['Air Programs']

['Air Emissions']

03/22/2023

...

This section describes a compliance approach for trailers that is consistent with the modeling for vocational vehicles and tractors described in §1037.520, but is simplified consistent with the smaller number of trailer parameters that affect CO2 emissions. Note that the calculated CO2 emission rate, eCO2, is equivalent to the value that would result from running GEM with the same input values.

(a) Compliance equation. Calculate CO2 emissions for demonstrating compliance with emission standards for each trailer configuration.

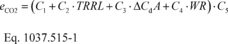

(1) Use the following equation:

Where:

Ci = constant values for calculating CO2 emissions from this regression equation derived from GEM, as shown in Table 1 of this section. Let C5 = 0.988 for trailers that have automatic tire inflation systems with all wheels, and let C5 = 0.990 for trailers that have tire pressure monitoring systems with all wheels (or a mix of the two systems); otherwise, let C5 1.

TRRL = tire rolling resistance level as specified in paragraph (b) of this section.

ΔCdA = the ΔCdA value for the trailer as specified in paragraph (c) of this section.

WR = weight reduction as specified in paragraph (d) or (e) of this section.

| Trailer category | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| Long dry box van | 76.1 | 1.67 | −5.82 | −0.00103 |

| Long refrigerated box van | 77.4 | 1.75 | −5.78 | −0.00103 |

| Short dry box van | 117.8 | 1.78 | −9.48 | −0.00258 |

| Short refrigerated box van | 121.1 | 1.88 | −9.36 | −0.00264 |

(2) The following is an example for calculating the mass of CO2 emissions, eCO2, from a long dry box van that has a tire pressure monitoring system for all wheels, an aluminum suspension assembly, aluminum floor, and is designated as Bin IV:

C1 = 76.1

C2 = 1.67

TRRL = 4.6 kg/tonne

C3 = -5.82

ΔCdA = 0.7 m 2

C4 = -0.00103

WR = 655 lbs

C5 = 0.990

eCO2 = (76.1 1.67 (−5.82 ·0.7) (−0.00103 ·655)) ·0.990

eCO2 = 78.24 g/ton-mile

(b) Tire rolling resistance. Use the procedure specified in §1037.520(c) to determine the tire rolling resistance level for your tires. Note that you may base tire rolling resistance levels on measurements performed by tire manufacturers, as long as those measurements meet this part's specifications.

(c) Drag area. You may use ΔCdA values approved under §1037.211 for device manufacturers if your trailers are properly equipped with those devices. Determine ΔCdA values for other trailers based on testing. Measure CdA and determine ΔCdA values as described in §1037.526(a). You may use ΔCdA values from one trailer configuration to represent any number of additional trailers based on worst-case testing. This means that you may apply ΔCdA values from your measurements to any trailer models of the same category with drag area at or below that of the tested configuration. For trailers in the short dry box vans and short refrigerated box vans that are not 28 feet long, apply the ΔCdA value established for a comparable 28-foot trailer model; you may use the same devices designed for 28-foot trailers or you may adapt those devices as appropriate for the different trailer length, consistent with good engineering judgment. For example, 48-foot trailers may use longer side skirts than the skirts that were tested with a 28-foot trailer. Trailer and device manufacturers may seek preliminary approval for these adaptations. Determine bin levels based on ΔCdA test results as described in the following table:

| If a trailer's measured ΔCDA is . . . | Designate the trailer as . . . | And use the following value for ΔCDA . . . |

|---|---|---|

| ≤0.09 | Bin I | 0.0 |

| 0.10-0.39 | Bin II | 0.1 |

| 0.40-0.69 | Bin III | 0.4 |

| 0.70-0.99 | Bin IV | 0.7 |

| 1.00-1.39 | Bin V | 1.0 |

| 1.40-1.79 | Bin VI | 1.4 |

| ≥1.80 | Bin VII | 1.8 |

(d) Weight reduction. Determine weight reduction for a trailer configuration by summing all applicable values, as follows:

(1) Determine weight reduction for using lightweight materials for wheels as described in §1037.520(e).

(2) Apply weight reductions for other components made with light-weight materials as shown in the following table:

| Component | Material | Weight reduction (pounds) |

| Structure for Suspension Assembly | Aluminum | 280 |

| Hub and Drum (per axle) | Aluminum | 80 |

| Floor | Aluminum | 375 |

| Floor | Composite (wood and plastic) | 245 |

| Floor Crossmembers | Aluminum | 250 |

| Landing Gear | Aluminum | 50 |

| Rear Door | Aluminum | 187 |

| Rear Door Surround | Aluminum | 150 |

| Roof Bows | Aluminum | 100 |

| Side Posts | Aluminum | 300 |

| Slider Box | Aluminum | 150 |

| Upper Coupler Assembly | Aluminum | 430 |

| a For tandem-axle suspension sub-frames made of aluminum, apply a weight reduction of 280 pounds. Use good engineering judgment to estimate a weight reduction for using aluminum sub-frames with other axle configurations. | ||

| b Calculate a smaller weight reduction for short trailers by multiplying the indicated values by 0.528 (28/53). | ||

(e) Off-cycle. You may apply the off-cycle provisions of §1037.610 to trailers as follows:

(1) You may account for weight reduction based on measured values instead of using paragraph (d) of this section. Quantify the weight reduction by measuring the weight of a trailer in a certified configuration and comparing it to the weight of an equivalent trailer without weight-reduction technologies. This qualifies as A to B testing under §1037.610. Use good engineering judgment to select an equivalent trailer representing a baseline configuration. Use the calculated weight reduction in Eq. 1037.515-1 to calculate the trailer's CO2 emission rate.

(2) If your off-cycle technology reduces emissions in a way that is proportional to measured emissions as described in §1037.610(b)(1), multiply the trailer's CO2 emission rate by the appropriate improvement factor.

(3) If your off-cycle technology does not yield emission reductions that are proportional to measured emissions, as described in §1037.610(b)(2), calculate an adjusted CO2 emission rate for your trailers by subtracting the appropriate off-cycle credit.

(4) Note that these off-cycle provisions do not apply for trailers subject to design standards.

[86 FR 34466, Jun. 29, 2021]

READ MORESHOW LESS

['Air Programs']

['Air Emissions']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.