['Air Programs']

['Air Quality', 'Air Emissions']

07/12/2023

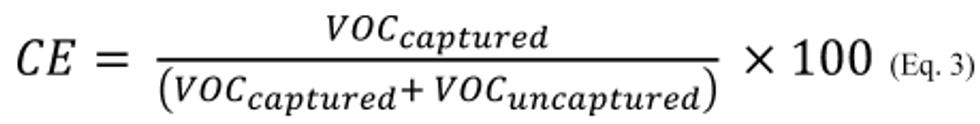

...

ENVIRONMENTAL PROTECTION AGENCY

40 CFR Part 60

[EPA–HQ–OAR–2021–0664; FRL–8511–02–OAR]

RIN 2060–AV30

Review of Standards of Performance for Automobile and Light Duty Truck Surface Coating Operations

AGENCY: Environmental Protection Agency (EPA).

ACTION: Final rule.

SUMMARY: The Environmental Protection Agency (EPA) is finalizing amendments to the new source performance standards for Automobile and Light Duty Truck Surface Coating Operations pursuant to the review required by the Clean Air Act. The EPA determined that revisions to the NSPS were needed to reflect the degree of emission limitation achievable through the application of the best system of emission reduction (BSER). The EPA is therefore finalizing, as proposed, in a new NSPS subpart MMa, revised volatile organic compound (VOC) emission limits for prime coat, guide coat, and topcoat operations for affected facilities that commence construction, modification, or reconstruction after May 18, 2022. In addition, in the new NSPS subpart, the EPA is finalizing the proposed amendments: the addition of work practices to minimize VOC emissions; revision of the plastic parts provision; updates to the capture and control devices and the associated testing and monitoring requirements; revision of the transfer efficiency provisions; new test methods and alternative test methods; revision of the recordkeeping and reporting requirements, including the addition of electronic reporting; removing exemptions for periods of startup, shutdown, and malfunction; and other amendments to harmonize the new NSPS subpart and Automobile and Light Duty Truck Surface Coating National Emission Standards for Hazardous Air Pollutants (NESHAP) requirements. The EPA is also finalizing the proposed electronic reporting requirements in the NSPS subpart MM, applicable to sources that commence construction, reconstruction, or modification after October 5, 1979, and on or before May 18, 2022.

DATES: This final rule is effective on May 9, 2023. The incorporation by reference of certain publications listed in the rule is approved by the Director of the Federal Register as of May 9, 2023.

ADDRESSES: The U.S. Environmental Protection Agency (EPA) has established a docket for this action under Docket ID No. EPA–HQ–OAR–2021–0664. All documents in the docket are listed on the https://www.regulations.gov/ website. Although listed, some information is not publicly available, e.g., Confidential Business Information (CBI) or other information whose disclosure is restricted by statute. Certain other material, such as copyrighted material, is not placed on the internet and will be publicly available only in hard copy form. Publicly available docket materials are available electronically through https://www.regulations.gov/.

FOR FURTHER INFORMATION CONTACT: Ms. Paula Deselich Hirtz, Sector Policies and Programs Division (D243–04), Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency, Research Triangle Park, North Carolina 27711; telephone number: (919) 541–2618; and email address: hirtz.paula@epa.gov.

SUPPLEMENTARY INFORMATION:

Preamble acronyms and abbreviations. Throughout this preamble the use of “we,” “us,” or “our” is intended to refer to the EPA. We use multiple acronyms and terms in this preamble. While this list may not be exhaustive, to ease the reading of this preamble and for reference purposes, the EPA defines the following terms and acronyms here:

ALDT Automobile and Light Duty Truck

ANSI American National Standards Institute

ASTM American Society for Testing and Materials

ASME American Society of Mechanical Engineers

BACT best available control technology

BID background information document

BSER best system of emission reduction

CAA Clean Air Act

CBI Confidential Business Information

CDX Central Data Exchange

CEDRI Compliance and Emissions Data Reporting Interface

CEMS continuous emission monitoring system

CEPCI Chemical Engineering Plant Cost Index

CPMS Continuous Parametric Monitoring System

EDP electrodeposition

EIA economic impact analysis

EPA Environmental Protection Agency

ERT Electronic Reporting Tool

FID flame ionization detector

FR Federal Register

GC gas chromatography

GHG greenhouse gas

IBR incorporation by reference

ICR information collection request

LAER lowest available control technology

kg/lacs kilograms per liter of applied coating solids

km kilometer

kwh kilowatt hours

mtCO 2 e metric tons of carbon dioxide equivalents

NAICS North American Industry Classification System

NESHAP National Emission Standard for Hazardous Air Pollutant

NMOC nonmethane organic compound(s)

Non-EDP non-electrodeposition

NSPS New Source Performance Standards

NSR New Source Review

NTTAA National Technology Transfer and Advancement

OMB Office of Management and Budget

lb/gal acs pounds per gallon of applied coating solids

PM particulate matter

PRA Paperwork Reduction Act

PSD Prevention of Significant Deterioration

RACT reasonably available control technology

RFA Regulatory Flexibility Act

RIN Regulatory Information Number

RTO regenerative thermal oxidizer

SSM startup, shutdown, and malfunction

scf standard cubic feet

TE transfer efficiency

THC total hydrocarbon

tpy tons per year

UMRA Unfunded Mandates Reform Act

U.S.C. United States Code

VCS Voluntary Consensus Standards

VOC volatile organic compound(s)

Organization of this document. The information in this preamble is organized as follows:

I. General Information

A. Does this action apply to me?

B. Where can I get a copy of this document and other related information?

C. Judicial Review and Administrative Review

II. Background

A. What is the statutory authority for this final action?

B. How does the EPA perform the NSPS review?

C. What is the ALDT surface coating source category regulated in this final action?

D. What changes did we propose for the ALDT surface coating NSPS?

III. What actions are we finalizing and what is our rationale for such decisions?

A. Emission Limits

B. Work Practice Standards

C. Plastic Parts Provision

D. Testing, Monitoring, Recordkeeping, and Reporting Provisions

E. Transfer Efficiency Provisions

F. NSPS Subpart MMa Without Startup, Shutdown, Malfunction Exemptions

G. Electronic Reporting

H. Test Methods

I. Other Final Amendments

J. Effective Date and Compliance Dates

IV. Summary of Cost, Environmental, and Economic Impacts

A. What are the air quality impacts?

B. What are the energy impacts?

C. What are the cost impacts?

D. What are the economic impacts?

E. What are the benefits?

F. What analysis of environmental justice did we conduct?

V. Statutory and Executive Order Reviews

A. Executive Order 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulation and Regulatory Review

B. Paperwork Reduction Act (PRA)

C. Regulatory Flexibility Act (RFA)

D. Unfunded Mandates Reform Act of 1995 (UMRA)

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

G. Executive Order 13045: Protection of Children From Environmental Health Risks and Safety Risks

H. Executive Order 13211: Actions Concerning Regulations That Significantly Affect Energy Supply, Distribution, or Use

I. National Technology Transfer and Advancement Act (NTTAA) and 1 CFR Part 51

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations

K. Congressional Review Act (CRA)

I. General Information

A. Does this action apply to me?

The source category that is the subject of this final action is automobile and light duty truck (ALDT) surface coating operations regulated under CAA section 111 NSPS. The 2022 North American Industry Classification System (NAICS) codes for the ALDT manufacturing industry are 336111 (automotive manufacturing), 336112 (light truck and utility vehicle manufacturing), and 336211 (manufacturing of truck and bus bodies and cabs and automobile bodies). The NAICS codes serve as a guide for readers outlining the types of entities that this final action is likely to affect. We estimate that 60 facilities engaged in ALDT manufacturing will be affected by this final action. The NSPS requirements finalized in this action and codified in 40 CFR part 60, subpart MMa are directly applicable to affected facilities that begin construction, reconstruction, or modification after May 18, 2022, which is the date of publication of the proposed NSPS subpart MMa in the Federal Register. The requirements in 40 CFR part 60, subpart MM are applicable to affected facilities that begin construction, reconstruction, or modification after October 5, 1979, but that begin construction, reconstruction, or modification no later than May 18, 2022. Federal, state, local, and tribal government entities will not be affected by this final action. If you have any questions regarding the applicability of this action to a particular entity, you should carefully examine the applicability criteria found in 40 CFR part 60, subparts MM and MMa, and consult the person listed in the FOR FURTHER INFORMATION CONTACT section of this preamble, your state or local air pollution control agency with delegated authority for the NSPS, or your EPA Regional Office.

B. Where can I get a copy of this document and other related information?

In addition to being available in the docket, an electronic copy of this final action is available on the internet at https://www.epa.gov/stationary-sources-air-pollution/automobile-and-light-duty-truck-surface-coating-operations-new. Following publication in the Federal Register, the EPA will post the Federal Register version of the final rule and key technical documents at this same website.

