['Air Programs']

['Air Quality']

08/02/2023

...

(a) Definitions. All terms not defined in this paragraph (a) shall have the meaning given to them in the Act and in subpart A of 40 CFR part 60.

Affected unit means an engine meeting the applicability criteria of this section.

Cap means the total amount of NO X emissions, in tons per day on a 30-day rolling average basis, that is collectively allowed from all of the affected units covered by a Facility-Wide Averaging Plan and is calculated as the sum each affected unit's NO X emissions at the emissions limit applicable to such unit under paragraph (c) of this section, converted to tons per day in accordance with paragraph (d)(3) of this section.

Emergency engine means any stationary reciprocating internal combustion engine (RICE) that meets all of the criteria in paragraphs (i) and (ii) of this definition. All emergency stationary RICE must comply with the requirements specified in paragraph (b)(1) of this section in order to be considered emergency engines. If the engine does not comply with the requirements specified in paragraph (b)(1), it is not considered an emergency engine under this section.

(i) The stationary engine is operated to provide electrical power or mechanical work during an emergency situation. Examples include stationary RICE used to produce power for critical networks or equipment (including power supplied to portions of a facility) when electric power from the local utility (or the normal power source, if the facility runs on its own power production) is interrupted, or stationary RICE used to pump water in the case of fire or flood, etc.

(ii) The stationary RICE is operated under limited circumstances for purposes other than those identified in paragraph (i) of this definition, as specified in paragraph (b)(1) of this section.

Facility means all of the pollutant-emitting activities which belong to the same industrial grouping, are located on one or more contiguous or adjacent properties, and are under the control of the same person (or persons under common control). Pollutant-emitting activities shall be considered as part of the same industrial grouping if they belong to the same “Major Group” (i.e., which have the same first two digit code as described in the Standard Industrial Classification Manual, 1987). For purposes of this section, a facility may not extend beyond the 20 states identified in §52.40(b)(2).

Four stroke means any type of engine which completes the power cycle in two crankshaft revolutions, with intake and compression strokes in the first revolution and power and exhaust strokes in the second revolution.

ISO conditions means 288 Kelvin (15°C), 60 percent relative humidity, and 101.3 kilopascals pressure.

Lean burn means any two?stroke or four?stroke spark ignited reciprocating internal combustion engine that does not meet the definition of a rich burn engine.

Local Distribution Companies (LDCs) are companies that own or operate distribution pipelines, but not interstate pipelines or intrastate pipelines, that physically deliver natural gas to end users and that are within a single state that are regulated as separate operating companies by State public utility commissions or that operate as independent municipally-owned distribution systems. LDCs do not include pipelines (both interstate and intrastate) delivering natural gas directly to major industrial users and farm taps upstream of the local distribution company inlet.

Local Distribution Company (LDC) custody transfer station means a metering station where the LDC receives a natural gas supply from an upstream supplier, which may be an interstate transmission pipeline or a local natural gas producer, for delivery to customers through the LDC's intrastate transmission or distribution lines.

Nameplate rating means the manufacturer's maximum design capacity in horsepower (hp) at the installation site conditions. Starting from the completion of any physical change in the engine resulting in an increase in the maximum output (in hp) that the engine is capable of producing on a steady state basis and during continuous operation, such increased maximum output shall be as specified by the person conducting the physical change.

Natural gas means a fluid mixture of hydrocarbons (e.g., methane, ethane, or propane) or non-hydrocarbons, composed of at least 70 percent methane by volume or that has a gross calorific value between 35 and 41 megajoules (MJ) per dry standard cubic meter (950 and 1,100 Btu per dry standard cubic foot), that maintains a gaseous state under ISO conditions. Natural gas does not include the following gaseous fuels: Landfill gas, digester gas, refinery gas, sour gas, blast furnace gas, coal-derived gas, producer gas, coke oven gas, or any gaseous fuel produced in a process which might result in highly variable CO 2 content or heating value.

