['Air Programs']

['Air Quality']

05/13/2024

...

ENVIRONMENTAL PROTECTION AGENCY

40 CFR Part 82

[EPA–HQ–OAR–2021–0836; FRL–6399–02–OAR]

RIN 2060–AT78

Protection of Stratospheric Ozone: Listing of Substitutes Under the Significant New Alternatives Policy Program in Refrigeration, Air Conditioning, and Fire Suppression

AGENCY: Environmental Protection Agency (EPA).

ACTION: Final rule.

SUMMARY: Pursuant to the U.S. Environmental Protection Agency's Significant New Alternatives Policy program, this action lists certain substances as acceptable, subject to use conditions, in the refrigeration and air conditioning sector for chillers—comfort cooling, residential dehumidifiers, residential and light commercial air conditioning and heat pumps, and a substance as acceptable, subject to use conditions and narrowed use limits, in very low temperature refrigeration. Through this action, EPA is incorporating by reference standards which establish requirements for electrical air conditioners, heat pumps, and dehumidifiers, laboratory equipment containing refrigerant, safe use of flammable refrigerants, and safe design, construction, installation, and operation of refrigeration systems. Finally, this action lists certain substances as acceptable, subject to use conditions, in the fire suppression sector for certain streaming and total flooding uses.

DATES: This rule is effective May 30, 2023. The incorporation by reference of certain material listed in the rule is approved by the Director of the Federal Register as of May 30, 2023. The incorporation by reference of certain other material listed in the rule was approved by the Director of the Federal Register as of May 11, 2015 and September 7, 2018.

ADDRESSES: EPA has established a docket for this action under Docket ID No. EPA–HQ–OAR–2021–0836. All documents in the docket are listed on the https://www.regulations.gov website. Although listed in the index, some information is not publicly available, e.g., Confidential Business Information (CBI) or other information whose disclosure is restricted by statute. Certain other material, such as copyrighted material, is not placed on the internet and will be publicly available only in hard copy form. Publicly available docket materials are available electronically through https://www.regulations.gov or in hard copy at the Air and Radiation Docket, EPA/DC, EPA West, Room 3334, 1301 Constitution Avenue NW, Washington, DC 20460. The Docket Center's hours of operations are 8:30 a.m.–4:30 p.m., Monday–Friday (except Federal Holidays). For further information on EPA Docket Center services and the current status, please visit https://www.epa.gov/dockets.

FOR FURTHER INFORMATION CONTACT: Holly Tapani, Stratospheric Protection Division, Office of Atmospheric Protection (Mail Code 6205A), Environmental Protection Agency, 1200 Pennsylvania Ave. NW, Washington, DC 20460; telephone number: 202–564–0679; email address: tapani.holly@epa.gov. Notices and rulemakings under EPA's Significant New Alternatives Policy program are available on EPA's SNAP website at https://www.epa.gov/snap/snap-regulations.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. General Information

A. Executive Summary and Background

B. Does this action apply to me?

C. What acronyms and abbreviations are used in the preamble?

II. What is EPA finalizing in this action?

A. Chillers—Listing of HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C as Acceptable, Subject to Use Conditions, for Use in New Chiller Equipment Used in Comfort Cooling, Including Both Commercial AC and Industrial Process Air Conditioning (IPAC)

1. Background on Chillers—Commercial AC and IPAC

2. What are the ASHRAE classifications for refrigerant flammability?

3. What are HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C and how do they compare to other refrigerants in the same end-use?

4. Why is EPA finalizing these specific use conditions?

5. What additional information is EPA including in these final listings?

6. How is EPA responding to comments on chillers?

B. Residential Dehumidifiers—Listing of HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C as Acceptable, Subject to Use Conditions, for Use in New Residential Dehumidifiers

1. Background on Residential Dehumidifiers

2. What are the ASHRAE classifications for refrigerant flammability?

3. What are HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C and how do they compare to other refrigerants in the same end-use?

4. Why is EPA finalizing these specific use conditions?

5. What additional information is EPA including in these final listings?

6. How is EPA responding to comments on residential dehumidifiers?

C. Non-Residential Dehumidifiers—Decision Not To Finalize the Proposed Listing of HFC–32 as Acceptable, Subject to Use Conditions, for Use in New Non-Residential Dehumidifiers

1. Why is EPA not finalizing the proposal to list HFC–32 as acceptable, subject to use conditions, in new non-residential dehumidifiers?

2. How is EPA responding to comments on non-residential dehumidifiers?

D. Residential and Light Commercial AC and Heat Pumps (HPs)—Revision of Use Conditions Provided in the Previous Listing of HFC–32 as Acceptable for Use in New Self-Contained Room ACs and HPs

1. Background on Self-Contained Room ACs and HPs

2. What are the ASHRAE classifications for refrigerant flammability?

3. What is HFC–32 and how does it compare to other refrigerants in the same end-use?

4. What use conditions previously applied to this refrigerant in this end-use category?

5. What updates to the use conditions is EPA finalizing?

6. How do the updated use conditions differ from the previous requirements and why is EPA finalizing the change to the use conditions?

7. What is the acceptability status of HFC–32 in self-contained room ACs and HPs?

8. What additional information is EPA including in these final listings?

9. How is EPA responding to comments on updating use conditions for HFC–32 in self-contained AC and HPs?

E. Use Conditions and Further Information in Final Listings for Chillers, Residential Dehumidifiers, and HFC–32 Self-Contained Room ACs and HPs

1. What use conditions is EPA finalizing and why?

2. What additional information is EPA including in these final listings?

3. How is EPA responding to comments on use conditions and further information for chillers, residential dehumidifiers, and HFC–32 self-contained room ACs and HPs?

F. Very Low Temperature Refrigeration (VLTR)—Listing of R–1150 as Acceptable, Subject to Use Conditions and Narrowed Use Limits, for Use in New VLTR

1. Background on VLTR

2. What is EPA's final listing decision for R–1150?

3. What is R–1150 and how does it compare to other refrigerants in the same end-use?

4. What use conditions is EPA finalizing?

5. Why is EPA finalizing these specific use conditions?

6. What narrowed use limits is EPA finalizing?

7. Why is EPA finalizing these specific narrowed use limits?

8. What additional information is EPA including in this final listing?

9. How is EPA responding to comments on VLTR?

G. Streaming and Total Flooding Fire Suppression—Listing of 2-bromo-3,3,3-trifluoropropene (2–BTP) as Acceptable, Subject to Use Conditions, as a Streaming Agent in Non-Residential Applications and as a Total Flooding Agent in Normally Unoccupied Spaces Under 500 ft 3

1. Background on Streaming and Total Flooding Fire Suppression

2. What is EPA's final listing decision for 2–BTP?

3. What is 2–BTP and how does it compare to other fire suppressants in the same end-uses?

4. What use conditions is EPA finalizing?

5. Why is EPA finalizing these specific use conditions?

6. How is EPA responding to comments on 2–BTP?

H. Total Flooding Fire Suppression—Listing of EXXFIRE® as Acceptable, Subject to Use Conditions, for Use in Normally Unoccupied Spaces

1. What is EPA's final listing decision for EXXFIRE®?

2. What is EXXFIRE® and how does it compare to other fire suppressants in the same end-use?

3. What use conditions is EPA finalizing and why?

4. How is EPA responding to comments on EXXFIRE®?

I. Total Flooding Fire Suppression—Listing of Powdered Aerosol H (Pyroquench-α TM) as Acceptable, Subject to Use Conditions, for Use in Normally Unoccupied Spaces

1. What is EPA's final listing decision for Powdered Aerosol H?

2. What is Powdered Aerosol H and how does it compare to other fire suppressants in the same end-use?

3. What use conditions is EPA finalizing and why?

4. How is EPA responding to comments on Powdered Aerosol H?

J. How is EPA responding to other comments?

III. Statutory and Executive Order Reviews

A. Executive Order 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulation and Regulatory Review

B. Paperwork Reduction Act (PRA)

C. Regulatory Flexibility Act (RFA)

D. Unfunded Mandates Reform Act (UMRA)

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

G. Executive Order 13045: Protection of Children From Environmental Health and Safety Risks

H. Executive Order 13211: Actions That Significantly Affect Energy Supply, Distribution, or Use

I. National Technology Transfer and Advancement Act and 1 CFR Part 51

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations

K. Congressional Review Act (CRA)

IV. References

I. General information

A. Executive Summary and Background

This action finalizes listings of new alternatives for the refrigeration and air conditioning (AC) and fire suppression sectors. Specifically, EPA is:

- Listing hydrofluoroolefin (HFO)-1234yf, hydrofluorocarbon (HFC)-32, R–452B, R–454A, R–454B, and R–454C as acceptable, subject to use conditions, for use in chillers used in comfort cooling, including commercial AC and industrial process AC (IPAC);

- Listing HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C as acceptable, subject to use conditions, for use in residential dehumidifiers;

- Listing HFC–32 as acceptable, subject to use conditions, for use in self-contained room ACs and heat pumps (HPs);

- Listing R–1150 as acceptable, subject to use conditions and narrowed use limits, for use in very low temperature refrigeration (VLTR);

- Listing 2-bromo-3,3,3-trifluoropropene (2–BTP) as acceptable, subject to use conditions, in streaming—for non-residential use, except home offices and boats—and total flooding—in normally unoccupied spaces under 500 ft 3;

- Listing EXXFIRE® as acceptable, subject to use conditions, in total flooding—for normally unoccupied areas; and

- Listing Powdered Aerosol H, also known as Pyroquench-α TM, as acceptable, subject to use conditions, in total flooding—for normally unoccupied areas.