C. Judicial Review and Administrative Review

Under Clean Air Act (CAA) section 307(b)(1), judicial review of this final action is available only by filing a petition for review in the United States Court of Appeals for the District of Columbia Circuit by July 10, 2023. Under CAA section 307(b)(2), the requirements established by this final rule may not be challenged separately in any civil or criminal proceedings brought by the EPA to enforce the requirements.

Section 307(d)(7)(B) of the CAA further provides that “[o]nly an objection to a rule or procedure which was raised with reasonable specificity during the period for public comment (including any public hearing) may be raised during judicial review.” This section also provides a mechanism for the EPA to convene a proceeding for reconsideration, “[i]f the person raising an objection can demonstrate to the Administrator that it was impracticable to raise such objection within [the period for public comment] or if the grounds for such objection arose after the period for public comment (but within the time specified for judicial review) and if such objection is of central relevance to the outcome of the rule.” Any person seeking to make such a demonstration should submit a Petition for Reconsideration to the Office of the Administrator, U.S. Environmental Protection Agency, Room 3000, WJC South Building, 1200 Pennsylvania Ave. NW, Washington, DC 20460, with a copy to both the person(s) listed in the preceding FOR FURTHER INFORMATION CONTACT section, and the Associate General Counsel for the Air and Radiation Law Office, Office of General Counsel (Mail Code 2344A), U.S. Environmental Protection Agency, 1200 Pennsylvania Ave. NW, Washington, DC 20460.

II. Background

A. What is the statutory authority for this final action?

The EPA's authority for this final rule is CAA section 111, which governs the establishment of standards of performance for stationary sources. Section 111(b)(1)(A) of the CAA requires the EPA Administrator to list categories of stationary sources that in the Administrator's judgment cause or contribute significantly to air pollution that may reasonably be anticipated to endanger public health or welfare. The EPA must then issue performance standards for new (and modified or reconstructed) sources in each source category pursuant to CAA section 111(b)(1)(B). These standards are referred to as new source performance standards or NSPS. The EPA has the authority to define the scope of the source categories, determine the pollutants for which standards should be developed, set the emission level of the standards, and distinguish among classes, types, and sizes within categories in establishing the standards.

CAA section 111(b)(1)(B) requires the EPA to “at least every 8 years review and, if appropriate, revise” new source performance standards. However, the Administrator need not review any such standard if the “Administrator determines that such review is not appropriate in light of readily available information on the efficacy” of the standard. When conducting a review of an existing performance standard, the EPA has the discretion and authority to add emission limits for pollutants or emission sources not currently regulated for that source category.

In setting or revising a performance standard, CAA section 111(a)(1) provides that performance standards are to reflect “the degree of emission limitation achievable through the application of the best system of emission reduction which (taking into account the cost of achieving such reduction and any nonair quality health and environmental impact and energy requirements) the Administrator determines has been adequately demonstrated.” The term “standard of performance” in CAA section 111(a)(1) makes clear that the EPA is to determine both the best system of emission reduction (BSER) for the regulated sources in the source category and the degree of emission limitation achievable through application of the BSER. The EPA must then, under CAA section 111(b)(1)(B), promulgate standards of performance for new sources that reflect that level of stringency.

CAA section 111(h)(1) authorizes the Administrator to promulgate “a design, equipment, work practice, or operational standard, or combination thereof” if in his or her judgment, “it is not feasible to prescribe or enforce a standard of performance.” CAA section 111(h)(2) provides the circumstances under which prescribing or enforcing a standard of performance is “not feasible,” such as, when the pollutant cannot be emitted through a conveyance designed to emit or capture the pollutant, or when there is no practicable measurement methodology for the particular class of sources. Except as authorized under CAA section 111(h), CAA section 111(b)(5) precludes the EPA from prescribing a particular technological system that must be used to comply with a standard of performance. Rather, sources can select any measure or combination of measures that will achieve the standard.

Pursuant to the definition of new source in CAA section 111(a)(2), standards of performance apply to facilities that begin construction, reconstruction, or modification after the date of publication of the proposed standards in the Federal Register. Under CAA section 111(a)(4), “modification” means any physical change in, or change in the method of operation of, a stationary source which increases the amount of any air pollutant emitted by such source or which results in the emission of any air pollutant not previously emitted. Changes to an existing facility that do not result in an increase in emissions are not considered modifications. Under the provisions in 40 CFR 60.15, reconstruction means the replacement of components of an existing facility such that: (1) the fixed capital cost of the new components exceeds 50 percent of the fixed capital cost that would be required to construct a comparable entirely new facility; and (2) it is technologically and economically feasible to meet the applicable standards. Pursuant to CAA section 111(b)(1)(B), the standards of performance or revisions thereof shall become effective upon promulgation.

B. How does the EPA perform the NSPS review?

As noted in section II.A of this preamble, CAA section 111 requires the EPA to, at least every 8 years, review and, if appropriate, revise the standards of performance applicable to new, modified, and reconstructed sources. If the EPA revises the standards of performance, they must reflect the degree of emission limitation achievable through the application of the BSER considering the cost of achieving such reduction and any nonair quality health and environmental impact and energy requirements. CAA section 111(a)(1).

In reviewing an NSPS to determine whether it is “appropriate” to review and revise the standards of performance, the EPA evaluates the statutory factors, which may include consideration of the following information:

- Expected growth for the source category, including how many new facilities, reconstructions, and modifications may trigger NSPS in the future.

- Pollution control measures, including advances in control technologies, process operations, design or efficiency improvements, or other systems of emission reduction, that are “adequately demonstrated” in the regulated industry.

- Available information from the implementation and enforcement of current requirements indicating that emission limitations and percent reductions beyond those required by the current standards are achieved in practice.

- Costs (including capital and annual costs) associated with implementation of the available pollution control measures.

- The amount of emission reductions achievable through application of such pollution control measures.

- Any non-air quality health and environmental impact and energy requirements associated with those control measures.

In evaluating whether the cost of a particular system of emission reduction is reasonable, the EPA considers various costs associated with the particular air pollution control measure or a level of control, including capital costs and operating costs, and the emission reductions that the control measure or particular level of control can achieve. The Agency considers these costs in the context of the industry's overall capital expenditures and revenues. The Agency also considers cost-effectiveness analysis as a useful metric, and a means of evaluating whether a given control achieves emission reduction at a reasonable cost. A cost-effectiveness analysis allows comparisons of relative costs and outcomes (effects) of 2 or more options. In general, cost effectiveness is a measure of the outcomes produced by resources spent. In the context of air pollution control options, cost effectiveness typically refers to the annualized cost of implementing an air pollution control option divided by the amount of pollutant reductions realized annually.

After the EPA evaluates the statutory factors, the EPA compares the various systems of emission reductions and determines which system is “best,” and therefore represents the BSER. The EPA then establishes a standard of performance that reflects the degree of emission limitation achievable through the implementation of the BSER. In doing this analysis, the EPA can determine whether subcategorization is appropriate based on classes, types, and sizes of sources, and may identify a different BSER and establish different performance standards for each subcategory. The result of the analysis and BSER determination leads to standards of performance that apply to facilities that begin construction, reconstruction, or modification after the date of publication of the proposed standards in the Federal Register. Because the new source performance standards reflect the best system of emission reduction under conditions of proper operation and maintenance, in doing its review, the EPA also evaluates and determines the proper testing, monitoring, recordkeeping and reporting requirements needed to ensure compliance with the emission standards.

C. What is the ALDT surface coating source category regulated in this final action?

Pursuant to the CAA section 111 authority described earlier in this preamble, the EPA listed the ALDT surface coating source category under CAA section 111(b)(1). 44 FR 49222, 49226 (August 21, 1979). The EPA first promulgated NSPS for ALDT surface coating operations on December 24, 1980 (45 FR 85415; December 24, 1980). The 1980 ALDT NSPS are codified in 40 CFR part 60, subpart MM and are applicable to sources that commence construction, modification, or reconstruction after October 5, 1979 (ALDT NSPS MM). The ALDT NSPS MM regulate VOC emissions from surface coating operations located at automobile and light duty truck assembly plants. Subpart MM was amended in a series of actions and the last amendment was promulgated in 1994 (59 FR 51383; October 11, 1994).

The ALDT surface coating source category consists of each prime coat operation, each guide coat operation, and each topcoat operation in an automobile or light duty truck assembly plant. Subpart MM requires a monthly compliance demonstration with the VOC emission limit established for each surface coating operation:

- For prime coat operations:

- For electrodeposition (EDP) prime coat: 0.17 to 0.34 kilograms VOC/liter applied coating solids (kg VOC/l acs) (1.42 to 2.84 lbs VOC/gallon (gal) acs) depending on the solids turnover ratio (R T); for R T greater than 0.16, the limit is 0.17 kg VOC/l acs (1.42 lb VOC/gal acs); for turnover ratios less than 0.04, there is no emission limit.