Natural gas-fired means that greater than or equal to 90% of the engine's heat input, excluding recirculated or recuperated exhaust heat, is derived from the combustion of natural gas.

Natural gas processing plant means any processing site engaged in the extraction of natural gas liquids from field gas, fractionation of mixed natural gas liquids to natural gas products, or both. A Joule-Thompson valve, a dew point depression valve, or an isolated or standalone Joule-Thompson skid is not a natural gas processing plant.

Natural gas production facility means all equipment at a single stationary source directly associated with one or more natural gas wells upstream of the natural gas processing plant. This equipment includes, but is not limited to, equipment used for storage, separation, treating, dehydration, artificial lift, combustion, compression, pumping, metering, monitoring, and flowline.

Operating day means a 24-hour period beginning at 12:00 midnight during which any fuel is combusted at any time in the engine.

Pipeline transportation of natural gas means the movement of natural gas through an interconnected network of compressors and pipeline components, including the compressor and pipeline network used to transport the natural gas from processing plants over a distance (intrastate or interstate) to and from storage facilities, to large natural gas end?users, and prior to delivery to a “local distribution company custody transfer station” (as defined in this section) of an LDC that provides the natural gas to end-users. Pipeline transportation of natural gas does not include natural gas production facilities, natural gas processing plants, or the portion of a compressor and pipeline network that is upstream of a natural gas processing plant.

Reciprocating internal combustion engine (RICE) means a reciprocating engine in which power, produced by heat and/or pressure that is developed in the engine combustion chambers by the burning of a mixture of air and fuel, is subsequently converted to mechanical work.

Rich burn means any four?stroke spark ignited reciprocating internal combustion engine where the manufacturer's recommended operating air/fuel ratio divided by the stoichiometric air/fuel ratio at full load conditions is less than or equal to 1.1. Internal combustion engines originally manufactured as rich burn engines but modified with passive emissions control technology for nitrogen oxides (NO X) (such as pre?combustion chambers) will be considered lean burn engines. Existing affected unit where there are no manufacturer's recommendations regarding air/fuel ratio will be considered rich burn engines if the excess oxygen content of the exhaust at full load conditions is less than or equal to 2 percent.

Spark ignition means a reciprocating internal combustion engine utilizing a spark plug (or other sparking device) to ignite the air/fuel mixture and with operating characteristics significantly similar to the theoretical Otto combustion cycle.

Stoichiometric means the theoretical air?to?fuel ratio required for complete combustion.

Two stroke means a type of reciprocating internal combustion engine which completes the power cycle in a single crankshaft revolution by combining the intake and compression operations into one stroke (one?half revolution) and the power and exhaust operations into a second stroke. This system requires auxiliary exhaust scavenging of the combustion products and inherently runs lean (excess of air) of stoichiometry.

(b) Applicability. You are subject to the requirements under this section if you own or operate a new or existing natural gas-fired spark ignition engine, other than an emergency engine, with a nameplate rating of 1,000 hp or greater that is used for pipeline transportation of natural gas and is located within any of the States listed in §52.40(c)(2), including Indian country located within the borders of any such State(s).

(1) For purposes of this section, the owner or operator of an emergency stationary RICE must operate the RICE according to the requirements in paragraphs (b)(1)(i) through (iii) of this section to be treated as an emergency stationary RICE. In order for stationary RICE to be treated as an emergency RICE under this subpart, any operation other than emergency operation, maintenance and testing, and operation in non-emergency situations for up to 50 hours per year, as described in paragraphs (b)(1)(i) through (iii), is prohibited. If you do not operate the RICE according to the requirements in paragraphs (b)(1)(i) through (iii), the RICE will not be considered an emergency engine under this section and must meet all requirements for affected units in this section.

(i) There is no time limit on the use of emergency stationary RICE in emergency situations.

