['Air Programs']

['Air Emissions']

07/11/2024

...

Smokemeters measure exhaust opacity using full-flow open-path light extinction with a built-in light beam across the exhaust stack or plume. Prepare and install a smokemeter system as follows:

(a) Except as specified in paragraph (d) of this section, use a smokemeter capable of providing continuous measurement that meets the following specifications:

(1) Use an incandescent lamp with a color temperature between (2800 and 3250) K or a different light source with a spectral peak between (550 and 570) nm.

(2) Collimate the light beam to a nominal diameter of 3 centimeters and maximum divergence angle of 6 degrees.

(3) Include a photocell or photodiode as a detector. The detector must have a maximum spectral response between (550 and 570) nm, with less than 4 percent of that maximum response below 430 nm and above 680 nm. These specifications correspond to visual perception with the human eye.

(4) Use a collimating tube with an aperture that matches the diameter of the light beam. Restrict the detector to viewing within a 16 degree included angle.

(5) Optionally use an air curtain across the light source and detector window to minimize deposition of smoke particles, as long as it does not measurably affect the opacity of the sample.

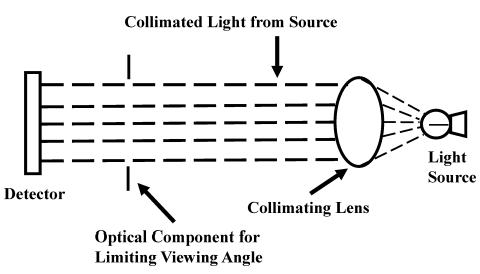

(6) The diagram in the following figure illustrates the smokemeter configuration:

Figure 1 to paragraph (a)(6) of §1065.1125—Smokemeter Diagram

(b) Smokemeters for locomotive applications must have a full-scale response time of 0.5 seconds or less. Smokemeters for locomotive applications may attenuate signal responses with frequencies higher than 10 Hz with a separate low-pass electronic filter that has the following performance characteristics:

(1) Three decibel point: 10 Hz.

(2) Insertion loss: (0.0 ±0.5) dB.

(3) Selectivity: 12 dB down at 40 Hz minimum.

(4) Attenuation: 27 dB down at 40 Hz minimum.

(c) Configure exhaust systems as follows for measuring exhaust opacity:

(1) For locomotive applications:

(i) Optionally add a stack extension to the locomotive muffler.

(ii) For in-line measurements, the smokemeter is integral to the stack extension.

(iii) For end-of-line measurements, mount the smokemeter directly at the end of the stack extension or muffler.

(iv) For all testing, minimize distance from the optical centerline to the muffler outlet; in no case may it be more than 300 cm. The maximum allowable distance of unducted space upstream of the optical centerline is 50 cm, whether the unducted portion is upstream or downstream of the stack extensions.

(2) Meet the following specifications for all other applications:

(i) For in-line measurements, install the smokemeter in an exhaust pipe segment downstream of all engine components. This will typically be part of a laboratory configuration to route the exhaust to an analyzer. The exhaust pipe diameter must be constant within 3 exhaust pipe diameters before and after the smokemeter's optical centerline. The exhaust pipe diameter may not change by more than a 12-degree half-angle within 6 exhaust pipe diameters upstream of the smokemeter's optical centerline.

(ii) For end-of-line measurements with systems that vent exhaust to the ambient, add a stack extension and position the smokemeter such that its optical centerline is (2.5 ±0.625) cm upstream of the stack extension's exit. Configure the exhaust stack and extension such that at least the last 60 cm is a straight pipe with a circular cross section with an approximate inside diameter as specified in the following table:

| Maximum rated power | Approximate exhaust pipe diameter (mm) |

|---|---|

| kW<40 | 38 |

| 40≤kW<75 | 50 |

| 75≤kW<150 | 76 |

| 150≤kW<225 | 102 |

| 225≤kW<375 | 127 |

| kW ≥ 375 | 152 |

(iii) For both in-line and end-of-line measurements, install the smokemeter so its optical centerline is (3 to 10) meters further downstream than the point in the exhaust stream that is farthest downstream considering all the following components: exhaust manifolds, turbocharger outlets, exhaust aftertreatment devices, and junction points for combining exhaust flow from multiple exhaust manifolds.

(3) Orient the light beam perpendicular to the direction of exhaust flow. Install the smokemeter so it does not influence exhaust flow distribution or the shape of the exhaust plume. Set up the smokemeter's optical path length as follows:

(i) For locomotive applications, the optical path length must be at least as wide as the exhaust plume.

(ii) For all other applications, the optical path length must be the same as the diameter of the exhaust flow. For noncircular exhaust configurations, set up the smokemeter such that the light beam's path length is across the longest axis with an optical path length equal to the hydraulic diameter of the exhaust flow.

(4) The smokemeter must not interfere with the engine's ability to meet the exhaust backpressure requirements in §1065.130(h).

(5) For engines with multiple exhaust outlets, measure opacity using one of the following methods:

(i) Join the exhaust outlets together to form a single flow path and install the smokemeter (3 to 10) m downstream of the point where the exhaust streams converge or the last exhaust aftertreatment device, whichever is farthest downstream.

(ii) Install a smokemeter in each of the exhaust flow paths. Report all measured values. All measured values must comply with standards.

(6) The smokemeter may use purge air or a different method to prevent carbon or other exhaust deposits on the light source and detector. Such a method used with end-of-line measurements may not cause the smoke plume to change by more than 0.5 cm at the smokemeter. If such a method affects the smokemeter's optical path length, follow the smokemeter manufacturer's instructions to properly account for that effect.

(d) You may use smokemeters meeting alternative specifications as follows:

(1) You may use smokemeters that use other electronic or optical techniques if they employ substantially identical measurement principles and produce substantially equivalent results.

(2) You may ask us to approve the use of a smokemeter that relies on partial flow sampling. Follow the instrument manufacturer's installation, calibration, operation, and maintenance procedures if we approve your request. These procedures must include correcting for any change in the path length of the exhaust plume relative to the diameter of the engine's exhaust outlet.

[88 FR 4693, Jan. 24, 2023]

READ MORESHOW LESS

['Air Programs']

['Air Emissions']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.