- For non-EDP (spray applied) prime coat: 0.17 kg VOC/l acs (1.42 lb VOC/gal acs);

- For guide coat operations: 1.40 kg VOC/l acs (11.7 lb VOC/gal acs); and

- For topcoat operations: 1.47 kg VOC/l acs (12.3 lb VOC/gal acs).

Subpart MM provides default transfer efficiencies (TE) for various surface coating application methods for the monthly compliance calculation. The default TE values in subpart MM also account for the recovery of purge solvent. The monthly compliance calculation also includes control device VOC destruction efficiency as determined by the initial or the most recent control device performance test. The control devices identified in the ALDT NSPS MM include thermal and catalytic oxidizers. In addition, subpart MM requires continuous monitoring of thermal and catalytic oxidizer operating temperatures. Quarterly or semiannual reporting is required to report emission limit exceedances and negative reports are required for no exceedances. Surface coating operations for plastic body components or all-plastic automobile or light-duty truck bodies on separate coating lines are exempted from the ALDT NSPS MM. However, the attachment of plastic body parts to a metal body before the body is coated does not cause the metal body coating operation to be exempted. Additional detail on the ALDT surface coating source category and ALDT NSPS MM requirements are provided in the proposal (87 FR 30141; May 18, 2022).

The EPA estimates that the ALDT NSPS MM currently affects surface coating operations at 44 ALDT assembly plants operating in the U.S. ALDT NSPS MM sources and will be subject to the electronic reporting amendments being finalized by this action. The EPA also expects that an additional 16 ALDT assembly plants will commence construction, reconstruction, or modification of the affected surface coating operations over the next 8 years (after May 18, 2022). These new sources will be subject to the new ALDT NSPS MMa being finalized in this action.

The EPA proposed the current review of the ALDT NSPS MM on May 18, 2022 (87 FR 30141; May 18, 2022). We received 5 comment letters from the affected industry, the industry association, environmental groups, and a state environmental agency during the comment period. In addition, we met with the affected industry and the industry association on December 8 and 13, 2022. A summary of the more significant comments we timely received regarding the proposed rule and our responses are provided in this preamble. A summary of all other public comments on the proposal and the EPA's responses to those comments is available in the document titled, Summary of Public Comments and Responses on Proposed Rule: New Source Performance Standards for Automobile and Light Duty Truck Surface Coating Operations (40 CFR part 60, subpart MM) Best System of Emission Reduction Review, Final Amendments, Docket ID No. EPA–HQ–OAR–2021–0664. Additional information provided by the affected industry and the industry association in meetings held on December 8 and 13, 2022, to support their written comments and meeting minutes are provided in separate memoranda available in the docket. A “track changes” version of the regulatory language that incorporates the changes in this final action for ALDT NSPS MM is also available in the docket. In this action, the EPA is finalizing decisions and revisions pursuant CAA section 111(b)(1)(B) review for the ALDT surface coating source category after our consideration of all the comments received.

D. What changes did we propose for the ALDT surface coating NSPS?

The EPA proposed the results of the CAA 111(b)(1)(B) review of the ALDT NSPS, 40 CFR part 60, subpart MM on May 18, 2022 (87 FR 30141; May 18, 2022). The EPA proposed to codify the revisions to the ALDT NSPS MM in a new NSPS subpart, MMa. In the new subpart MMa, the EPA proposed requirements that apply to sources that commence construction, reconstruction, or modification after May 18, 2022. The revisions proposed to be codified in subpart MMa were: revised VOC emission limits for the prime coat, guide coat, and topcoat operations; the addition of work practices to minimize VOC emissions; revision of the plastic parts provision; updates to the capture and control devices and the associated testing and monitoring requirements; revision of the transfer efficiency provisions; revision of the recordkeeping and reporting requirements; the addition of electronic reporting; clarification of the requirements for periods of startup, shutdown, and malfunction (SSM); new test methods and incorporation by reference (IBR) of alternative methods; minor corrections and clarifications; and other amendments to harmonize the new NSPS subpart requirements with the Automobile and Light Duty Truck Surface Coating National Emission Standards for Hazardous Air Pollutants, 40 CFR part 63, subpart IIII (ALDT NESHAP) requirements.

The EPA also proposed electronic reporting requirements in subpart MM, which applies to affected sources that commenced construction, reconstruction, or modification after October 5, 1979, and on or before May 18, 2022.

III. What actions are we finalizing and what is our rationale for such decisions?

The EPA is finalizing revisions to the NSPS for the ALDT surface coating source category pursuant to CAA section 111(b)(1)(B) review. The EPA is promulgating the NSPS revisions in a new subpart, 40 CFR part 60, subpart MMa. Subpart MMa is applicable to affected sources constructed, modified, or reconstructed after May 18, 2022. This action also finalizes revisions to ALDT NSPS subpart MM. Subpart MM is applicable to affected sources that are constructed, modified, or reconstructed after October 5, 1979, but on or before May 18, 2022.

The final requirements in subpart MMa include the following revisions that the EPA proposed: VOC emission limits for the prime coat, guide coat, and topcoat operations; work practices to minimize VOC emissions; plastic parts provision; capture and control devices and the associated testing and monitoring requirements; transfer efficiency provisions; recordkeeping and reporting requirements; electronic reporting; requirements for periods of SSM; test methods and IBR of alternative methods; and other requirements to harmonize the new NSPS subpart MMa requirements with the Automobile and Light Duty Truck Surface Coating National Emission Standards for Hazardous Air Pollutants, 63 subpart IIII (ALDT NESHAP) requirements.

The final requirements also include the addition of electronic reporting requirements in subpart MM, which applies to affected sources that commenced construction, reconstruction, or modification after October 5, 1979, but on or before May 18, 2022.

A. Emission Limits

The EPA is finalizing VOC emission limits in new subpart MMa for each prime coat operation, each guide coat operation, and each topcoat operation in an automobile or light duty truck assembly plant, calculated monthly. For the prime coat operation, we are finalizing the proposed numeric limit with the addition of a solids turnover ratio (R T) in response to comments. For the guide coat and topcoat operations we are finalizing the proposed numeric limits.

- For prime coat operations:

- Electrodeposition (EDP) prime coat, 0.027 to 0.055 kilograms VOC/liter applied coating solids (kg VOC/l acs) (0.23 to 0.46 lbs VOC/gal acs) depending on the solids turnover ratio (R T) when R T is between 0.04 and 0.16; For R T greater than 0.16, the limit is 0.027 kg VOC/l acs (0.23 lb VOC/gal acs); for turnover ratios less than 0.04, there is no emission limit.

- Non-EDP (spray applied) prime coat, 0.028 kg VOC/l acs (0.23 lb VOC/gal acs).

- For guide coat operations, 0.35 kg VOC/l acs (2.92 lb VOC/gal acs); and

- For topcoat operations, 0.42 kg VOC/l acs (3.53 lb VOC/gal acs).

For prime coat operations, the final VOC emission limit reflects the EPA's determination that use of waterborne prime coat applied by EDP with control of the curing oven emissions with thermal oxidation that is capable of achieving 95 percent destruction or removal efficiency (DRE) represents the updated BSER for this surface coating operation. The final emission limit for EDP prime coat operations in subpart MMa includes the R T, which is a factor in determining compliance with the VOC emission limit for the prime coat in the current subpart MM. EPA determined the final emission limit for the prime coat operation was cost effective.

For guide coat operations, the final VOC limit reflects the EPA's determination that use of waterborne or solvent borne guide coats applied by spray application with control of the waterborne flash off area or control of the solvent borne booth and oven with either a carbon adsorber concentrator and an RTO or just an RTO, with the RTO achieving 95 percent DRE of the captured emissions represents the updated BSER for this surface coating operation. The final emission limit for guide coat operations in subpart MMa is based on facilities that are subject to and achieve the emission limit of 0.35 kg VOC/l acs (2.92 lb VOC/gal acs) by using either: (1) waterborne guide coat with control of the flash off area with a carbon adsorber concentrator and an RTO but no control of the booth; or (2) solvent borne guide coat and control of the booth and oven with either a carbon adsorber concentrator and an RTO or just an RTO, with the RTO achieving 95 percent DRE of the captured emissions. The EPA determined the final emission limit for the guide coat operation was cost effective.

For topcoat operations, the final VOC limit reflects the EPA's determination that the use of waterborne basecoats and solvent borne clearcoats applied by spray application with control of the waterborne basecoat booth and/or the flash off area and control of the solvent borne clearcoat booth, flash off area, and topcoat oven with an RTO or a combination of a concentrator and an RTO, with the RTO achieving 95 percent DRE of the captured emissions represents the updated BSER for this surface coating operation. The final emission limit for topcoat operations in subpart MMa is based on facilities that are subject to and achieve the emission limit of 0.42 kg VOC/l acs (3.53 lb VOC/gal acs) by using: (1) waterborne basecoat with control of the booth and/or the flash off area with a combination of a concentrator and an RTO; and (2) solvent borne clearcoat with control of the automated sections of the clearcoat booth, the clearcoat flash off area and the topcoat oven with an RTO or a combination of a concentrator and an RTO, with the RTO achieving 95 percent DRE of the captured emissions. The EPA determined the final emission limit for the topcoat operation was cost effective.