EPA is finalizing these new listings after its evaluation of human health and environmental information for these substitutes in the refrigeration and AC sector and the fire suppression sector under the Significant New Alternatives Policy (SNAP) program based on the information that EPA has included in the docket. This action provides additional flexibility for industry by providing new options in specific uses.

SNAP Program Background

The SNAP program implements section 612 of the Clean Air Act (CAA). Several major provisions of section 612 are:

1. Rulemaking

Section 612(c) requires EPA to promulgate rules making it unlawful to replace any class I (chlorofluorocarbon (CFC), halon, carbon tetrachloride, methyl chloroform, methyl bromide, hydrobromofluorocarbon, and chlorobromomethane) or class II (hydrochlorofluorocarbon (HCFC)) ozone depleting substance (ODS) with any substitute that the Administrator determines may present adverse effects to human health or the environment where the Administrator has identified an alternative that (1) reduces the overall risk to human health and the environment and (2) is currently or potentially available.

2. Listing of Unacceptable/Acceptable Substitutes

Section 612(c) requires EPA to publish a list of the substitutes that it finds to be unacceptable for specific uses and to publish a corresponding list of acceptable substitutes for specific uses.

3. Petition Process

Section 612(d) grants the right to any person to petition EPA to add a substance to, or delete a substance from, the lists published in accordance with section 612(c).

4. 90-Day Notification

Section 612(e) directs EPA to require any person who produces a chemical substitute for a class I substance to notify the Agency not less than 90 days before a new or existing chemical is introduced into interstate commerce for significant new use as a substitute for a class I substance. The producer must also provide the Agency with the producer's unpublished health and safety studies on such substitutes.

The regulations for the SNAP program are promulgated at 40 Code of Federal Regulations (CFR) part 82, subpart G, and the Agency's process for reviewing SNAP submissions is described in regulations at 40 CFR 82.180. Under these rules, the Agency has identified five types of listing decisions: acceptable; acceptable, subject to use conditions; acceptable, subject to narrowed use limits; unacceptable; and pending (40 CFR 82.180(b)). Use conditions and narrowed use limits are both considered “use restrictions,” as described below. Substitutes that are deemed acceptable with no use restrictions (no use conditions or narrowed use limits) can be used for all applications within the relevant end-uses in the sector. After reviewing a substitute, the Agency may determine that a substitute is acceptable only if certain conditions in the way that the substitute is used are met, to minimize risks to human health and the environment. EPA describes such substitutes as “acceptable, subject to use conditions” (40 CFR 82.180(b)(2)). For some substitutes, the Agency may permit a narrowed range of use within an end-use or sector. For example, the Agency may limit the use of a substitute to certain end-uses or specific applications within an industry sector. EPA describes these substitutes as “acceptable, subject to narrowed use limits.” Under the narrowed use limit, users intending to adopt these substitutes “must ascertain that other alternatives are not technically feasible.” (40 CFR 82.180(b)(3)).

In making decisions regarding whether a substitute is acceptable or unacceptable, and whether substitutes present risks that are lower than or comparable to risks from other substitutes that are currently or potentially available in the end-uses under consideration, EPA examines the criteria in 40 CFR 82.180(a)(7)(i) through (vii):

“(i) Atmospheric effects and related health and environmental impacts; (ii) General population risks from ambient exposure to compounds with direct toxicity and to increased ground-level ozone; (iii) Ecosystem risks; (iv) Occupational risks; (v) Consumer risks; (vi) Flammability; and (vii) Cost and availability of the substitute.”.

Many SNAP listings include “comments” or “further information” to provide additional information on substitutes. Since this additional information is not part of the regulatory decision under SNAP, these statements are not binding for use of the substitute under the SNAP program. However, regulatory requirements so listed are binding under other regulatory programs (e.g., worker protection regulations promulgated by the U.S. Occupational Safety and Health Administration (OSHA)). The “further information” classification does not necessarily include all other legal obligations pertaining to the use of the substitute. While the items listed are not legally binding under the SNAP program, EPA encourages users of substitutes to apply all statements in the “Further Information” column in their use of these substitutes. In many instances, the information simply refers to sound operating practices that have already been identified in existing industry and/or building codes or standards. Thus, many of the statements, if adopted, would not require the affected user to make significant changes in existing operating practices.

For additional information on the SNAP program, visit the SNAP website at https://www.epa.gov/snap. The full lists of acceptable substitutes for ODS in all industrial sectors are available at https://www.epa.gov/snap/snap-substitutes-sector. For more information on the Agency's process for administering the SNAP program or criteria for evaluation of substitutes, refer to the initial SNAP rulemaking published March 18, 1994 (59 FR 13044), codified at 40 CFR part 82, subpart G. SNAP decisions and the appropriate Federal Register citations can be found at: https://www.epa.gov/snap/snap-regulations. Substitutes listed as unacceptable; acceptable, subject to narrowed use limits; or acceptable, subject to use conditions, are also listed in the appendices to 40 CFR part 82, subpart G.

B. Does this action apply to me?

The following list identifies regulated entities that may be affected by this rule and their respective North American Industrial Classification System (NAICS) codes:

- Plumbing, Heating, and Air Conditioning Contractors (NAICS 238220)

- All Other Basic Organic Chemical Manufacturing (NAICS 325199)

- Pharmaceutical Preparations (e.g., Capsules, Liniments, Ointments, Tablets) Manufacturing (NAICS 325412)

- Air Conditioning and Warm Air Heating Equipment and Commercial and Industrial Refrigeration Equipment Manufacturing (NAICS 333415)

- Household Appliances, Electric Housewares, and Consumer Electronics Merchant Wholesalers (NAICS 423620)

- Refrigeration Equipment and Supplies Merchant Wholesalers (NAICS 423740)

- Recyclable Material Merchant Wholesalers (NAICS 423930)

- Appliance Repair and Maintenance (NAICS 811412)

- Fire Protection (NAICS 922160)

This list is not intended to be exhaustive, but rather to provide a guide for readers regarding entities likely to be affected by this action. To determine whether your facility, company, business, or organization could be affected by this action, you should carefully examine the regulations at 40 CFR part 82, subpart G and the revisions below. If you have questions regarding the applicability of this action to a particular entity, consult the person listed in the FOR FURTHER INFORMATION CONTACT section.

C. What acronyms and abbreviations are used in the preamble?

Below is a list of acronyms and abbreviations used in the preamble of this document:

2–BTP—2-bromo-3,3,3-trifluoropropene

AC—Air Conditioning or Air Conditioner

ACGIH—American Conference of Governmental Industrial Hygienists

AEL—Acceptable Exposure Limit

AHAM—Association of Home Appliance Manufacturers

AHRI—Air-Conditioning, Heating, and Refrigeration Institute

AIHA—American Industrial Hygiene Association AIM Act—American Innovation and Manufacturing Act of 2020

ANSI—American National Standards Institute

ASHRAE—American Society of Heating, Refrigerating and Air-Conditioning Engineers

ASTM—American Society for Testing and Materials

CAA—Clean Air Act

CAS Reg. No.—Chemical Abstracts Service Registry Identification Number

CBI—Confidential Business Information

CFC—Chlorofluorocarbon

CFR—Code of Federal Regulations

CRA—Congressional Review Act

CO 2 —Carbon Dioxide

EEAP—Environmental Effects Assessment Panel

EIA—Environmental Investigation Agency

EPA—United States Environmental Protection Agency

FR—Federal Register

GWP—Global Warming Potential

HCFC—Hydrochlorofluorocarbon

HCFO—Hydrochlorofluoroolefin

HFC—Hydrofluorocarbon

HFO—Hydrofluoroolefin

HP—Heat Pump

ICF—ICF International, Inc.

