.75 |

| Methyl Propionate | 554-12-1 | 0.71 |

| 1,2 Butanediol | 584-03-2 | 2.21 |

| n-Butyl Propionate | 590-01-2 | 0.89 |

| Methyl n-Butyl Ketone (2-Hexanone) | 591-78-6 | 3.55 |

| Dimethyl carbonate | 616-38-6 | 0.06 |

| Ethyl Isopropyl Ether | 625-54-7 | 3.86 |

| Dimethyl Adipate | 627-93-0 | 1.95 |

| Methy n-Butyl Ether | 628-28-4 | 3.66 |

| Amyl Acetate (Pentyl Ethanoate, Pentyl Acetate) | 628-63-7 | 0.96 |

| Ethyl n-Butyl Ether | 628-81-9 | 3.86 |

| Ethyl t-Butyl Ether | 637-92-3 | 2.11 |

| 1,3-Dioxolane | 646-06-0 | 5.47 |

| Ethyl-3-Ethoxypropionate | 763-69-9 | 3.61 |

| Methyl Pyrrolidone (n-Methyl-2-Pyrrolidone) | 872-50-4 | 2.56 |

| Dimethyl Gluterate | 1119-40-0 | 0.51 |

| Ethylene Glycol 2-Ethylhexyl Ether [2-(2-Ethylhexyloxy) Ethanol] | 1559-35-9 | 1.71 |

| Propylene Glycol Monopropyl Ether (1-Propoxy-2-Propanol) | 1569-01-3 | 2.86 |

| Propylene Glycol Monoethyl Ether (1-Ethoxy-2-Propanol) | 1569-02-4 | 3.25 |

| 2-Methoxy-1-Propanol | 1589-47-5 | 3.01 |

| Methyl t-Butyl Ether | 1634-04-4 | 0.78 |

| Ethylcyclohexane | 1678-91-7 | 1.75 |

| Isoamyl Isobutyrate | 2050-01-3 | 0.89 |

| 2-Propoxyethanol (Ethylene Glycol Monopropyl Ether) | 2807-30-9 | 3.52 |

| n-Butoxy-2-Propanol | 5131-66-8 | 2.70 |

| d-Limonene (Dipentene or Orange Terpene) | 5989-27-5 | 3.99 |

| Dipropylene Glycol Methyl Ether Isomer (2-[2Methoxypropoxy]-1-Propanol) | 13588-28-8 | 3.02 |

| Texanol (1,3 Pentanediol, 2,2,4-Trimethyl, 1-Isobutyrate) | 25265-77-4 | 0.89 |

| Isodecyl Alcohol (8-Methyl-1-Nonanol) | 25339-17-7 | 1.23 |

| Tripropylene Glycol Monomethyl Ether | 25498-49-1 | 1.90 |

| Glycol Ether DPNB (1-(2-Butoxy-1-Methylethoxy) 2-Propanol) | 29911-28-2 | 1.96 |

| Propylene Glycol t-Butyl Ether (1-tert-Butoxy-2-Propanol) | 57018-52-7 | 1.71 |

| 2-Methoxy-1-Propyl Acetate | 70657-70-4 | 1.12 |

| Oxo-Heptyl Acetate | 90438-79-2 | 0.97 |

| 2-tert-Butoxy-1-Propanol | 94023-15-1 | 1.81 |

| Oxo-Octyl Acetate | 108419-32-5 | 0.96 |

| C8 Disubstituted Benzenes | na | 7.48 |

| C9 Styrenes | na | 1.72 |

[77 FR 14284, Mar. 9, 2012]

Table 2B to Subpart E of Part 59 - Reactivity Factors for Aliphatic Hydrocarbon Solvent Mixtures

| Bin | Average boiling point* (degrees F) | Criteria | Reactivity factor (g O3/g VOC) |

|---|---|---|---|

| * Average Boiling Point = (Initial Boiling Point Dry Point)/2(b) Aromatic Hydrocarbon Solvents | |||

| 1 | 80-205 | Alkanes (<2% Aromatics) | 2.08 |

| 2 | 80-205 | N- & Iso-Alkanes (≥90% and <2% Aromatics) | 1.59 |

| 3 | 80-205 | Cyclo-Alkanes (≥90% and <2% Aromatics) | 2.52 |

| 4 | 80-205 | Alkanes (2 to <8% Aromatics) | 2.24 |

| 5 | 80-205 | Alkanes (8 to 22% Aromatics) | 2.56 |

| 6 | >205-340 | Alkanes (<2% Aromatics) | 1.41 |

| 7 | >205-340 | N- & Iso-Alkanes (≥90% and <2% Aromatics) | 1.17 |

| 8 | >205-340 | Cyclo-Alkanes (≥90% and <2% Aromatics) | 1.65 |

| 9 | >205-340 | Alkanes (2 to <8% Aromatics) | 1.62 |

| 10 | >205-340 | Alkanes (8 to 22% Aromatics) | 2.03 |

| 11 | >340-460 | Alkanes (<2% Aromatics) | 0.91 |

| 12 | >340-460 | N- & Iso-Alkanes (≥90% and <2% Aromatics) | 0.81 |

| 13 | >340-460 | Cyclo-Alkanes (≥90% and <2% Aromatics) | 1.01 |

| 14 | >340-460 | Alkanes (2 to <8% Aromatics) | 1.21 |

| 15 | >340-460 | Alkanes (8 to 22% Aromatics) | 1.82 |

| 16 | >460-580 | Alkanes (<2% Aromatics) | 0.57 |

| 17 | >460-580 | N- & Iso-Alkanes (≥90% and <2% Aromatics) | 0.51 |

| 18 | >460-580 | Cyclo-Alkanes (≥90% and <2% Aromatics) | 0.63 |

| 19 | >460-580 | Alkanes (2 to <8% Aromatics) | 0.88 |

| 20 | >460-580 | Alkanes (8 to 22% Aromatics) | 1.49 |

[77 FR 14286, Mar. 9, 2012]

Table 2C to Subpart E of Part 59 - Reactivity Factors for Aromatic Hydrocarbon Solvent Mixtures

| Bin | Boiling range (degrees F) | Criteria | Reactivity factor (g O3/g VOC) |

|---|---|---|---|

| 21 | 280-290 | Aromatic Content (≥98%) | 7.37 |

| 22 | 320-350 | Aromatic Content (≥98%) | 7.51 |

| 23 | 355-420 | Aromatic Content (≥98%) | 8.07 |

| 24 | 450-535 | Aromatic Content (≥98%) | 5.00 |

[77 FR 14286, Mar. 9, 2012]

['Air Programs']

['Volatile Organic Compounds']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.