The EPA identified and considered more stringent emission limits in its review that were not selected for the proposed and final actions. The more stringent emission limits were not selected because the EPA determined they were based on coating technology that was not adequately demonstrated by the industry (i.e., powder coating for the guide coat operation) or because the EPA determined they were not cost effective (i.e., lower limits for the EDP prime coat and topcoat operations).

Pursuant to CAA section 111(b)(1)(B), the EPA conducted a BSER review of the requirements in 40 CFR part 60, subpart MM and presented the results of this review, along with our proposed determinations, in section IV.A of the proposed rule preamble (87 FR 30147; May 18, 2022). A detailed discussion of our review and proposed determinations are included in the memorandum titled, Final Rule Best System of Emission Reduction Review for Surface Coating Operations in the Automobile and Light-Duty Truck Source Category (40 CFR part 60, subpart MM), available in the docket for this action. Based on our review, we proposed revised VOC emission limits for each prime coat operation, each guide coat operation, and each topcoat operation in an automobile or light duty truck assembly plant. The final VOC emission limits are based on the proposed VOC emission limits and the revisions made in response to comments we received, as described here.

1. Prime Coat Operation

a. Proposed Emission Limit

For the prime coat operation, at proposal, the EPA evaluated 2 regulatory options based on facilities using an EDP prime coat dip tank system. Both options were more stringent than the ALDT NSPS MM limit for prime coat operations. The options were based on 19 facilities with 28 EDP prime coat operations that are currently subject to more stringent prime coat limits than the ALDT NSPS MM prime coat limit.

The first option was a numerical VOC emission limit of 0.028 kg VOC/l acs (0.23 lb VOC/gal acs) based on control of the curing oven emissions only with thermal oxidation (e.g., an RTO) achieving 95 percent DRE of the captured emissions. This VOC emission limit is demonstrated by 13 of the 44 existing ALDT facilities and the EPA determined the cost effectiveness for this option to be $6,800/ton of VOC reduced. The EPA considered this option to be cost-effective over the baseline level of control and to be consistent with one of the compliance options for EDP prime coat systems in the ALDT NESHAP.

The second option was a numerical VOC emission limit of 0.005 kg/l acs (0.040 lb VOC/gal acs) based on control of both the oven and the tank emissions with an RTO capable of achieving 95 percent DRE. Four plants control the emissions from the EDP prime coat dip tank in addition to the oven emissions with some form of thermal oxidation. At proposal, the EPA determined the second option to be not cost-effective and not reflective of BSER because the cost effectiveness of controlling the tank emissions was estimated to be $91,100 per ton of VOC reduced. In addition, the EPA estimated the second option would only achieve an additional 3 tpy of VOC reductions over the first option and would have an estimated incremental cost effectiveness of $46,000 per ton of VOC reduced compared to the first option. Due to the poor cost-effectiveness of this option relative to the baseline level of control and the likewise unfavorable incremental cost-effectiveness of this option when compared to the first option, we rejected the second option as the BSER.

The EPA proposed the first option of 0.028 kg VOC/l acs (0.23 lb VOC/gal acs) with a cost effectiveness of $6,800/ton of VOC reduced, which reflects the EPA's determination that control of the curing oven emissions with thermal oxidation that is capable of achieving 95 percent DRE represents the updated BSER for the prime coat operations. The proposed emission limit for the EDP prime coat operation did not include the solids turnover ratio (R T), which is a factor in determining compliance with the VOC emission limit for the prime coat dip tank in the subpart MM. This factor was not proposed because it is not included in the facility permits with more stringent limits than the current prime coat operation VOC limits, which were the basis of our revised BSER determination (87 FR 30148, May 18, 2022). We also proposed a non-EDP limit of 0.028 kg VOC/l acs (0.23 lb VOC/gal acs) for spray application of the prime coat based on industry input.

b. How the Final Revisions to Prime Coat Limits Differ From the Proposed Revisions

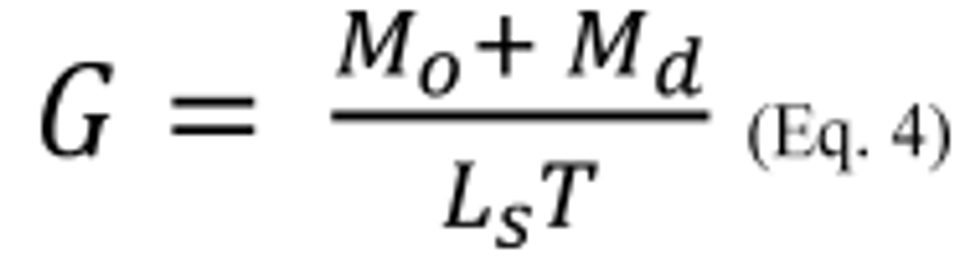

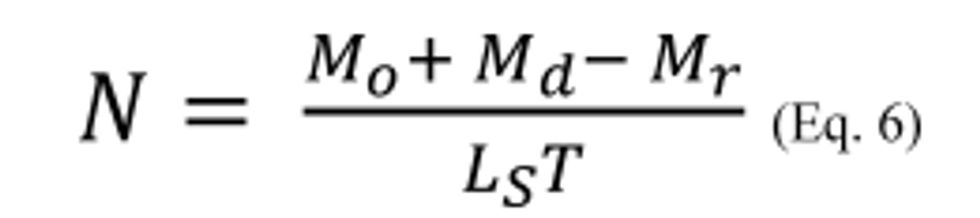

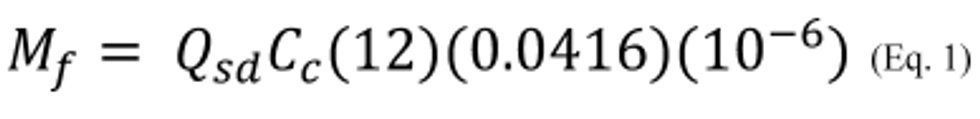

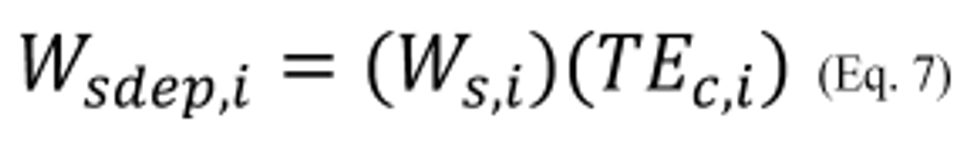

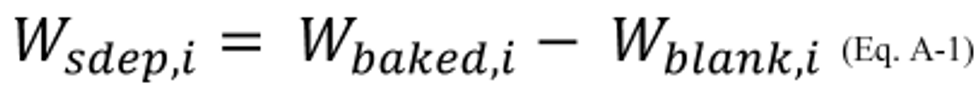

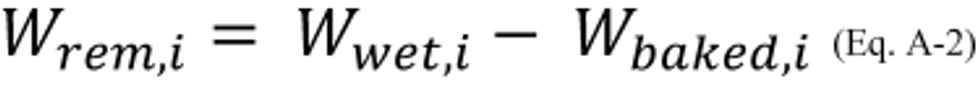

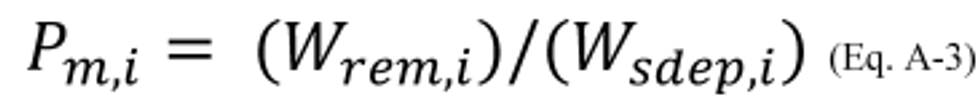

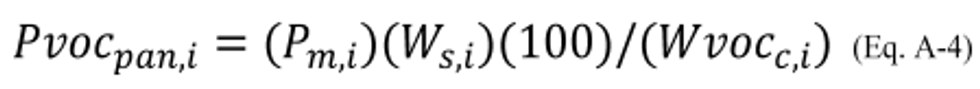

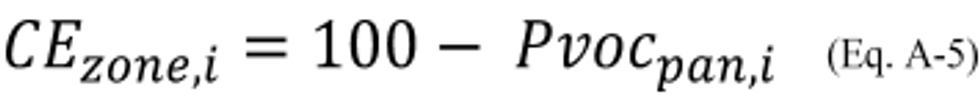

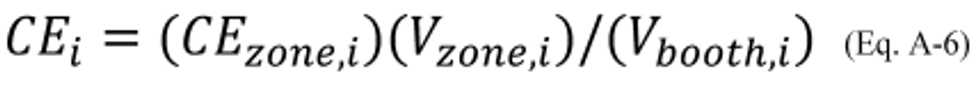

As a result of comments received for the prime coat operation, in subpart MMa the EPA is finalizing a revised prime coat operation limit with the inclusion of the solids turnover ratio (R T). The EPA is promulgating the following limits for the prime coat operation in 40 CFR 60.392a depending on the solids turnover ratio (R T); for R T greater than 0.16, the limit is 0.027 kg VOC/l acs (0.23 lb VOC/gal acs); for turnover ratios less than 0.04 (i.e., periods of non-production), there is no emission limit; and when the solids turnover ratio is between 0.04 and 0.16 (inclusive), the emission limit is determined using the following equation:

Limit = 0.027 × 350 (0.160−R T) kg of VOC per liter of applied coating solids. The EPA is also including the definition of solids turnover ratio in 40 CFR 60.391a.

c. Prime Coat Limits Comments and Responses

Comment: One commenter stated that the subpart MMa prime coat operation standards should reflect a modern E-coat system with VOC controls on emissions from the curing oven. According to the commenter, anything more would not be cost-effective and would only reduce insignificant amounts of VOC.