IEC—International Electrotechnical Commission

IPAC—Industrial Process Air Conditioning

IPCC—Intergovernmental Panel on Climate Change

LFL—Lower Flammability Limit

LOAEL—Lowest Observed Adverse Effect Level

MIAQ—Madison Indoor Air Quality

MVAC—Motor Vehicle Air Conditioning

NAAQS—National Ambient Air Quality Standards

NAICS—North American Industrial Classification System

NARA—National Archives and Records Administration

NFPA—National Fire Protection Association

NIOSH—National Institute for Occupational Safety and Health

NPRM—Notice of Proposed Rulemaking

NRTL—Nationally Recognized Testing Laboratories

ODP—Ozone Depletion Potential

ODS—Ozone Depleting Substances

OMB—United States Office of Management and Budget

OSHA—United States Occupational Safety and Health Administration

PFAS—Per- and poly-fluoroalkyl substances

PFCs—Perfluorocarbons

PMS—Pantone® Matching System

ppm—Parts Per Million

PRA—Paperwork Reduction Act

PTAC—Packaged Terminal Air Conditioner

PTHP—Packaged Terminal Heat Pump

RAL—“Reichs-Ausschuß für Lieferbedingungen und Gütesicherung,” Germany's National Commission for Delivery Terms and Quality Assurance

RCRA—Resource Conservation and Recovery Act

RFA—Regulatory Flexibility Act

SCBA—Self-Contained Breathing Apparatus

SDS—Safety Data Sheet

SIP—State Implementation Plan

SNAP—Significant New Alternatives Policy

TFA—trifluoroacetic acid

TLV–TWA—Threshold Limit Value-Time-Weighted Average

TSCA—Toxic Substances Control Act

TWA—Time Weighted Average

UL—UL, formerly known as Underwriters Laboratories, Inc.

UMRA—Unfunded Mandates Reform Act

VOC—Volatile Organic Compound, Volatile Organic Compounds

VLTR—Very Low Temperature Refrigeration

WCFF—Worst Case of Fractionation for Flammability

WCF—Worst Case of Formulation for Flammability

WEEL—Workplace Environmental Exposure Limit

WMO—World Meteorological Organization

II. What is EPA finalizing in this action?

This section of the preamble describes EPA's final listings for certain refrigerants and fire suppressants in specific end-uses, including final use restrictions. In addition, this section provides responses to comments EPA received on the proposed listings during the public comment period for the proposed rule. One comment was received after the close of the comment period, to which no response from the Agency is required. The regulatory text for new listings is codified in appendix X of 40 CFR part 82, subpart G. The regulatory text for a revised listing is codified in appendix R of 40 CFR part 82, subpart G. The final regulatory text contains listing decisions for the end-uses discussed throughout this section below.

A. Chillers—Listing of HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C as Acceptable, Subject to Use Conditions, for Use in New Chiller Equipment Used in Comfort Cooling, Including Both Commercial AC and Industrial Process Air Conditioning (IPAC)

EPA previously listed HFO–1234yf as acceptable, subject to use conditions, in motor vehicle AC, in light-duty vehicles (74 FR 53445; October 19, 2009), in heavy-duty pickup trucks and complete heavy-duty vans (81 FR 86778; December 1, 2016) and in nonroad vehicles and service fittings for small refrigerant cans (87 FR 26276; May 4, 2022). EPA previously listed HFC–32 as acceptable, subject to use conditions, as a substitute in residential and light commercial AC and HPs (80 FR 19454; April 10, 2015) (86 FR 24444; May 6, 2021) and previously listed R–452B, R–454A, R–454B, and R–454C, (hereafter called “the four refrigerant blends”), as acceptable, subject to use conditions, as substitutes in residential and light commercial AC and HPs (86 FR 24444; May 6, 2021). 1

1 In this final rule, we use the term “air conditioner” and “AC” to cover equipment that cools air, heats air, or has the function to do both (typically referred to as a “heat pump”). While such equipment might humidify or dehumidify the air, the term does not include equipment whose purpose is for latent cooling only (i.e., dehumidifiers), which are a separate end-use under SNAP and are addressed in section II.B of this final rule.

This final rulemaking finds HFC–32, HFO–1234yf, and the four refrigerant blends acceptable, subject to use conditions, as substitutes in chillers. The SNAP program divides chillers for comfort cooling into two general types based on the type of compressor used in the system, i.e., centrifugal and positive displacement compressors (including reciprocating, screw, scroll and rotary) chillers. EPA proposed to list HFO–1234yf, R–454A, R–454B, and R–454C as acceptable in all new chillers for comfort cooling and proposed to list HFC–32 and R–452B as acceptable only in new scroll and rotary chillers for comfort cooling. After consideration and evaluation of the comments received by the Agency in response to the July 28, 2022, notice of proposed rulemaking (87 FR 45508; hereafter, “NPRM”), EPA is finalizing the listings for HFO–1234yf, R–454A, R–454B, and R–454C in chillers for comfort cooling as proposed. After consideration and evaluation of the comments received, EPA is broadening the listings for HFC–32 and R–452B relative to the NPRM, and is listing these alternatives as acceptable with use conditions across all chiller types for all comfort cooling applications, including but not limited to use in commercial AC and IPAC.

Several use conditions finalized for chillers are identical to those finalized for other end-uses (residential dehumidifiers and residential and light commercial AC and HPs) finalized in sections II.B and II.D. below. Because of this similarity, EPA discusses the use conditions that would apply to all three end-uses in detail in section II.E below. For chillers, EPA is also finalizing an additional use condition related to adherence to the ASHRAE 15–2019 standard. In summary, the use conditions for chillers are:

(1) New equipment only—These refrigerants may be used only in new equipment designed specifically and clearly identified for the refrigerant, i.e., none of these substitutes may be used as a conversion or “retrofit” refrigerant for existing equipment.

(2) UL Standard—These refrigerants may be used only in chiller equipment that meet all requirements listed in the 3rd edition, dated November 1, 2019, of UL Standard 60335–2–40, “Household and Similar Electrical Appliances—Safety—Part 2–40: Particular Requirements for Electrical Heat Pumps, Air Conditioners and Dehumidifiers.” In cases where this final rule includes requirements different than those of the 3rd edition of UL Standard 60335–2–40, the appliance would need to meet the requirements of this final rule in place of the requirements in UL 60335–2–40, 3rd Edition. See section II.E below for further discussion on the requirements of this standard that EPA is incorporating by reference.

(3) Warning labels—Several warning labels are required as use conditions as detailed in section II.E below. These labels are similar or verbatim in language to those required by UL 60335–2–40, 3rd Edition. The warning labels must be provided in letters no less than 6.4 mm (1/4 inch) high and must be permanent.

(4) Markings—Equipment must have distinguishing red (Pantone® Matching System (PMS) #185 or Reichs-Ausschuß für Lieferbedingungen und Gütesicherung 2 (RAL) 3020) color-coded hoses and piping to indicate use of a flammable refrigerant. The chiller equipment shall have marked service ports, pipes, hoses and other devices through which the refrigerant is serviced. Markings shall extend at least 1 inch (25 mm) from the servicing port and shall be replaced if removed.

2 Germany's National Commission for Delivery Terms and Quality Assurance.

(5) For chillers, EPA is also finalizing a use condition related to adherence to the ASHRAE 15–2019 standard in addition to those common finalized use conditions for chillers, residential dehumidifiers, and self-contained room ACs. Specifically, EPA is requiring that these refrigerants may only be used in chillers that meet all requirements listed in the American National Standards Institute (ANSI)/ASHRAE Standard 15–2019 (hereafter “ASHRAE 15–2019”). In cases where this final rule includes requirements different than those of ASHRAE 15–2019, 3 EPA is finalizing that the chiller appliance needs to meet the requirements of this final rule in place of the requirements in the ASHRAE Standard. This additional use condition is discussed further in section II.A.4, below.

3 ASHRAE, 2019b. American National Standards Institute (ANSI)/American Society for Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) Standard 15. Safety Standard for Refrigeration Systems. 2019.

EPA notes that there may be other requirements pertaining to the manufacture, use, handling, and disposal of the listed refrigerants that are not included in the information listed in the tables (e.g., the CAA section 608(c)(2) venting prohibition 4 or Department of Transportation requirements for transport of flammable gases). Flammable refrigerants being recovered or otherwise disposed of from chillers are likely to be hazardous waste under the Resource Conservation and Recovery Act (RCRA) (see 40 CFR parts 260–270).

4 Under section 608(c)(2) of the CAA and EPA's regulations at 40 CFR 82.154(a)(1), it is unlawful for any person, in the course of maintaining, servicing, repairing, or disposing of an appliance or industrial process refrigeration, to knowingly vent or otherwise knowingly release or dispose of any substitute substance for a class I or class II substance used as a refrigerant in such appliance (or industrial process refrigeration) in a manner which permits such substance to enter the environment. As provided in 40 CFR 82.154(a)(1), certain substitutes in certain end-uses have been exempted from this prohibition. References to the venting prohibition throughout this final rule refer to these provisions.