(ii) The owner or operator may operate your emergency stationary RICE for maintenance checks and readiness testing for a maximum of 100 hours per calendar year, provided that the tests are recommended by a Federal, state, or local government agency, the manufacturer, the vendor, or the insurance company associated with the engine. Any operation for non-emergency situations as allowed by paragraph (b)(1)(iii) of this section counts as part of the 100 hours per calendar year allowed by paragraph (b)(1)(ii) of this section. The owner or operator may petition the Administrator for approval of additional hours to be used for maintenance checks and readiness testing, but a petition is not required if the owner or operator maintains records confirming that Federal, state, or local standards require maintenance and testing of emergency RICE beyond 100 hours per calendar year. Any approval of a petition for additional hours granted by the Administrator under 40 CFR part 63, subpart ZZZZ, shall constitute approval by the Administrator of the same petition under this paragraph (b)(1)(ii).

(iii) Emergency stationary RICE may be operated for up to 50 hours per calendar year in non-emergency situations. The 50 hours of operation in non-emergency situations are counted as part of the 100 hours per calendar year for maintenance and testing provided in paragraph (b)(1)(ii) of this section.

(2) If you own or operate a natural gas-fired two stroke lean burn spark ignition engine manufactured after July 1, 2007 that is meeting the applicable emissions limits in 40 CFR part 60, subpart JJJJ, table 1, the engine is not an affected unit under this section and you do not have to comply with the requirements of this section.

(3) If you own or operate a natural gas-fired four stroke lean or rich burn spark ignition engine manufactured after July 1, 2010, that is meeting the applicable emissions limits in 40 CFR part 60, subpart JJJJ, table 1, the engine is not an affected unit under this section and you do not have to comply with the requirements of this section.

(c) Emissions limitations. If you are the owner or operator of an affected unit, you must meet the following emissions limitations on a 30-day rolling average basis during the 2026 ozone season and in each ozone season thereafter:

(1) Natural gas-fired four stroke rich burn spark ignition engine: 1.0 grams per hp-hour (g/hp-hr);

(2) Natural gas-fired four stroke lean burn spark ignition engine: 1.5 g/hp-hr; and

(3) Natural gas-fired two stroke lean burn spark ignition engine: 3.0 g/hp-hr.

(d) Facility-Wide Averaging Plan. If you are the owner or operator of a facility containing more than one affected unit, you may submit a request via the CEDRI or analogous electronic submission system provided by the EPA to the Administrator for approval of a proposed Facility-Wide Averaging Plan as an alternative means of compliance with the applicable emissions limits in paragraph (c) of this section. Any such request shall be submitted to the Administrator on or before October 1st of the year prior to each emissions averaging year. The Administrator will approve a proposed Facility-Wide Averaging Plan submitted under this paragraph (d) if the Administrator determines that the proposed Facility-Wide Averaging Plan meets the requirements of this paragraph (d), will provide total emissions reductions equivalent to or greater than those achieved by the applicable emissions limits in paragraph (c), and identifies satisfactory means for determining initial and continuous compliance, including appropriate testing, monitoring, recordkeeping, and reporting requirements. You may only include affected units (i.e., engines meeting the applicability criteria in paragraph (b) of this section) in a Facility-Wide Averaging Plan. Upon EPA approval of a proposed Facility-Wide Averaging Plan, you cannot withdraw any affected unit listed in such plan, and the terms of the plan may not be changed unless approved in writing by the Administrator.

(1) Each request for approval of a proposed Facility-Wide Averaging Plan shall include, but not be limited to:

(i) The address of the facility;

(ii) A list of all affected units at the facility that will be covered by the plan, identified by unit identification number, the engine manufacturer's name, and model;

(iii) For each affected unit, a description of any existing NO X emissions control technology and the date of installation, and a description of any NO X emissions control technology to be installed and the projected date of installation;

(iv) Identification of the emissions cap, calculated in accordance with paragraph (d)(3) of this section, that all affected units covered by the proposed Facility-Wide Averaging Plan will be subject to during the ozone season, together with all assumptions included in such calculation; and

(iv) Adequate provisions for testing, monitoring, recordkeeping, and reporting for each affected unit.