Response: As a result of the BSER determination for the prime coat operation, the EPA is finalizing, as proposed, standards that reflect a modern EDP prime coat (E-coat) system with control of VOC emissions from the curing oven. The final prime coat operation standard reflects a numeric limit of 0.23 lb VOC/gal acs with a cost effectiveness of $6,800/ton VOC reduced, as proposed. The EPA estimates the VOC emission reduction associated this final limit to be 40 tpy compared to the 1980 NSPS baseline level of control.

Comment: Two commenters asserted that the EPA must include the solids turnover ratio factor in the emission limit for prime coat operation. Regarding the decision to exclude the option of utilizing the solids turnover for prime coat compliance demonstrations, one commenter stated that the EPA needs to review the extensive data and supporting comments that served as the basis for the 1994 final rule that established the prime coat limits as a function of the solids turnover ratio. The commenter stated that the rationale was compelling then, and it is equally compelling now, and that the EPA has not adequately explained how prime coat downtime or reduced throughput would be accommodated under the newly proposed standard and why a change is needed. The commenter stated that eliminating consideration of the solids turnover ratio would be arbitrary and capricious. With the solids turnover ratio, the commenter stated, the prime coat limit of 0.23 lbs VOC/gal acs can be achieved when the solids turnover ratio is greater than or equal to 0.16. One commenter asserted that without the adjusted emission limit for low solid turnover ratios, the commenter could not achieve the existing NSPS limit.

Response: In the proposal the EPA noted that ALDT prime coat operation permit limits did not include a factor to account for the solids turnover ratio, and the EPA understood that to mean that facilities currently using the EDP prime coat process are now able to consistently maintain the solids turnover ratio (R T) at a value equal to or greater than 0.16 (87 FR 30148, May 18, 2022). Therefore, we proposed a prime coat limit of 0.23 lbs VOC/gal acs based on sources' control of the curing oven emissions with thermal oxidation (e.g., an RTO) achieving 95 percent DRE without the R T factor. After consideration of the 1994 final rule (59 FR 51383, October 11, 1994) and in response to the commenters' argument, we are retaining the R T factor to account for periods of non-production and reduced throughput. Thus, the EPA is promulgating the following limits in 40 CFR 60.392a depending on the solids turnover ratio (R T); for R T greater than 0.16, the limit is 0.027 kg VOC/l acs (0.23 lb VOC/gal acs); for turnover ratios less than 0.04 (periods of non-production), there is no emission limit; and when the solids turnover ratio is between 0.04 and 0.16 (inclusive), the emission limit is determined using the following equation:

Limit = 0.027 × 350 (0.160−R T) kg of VOC per liter of applied coating solids

2. Guide Coat Operation

a. Proposed Emission Limit

For the guide coat operation, at proposal the EPA evaluated four regulatory options. These regulatory options were more stringent than the ALDT NSPS MM limit of 1.40 kg VOC/l acs (11.7 lb VOC/gal acs). These options were based on 14 facilities with 31 guide coat operations subject to more stringent guide coat limits than the current ALDT NSPS MM guide coat limit (87 FR 30141; May 18, 2022). The guide coat emission limits found in permits for facilities using liquid coatings that were more stringent than the ALDT NSPS MM limit ranged from 0.060 to 1.21 kg VOC/l acs (0.050 to 10.11 lb VOC/gal acs) and 27 of the 31 guide coat operations were subject to limits less than or equal to 0.69 kg VOC/l acs (5.5 lb VOC/gal acs). Three of the 31 guide coat operations with limits more stringent than the ALDT NSPS MM are meeting a lower emission limit (less than 0.060 kg VOC/l acs (0.050 lb VOC/gal acs)) or have no emission limit based on the use of powder guide coat and no controls.

The first option evaluated at proposal for the guide coat operation was a numerical VOC emission limit of 0.57 kg VOC/l acs (4.8 lb VOC/gal acs) to reflect control of the guide coat oven with an RTO achieving 95 percent DRE and use of solvent borne or waterborne coating and no control of the guide coat spray booth or heated flash off area exhausts. The facilities using this system of emission reduction had limits in the range of 0.41 to 0.66 kg VOC/l acs (3.46 to 5.5 lb VOC/gal acs). This limit option was selected because it is the most common numerical limit for these facilities and matches the operating permit limit for 9 facilities with this control scenario. The EPA estimated that this option would reduce emissions from a typical guide coat operation by about 40 tpy of VOC at a cost of $4,400 per ton of VOC reduced.

The second option evaluated was a VOC emission limit of 0.35 kg VOC/l acs (2.92 lb VOC/gal acs) to reflect control of the guide coat spray booth and oven with either a carbon adsorber and an RTO or a concentrator and an RTO, with the RTO achieving 95 percent DRE of the captured emissions and the use of solvent borne guide coat. This VOC emission limit matches the 2020 presumptive best available control technology (BACT) emission limit for the guide coat operation identified by EPA Region 5, and 2 facilities are currently subject to this limit. The EPA estimated that this option would reduce emissions from a typical guide coat operation by about 50 tpy of VOC at a cost of $4,900 per ton of VOC reduced.

The third option was a VOC emission limit of 0.036 kg VOC/l acs (0.30 lb VOC/gal acs) to reflect the use of a waterborne guide coat demonstrated by 1 facility employing the use of a 3-wet coating process. As described in the proposal, in a 3-wet process the guide coat and topcoat operations are combined, and the guide coat oven is replaced by a heated flash off area, resulting in lower emissions from the guide coat operation and a more efficient process in terms of time and energy savings for the facility. The process consists of a series of 2 separate booths with heated flash off areas for partial cure (one for the guide coat and one for the basecoat), followed by a clearcoat booth, a flash off area, and a topcoat oven (where the guide coat, the basecoat, and the topcoat are fully cured). Only one facility with 2 guide coat operations is subject to this VOC emission limit (0.036 kg VOC/l acs (0.30 lb VOC/gal acs)) and uses the 3-wet process for the guide coat operation. The costs associated with this option are for controlling the guide coat heated flash off area emissions with an RTO achieving 95 percent DRE of the captured emissions. The EPA estimated that this option would reduce emissions (from a typical guide coat operation) by about 73 tpy of VOC at a cost of $3,250 per ton of VOC reduced. As discussed in the proposal, although this option is cost-effective when considering the cost of controls, the emission limit would be achievable only for guide coat operations as part of a 3-wet combined guide coat and topcoat operation. Further, it would be not cost-effective for the purposes of this BSER analysis due to the major capital investment associated with reconfiguring the guide coat operation so that it could become part of a 3-wet combined guide coat and topcoat operation.

The fourth option we considered was a numerical VOC limit of 0.016 kg VOC/l acs (0.13 lb VOC/gal acs) to reflect the use of a powder guide coat, instead of a liquid coating. One facility is subject to an emission limit of 0.016 kg VOC/l acs (0.13 lb VOC/gal acs), and 3 facilities either are subject to a lower emission limit than 0.016 kg VOC/l acs (0.13 lb VOC/gal acs) or have no emission limit based on the use of powder guide coat and no controls. As discussed in the proposal, operations using powder coatings are essentially non-emitting operations because the dry powder coating has no solvent. Therefore, guide coat operations using powder coatings emit virtually no VOCs from the booth, flash off area(s), or curing oven. The use of powder for the guide coat operation could eliminate all VOC emissions from a typical guide coat operation with no additional control costs and could be the best environmental outcome. However, the industry has experienced difficulties (including appearance and finish quality) with the application of powder coatings to ALDT vehicle bodies, so we considered this option to be not adequately demonstrated. Further, it would not be cost-effective for the purposes of this BSER analysis for a reconstructed or modified operation due to the major capital investment associated with switching the guide coat operation from a liquid coating application to a powder coating application.