1. Background on Chillers—Commercial AC and IPAC

This rulemaking applies to chillers that are covered by the UL 60335–2–40 standard “Household and Similar Electrical Appliances—Safety—Part 2–40: Requirements for Electrical Heat Pumps, Air Conditioners and Dehumidifiers” and ASHRAE Standard 15–2019, “Safety Standard for Refrigeration Systems.” EPA understands that UL 60335–2–40 covers chillers used for comfort cooling.

In the initial rule establishing the SNAP program (59 FR 13044; March 18, 1994), EPA included within the refrigeration and AC sector the end-use “commercial comfort air conditioning” and then elaborated on that end-use by saying that “CFCs are used in several different types of mechanical commercial comfort AC systems, known as chillers.” EPA indicated “that over time, existing cooling capacity [from chillers] will be either retrofitted or replaced by systems using non-CFC refrigerants in a vapor compression cycle or by alternative technologies.” EPA also explained in that rule that vapor compression chillers can be categorized by the type of compressor used, including centrifugal, rotary, screw, scroll and reciprocating compressors. These compressor types are also divided into centrifugal and positive displacement chillers, the latter of which includes those with reciprocating, screw, scroll or rotary compressors.

Centrifugal chillers are equipment that utilize a centrifugal compressor in a vapor-compression refrigeration cycle. Centrifugal chillers are typically used for commercial comfort AC, although other uses, that we are not addressing here, do exist. Centrifugal chillers can be found in office buildings, hotels, arenas, convention halls, airport terminals and other buildings. Centrifugal chillers tend to be used in larger buildings.

Positive displacement chillers are those that utilize positive displacement compressors such as reciprocating, screw, scroll or rotary types. Positive displacement chillers are applied in similar situations as centrifugal chillers, again primarily for commercial comfort AC, except that positive displacement chillers tend to be used for smaller capacity needs such as in mid- and low-rise buildings.

A chiller is a type of equipment using refrigerant that typically cools water or a brine solution, which is then pumped to fan coil units or other air handlers to cool the air that is supplied to the occupied spaces transferring the heat to the water. The heat absorbed by the water can then be used for heating purposes, and/or can be transferred directly to the air (“air-cooled”), to a cooling tower or body of water (“water-cooled”), or through evaporative coolers (“evaporative-cooled”). A chiller or a group of chillers could similarly be used for district cooling where the chiller plant cools water or another fluid that is then pumped to multiple locations being served such as several different buildings within the same complex. Chillers may also be used to maintain operating temperatures in various types of buildings, for example, in data centers, server farms, and agricultural/food operations. Chillers are used in other applications, for example, to cool process streams in industrial applications. Chillers are also used for comfort cooling of operators or climate control and protecting process equipment in industrial buildings, for example, in industrial processes when ambient temperatures could approach 200°F (93°C) and corrosive conditions could exist. The listing finalized today applies to all types of chillers in comfort cooling applications.

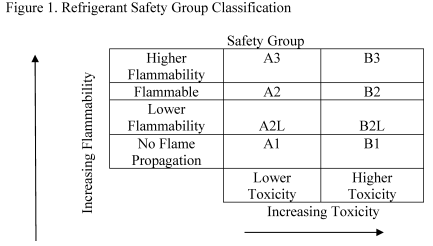

2. What are the ASHRAE classifications for refrigerant flammability?

The ANSI/ASHRAE Standard 34–2019 assigns a safety group classification for each refrigerant which consists of two to three alphanumeric characters (e.g., A2L or B1). The initial capital letter indicates the toxicity, and the numeral denotes the flammability. ASHRAE classifies Class A refrigerants as refrigerants for which toxicity has not been identified at concentrations less than or equal to 400 parts per million (ppm) by volume, based on data used to determine threshold limit value-time-weighted average (TLV–TWA) or consistent indices. Class B signifies refrigerants for which there is evidence of toxicity at concentrations below 400 ppm by volume, based on data used to determine TLV–TWA or consistent indices.

The refrigerants are also assigned a flammability classification of 1, 2, 2L, or 3. Tests for flammability are conducted in accordance with American Society for Testing and Materials (ASTM) E681 using a spark ignition source at 140°F (60°C) and 14.7 psia (101.3 kPa). 5 The flammability classification “1” is given to refrigerants that, when tested, show no flame propagation. The flammability classification “2” is given to refrigerants that, when tested, exhibit flame propagation, have a heat of combustion less than 19,000 kJ/kg (8,169 Btu/lb), and have a lower flammability limit (LFL) greater than 0.10 kg/m 3 . The flammability classification “2L” is given to refrigerants that, when tested, exhibit flame propagation, have a heat of combustion less than 19,000 kJ/kg (8,169 BTU/lb), have an LFL greater than 0.10 kg/m 3, and have a maximum burning velocity of 10 cm/s or lower when tested in dry air at 73.4°F (23.0°C) and 14.7 psi (101.3 kPa). The flammability classification “3” is given to refrigerants that, when tested, exhibit flame propagation and that either have a heat of combustion of 19,000 kJ/kg (8,169 BTU/lb) or greater or have an LFL of 0.10 kg/m 3 or lower.

5 ASHRAE, 2019a. ANSI/ASHRAE Standard 34–2019: Designation and Safety Classification of Refrigerants.

For flammability classifications, refrigerant blends are designated based on the worst case of formulation for flammability and the worst case of fractionation for flammability determined for the blend.

Using these safety group classifications, ANSI/ASHRAE Standard 34–2019 categorizes HFO–1234yf, HFC–32 and the four refrigerant blends in this section of this final rule in the A2L Safety Group.

3. What are HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C and how do they compare to other refrigerants in the same end-use?

HFO–1234yf and HFC–32 are lower flammability refrigerants, and the four refrigerant blends are lower flammability refrigerant blends, all with an ASHRAE safety classification of A2L. The respective Chemical Abstracts Service Registry Identification Numbers (CAS Reg. Nos.) of HFO–1234yf, HFC–32 and the components of the four refrigerant blends are listed below.

HFO–1234yf, also known by the trade names “Solstice® yf” and “Opteon TM YF,” is also known as 2,3,3,3-tetrafluoroprop-1-ene (CAS Reg. No. 754–12–1). HFC–32 is also known as R–32 or difluoromethane (CAS Reg. No. 75–10–5). R–452B, also known by the trade names “Opteon TM XL 55” and “Solstice® L41y,” is a blend consisting of 67 percent by weight HFC–32; seven percent HFC–125, also known as 1,1,1,2,2-pentafluoroethane (CAS Reg. No. 354–33–6); and 26 percent HFO–1234yf. R–454A, also known by the trade name “Opteon TM XL 40,” is a blend consisting of 35 percent HFC–32 and 65 percent HFO–1234yf. R–454B, also known by the trade names “Opteon TM XL 41” and “Puron Advance TM,” is a blend consisting of 68.9 percent HFC–32 and 31.1 percent HFO–1234yf. R–454C, also known by the trade name “Opteon TM XL 20,” is a blend consisting of 21.5 percent HFC–32 and 78.5 percent HFO–1234yf.

Redacted submissions and supporting documentation for HFO–1234yf, HFC–32, and the four refrigerant blends are provided in the docket for this final rule (EPA–HQ–OAR–2021–0836) at https://www.regulations.gov. EPA performed an assessment to examine the health and environmental risks of each of these substitutes. These assessments are available in the docket for this final rule. 6789101112

6 ICF, 2022a. Risk Screen on Substitutes in Chillers and Industrial Process Air Conditioning (New Equipment); Substitute: R–32.

7 ICF, 2022b. Risk Screen on Substitutes in Chillers and Industrial Process Air Conditioning (New Equipment); Substitute: HFO–123yf.

8 ICF, 2022c. Risk Screen on Substitutes in Chillers and Industrial Process Air Conditioning (New Equipment); Substitute: R–452B.

9 ICF, 2022d. Risk Screen on Substitutes in Chillers and Industrial Process Air Conditioning (New Equipment); Substitute: R–454A.

10 ICF, 2022e. Risk Screen on Substitutes in Chillers and Industrial Process Air Conditioning (New Equipment); Substitute: R–454B.

11 ICF, 2022f. Risk Screen on Substitutes in Chillers and Industrial Process Air Conditioning (New Equipment); Substitute: R–454C.

12 EPA notes that UL 60335–2–40 uses the Worst Case Formulation of Flammability (WCF) LFL, but that ASHRAE 34–2019 uses the Worst Case Fractionation of Flammability (WCFF) LFL for all of the blends except R–452B, in which case ASHRAE 34 references the WCF LFL. To be conservative, the Agency uses the WCFF LFL values for our flammability risk analysis. ASHRAE 34 plans to update their WCFF LFL values to WCF LFL values in future editions of the standard as a way to standardize LFLs going forward, after which the Agency may also consider switching to using WCF LFL values in the risk screens.