(2) Upon the Administrator's approval of a proposed Facility-Wide Averaging Plan, the owner or operator of the affected units covered by the Facility-Wide Averaging Plan shall comply with the cap identified in the plan in lieu of the emissions limits in paragraph (c) of this section. You will be in compliance with the cap if the sum of NO X emissions from all units covered by the Facility-Wide Averaging Plan, in tons per day on a 30-day rolling average basis, is less than or equal to the cap.

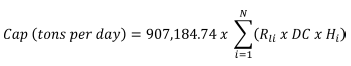

(3) The owner or operator will calculate the cap according to equation 1 to this paragraph (d)(3). You will monitor and record daily hours of engine operation for use in calculating the cap on a 30-day rolling average basis. You will base the hours of operation on hour readings from a non-resettable hour meter or an equivalent monitoring device.

Equation 1 to Paragraph (d)(3)

Where:

H i = the average daily operating hours based on the highest consecutive 30-day period during the ozone season of the two most recent years preceding the emissions averaging year (hours).

i = each affected unit included in the Cap.

N = number of affected units.

DC = the engine manufacturer's design maximum capacity in horsepower (hp) at the installation site conditions.

R li = the emissions limit for each affected unit from paragraph (c) of this section (grams/hp-hr).

(i) Any affected unit for which less than two years of operating data are available shall not be included in the Facility-Wide Averaging Plan unless the owner or operator extrapolates the available operating data for the affected unit to two years of operating data, for use in calculating the emissions cap in accordance with paragraph (d)(3) of this section.

(ii) [Reserved]

(4) The owner or operator of an affected units covered by an EPA-approved Facility-Wide Averaging Plan will be in violation of the cap if the sum of NO X emissions from all such units, in tons per day on a 30-day rolling average basis, exceeds the cap. Each day of noncompliance by each affected unit covered by the Facility-Wide Averaging Plan shall be a violation of the cap until corrective action is taken to achieve compliance.

(e) Testing and monitoring requirements.(1) If you are the owner or operator of an affected unit subject to a NO X emissions limit under paragraph (c) of this section, you must keep a maintenance plan and records of conducted maintenance and must, to the extent practicable, maintain and operate the engine in a manner consistent with good air pollution control practice for minimizing emissions.

(2) If you are the owner or operator of an affected unit and are operating a NO X continuous emissions monitoring system (CEMS) that monitors NO X emissions from the affected unit, you may use the CEMS data in lieu of the annual performance tests and parametric monitoring required under this section. You must meet the following requirements for using CEMS to monitor NO X emissions:

(i) You shall install, calibrate, maintain, and operate a continuous emissions monitoring system (CEMS) for measuring NO X emissions and either oxygen (O 2) or carbon dioxide (CO 2).

(ii) The CEMS shall be operated and data recorded during all periods of operation during the ozone season of the affected unit except for CEMS breakdowns and repairs. Data shall be recorded during calibration checks and zero and span adjustments.

(iii) The 1-hour average NO X emissions rates measured by the CEMS shall be used to calculate the average emissions rates to demonstrate compliance with the applicable emissions limits in this section.

(iv) The procedures under 40 CFR 60.13 shall be followed for installation, evaluation, and operation of the continuous monitoring systems.

(v) When NO X emissions data are not obtained because of CEMS breakdowns, repairs, calibration checks, and zero and span adjustments, emissions data will be obtained by using standby monitoring systems, Method 7 of 40 CFR part 60, appendix A–4, Method 7A of 40 CFR part 60, appendix A–4, or other approved reference methods to provide emissions data for a minimum of 75 percent of the operating hours in each affected unit operating day, in at least 22 out of 30 successive operating days.

(3)(i) If you are the owner or operator of a new affected unit, you must conduct an initial performance test within six months of engine startup and conduct subsequent performance tests every twelve months thereafter to demonstrate compliance. If pollution control equipment is installed to comply with a NO X emissions limit in paragraph (c) of this section, however, the initial performance test shall be conducted within 90 days of such installation.