After consideration of all guide coat options, the EPA proposed a revised VOC limit of 0.35 kg VOC/l acs (2.92 lb VOC/gal acs) for the guide coat operation based on Option 2, being the use of solvent borne guide coat and 95 percent control of the spray booth and oven with either a carbon adsorber and an RTO or a concentrator and an RTO, with the RTO achieving 95 percent DRE of the captured emissions, as the updated BSER for guide coat operation. This option also represents the lower range of emission limits for facilities using solvent borne guide coats and is demonstrated by 3 of 44 existing ALDT plants.

b. How the Final Revisions to Guide Coat Limits Differ From the Proposed Revisions

After considering the comments on the proposed revisions to the guide coat emission limit, the EPA is finalizing the guide coat operation VOC emission limit as proposed.

c. Guide Coat Comments and Responses

The EPA received comments on the guide coat operation that caused us to further evaluate the use of waterborne and solvent borne coatings and to investigate the controls used for each, as described in the EPA response in this section.

Comment: One commenter asserted that reliance on New Source Review (NSR) BACT and LAER determinations in setting subpart MMa emissions standards would result in unreasonably constrained national standards. For example, according to the commenter, the proposed guide coat standard based on a BACT determination for solvent-based systems using add-on booth controls does not reasonably or adequately accommodate waterborne guide coat systems.

The commenter also provided determinations for 2 case studies for guide coat operations with BACT limits in ALDT plants located in the state of Indiana to support their claim that the proposed subpart MMa emissions standards for the guide coat operations are not cost-effective for sources using waterborne coatings. The commenter stated the standards must be adjusted to avoid the need to install cost-ineffective spray booth controls on waterborne guide coat lines.

Response: The EPA considered the VOC emission limits in ALDT plant title V permits in its BSER analysis, including those that were derived from BACT determinations. The EPA did not consider the limits that were derived from LAER determinations in its BSER analysis, except for limits that were determined to be both BACT and LAER. The EPA considered these VOC emission limits in its BSER review because they represented the best available control technology at the time, were developed by the individual ALDT plants, are inherently cost-effective, and were approved by state and local permitting authorities. However, as required by CAA section 111(b)(1)(B), the EPA conducted its own cost-effectiveness and other analyses to determine BSER, as described in the proposal (87 FR 30141, May 18, 2022).

The EPA disagrees that the proposed guide coat standard is based on a BACT determination for solvent-based systems using add-on booth controls that does not reasonably or adequately accommodate waterborne guide coat systems. In our review of guide coat operations, we generally found that most operations use solvent borne coatings. However, for guide coat operations with VOC emission limits lower than the 1980 ALDT NSPS limit, we found 8 operations using a waterborne coating (the rest use a solvent borne coating). For guide coat operations, we are clarifying the description included in the proposal for the 2 cost-effective options (Option 1 and Option 2) to distinguish between the use of waterborne basecoat and solvent borne coatings, as described here.

The first option for guide coat operations was represented by plants using either waterborne or solvent borne coatings achieving a numerical VOC emission limit of 4.8 lb VOC/gal acs (0.57 kg VOC/l acs). We found that plants achieving the 4.8 lb VOC/gal acs limit using waterborne guide coat had no control of the booth or flash off area (for 3-wet operations) or controlled the guide coat oven with an RTO achieving 95 percent DRE of the captured emissions (if not a 3-wet operation). Plants achieving the 4.8 lb VOC/gal acs limit using solvent borne guide coat generally control one of the following: the guide coat spray booth, the guide coat flash off area, or the guide coat oven (if not a 3-wet operation).

The second proposed option for guide coat operations was represented by plants using either waterborne or solvent borne coatings achieving a numerical VOC emission limit of 2.92 lb VOC/gal acs (0.35 kg VOC/l acs). We found that plants subject to and achieving the 2.92 lb VOC/gal acs limit used either: (1) waterborne guide coat and control of the flash off area with no control of the booth; or (2) solvent borne guide coat and control of the booth and oven with either a carbon adsorber and an RTO or a concentrator and an RTO, with the RTO achieving 95 percent DRE of the captured emissions.

During our review since proposal, we updated the cost effectiveness calculations for the guide coat operation by increasing the interest rate to 7 percent and the Chemical Engineering Plant Cost Index (CEPCI) to the 2021 index, to estimate the incremental cost effectiveness between two guide coat options and found it to be reasonable at $6,670/ton VOC reduced. We determined this incremental cost effectiveness has a lower cost per ton of VOC reduced than the cost effectiveness for the prime coat operation ($6,800/ton VOC reduced) and results in greater VOC emission reductions (147 tpy compared to 40 tpy for prime coat) when compared to the 1980 NSPS baseline level of control.

The EPA also collected compliance data from one ALDT plant cited by the commenter, Subaru of Indiana, covering the period from 2019 to 2021 and these data show that the waterborne guide coat operations are consistently achieving a daily emission rate of 2.1 to 2.2 lb VOC/gal acs. These achieved emission rates are about 75 percent of the proposed monthly emission rate of 2.92 lb VOC/gal acs. The waterborne guide coat operations at Subaru Indiana Automotive are subject to a BACT emission limit of 4.8 lb VOC/gal acs, and do not apply emission reductions from any add-on controls to achieve compliance. These data support the EPA's proposed emission limit of 2.92 lb VOC/gal acs and the determination that this emission limit is achievable in a cost-effective manner for both waterborne and solvent borne guide coat systems.

Therefore, the EPA disagrees that the proposed standard does not reasonably or adequately accommodate waterborne guide coat systems and is finalizing the guide coat emission limit, as proposed. Additional detail is provided in the memorandum titled, Final Cost and Environmental Impacts Memo for Surface Coating Operations in the Automobiles and Light-Duty Trucks Source Category (40 CFR part 60, subpart MMa), located in the docket for this action.

Comment: One commenter recommended a guide coat standard of 4.8 lb VOC/gal acs for new and reconstructed facilities. This standard has been achieved in the ALDT sector in cases where a waterborne guide coat is used with VOC controls on the oven, but no additional VOC controls on the booth. For modifications, the commenter recommended the EPA maintain in subpart MMa the subpart MM VOC emission limit for guide coat operations. The commenter stated that the EPA has not considered the cost-effectiveness to implement a lower standard in the event of a modification of a guide coat affected facility.

Response: As a result of the BSER review, the EPA has determined that a guide coat standard of 2.92 lb VOC/gal acs reflects BSER for new, reconstructed, and modified sources. We found this option to be achievable for both waterborne and solvent borne coating applications and the emission limit is consistent with the 2020 presumptive BACT emission limit identified by U.S. EPA Region 5. Contrary to the commenter's statement, we found that plants achieving the 4.8 lb VOC/gal acs limit used waterborne guide coat and no control of the booth or flash off area. This numeric limit would represent no change from the 1980 NSPS MM level of no control for waterborne guide coat operations (i.e., the 1980 limit and the limit of 4.8 lb VOC/gal acs could both be achieved by plants with no add-control of the waterborne guide coat operations). Our analysis indicates that waterborne guide coat operations can achieve a limit of 2.92 lb VOC/gal acs by controlling the emissions from the waterborne guide coat flash off area. The EPA identified this as the difference between the 2 guide coat options with an incremental cost effectiveness of $6,670 per ton of VOC reduced.

During our review we identified no modifications (consistent with part 60 definitions and proposed subpart MMa exceptions) for guide coat operations. Instead, we found that guide coat systems are newly constructed or reconstructed (and not modified) at existing ALDT plants. Subpart MMa would not be triggered if the changes to an existing system do not meet either the part 60 definition of modification or the subpart MMa exceptions for modifications. For these reasons subpart MM did not include separate emission limits for guide coat modifications, and separate emission limits were not proposed for the new subpart MMa. The commenter also provided no data or information to support a separate emission limit for modifications. Therefore, we are finalizing the proposed standard for the guide coat operation, including for modifications.

Additional detailed on modifications for ALDT affected facilities is provided in the document titled, Summary of Public Comments and Responses on Proposed Rule: New Source Performance Standards for Automobile and Light Duty Truck Surface Coating Operations (40 CFR part 60, subpart MM) Best System of Emission Reduction Review, Final Amendments, Docket ID No. EPA–HQ–OAR–2021–0664.

3. Topcoat Operation

a. Proposed Emission Limit

The ALDT NSPS subpart MM topcoat limit is based on the application of topcoat in one booth. It is also based on no control of waterborne topcoats (e.g., waterborne base coat and clearcoat) if used, or based on 95-percent control of the topcoat booth and oven VOC emissions if solvent borne topcoats (solvent borne base coat and clearcoat) are used with a thermal or catalytic oxidizer.