Environmental information: HFO–1234yf, HFC–32, and the four refrigerant blends have ODPs of zero.

HFO–1234yf has a 100-year integrated GWP of less than four. 131415 HFC–32 has a GWP of 675. The four refrigerant blends are made up of the components HFC–32, HFC–125, and HFO–1234yf, which have GWPs of 675, 3,500, and less than four, respectively. 16 If these values are weighted by mass percentage, then R–452B, R–454A, R–454B, and R–454C have GWPs of about 700, 240, 470, and 150, respectively.

13 The GWP in World Meteorological Organization (2018) is listed as less than 1. Burkholder et al. Appendix A, Table A–1 in Scientific Assessment of Ozone Depletion: 2018, Global Ozone Research and Monitoring Project, Report No. 58, World Meteorological Organization, Geneva, Switzerland, http://ozone.unep.org/science/assessment/sap. (WMO, 2018)

14 Nielsen et al., 2007. Nielsen, O.J., Javadi, M.S., Sulbaek Andersen, M.P., Hurley, M.D., Wallington, T.J., Singh, R. 2007. Atmospheric chemistry of CF3CF=CH2: Kinetics and mechanisms of gas-phase reactions with Cl atoms, OH radicals, and O3. Chemical Physics Letters 439, 18–22. Available online at http://www.lexissecuritiesmosaic.com/gateway/FedReg/network_OJN_174_CF3CF=CH2.pdf.

15 Hodnebrog Ø;. et al., 2013. Hodnebrog Ø;., Etminan, M., Fuglestvedt, J.S., Marston, G., Myhre, G., Nielsen, C.J., Shine, K.P., Wallington, T.J.: Global Warming Potentials and Radiative Efficiencies of Halocarbons and Related Compounds: A Comprehensive Review, Reviews of Geophysics, 51, 300–378, doi:10.1002/rog.20013, 2013

16 Unless otherwise specified, GWP values are 100-year values from Intergovernmental Panel on Climate Change (IPCC) (2007) Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. S. Solomon, D. Qin, M. Manning, Z. Chen, M. Marquis, K.B. Averyt, M. Tignor and H.L. Miller (eds.). Cambridge University Press. Cambridge, United Kingdom 996 pp.

HFC–32, HFO–1234yf, and the other component of one of the four refrigerant blends, HFC–125, are excluded from EPA's regulatory definition of volatile organic compounds (VOC) (see 40 CFR 51.100(s)) for the purpose of addressing the development of State Implementation Plans (SIPs) to attain and maintain the National Ambient Air Quality Standards (NAAQS). The regulatory definition provides that “any compound of carbon” which “participates in atmospheric photochemical reactions” is considered a VOC unless expressly excluded based on a determination of “negligible photochemical reactivity.” Under section 608(c)(2) of the CAA and EPA's regulations at 40 CFR 82.154(a)(1), it is unlawful for any person, in the course of maintaining, servicing, repairing, or disposing of an appliance or industrial process refrigeration, to knowingly vent or otherwise knowingly release or dispose of any substitute substance for a class I or class II substance used as a refrigerant in such appliance (or industrial process refrigeration) in a manner which permits such substance to enter the environment.

Flammability information: HFO–1234yf, HFC–32 and the four refrigerant blends are all classified as 2L under ASHRAE Standards reflecting that these compounds are flammable but have lower burning velocity than compounds listed as 2 or 3 under the ASHRAE standard.

Toxicity and exposure data: HFO–1234yf, HFC–32 and the four refrigerant blends have an ASHRAE toxicity classification of A. Potential health effects of exposure to these substitutes include drowsiness or dizziness. The substitutes may also irritate the skin or eyes or cause frostbite. At sufficiently high concentrations, the substitutes may cause irregular heartbeat. The substitutes could cause asphyxiation if air is displaced by vapors in a confined space. These potential health effects are common to many refrigerants.

The American Industrial Hygiene Association (AIHA) has established Workplace Environmental Exposure Limits (WEELs) of 1,000 ppm as an eight-hour time-weighted average (8-hr TWA) for HFC–32 and the component refrigerant HFC–125; the AIHA has established a WEEL of 500 ppm as an 8-hr TWA for HFO–1234yf. The manufacturer of R–452B, R–454A, R–454B, and R–454C recommends Acceptable Exposure Limits (AELs) for the workplace, respectively, of 874, 690, 854, and 615 ppm on an 8-hr TWA for these blends. EPA anticipates that users will be able to meet the AIHA WEELs and manufacturers' AELs and address potential health risks by following requirements and recommendations in the manufacturers' safety data sheet (SDS), the final use conditions (including adherence to ASHRAE Standard 15), and other safety precautions common to the refrigeration and AC industry. 171819202122

17 ICF, 2022a. Op. cit.

18 ICF, 2022b. Op. cit.

19 ICF, 2022c. Op. cit

20 ICF, 2022d. Op. cit.

21 ICF, 2022e. Op. cit.

22 ICF, 2022e. Op. cit.

Comparison to other substitutes in this end-use: HFO–1234yf, HFC–32, and the four refrigerant blends all have an ODP of zero, comparable to or lower than some of the acceptable substitutes in these end-uses, such as HFO–1234ze(E) with an ODP of zero. Although HCFC–123 and R–406A (with components HCFC–22 and HCFC–142b) have been listed acceptable in this end-use with ODPs of 0.02 and 0.057, respectively, HCFC–123 (unless used, recovered, and recycled) may not be used as a refrigerant in equipment manufactured on or after January 1, 2020, under 40 CFR 82.15(g)(5)(i). 23 Similarly, components of R–406A (HCFC–22 and HCFC–142b) (unless used, recovered, and recycled) may not be used as a refrigerant for use in chillers manufactured on or after January 1, 2010, under 40 CFR 82.15(g)(2)(i). 24 Under 40 CFR 82.16, EPA has not issued any production and consumption allowances for HCFC–22 and HCFC–142b since 2019.

23 The regulations at 40 CFR 82.15(g)(5)(iii) provide a limited exception to the prohibition on use in 82.15(g)(5)(i), for use of HCFC–123 as a refrigerant in equipment manufactured on or after January 1, 2020 but before January 1, 2021 if the conditions of 40 CFR 82.15(g)(5)(iii) are met.

24 The regulations at 40 CFR 82.15(g)(2)(ii) provide limited exceptions to the prohibitions in 82.15(g)(2)(i), including for HCFC–22 “for use as a refrigerant in appliances manufactured before January 1, 2012, provided that the components are manufactured prior to January 1, 2010, and are specified in a building permit or a contract dated before January 1, 2010, for use on a particular project.”

HFC–32 and the four refrigerant blends' GWPs, ranging from about 150 to 700, are higher than those of some of the acceptable substitutes for new centrifugal and positive displacement chillers, including HCFO–1233zd(E), HFO–1336mzz(Z), and R–515B, with GWPs of 3.7, 9, and 287, respectively. The GWPs of HFO–1234yf, R–454A, R–454B, and R–454C are lower than some of the acceptable substitutes for new centrifugal and positive displacement chillers, such as R–450A and R–513A, with GWPs of approximately 600 and 630, respectively. HFC–32's and R–452B's GWPs of 675 and about 700 are higher than the GWPs of those refrigerants. The GWPs of HFC–32 and R–452B are, however, lower than those of all the refrigerants that EPA listed as unacceptable for chillers as of January 1, 2024, in the final rule issued December 1, 2016, which had GWPs of 1,000 or higher. Further, HFC–32 and HFC–452B can be used in chillers that are designed to be used with refrigerants having higher pressure and higher volumetric capacity, unlike most of the other refrigerants listed acceptable in chillers (e.g., HCFO–1233zd(E), R–450A, and R–513A). Volumetric capacity is important to achieve the cooling capacity needed without increasing equipment sizes, which could lead to weights exceeding code requirements, for instance, when a chiller on top of an existing building is replaced with a new one. Given the wide range of applications, not all refrigerants listed as acceptable under SNAP will be suitable for all equipment in the end-use. To provide additional options to ensure the availability of substitutes for the full range of chiller equipment for comfort cooling, EPA is finalizing the listings for HFC–32 and R–452B for all types of positive displacement chillers, as well as for centrifugal chillers and chillers for IPAC.