(ii) If you are the owner or operator of an existing affected unit, you must conduct an initial performance test within six months of becoming subject to an emissions limit under paragraph (c) of this section and conduct subsequent performance tests every twelve months thereafter to demonstrate compliance. If pollution control equipment is installed to comply with a NO X emissions limit in paragraph (c) of this section, however, the initial performance test shall be conducted within 90 days of such installation.

(iii) If you are the owner or operator of a new or existing affected unit that is only operated during peak demand periods outside of the ozone season and the engine's hours of operation during the ozone season are 50 hours or less, the affected unit is not subject to the testing and monitoring requirements of this paragraph (e)(3)(iii) as long as you record and report your hours of operation during the ozone season in accordance with paragraphs (f) and (g) of this section.

(iv) If you are the owner or operator of an affected unit, you must conduct all performance tests consistent with the requirements of 40 CFR 60.4244 in accordance with the applicable reference test methods identified in table 2 to subpart JJJJ of 40 CFR part 60, any alternative test method approved by the EPA as of June 5, 2023, under 40 CFR 59.104(f), 60.8(b)(3), 61.13(h)(1)(ii), 63.7(e)(2)(ii), or 65.158(a)(2) and available at the EPA's website (https://www.epa.gov/emc/broadly-applicable-approved-alternative-test-methods), or other methods and procedures approved by the EPA through notice-and-comment rulemaking. To determine compliance with the NO X emissions limit in paragraph (c) of this section, the emissions rate shall be calculated in accordance with the requirements of 40 CFR 60.4244(d).

(4) If you are the owner or operator of an affected unit that has a non-selective catalytic reduction (NSCR) control device to reduce emissions, you must:

(i) Monitor the inlet temperature to the catalyst daily and conduct maintenance if the temperature is not within the observed inlet temperature range from the most recent performance test or the temperatures specified by the manufacturer if no performance test was required by this section; and

(ii) Measure the pressure drop across the catalyst monthly and conduct maintenance if the pressure drop across the catalyst changes by more than 2 inches of water at 100 percent load plus or minus 10 percent from the pressure drop across the catalyst measured during the most recent performance test.

(5) If you are the owner of operator of an affected unit not using an NSCR control device to reduce emissions, you are required to conduct continuous parametric monitoring to assure compliance with the applicable emissions limits according to the requirements in paragraphs (e)(5)(i) through (vi) of this section.

(i) You must prepare a site-specific monitoring plan that includes all of the following monitoring system design, data collection, and quality assurance and quality control elements:

(A) The performance criteria and design specifications for the monitoring system equipment, including the sample interface, detector signal analyzer, and data acquisition and calculations.

(B) Sampling interface (e.g., thermocouple) location such that the monitoring system will provide representative measurements.

(C) Equipment performance evaluations, system accuracy audits, or other audit procedures.

(D) Ongoing operation and maintenance procedures in accordance with the requirements of paragraph (e)(1) of this section.

(E) Ongoing recordkeeping and reporting procedures in accordance with the requirements of paragraphs (f) and (g) of this section.

(ii) You must continuously monitor the selected operating parameters according to the procedures in your site-specific monitoring plan.

(iii) You must collect parametric monitoring data at least once every 15 minutes.

(iv) When measuring temperature range, the temperature sensor must have a minimum tolerance of 2.8 degrees Celsius (5 degrees Fahrenheit) or 1 percent of the measurement range, whichever is larger.

(v) You must conduct performance evaluations, system accuracy audits, or other audit procedures specified in your site-specific monitoring plan at least annually.

(vi) You must conduct a performance evaluation of each parametric monitoring device in accordance with your site-specific monitoring plan.