For the topcoat operation, at proposal, the EPA evaluated 2 regulatory options. These regulatory options were more stringent than the ALDT NSPS MM limit of 1.47 kg VOC/l acs (12.3 lb VOC/gal acs). These options were based on 20 facilities operating approximately 25 topcoat lines that are subject to more stringent topcoat limits than the topcoat VOC limit in the ALDT NSPS MM (87 FR 30150; May 18, 2022). The topcoat VOC emission limits more stringent than the current ALDT NSPS MM range from 0.28 to 1.44 kg VOC/l acs (2.32 to 12.0 lb VOC/gal acs). The regulatory options include the use of add-on controls for both waterborne and solvent borne basecoats and the use of add-on controls for solvent borne clearcoats (the EPA is not aware of any facilities in the U.S. using waterborne clearcoats).

The first option evaluated in the ALDT NSPS review for the topcoat operation is a numerical topcoat limit of 0.62 kg VOC/l acs (5.20 lb VOC/gal acs) demonstrated by 6 facilities with 11 topcoat operations with control of the clearcoat spray booth and the topcoat oven with a concentrator, such as a carbon adsorber or rotary carbon adsorber, followed by a thermal oxidizer, usually an RTO achieving 95 percent DRE of the captured emissions. The EPA estimated this option would reduce VOC emissions from a typical topcoat operation by 110 tpy of VOC at a cost of $5,200 per ton of VOC reduced.

The second option considered by the EPA for the topcoat operation is a numerical topcoat limit of 0.42 kg VOC/l acs (3.53 lb VOC/gal acs) demonstrated by 2 facilities operating 3 coating lines (corrected in this final action to reflect 3 facilities operating 4 coating lines) with control of the basecoat spray booth and/or the basecoat flash off area, as well as the clearcoat spray booth and topcoat oven. The add-on controls used by facilities include a thermal oxidizer, usually an RTO achieving 95 percent control of the captured emissions and a concentrator, such as a carbon adsorber or rotary carbon adsorber before the RTO (same as the first option). For this option, the emissions from the basecoat spray booth and/or the basecoat flash off area would also be routed to the concentrator before going to the RTO. This option also represents the lower range of emission limits for topcoat operations using solvent borne basecoat and clearcoats and it matches the 2020 presumptive BACT emission limit identified by EPA Region 5. The EPA estimated that this option would reduce emissions from a typical topcoat operation by 160 tpy of VOC at a cost of $7,900 per ton of VOC reduced (corrected in this final action). The EPA proposed a revised VOC limit of 0.42 kg VOC/l acs (3.53 lb VOC/gal acs) for the topcoat operation based on Option 2.

After consideration of the 2 topcoat options, the EPA proposed option 2, a revised VOC limit of 0.42 kg VOC/l acs (3.53 lb VOC/gal acs) for the topcoat operation based on control of the basecoat spray booth and/or the basecoat heated flash off area, as well as the clearcoat booth and the topcoat oven with an RTO or a combination of a concentrator and RTO, with the RTO achieving 95 percent DRE of the captured emissions.

b. How the Final Revisions to Topcoat Limits Differ From the Proposed Revisions

After considering the comments on the proposed revisions to the topcoat emission limit, the EPA is finalizing the topcoat operation VOC emission limit, as proposed.

c. Topcoat Comments and Responses

Similar to the guide coat operation, the EPA received comments on the topcoat operation that caused us to further evaluate the use of waterborne and solvent borne coatings and to further investigate the controls used for each. This evaluation resulted in the finding that topcoat operations using a waterborne basecoat and achieving the 3.53 lb VOC/gal acs limit are doing so by controlling the waterborne basecoat booth and/or flash off area, as stated in the EPA response in this section. During this evaluation we also updated the cost effectiveness calculations for the topcoat operation by increasing the interest rate to 7 percent and the CEPCI to the 2021 index, we made a correction to the proposed topcoat cost effectiveness calculations, and we estimated the incremental cost effectiveness between the two topcoat options.

Comment: One commenter stated that the EPA cannot use Prevention of Significant Deterioration (PSD) permits by themselves as a basis for setting national emissions standards, but that PSD permits do provide useful information as to what emissions control alternatives should be rejected, since state permitting agencies routinely use incremental cost-effectiveness analysis in assessing emissions control alternatives in PSD permitting. The commenter provided determinations for 2 case studies for topcoat operations with BACT limits in the state of Indiana to support their claim that the proposed subpart MMa emissions standards for the topcoat operations are not cost-effective for sources using waterborne coatings. The commenter stated the standards must be adjusted to avoid the need to install cost-ineffective spray booth controls on waterborne topcoat lines.

Response: CAA section 111(b)(1)(B) requires the EPA to conduct its own cost effectiveness determination as part of the BSER analysis. As part of that analysis, the EPA also considered these same topcoat operations identified by the commenter in the 2 case studies cited by the commenter in its BSER review. The BACT limits referred to by the commenter, reflected in the ALDT plants' title V operating permits, are lower than the 1980 subpart MM emissions limits for topcoat operations. Thus, even the examples provided by the commenters indicate that ALDT plants can achieve a greater level of emission reductions in topcoat operations than the current standards. In addition, the EPA identified topcoat operations achieving lower VOC emission limits than those reflected in the 2 case studies and determined the proposed limit for the topcoat operation is achievable and cost-effective.

In our review of topcoat operations, we found that more plants use waterborne than solvent borne coatings for the basecoat and that all plants use solvent borne clearcoats. For topcoat operations, we are clarifying the description of the 2 cost-effective options included in the proposal to better distinguish between the use of waterborne and solvent borne coatings, as described here.

For topcoat operations, the first option was represented by plants achieving a BACT limit of 5.2 lb VOC/gal acs by controlling the solvent borne clearcoat process only and no control of the waterborne basecoat part of the topcoat operation. We found that plants achieving a limit of 5.2 lb VOC/gal acs used: (1) waterborne basecoat and no control of the basecoat booth and no control of the heated flash off area; and (2) solvent borne clearcoat with control of the automated sections of the clearcoat booth and the clearcoat flash off area and the topcoat (combined basecoat and clearcoat) oven. The automated sections of the solvent borne clearcoat booth are controlled by either an RTO or a combination of a concentrator and an RTO. The concentrators include a carbon or zeolite adsorber (either a dual bed system or rotary wheel system) before the RTO, and most RTOs achieve greater than 95 percent DRE of the captured emissions. The topcoat oven is controlled with an RTO that achieves 95 percent DRE of the captured emissions. For topcoat operations using a waterborne basecoat, this numeric limit would represent no change from the 1980 NSPS level of no add-on control of the waterborne basecoat. For topcoat operations using a solvent borne clearcoat, this numeric limit would represent an increase from the 1980 NSPS level of add-on control (control of the automated sections of the clearcoat booth and flash off area). Therefore, the cost effectiveness for this option reflects the emission reductions and costs associated with controlling the solvent borne clearcoat process.

For topcoat operations, the proposed second option was represented by plants achieving a BACT limit of 3.53 lb VOC/gal acs by controlling both the waterborne basecoat and solvent borne clearcoat parts of the topcoat operation. We found that plants achieving a limit of 3.53 lb VOC/gal acs limit used: (1) waterborne basecoat with control of the booth and/or the flash off area with an RTO; and (2) solvent borne clearcoat with control of the automated sections of the clearcoat booth, the clearcoat flash off area and the topcoat (combined basecoat and clearcoat) oven, as described in the first topcoat option. For waterborne basecoat operations, this numeric limit represents an increase in the level of control (control of the waterborne basecoat booth and/or flash off area) compared to the 1980 NSPS (no control). For solvent borne clearcoat operations, this numeric limit represents the same increase in the level of control (compared to the 1980 NSPS) as the first topcoat option (by adding control of the automated sections of the clearcoat booth and flash off area), and no change when compared to the first topcoat option. Therefore, the cost effectiveness for the second topcoat option reflects the emission reductions and costs associated with controlling the water borne basecoat process.

As a result of the BSER analysis for the topcoat operation, the EPA is clarifying that the difference between the 2 options is due to control of VOC emissions from the waterborne base coat booth and/or flash off area with an incremental cost effectiveness of $6,500 per ton of VOC reduced. Therefore, the EPA has determined that the proposed standard is achievable using either solvent borne or waterborne topcoat systems and is finalizing the proposed limits for the topcoat operation in subpart MMa. Additional detail is provided in the memorandum titled, Final Cost and Environmental Impacts Memo for Surface Coating Operations in the Automobiles and Light-Duty Trucks Source Category (40 CFR part 60, subpart MMa), located in the docket for this action.