HFC–32's and the four refrigerant blends' GWPs, ranging from about 150 to 700, are higher than or comparable to those of some of the acceptable substitutes for new IPAC, including carbon dioxide (CO 2), HFO–1336mzz(Z) and R–515B with GWPs of 1, 9 and 287 respectively. Their GWPs are lower than some of the acceptable substitutes for new IPAC, such as HFC–134a, R–410A, and R–507A with GWPs of 1,430, 2,090 and 3,990 respectively. HFO–1234yf's GWP less than four is comparable to or lower than that of other acceptable substitutes for new IPAC, such as CO 2, HFO–1336mzz(Z) and R–515B with GWPs of 1, 9 and 287, respectively.

Information regarding the toxicity of other available alternatives is provided in the listing decisions previously made (see https://www.epa.gov/snap/substitutes-chillers). Toxicity risks of use, determined by the likelihood of exceeding the exposure limit, of HFO–1234yf, HFC–32, and the four refrigerant blends in these end-uses are evaluated in the risk screens referenced above. The toxicity risks of using HFO–1234yf, HFC–32, and the four refrigerant blends in chillers and IPAC are comparable to or lower than toxicity risks of other available substitutes in the same end-uses. Toxicity risks of the refrigerants can be minimized by use consistent with ASHRAE 15–2019—which applies under the use conditions—and other industry standards, recommendations in the manufacturers' SDS, and other safety precautions common in the refrigeration and AC industry.

The flammability risks with HFO–1234yf, HFC–32, and the four refrigerant blends in these end-uses, determined by the likelihood of exceeding their respective lower flammability limits, are evaluated in the risk screens referenced above. In conclusion, while these refrigerants may pose greater flammability risk than other available substitutes in the same end-uses, this risk can be minimized by use consistent with ASHRAE 15–2019—which applies for certain charge sizes under the use conditions—and other industry standards such as UL 60335–2–40—which also applies under the use conditions—as well as recommendations in the manufacturers' SDS and other safety precautions common in the refrigeration and AC industry. EPA is finalizing use conditions to reduce the potential risk associated with the flammability of these alternatives so that they will not pose significantly greater risk than other acceptable substitutes in this end-use.

4. Why is EPA finalizing these specific use conditions?

The UL Standard 60335–2–40 discussed in section II.E indicates that refrigerant charges greater than a specific amount (called “m 3" in the UL Standard and based on the refrigerant's LFL) are beyond its scope and that national standards apply, such as ASHRAE 15–2019. Given that depending on the charge size of the equipment, either UL 60335–2–40 or ASHRAE 15–2019 would apply, EPA is including adherence to both standards as use conditions for chillers.

EPA is finalizing that chillers using HFO–1234yf, HFC–32, or one of the four refrigerant blends must adhere to ASHRAE Standard 15–2019, with all addenda published by the date of the NPRM for this rule, including addenda a, b, c, d, e, f, i, j, k, m, n, o, q, and r. Where the requirements specified in this final rule and ASHRAE Standard 15 are different, the requirements of this final rule would apply.

A summary of relevant aspects of ASHRAE 15–2019 is provided here for information only. This is not meant to be a full explanation of the Standard or how it is applied. ASHRAE 15–2019 specifies requirements for refrigeration systems, 25 including chillers, based on the safety group classification of the refrigerant used, the type of occupancy in the location for which the system is used, and whether refrigerant-containing parts of the system enter the space or ductwork and so leakage in the space is deemed “probable.” “High-Probability” installations are those such that leaks or failures will result in refrigerant entering the occupied space. As explained above, HFO–1234yf, HFC–32 and the four refrigerant blends are all classified as A2L refrigerants. Occupancies are divided into six classifications: institutional, public assembly, residential, commercial, large mercantile, and industrial. Examples of these include jails, theaters, apartment buildings, office buildings, shopping malls, and chemical plants, respectively.

25 We note that while the ASHRAE 15–2019 purpose indicates “refrigeration systems,” EPA believes this includes applications that are typically called “air conditioning.”

Sections 7.2 and 7.3 of ASHRAE Standard 15 determine the maximum amount of refrigerant allowed in the system, while section 7.4 provides an option to locate equipment outdoors or in a machinery room constructed and maintained under conditions specified in the standard. Section 7.6 of ASHRAE Standard 15 addresses the refrigerants in this proposal when used for human comfort in “high-probability” systems, including requirements for nameplates, labels, refrigerant detectors (under certain conditions), airflow initiation and other actions (if a rise in refrigerant concentration is detected), and other restrictions.

In the interest of providing these ODS alternatives to industry quickly, as requested by commenters, and achieving reductions in other, less safe alternatives sooner, the Agency is finalizing use conditions that incorporate by reference the ASHRAE 15–2019 edition, as proposed, rather than a more recent version. EPA recognizes that ASHRAE 15 was recently updated and republished in late 2022. This final rule incorporates by reference all addenda published by the date of the NPRM, as proposed. EPA intends to review the 2022 version of ASHRAE Standard 15 and consider proposing revisions to the use conditions to incorporate by reference the 2022 version of that standard in a future notice and comment rulemaking.

EPA is finalizing the use conditions to ensure safe use of these ODS alternatives regarding their flammability, toxicity, exposure, and environmental effects. As discussed below, commenters generally supported the use conditions. The use conditions identified in this section above are explained below, in section II.E.1, in greater detail.

5. What additional information is EPA including in these final listings?

EPA is providing additional information related to these final listings. Since this additional information is not part of the regulatory decision under SNAP, these statements are not binding for use of the substitute under the SNAP program. See section II.E.2 below for further discussion on what additional information EPA is including in these final listings. While the items listed are not legally binding under the SNAP program, EPA encourages users of substitutes to apply all statements in the “Further Information” column in their use of these substitutes as best practices for safer use.

6. How is EPA responding to comments on chillers?

Comment: Carrier commented expressing their support of listing HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C as acceptable in chillers. Daikin described their support for listing HFC–32 and R–452B as acceptable in positive displacement chillers. Daikin agreed with “EPA's analysis of its application, and strongly supported the Agency's proposal to approve R–32 under the SNAP program for the end uses of new rotary and scroll comfort cooling and industrial process air conditioning chillers.” Daikin voiced strong support and encouraged EPA to approve HFC–32 quickly.

Response: EPA thanks Carrier and Daikin for their support of these listings in the chillers end-use. In this final rule, EPA is listing HFO–1234yf, R–454A, R–454B, R–454C, HFC–32, and R–452B in all centrifugal and positive displacement chillers for comfort cooling, including both commercial AC and IPAC.

Comment: The Air-Conditioning, Heating, and Refrigeration Institute (AHRI), Carrier, Multistack, and Chemours all commented that EPA should not segment the chillers end-uses further by compressor type. Carrier stated that such segmentation leads to unnecessary complexity, while Multistack said it was likely to produce confusion regarding the application of products. Chemours commented that segmentation by compressor type may stifle innovation and create additional challenges for equipment manufacturers and end users working to adopt lower-GWP refrigerants. Chemours further stated that compressor type differentiation should only occur when necessary, because of technology limitations. Chemours also recommended that EPA remove references to chillers for industrial process refrigeration (IPR) to avoid confusion, as well as not distinguishing IPR equipment by compressor type.

Response: EPA acknowledges the concerns commenters expressed regarding segmenting the current chillers end-uses by compressor types for the proposed listings of HFC–32 and R–452B in scroll and rotary chillers. After consideration of the comments received, in particular, the concerns for innovation and unnecessary complexity as summarized above, EPA agrees that such segmentation is not necessary and could hinder the technical transition to lower-GWP refrigerants. Moreover, EPA does not view segmentation in this instance as providing any additional environmental benefit. Given EPA's understanding of the comments and the SNAP program's historical precedent of grouping together all positive displacement chillers despite their varying compressor types, EPA is finalizing the listings for HFC–32 and R–452B for all chillers rather than breaking out the listings by compressor type for scroll and rotary chillers.

In response to Chemours's comment referencing IPR for chillers, EPA acknowledges the complexities associated with breaking out IPR by compressor type, similarly to chillers. EPA understands the standard UL 60335–2–40 to apply only to comfort cooling and not to process cooling such as occurs in IPR. EPA may address additional substitutes for use in IPR in future rulemakings. The reference to chillers used for IPR remains in the preamble for this final rule to clarify that IPR is not in the scope of listings in this rule.

Comment: Daikin commented on EPA's statement that “EPA understands that the UL standard [60335–2–40] applies to chillers used for comfort cooling.” Daikin went on to say “that neither the scope statement nor the body of this UL standard make any such restriction as to the purpose of the heat pump, air-conditioner, or dehumidifier. Products evaluated to this UL standard are not limited to applications for human comfort and may also be applied to cool or heat various products or processes.” They suggested that if EPA has safety concerns for IPAC, the Agency should include an ambient operating temperature limit of 140°F. Daikin addressed the suitability of HFC–32 in IPAC and IPR, noting that “EPA states in the preamble (87 FR 45514) that `HFC–32's . . . GWP [is] higher than those of some of the acceptable substitutes for new industrial process AC . . .', implying that HFC–32 is not suitable for industrial process refrigeration. Regardless of whether Daikin's SNAP information notice requested SNAP approval of HFC–32 in the industrial process refrigeration application, HFC–32 is also suitable for that application.”