(6) If you are the owner or operator of an affected unit that is only operated during peak periods outside of the ozone season and your hours of operation during the ozone season are 0, you are not subject to the testing and monitoring requirements of this paragraph (e)(6) so long as you record and report your hours of operation during the ozone season in accordance with paragraphs (f) and (g) of this section.

(f) Recordkeeping requirements. If you are the owner or operator of an affected unit, you must keep records of:

(1) Performance tests conducted pursuant to paragraph (e)(2) of this section, including the date, engine settings on the date of the test, and documentation of the methods and results of the testing.

(2) Catalyst monitoring required by paragraph (e)(3) of this section, if applicable, and any actions taken to address monitored values outside the temperature or pressure drop parameters, including the date and a description of actions taken.

(3) Parameters monitored pursuant to the facility's site-specific parametric monitoring plan.

(4) Hours of operation on a daily basis.

(5) Tuning, adjustments, or other combustion process adjustments and the date of the adjustment(s).

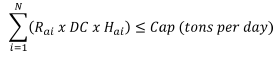

(6) For any Facility-Wide Averaging Plan approved by the Administrator under paragraph (d) of this section, daily calculations of total NO X emissions to demonstrate compliance with the cap during the ozone season. You must use the equation in this paragraph (f)(6) to calculate total NO X emissions from all affected units covered by the Facility-Wide Averaging Plan, in tons per day on a 30-day rolling average basis, for purposes of determining compliance with the cap during the ozone season. A new 30-day rolling average emissions rate in tpd is calculated for each operating day during the ozone season, using the 30-day rolling average daily operating hours for the preceding 30 operating days.

Equation 2 to Paragraph (f)(6)

Where:

H ai = the consecutive 30-day rolling average daily operating hours for the preceding 30 operating days during ozone season (hours).

i = each affected unit.

N = number of affected units.

DC = the engine manufacturer's maximum design capacity in horsepower (hp) at the installation site conditions.

R ai = the actual emissions rate for each affected unit based on the most recent performance test results, (grams/hp-hr).

(g) Reporting requirements.(1) If you are the owner or operator of an affected unit, you must submit the results of the performance test or performance evaluation of the CEMS following the procedures specified in §52.40(g) within 60 days after completing each performance test required by this section.

(2) If you are the owner or operator of an affected unit, you are required to submit excess emissions reports for any excess emissions that occurred during the reporting period. Excess emissions are defined as any calculated 30-day rolling average NO X emissions rate that exceeds the applicable emissions limit in paragraph (c) of this section. Excess emissions reports must be submitted in PDF format to the EPA via CEDRI or analogous electronic reporting approach provided by the EPA to report data required by this section following the procedures specified in §52.40(g).

(3) If you are the owner or operator of an affected unit, you must submit an annual report in PDF format to the EPA by January 30th of each year via CEDRI or analogous electronic reporting approach provided by the EPA to report data required by this section. Annual reports shall be submitted following the procedures in paragraph (g) of this section. The report shall contain the following information:

(i) The name and address of the owner and operator;

(ii) The address of the subject engine;

(iii) Longitude and latitude coordinates of the subject engine;

(iv) Identification of the subject engine;

(v) Statement of compliance with the applicable emissions limit under paragraph (c) of this section or a Facility-Wide Averaging Plan under paragraph (d) of this section;

(vi) Statement of compliance regarding the conduct of maintenance and operations in a manner consistent with good air pollution control practices for minimizing emissions;

(vii) The date and results of the performance test conducted pursuant to paragraph (e) of this section;

(viii) Any records required by paragraph (f) of this section, including records of parametric monitoring data, to demonstrate compliance with the applicable emissions limit under paragraph (c) of this section or a Facility-Wide Averaging Plan under paragraph (d) of this section, if applicable;

(ix) If applicable, a statement documenting any change in the operating characteristics of the subject engine; and

(x) A statement certifying that the information included in the annual report is complete and accurate.

[88 FR 36869, June 5, 2023]

READ MORESHOW LESS

['Air Programs']

['Air Quality']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.