Comment: One commenter claimed the proposed analysis is flawed because it is not based on an incremental evaluation of regulatory alternatives. The commenter stated that the subpart MMa proposal contains analysis of 2 control options for topcoat lines and it does not evaluate the incremental cost-effectiveness of option 2 as compared to option 1. The commenter stated that option 1 was based on control of the clearcoat spray booth and the topcoat oven and option 2 was based on control of the basecoat spray booth/flash off area as well as clearcoat booth and oven. According to the commenter, option 2 further reduces VOC by 50 tons with an incremental cost-effectiveness of $13,840/ton of VOC reduced, a value that is facially not cost-effective using the EPA's usual cost effectiveness thresholds for VOCs. Moreover, the commenter stated that this value exceeds levels that the EPA has rejected in other rules as not being incrementally cost-effective. According to the commenter, in a recently proposed NSPS for Bulk Gasoline Terminals, the EPA determined that in setting emission limits for loading operations the incremental cost effectiveness of $8,300/ton of VOC reduced was not cost-effective.

Response: The EPA is clarifying the description of the options in the proposal to distinguish between the use of waterborne and solvent borne coatings for the topcoat operation and has estimated the incremental cost-effectiveness of those options.

The 1980 subpart MM baseline level of control for topcoat operations (including basecoats) was a limit of 12.3 lb VOC/gal acs and required no control on waterborne coating operations. Our analysis indicates topcoat operations using waterborne basecoats are now achieving a limit of 5.2 lb VOC/gal acs using no control and that a lower limit of 3.53 lb VOC/gal acs is achieved by ALDT plants by controlling the emissions from the waterborne basecoat booth and/or flash off area. The cost effectiveness to control the waterborne basecoat booth or flash off area is $6,010 per ton of VOC reduced, which is the incremental cost effectiveness between the 2 topcoat options.

In this final action, the EPA is correcting an error in the proposal found while estimating the incremental cost effectiveness between the topcoat options. In its proposal for the second topcoat option, the EPA estimated an emission reduction of 160 tpy and a cost effectiveness of $7,900/ton VOC reduced to achieve the lower FCA Sterling Heights Assembly Plant limit of 2.32 lb VOC/gal acs (instead of the proposed 3.53 lb VOC/gal acs). The final estimated emission reduction and cost per ton for option 1 (5.2 lb VOC/gal acs) is 137 tons VOC reduced per year and $3,980/ton reduced. The revised emission reduction and cost effectiveness for the second topcoat option of 3.53 lb VOC/gal acs is 169 tpy and $4,370 per ton of VOC reduced compared to the 1980 baseline level of control, which the EPA determined to be reasonable. As a result, the EPA estimated the incremental emission reduction to be 32 tpy and estimated an incremental cost effectiveness between the 2 topcoat options to be $6,010 per ton of VOC reduced when compared to the cost and emission reduction estimated for option 1 at 5.2 lb VOC/gal asc.

The EPA determined the topcoat incremental cost effectiveness of $6,010 per ton of VOC reduced to be reasonable as an incremental cost. The topcoat incremental cost effectiveness of $6,010 per ton of VOC reduced is lower than the cost per ton of VOC reduced for the prime coat operation ($6,800/ton VOC reduced) and results in greater VOC emission reductions (169 tpy compared to 40 tpy for prime coat) when compared to the 1980 NSPS baseline level of control. This incremental cost effectiveness ($6,010 per ton of VOC reduced) is also lower than the incremental cost effectiveness value of $8,300/ton for modified and reconstructed loading operations that was rejected in the Bulk Gasoline Terminals NSPS cited by the commenter. The EPA also notes that, in any event, the Bulk Gasoline Terminals source category is a very different industry and emission source type and cannot be used to establish an incremental cost effectiveness boundary or threshold for ALDT surface coating operations. Revision of the standards of performance for each source category must reflect the degree of emission limitation achievable through the application of the BSER considering the cost of achieving such reduction and any nonair quality health and environmental impact and energy requirements (CAA section 111(a)(1)). Therefore, we are finalizing the 3.53 lb VOC/gal acs emission limit for the topcoat operation, as proposed. Additional detail on the topcoat cost effectiveness analysis is provided in the memorandum titled, Final Cost and Environmental Impacts Memo for Surface Coating Operations in the Automobiles and Light-Duty Trucks Source Category (40 CFR part 60, subpart MMa), located in the docket for this action.

B. Work Practice Standards

1. Proposed Work Practice Standards

The EPA proposed work practice standards in the new subpart MMa to minimize fugitive VOC emissions from: (1) the storage, mixing, and conveying of coatings, thinners, and cleaning materials used in, and waste materials generated by, the prime coat, guide coat and topcoat operations; and (2) the cleaning and purging of equipment associated with the prime coat, guide coat and topcoat operations. Subpart MMa affected sources are also required to develop and implement work practice plans consistent with the ALDT NESHAP provisions, which we have determined to be BSER. The work practices include: the use of low-VOC and no-VOC alternatives; controlled access to VOC-containing cleaning materials; capture and recovery of VOC-containing materials; use of high-pressure water systems to clean equipment in the place of VOC-containing materials; masking of spray booth interior walls, floors, and spray equipment to protect from over spray; and use of tack wipes or solvent moistened wipes.

For fugitive emissions of VOC, the EPA evaluated work practices demonstrated by 43 of 44 existing ALDT plants currently subject to ALDT NESHAP in 40 CFR 63.3094 as discussed in the proposal (87 FR 30151; May 18, 2022). The EPA proposed these work practices and the development and implementation of work practice plans for the ALDT NSPS MMa to minimize fugitive VOC emissions from the storage, mixing, and conveying of VOC-containing materials that include the coatings, thinners, and cleaning materials used in, and waste materials generated by, the prime coat, guide coat and topcoat operations. The EPA also proposed work practices and the development and implementation of work practice plans for the ALDT NSPS MMa to minimize fugitive VOC emissions from the cleaning and purging of equipment. The EPA proposed VOC minimizing practices including: the use of low-VOC and no-VOC alternatives; controlled access to VOC-containing cleaning materials; capture and recovery of VOC-containing materials; use of high-pressure water systems to clean equipment in the place of VOC-containing materials; masking of spray booth interior walls, floors, and spray equipment to protect from over spray; and use of tack wipes or solvent moistened wipes. The EPA considers these work practices to reflect BSER for controlling fugitive emissions of VOC.

As discussed in the proposal, CAA section 111(h)(1) authorizes the Administrator to promulgate “a design, equipment, work practice, or operational standard, or combination thereof” if in his or her judgment, “it is not feasible to prescribe or enforce a standard of performance.” CAA section 111(h)(2) provides the circumstances under which prescribing or enforcing a standard of performance is “not feasible,” such as when the pollutant cannot be emitted through a conveyance designed to emit or capture the pollutant, or when there is no practicable measurement methodology for the particular class of sources.

The results of our BSER review did not identify any ALDT facilities demonstrating add-on controls for these fugitive VOC emissions, and because these emissions are from various sources and activities located throughout the ALDT facility and are generally released into the ambient air from various locations throughout the facility, the EPA determined that it would not be feasible to route these fugitive VOC emissions to capture and control systems. The sources of fugitive VOC emissions include: containers for VOC-containing materials used for wipe-down operations and cleaning; spills of VOC-containing materials; the cleaning of spray booth interior walls, floors, grates and spray equipment; the cleaning of spray booth exterior surfaces; and the cleaning of equipment used to convey the vehicle body through the surface coating operations.

2. How the Final Revisions to Work Practice Standards Differ From the Proposed Revisions

After considering the comments on the proposed work practice standards, the EPA is finalizing the work practice standards, as proposed.

3. Work Practice Standards Comments and Responses

Comment: Three commenters requested that the EPA provide a compliance alternative such that compliance with the elements of the ALDT NESHAP work practice plan that incorporate subpart MMa requirements for VOC represent compliance with subpart MMa. The commenter refers to the subpart MMa proposal where the EPA stated that “[f]acilities demonstrating compliance with the ALDT NESHAP Subpart IIII work practice provisions will be in compliance with these same requirements in the revised ALDT NSPS Subpart MMa” and requests that this condition be added to the subpart MMa rule text to streamline the permitting process and to avoid the use of repetitive permit terms in site compliance systems. The commenters provided suggestions for subpart MMa regulatory text in their comments.

Response: In subpart MMa, 40 CFR 60.392a provides the work practices to minimize fugitive emissions of VOC from materials and equipment associated with coating operations for which emission limits are established under 40 CFR 60.392a(a). These coating operations are the prime coat, guide coat and topcoat operations that are subject to MMa due to construction, reconstruction, or modification after May 18, 2022. Subpart MMa, 40 CFR 60.392a(b) provides the work practices for storage, mixing, and conveying of coatings, thinners, and cleaning materials used in, and waste materials generated by, all coating operations for which emission limits are established under 40 CFR 60.392a(a). In subpart MMa, 40 CFR 60.392a(c) provides the work practices for cleaning and purging of equipment associated with all coating operations for which emission limits are established under 40 CFR 60.392a(a).