Response: EPA acknowledges Daikin's concerns about the scope of UL 60335–2–40. Determining the coverage of UL standards to applications not covered in this rule is outside the scope of this rulemaking. However, for informational purposes in response to Daikin's comment, the Agency is providing some additional information regarding UL 60335–2–40. As described in NOTE 104 in UL 60335–2–40, “This standard does not apply to. . .

- appliances designed exclusively for industrial processing;

- appliances intended to be used in locations where special conditions prevail, such as the presence of a corrosive or explosive atmosphere (dust, vapour or gas).”

Based on EPA's review of standard UL 60335–2–40 and conversations with UL, it is EPA's understanding that equipment for industrial processing, included in the bullet points above, is not covered by this standard, and instead is covered by UL 60335–2–89. Excluding equipment designed solely for industrial processes limits the scope of UL 60335–2–40 to chillers designed for commercial and industrial comfort cooling. If a chiller in an industrial application is used mostly for comfort cooling and also cools processes or industrial equipment, EPA would consider it to fall under the SNAP end-use IPAC rather than IPR. The listings for HFC–32, described in this section above, will apply to these types of chillers on and after the effective date of this rule.

The discussion of ambient operating temperature for IPAC equipment was included as part of the description of the end-use under SNAP, providing an example of possible operating conditions. Any safety concerns surrounding use of HFC–32 in this end-use are sufficiently addressed by the use conditions that apply as described in section II.E.1, below. EPA agrees with Daikin that HFC–32 is suitable for use in IPAC, given that the Agency proposed to list HFC–32 as acceptable in this end-use in SNAP NPRM 25 and is finalizing this listing in this rulemaking.

Under SNAP, IPAC is considered comfort cooling equipment, as it protects the operators in addition to process equipment. EPA's SNAP program considers IPR equipment to be primarily for cooling of a process or product, not primarily for comfort cooling. EPA has not addressed or implied the suitability of HFC–32 for IPR in the NPRM or in this final rule. Any comments on the suitability of HFC–32 in IPR are outside the scope of the rulemaking. EPA is finalizing the listings for HFC–32 in chillers used in comfort cooling for commercial and industrial uses as described in this section of the preamble above.

Comment: AHRI and Chemours noted that some of EPA's risk screens use the Worst Case of Fractionation for Flammability (WCFF) LFL values for the refrigerant blends rather than the Worst Case of Formulation for Flammability (WCF) when determining the lower flammability limit and requested that EPA uses the WCF LFL values for purposes of refrigerant risk analysis. Both commenters noted that UL 60335–2–40 uses the WCF LFL, but that ASHRAE 34–2019 uses the WCFF LFL for all of the blends, except R–452B, in which case both ASHRAE 34 and EPA reference the WCF LFL. The commenters stated that ASHRAE 34 plans to update their WCFF LFL values to WCF LFL values in future editions of the standard as a way to standardize LFLs going forward.

Response: EPA thanks the commenters for this information regarding WCFF and WCF LFL values. The Agency has added a footnote to this preamble acknowledging that this transition from using WCFF values to WCF values is taking place. EPA will consider updating risk screens for R–454A, R–454B, and R–454C in future rulemakings with more recent versions of the ASHRAE standards, using the WCF LFL values. Given the more conservative nature of WCFF LFL values over WCF LFL values, such an update to the risk screens' flammability analysis would result in a less conversative model. The determination of whether the LFL would be exceeded in a catastrophic refrigerant release scenario may change if using the WCF LFL values, possibly showing no flammability risk where there may have been flammability risk previously.

Comment: Several citizens commented, acknowledging the safety of using A2L refrigerants in terms of their flammability and risk to the environment, especially relative to other alternatives available. These commenters stated that EPA should proceed with listing these refrigerants as acceptable.

Response: EPA thanks the commenters for their support of listing the A2L refrigerants—HFO–1234yf and the refrigerants blends—as acceptable. EPA agrees that these refrigerants pose lower overall risk to human health and the environment, and thus we conclude it is appropriate to move forward with finalizing the listings for these refrigerants as described in the preamble above.

B. Residential Dehumidifiers—Listing of HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C as Acceptable, Subject to Use Conditions, for Use in New Residential Dehumidifiers

EPA previously listed HFO–1234yf as acceptable, subject to use conditions in motor vehicle AC in light-duty vehicles (74 FR 53445; October 19, 2009), in heavy-duty pickup trucks and complete heavy-duty vans (81 FR 86778; December 1, 2016) and in nonroad vehicles and service fittings for small refrigerant cans (87 FR 26276; May 4, 2022). EPA previously listed HFC–32 as acceptable, subject to use conditions, as a substitute in residential and light commercial AC and HPs (80 FR 19454; April 10, 2015 and 86 FR 24444, May 6, 2021) and previously listed R–452B, R–454A, R–454B, and R–454C (hereafter called “the four refrigerant blends”) as acceptable, subject to use conditions, as substitutes in residential and light commercial AC and HPs (86 FR 24444; May 6, 2021).

This final rulemaking finds HFC–32, HFO–1234yf, and the four refrigerant blends acceptable, subject to use conditions, as substitutes in residential dehumidifiers. After consideration and evaluation of the comments received by the Agency in response to the NPRM, EPA is finalizing the listings for HFC–32, HFO–1234yf, R–452B, R–454A, R–454B, and R–454C in residential dehumidifiers as proposed.

Several use conditions finalized for residential dehumidifiers are common to those for other end-uses in section II.A, above, and II.D, below. Because of this similarity, EPA discusses the use conditions that would apply to all three end-uses in section II.E. For residential dehumidifiers, those are the only use conditions EPA is finalizing and require the following:

(1) New equipment only—These refrigerants may be used only in new equipment designed specifically and clearly identified for the refrigerant, i.e., none of these substitutes may be used as a conversion or “retrofit” refrigerant for existing equipment.

(2) UL Standard—These refrigerants may be used only in residential dehumidifiers that meet all requirements listed in the 3rd edition, dated November 1, 2019, of UL Standard 60335–2–40, “Household and Similar Electrical Appliances—Safety—Part 2–40: Particular Requirements for Electrical Heat Pumps, Air Conditioners and Dehumidifiers” (UL Standard). In cases where this final rule includes requirements different from those of the 3rd edition of UL Standard 60335–2–40, the appliance must meet the requirements of the final rule in place of the requirements in UL 60335–2–40, 3rd Edition. See section II.E below for further discussion on the requirements of this standard that EPA is incorporating by reference.

(3) Warning labels—Several warning labels are required as use conditions as detailed in section II.E below. These labels are similar or verbatim in language to those required by the UL Standard. The warning labels must be provided in letters no less than 6.4 mm (1/4 inch) high and must be permanent.

(4) Markings—Equipment must have distinguishing red (PMS #185 or RAL 3020) color-coded hoses and piping to indicate use of a flammable refrigerant. The residential dehumidifier shall have marked service ports, pipes, hoses and other devices through which the refrigerant is serviced. Markings shall extend at least 1 inch (25mm) from the servicing port and shall be replaced if removed.

EPA notes that there may be other requirements pertaining to the manufacture, use, handling, and disposal of the refrigerants that are not included in the information listed in the tables (e.g., the CAA section 608(c)(2) venting prohibition or Department of Transportation requirements for transport of flammable gases). Flammable refrigerants being recovered or otherwise disposed of from residential dehumidifiers are likely to be hazardous waste under RCRA (see 40 CFR parts 260–270).

1. Background on Residential Dehumidifiers

Residential dehumidifiers are primarily used to remove water vapor from ambient air or directly from indoor air for comfort or material preservation purposes in the context of the home. 26 While AC systems often combine cooling and dehumidification, this end-use only serves the latter purpose and is often used in homes for comfort purposes. This equipment is self-contained and circulates air from a room, passes it through a cooling coil, and collects condensed water for disposal. Residential dehumidifiers fall under the scope of the UL 60335–2–40 standard “Household and Similar Electrical Appliances—Safety—Part 2–40: Requirements for Electrical Heat Pumps, Air Conditioners and Dehumidifiers.”

26 SNAP regulations (see 40 CFR 82.172) define residential use as use by a private individual of a chemical substance or any product containing the chemical substance in or around a permanent or temporary household, during recreation, or for any personal use or enjoyment. Use within a household for commercial or medical applications is not included in this definition, nor is use in automobiles, watercraft, or aircraft.

Some dehumidifiers for residential or light commercial use are integrated with the space air conditioning equipment, for instance via a separate bypass in the duct through which air is dehumidified, a dehumidifying heat pipe across the indoor coil, or other types of energy recovery devices that move sensible and/or latent heat between air streams (e.g., between incoming air and air vented to the outside). EPA classifies this application as a component of a residential or light commercial AC system or HP. As such, EPA has already listed HFC–32 as acceptable for such uses, subject to the use conditions specified in SNAP Rule 23 (86 FR 24444; May 6, 2021).

This final rulemaking finds HFO–1234yf, HFC–32, and the four refrigerant blends acceptable, subject to use conditions, in self-contained residential dehumidifiers. Note that dehumidifiers for residential or light commercial use that are integrated with AC equipment (i.e., not self-contained) are not addressed in this listing because EPA classifies that type of equipment as residential or light commercial AC and HPs.

2. What are the ASHRAE classifications for refrigerant flammability?

HFO–1234yf and HFC–32 are lower flammability refrigerants, and the four refrigerant blends are lower flammability refrigerant blends, all with an ASHRAE safety classification of A2L. See section II.A.2 above for further discussion on ASHRAE classifications.

3. What are HFO–1234yf, HFC–32, R–452B, R–454A, R–454B, and R–454C and how do they compare to other refrigerants in the same end-use?

See section II.A.3 above for further discussion on the environmental, flammability, toxicity, and exposure information for these refrigerants.

Redacted submissions and supporting documentation for HFO–1234yf, HFC–32 and the four refrigerant blends are provided in the docket for this proposed rule (EPA–HQ–OAR–2021–0836) at https://www.regulations.gov. EPA performed an assessment to examine the health and environmental risks of each of these substitutes. These assessments are available in the docket for this final rule. 272829303132

27 ICF, 2022g. Risk Screen on Substitutes in Residential Dehumidifiers (New Equipment); Substitute: HFC–32.

28 ICF, 2022h. Risk Screen on Substitutes in Residential Dehumidifiers (New Equipment); Substitute: R–452B.

29 ICF, 2022i Risk Screen on Substitutes in Residential Dehumidifiers (New Equipment); Substitute: R–454A.

30 ICF, 2022j. Risk Screen on Substitutes in Residential Dehumidifiers (New Equipment); Substitute: R–454B.

31 ICF, 2022k. Risk Screen on Substitutes in Residential Dehumidifiers (New Equipment); Substitute: R–454C.

32 ICF, 2022l. Risk Screen on Substitutes in Residential Dehumidifiers (New Equipment); Substitute: HFO–1234yf.

Comparison to other substitutes in this end-use: HFO–1234yf, HFC–32, and the four refrigerant blends all have an ODP of zero, comparable to or lower than some of the acceptable substitutes in new residential dehumidifiers, such as HFC–134a, R–410A, and R–513A, with ODPs of zero. HCFC–22 and R–406A (a blend of HCFC–22 and HCFC–142b) have ODPs of 0.055 and 0.057, respectively, and are listed as acceptable in new residential dehumidifiers. However, HCFC–22 and HCFC–142b are controlled substances under Title VI of the CAA and (unless used, recovered, and recycled) may not be used as a refrigerant in equipment manufactured on or after January 1, 2010, under 40 CFR 82.15(g)(2)(i). 33 Under 40 CFR 82.16, EPA has not issued any production and consumption allowances for HCFC–22 and HCFC–142b (which is a component of R–406A, along with HCFC–22) since 2019.

33 The regulations at 40 CFR 82.15(g)(2)(ii) provide limited exceptions to the prohibitions in 82.15(g)(2)(i), including for HCFC–22 “for use as a refrigerant in appliances manufactured before January 1, 2012, provided that the components are manufactured prior to January 1, 2010, and are specified in a building permit or a contract dated before January 1, 2010, for use on a particular project.”

HFO–1234yf, R–454A, R–454B, and R–454C have GWPs ranging up to about 470, lower than all the acceptable substitutes for new residential dehumidifiers, including R–513A and R–410A with GWPs of 630 and 2,090, respectively. HFC–32 and R–452B have GWPs of 675 and 700, respectively, which are lower than some of the other acceptable substitutes for new residential dehumidifiers, such as HFC–134a, R–410A, and R–507A with GWPs of 1,430, 2,090 and 3,990 respectively, but higher than R–513A, with a GWP of about 630.

Information regarding the toxicity of other available alternatives is provided in the previous listing decisions for new residential dehumidifiers (https://www.epa.gov/snap/substitutes-residential-dehumidifiers). Toxicity risks of use, determined by the likelihood of exceeding the exposure limit, of HFO–1234yf, HFC–32, and the four refrigerant blends in these end-uses are evaluated in the risk screens referenced above. The toxicity risks of using HFO–1234yf, HFC–32, and the four refrigerant blends in new residential dehumidifiers are comparable to or lower than toxicity risks of other available substitutes in the same end-use. Toxicity risks of the refrigerants can be mitigated by use consistent with ASHRAE 15 and other industry standards, recommendations in the manufacturers' SDS, and other safety precautions common in the refrigeration and AC industry.

The flammability risk with HFO–1234yf, HFC–32, and the four refrigerant blends in the new residential dehumidifiers end-use, determined by the likelihood of exceeding their respective lower flammability limits, are evaluated in the risk screens referenced in this section above. While these refrigerants may pose greater flammability risk than other available substitutes in the new residential dehumidifiers end-use, this risk can be mitigated by use consistent with ASHRAE 15 and UL 60335–2–40—which are applicable under the use conditions—as well as recommendations in the manufacturers' SDS and other safety precautions common in the refrigeration and AC industry. EPA is finalizing use conditions to reduce the potential risk associated with the flammability of these alternatives so that they will not pose significantly greater risk than other acceptable substitutes in the new residential dehumidifiers end-use.

4. Why is EPA finalizing these specific use conditions?

EPA is finalizing listing HFO–1234yf, HFC–32 and the four refrigerant blends as acceptable, subject to use conditions, for use in residential dehumidifiers for new equipment. EPA is finalizing the use conditions to ensure safe use of these ODS alternatives regarding their flammability, toxicity, exposure, and environmental effects. As discussed below, commenters generally supported the use conditions. The use conditions identified in this section above are explained below in section II.E.1 in greater detail.

5. What additional information is EPA including in these final listings?

EPA is providing additional information related to these final listings. Since this additional information is not part of the regulatory decision under SNAP, these statements are not binding for use of the substitute under the SNAP program. See section II.E.2 below for further discussion on what additional information EPA is including in these final listings. While the items listed are not legally binding under the SNAP program, EPA encourages users of substitutes to apply all statements in the “Further Information” column in their use of these substitutes as best practices for safer use.

6. How is EPA responding to comments on residential dehumidifiers?

Comment: Several commenters (AprilAire, the Association of Home Appliance Manufacturers (AHAM), Competition Advocates, GE Appliances/Hair, and Madison Indoor Air Quality (MIAQ)) voiced general support for the proposed listing of HFC–32 as acceptable, subject to use conditions, in residential dehumidifiers. AHAM noted the industry is “already in the process of transitioning to lower GWP refrigerants for these products and prefers a national regulatory framework under which it can operate with a clear path to compliances.” Competition Advocates commented on their SNAP application for HFC–32 in residential dehumidifiers and noted the importance of transitioning to lower-GWP alternatives. “SNAP approval of R–32 use in residential dehumidifiers will allow the direct and indirect climate benefits of this lower GWP and more energy efficient refrigerant to be realized as consumers purchase and use these products.” GE Appliances commented that they filed a SNAP application for the use of HFC–32 in residential dehumidifiers and noted support for SNAP Rule 25, urging EPA to move quickly in finalizing. MIAQ additionally expressed their support for listing R–454B as acceptable in the end-use.

Response: EPA acknowledges these commenters' general support for the proposed listings for HFC–32 and R–454B in residential dehumidifiers, and appreciates the additional information provided by AHAM and Competition Advocates on the transition to lower-GWP refrigerants. EPA agrees with these comments and is aware that industry has already started this transition. After considering all the public comments on this proposal, we are finalizing these listings as described in this section, II.B.

Comment: AHRI, Carrier, Chemours, Desert-Aire, and MIAQ suggested that “EPA may wish to incorporate residential and non-residential dehumidifiers into the currently used SNAP category of Residential and Light Commercial Air Conditioning and Heat Pumps,” as all these products are developed together through UL 60335–2–40 (AHRI). MIAQ also recommended EPA “revise and clarify the classification of different types of dehumidifiers to align with the definitions in the U.S. Department of Energy (DOE) test procedure at 10 Code of Federal Regulations (CFR) 430, Subpart B, Appendix X1 or in 10 CFR 430.2 and that the CFR definitions take precedence and may be modified by DOE.”